Production process of reflective thermal attachment film and special production line thereof

A production process and thermal film technology, which is applied in the field of reflective material manufacturing, can solve the problems of low acceptability of low-end users, high processing cost of reflective film, and reduced processing efficiency, so as to achieve considerable economic profits, improve processing efficiency and improve processing efficiency. Quality, the effect of saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

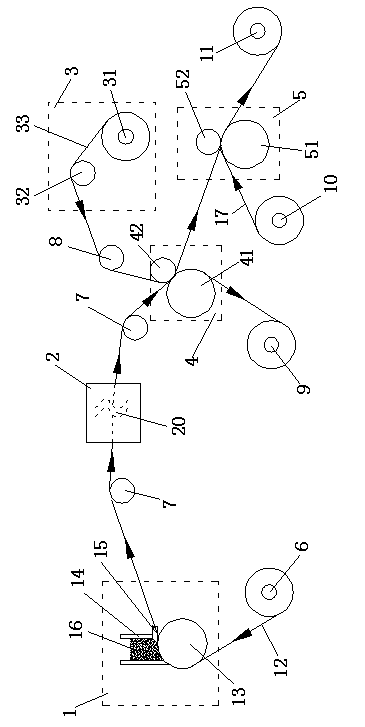

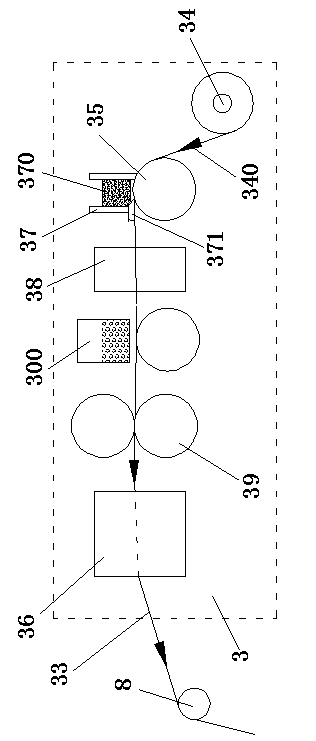

[0017] Embodiment 1-1: with reference to the attached figure 1 . A production line for reflective heat sticking film, comprising a composite glue coating mechanism 1, a plant mechanism 3, a transfer composite mechanism 4 and a composite mechanism 5 installed on a production line frame; the front part of the composite glue coating mechanism 1 is provided with an installation anti The rotating roller 6 of the mucous membrane 12 is provided with a drying device 2 and a guide roller 7 at the rear; the composite glue coating mechanism 1 includes a bottom roller 13 and a glue leakage box 14 and a flat scraper 15 installed on the top of the bottom roller 13; Composite glue 16 is housed in the leakage glue box 14; When the described anti-adhesive film 12 was around the bottom of the leakage glue box 14, the composite glue 16 leaked onto the surface of the anti-adhesion film 12; the composite glue 16 on the surface of the anti-adhesion film 12 Under the action of the scraper 15, it is...

Embodiment 1-2

[0018] Embodiment 1-2: with reference to attached figure 1 . Utilize the production line described in embodiment 1-1, process the production technology of reflective thermal film, comprise once completing following steps on above-mentioned production line:

[0019] ① One end of the anti-adhesive film 12 on the rotating roller 6 passes through the bottom roller 13 of the compound glue coating mechanism 1, and the compound glue 16 in the leakage box 14 above the bottom roller 13 leaks onto the anti-stick film 12 wound on the bottom roller 13 , when the anti-adhesive film 12 is transmitted with the rotation of the bottom roller 13, due to the effect of the flat scraper 15 above the bottom roller 13, the composite glue 16 is evenly laid on the surface of the anti-adhesive film 12 to form a composite adhesive layer;

[0020] ②The anti-adhesive film 12 that has been coated enters the drying tunnel 20 in the drying equipment 2 under the guidance and traction of the guide roller 7, a...

Embodiment 2-1

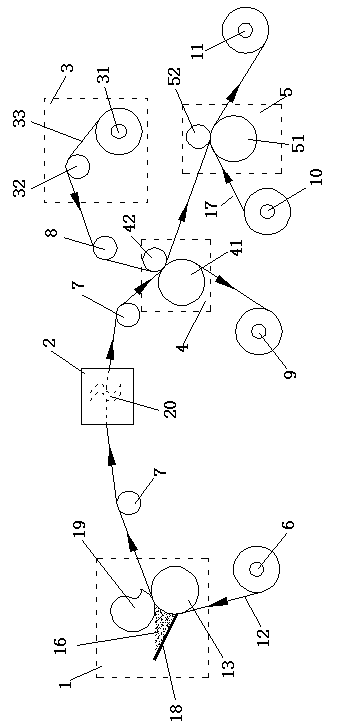

[0023] Embodiment 2-1: refer to the attached figure 2 . On the basis of Example 1-1, in the reflective thermal film production line, the composite glue coating mechanism 1 can also be another structure, that is, it includes a bottom roller 13, a scraper wheel 19 and a roller equipped with a composite glue 16. Glue groove 18; Glue groove 18 is arranged on the side top of bottom roller 13, and glue groove 18 bottom openings; Scraper wheel 19 is positioned at bottom roller 13, and is set correspondingly with bottom roller 13; Pass between the bottom roller 13 and the scraper wheel 19, and under the action of the scraper wheel 19 and the bottom roller 13, the composite glue 16 is evenly laid on the release film 12; the composite glue 16 is made of oily acrylic pressure-sensitive adhesive , solvent, color paste, filler and curing agent mixed uniformly to obtain the glue mixture; the guide roller 7 can be a plurality, and is arranged symmetrically at the front and the rear of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com