Anti-icing laminating membrane

An anti-icing and coating technology, applied in the direction of layered products, etc., can solve the problems of difficult preparation of hydrophobic materials, short-term use effect, environmental pollution, etc., and achieve the effect of reducing the adhesion strength of icing and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

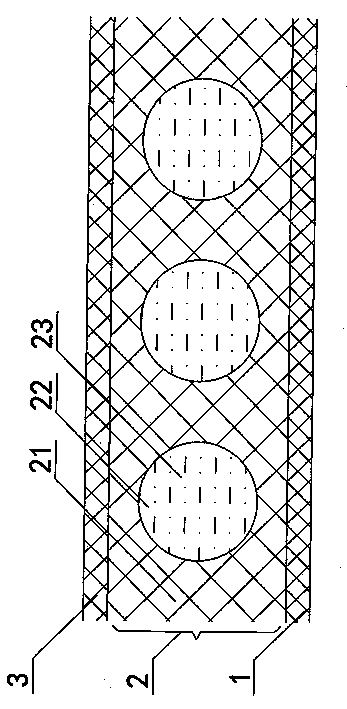

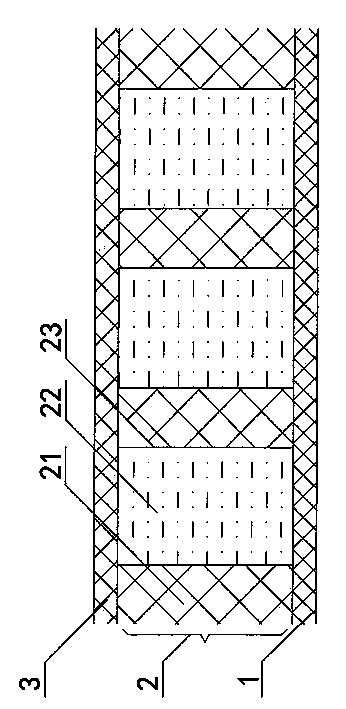

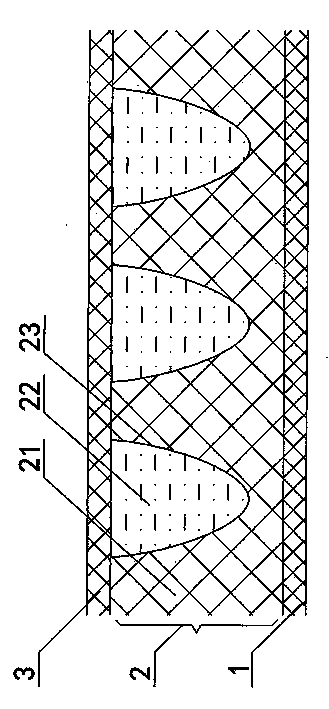

[0018] Such as image 3 Shown, the present invention is formed by bonding base layer 1, intermediate solution blister layer 2 and outer skin surface layer 3, and intermediate solution blister layer 2 is made of intermediate layer filling material 21, low freezing point solution 22 and blister 23, several blisters 23 are embedded in the middle layer filling material 21, the low freezing point solution 22 is filled in the blisters 23, and the outer skin surface layer 3 and the middle layer filling material 21 are bonded together.

[0019] The blister of the present invention can be in various shapes, such as figure 1 Shown, the shape of blister 23 is a spherical bubble; figure 2 As shown, the shape of the blister 23 is a columnar bubble; image 3 As shown, the shape of the blister 23 is a hemispherical bubble.

[0020] The low freezing point solution 22 is a chloride solution or a mixed solution of polyalcohols.

[0021] Working process and principle of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com