Patents

Literature

42results about How to "Smooth stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for presentation of revisions of an electronic document

ActiveUS8209308B2Smoothen visual transitionAbility to absorbDigital data processing detailsText processingElectronic documentDocumentation procedure

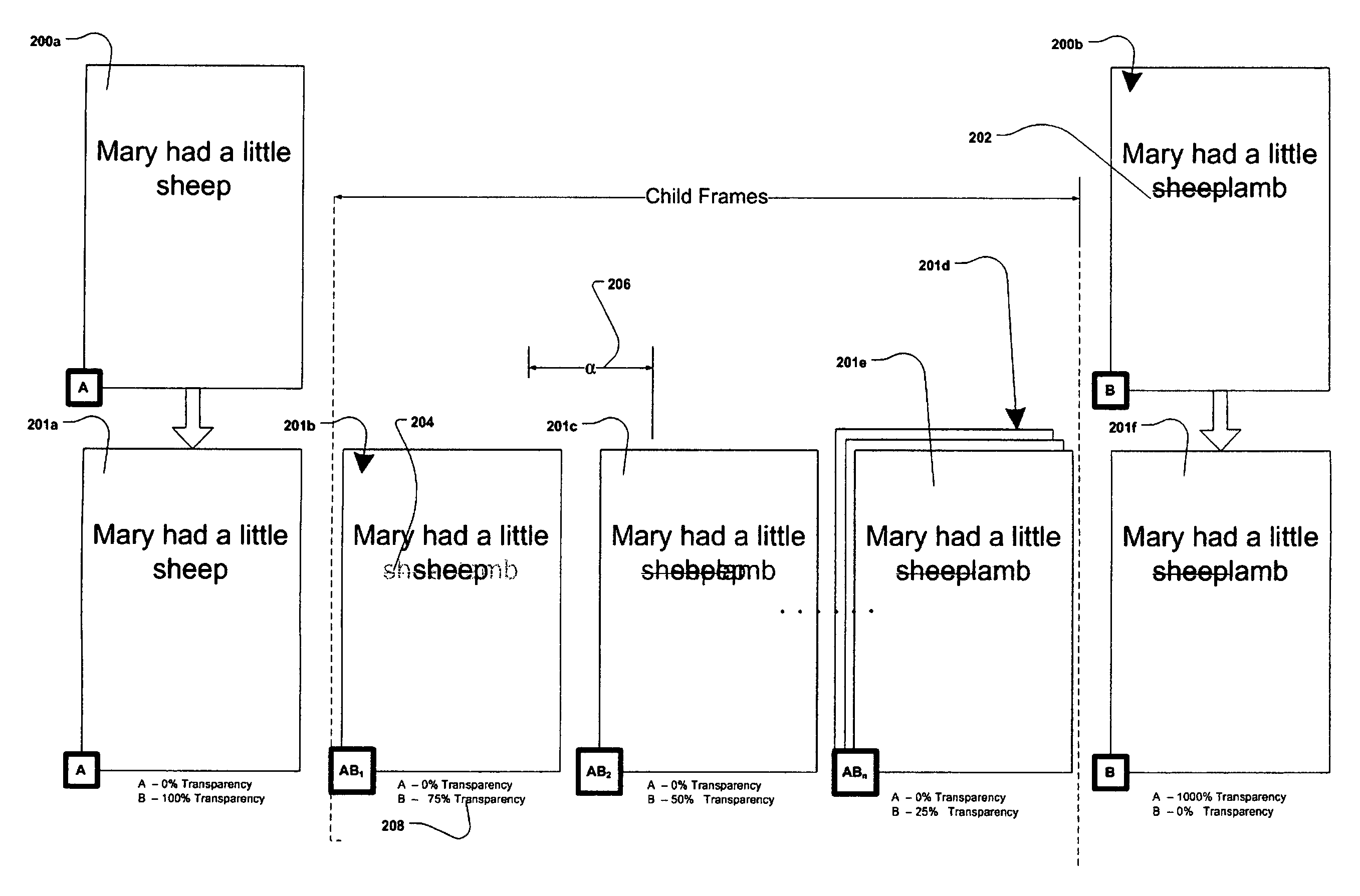

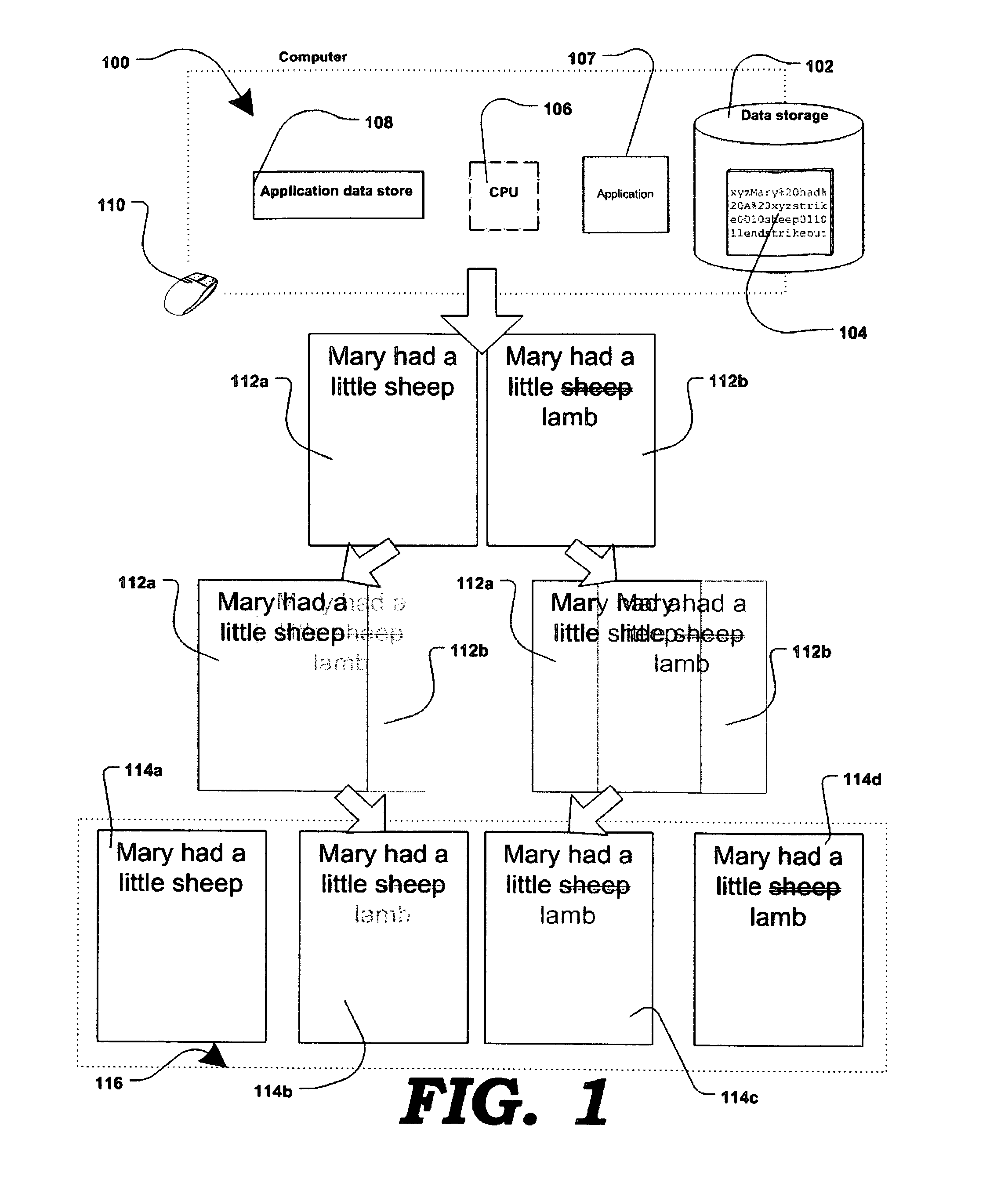

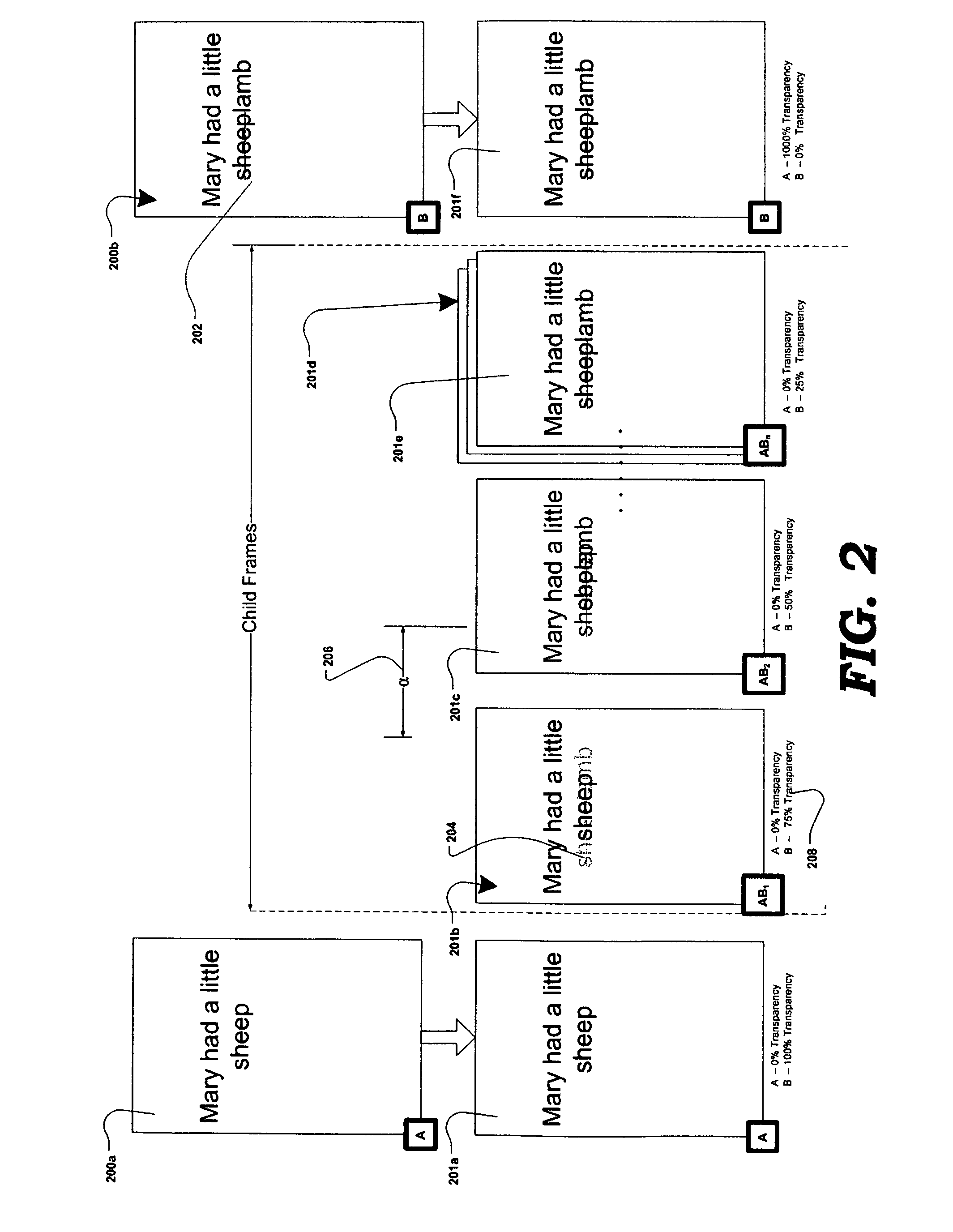

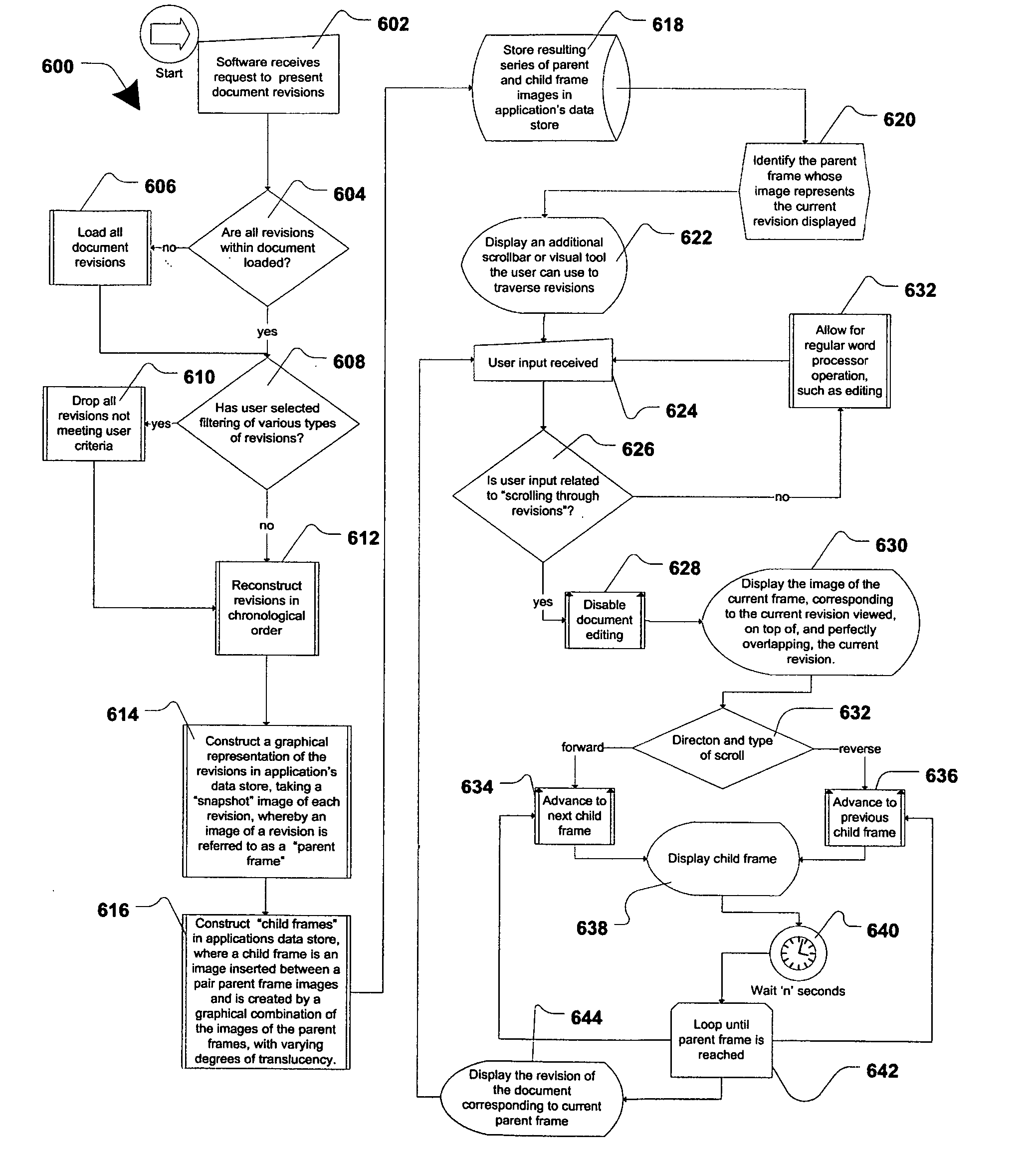

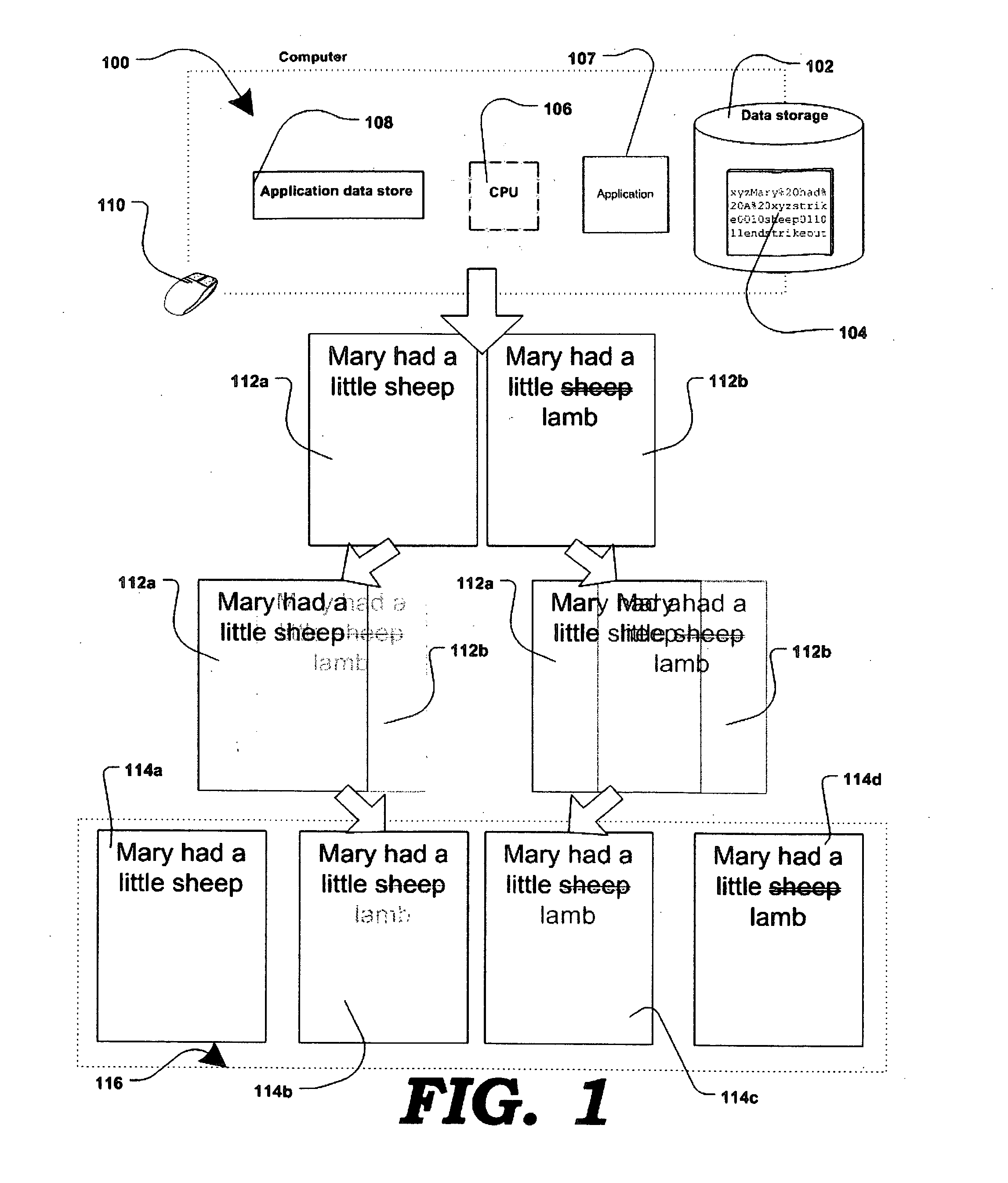

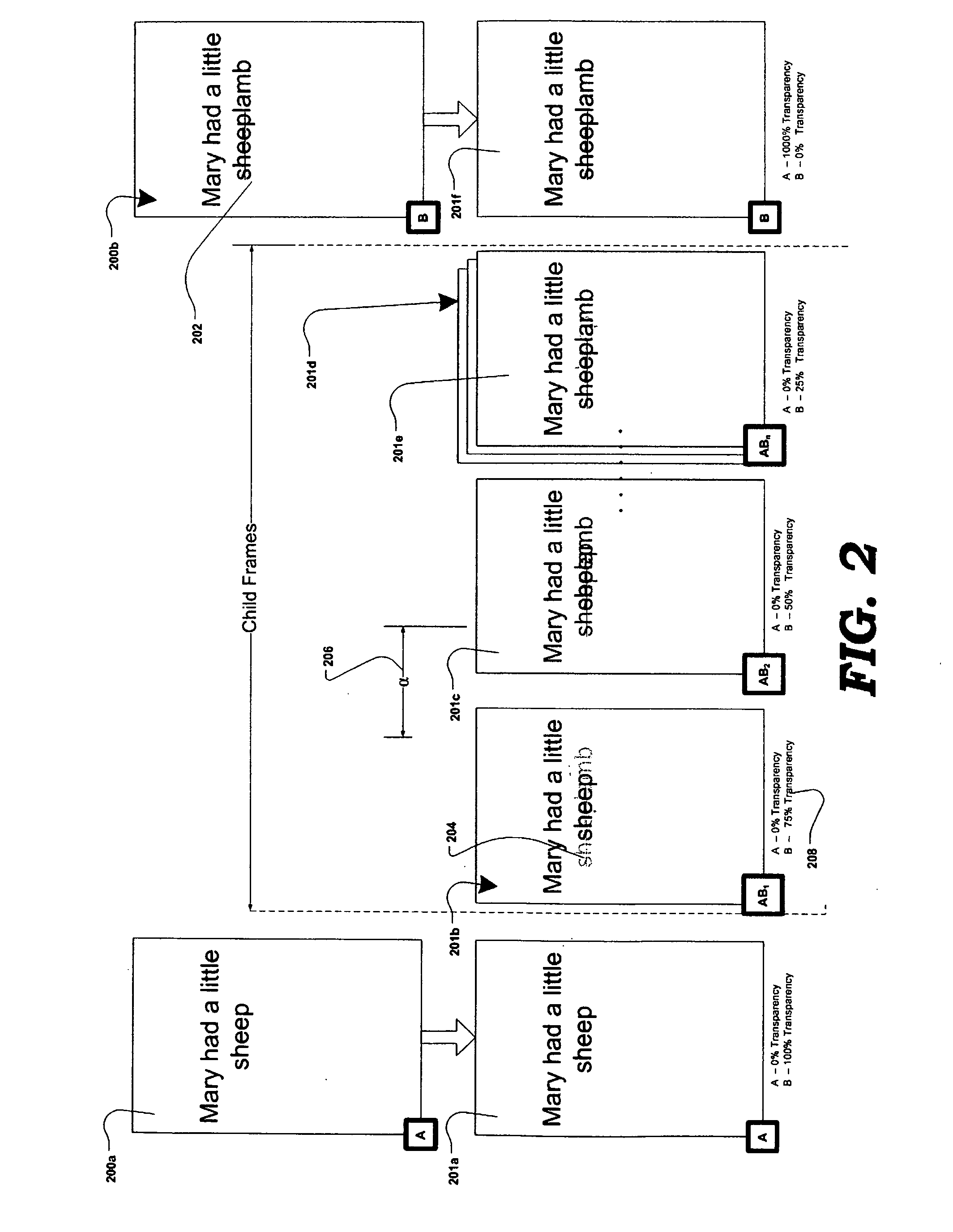

A method and apparatus for displaying the evolution of an electronic document (e.g. word-processing document, portable-document-format file, spreadsheet, drawing, and the like), containing tracked changes, is disclosed. In accordance with the disclosed method and apparatus, the revisions of an electronic document may be treated as parent frames. In between the parent frames, child frames may be constructed from the combined images of their parent frames. To form a child frame, an image of a parent frame has a degree of translucency as it is combined with the translucent image of the other parent frame, such that every child frame contains traces of the images of both its parent frames. An input device (e.g. keyboard, mouse, touchpad, stylus, voice activation, and the like) may be used to control the frame visible to the user at any one time. The user may use the input device to traverse the frames at various speeds and in either direction, creating the visual illusion that a certain revision of the document is being morphed into its future revisions—or stripped off its changes as it is morphed into previous revisions—depending on the direction chosen by the user.

Owner:DOMO

Method for presentation of revisions of an electronic document

ActiveUS20070260996A1Smoothen visual transitionAbility to absorbDigital data processing detailsText processingWord processingDigital document

A method and apparatus for displaying the evolution of an electronic document (e.g. word-processing document, portable-document-format file, spreadsheet, drawing, and the like), containing tracked changes, is disclosed. In accordance with the disclosed method and apparatus, the revisions of an electronic document may be treated as parent frames. In between the parent frames, child frames may be constructed from the combined images of their parent frames. To form a child frame, an image of a parent frame has a degree of translucency as it is combined with the translucent image of the other parent frame, such that every child frame contains traces of the images of both its parent frames. An input device (e.g. keyboard, mouse, touchpad, stylus, voice activation, and the like) may be used to control the frame visible to the user at any one time. The user may use the input device to traverse the frames at various speeds and in either direction, creating the visual illusion that a certain revision of the document is being morphed into its future revisions—or stripped off its changes as it is morphed into previous revisions—depending on the direction chosen by the user.

Owner:DOMO

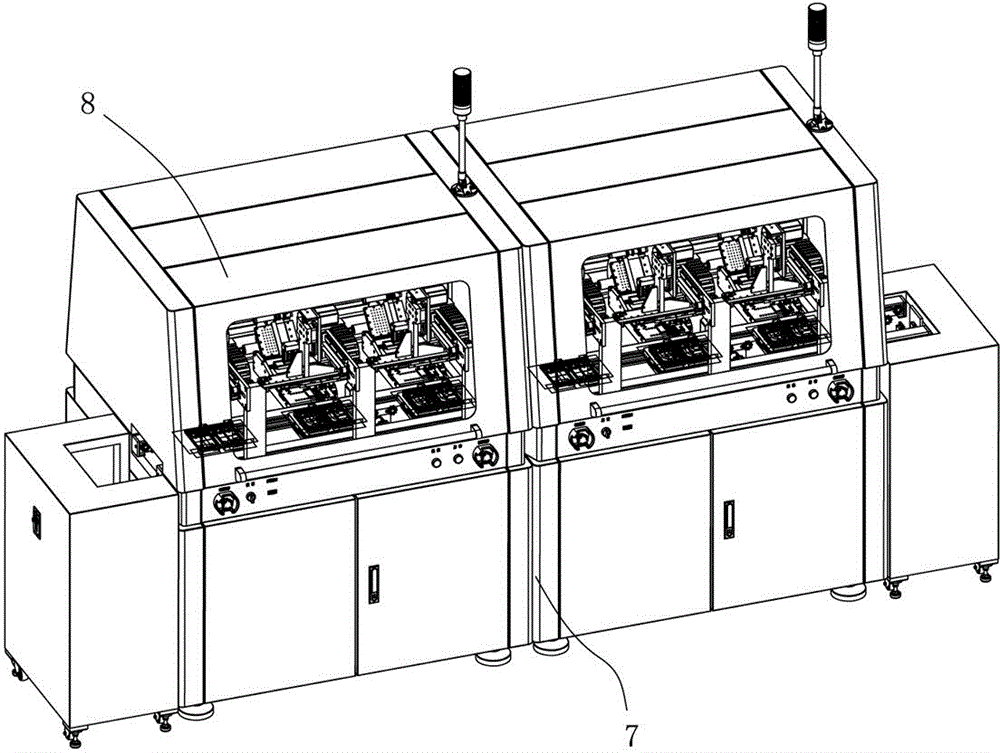

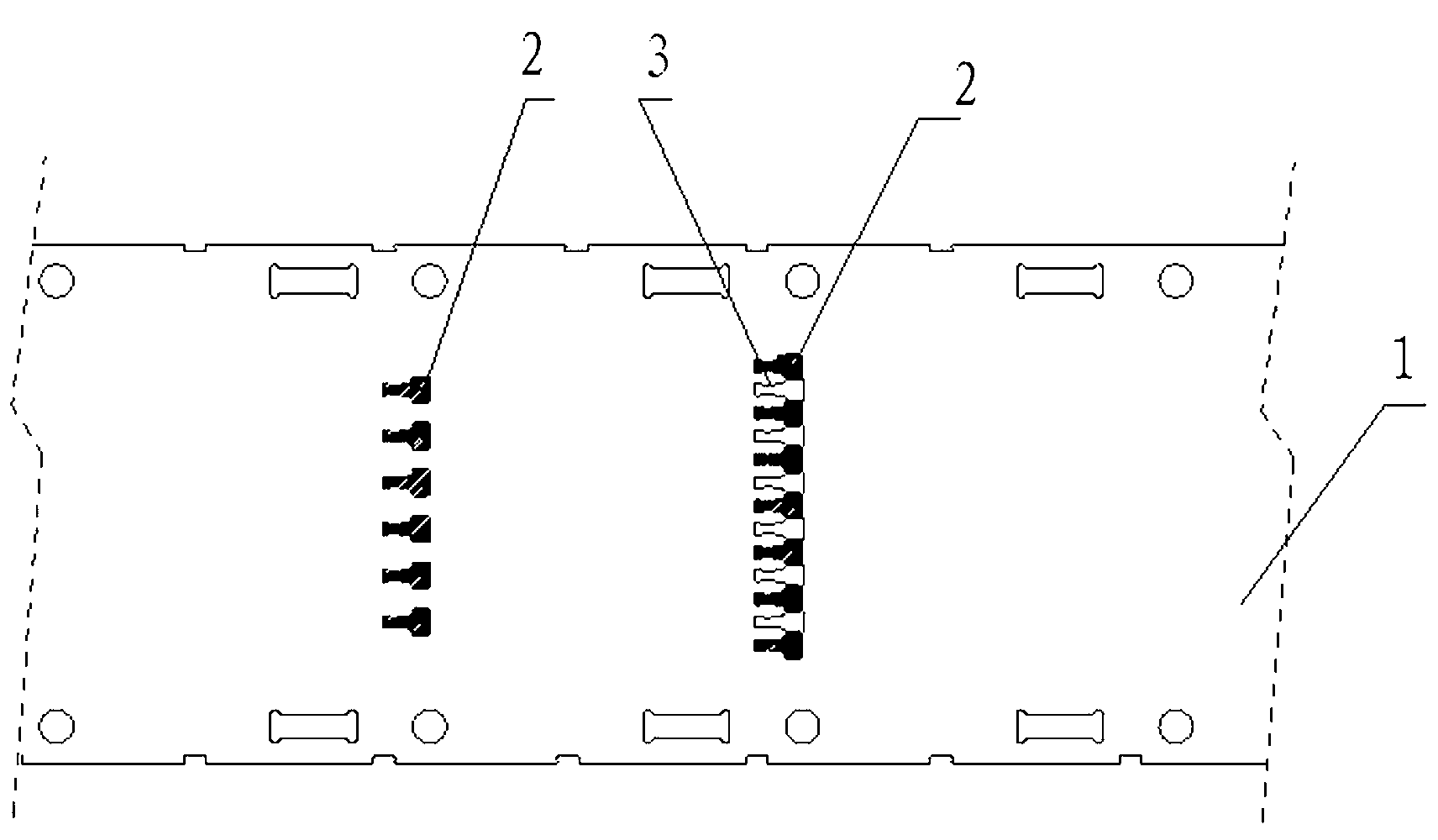

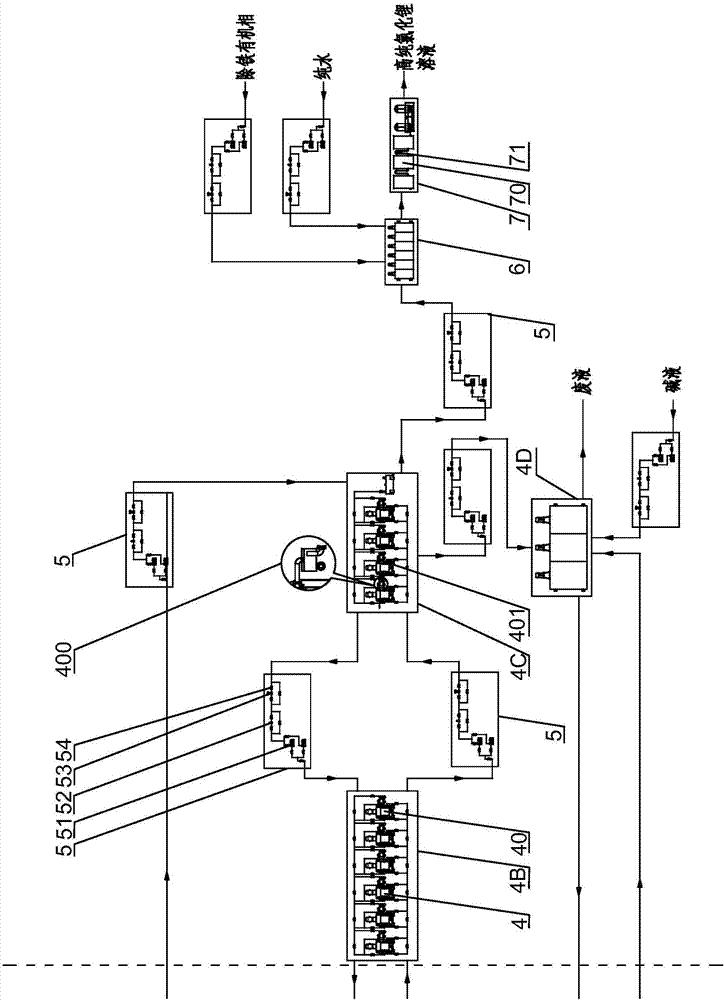

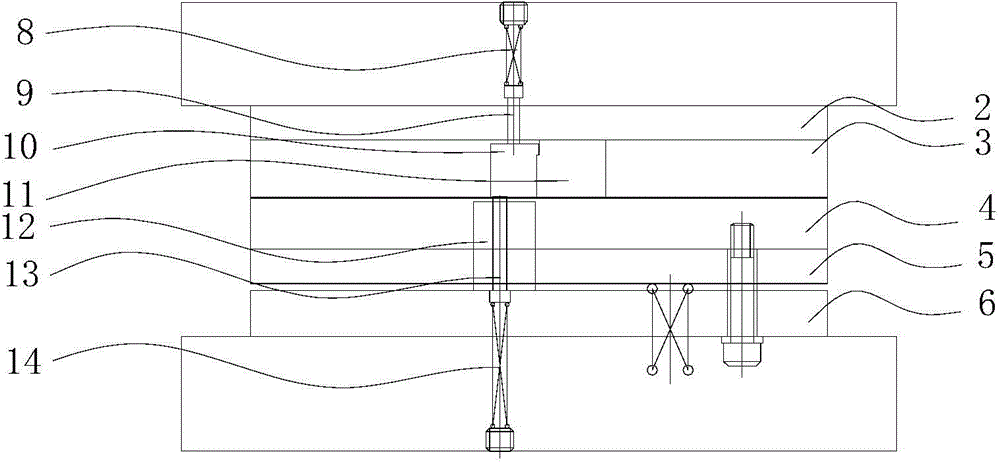

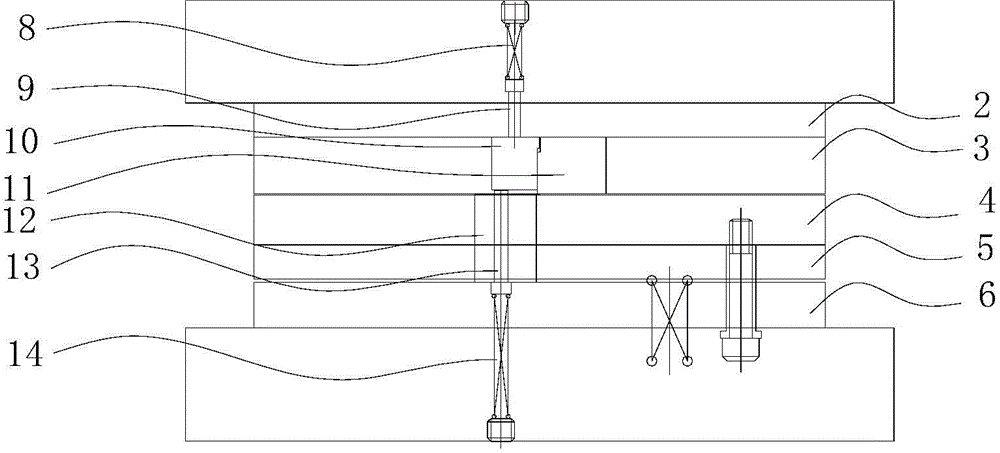

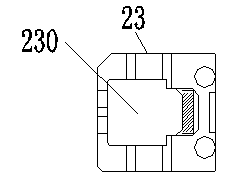

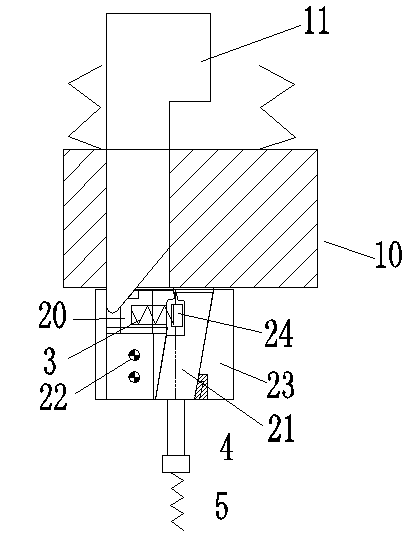

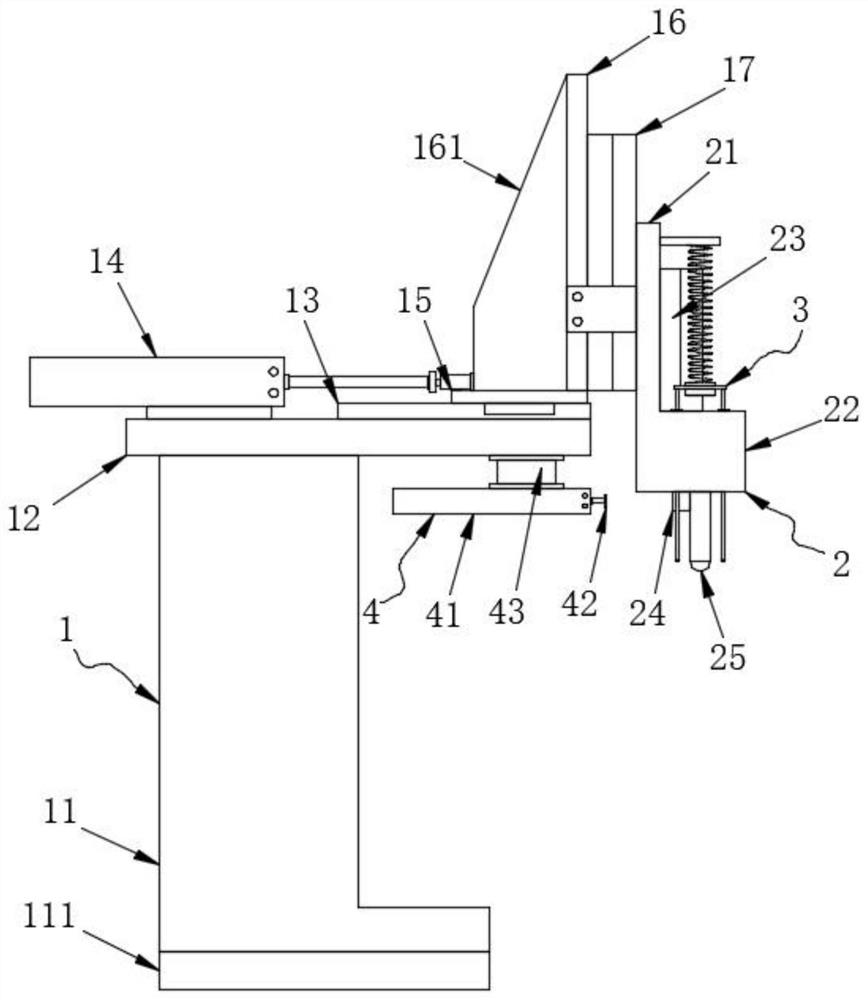

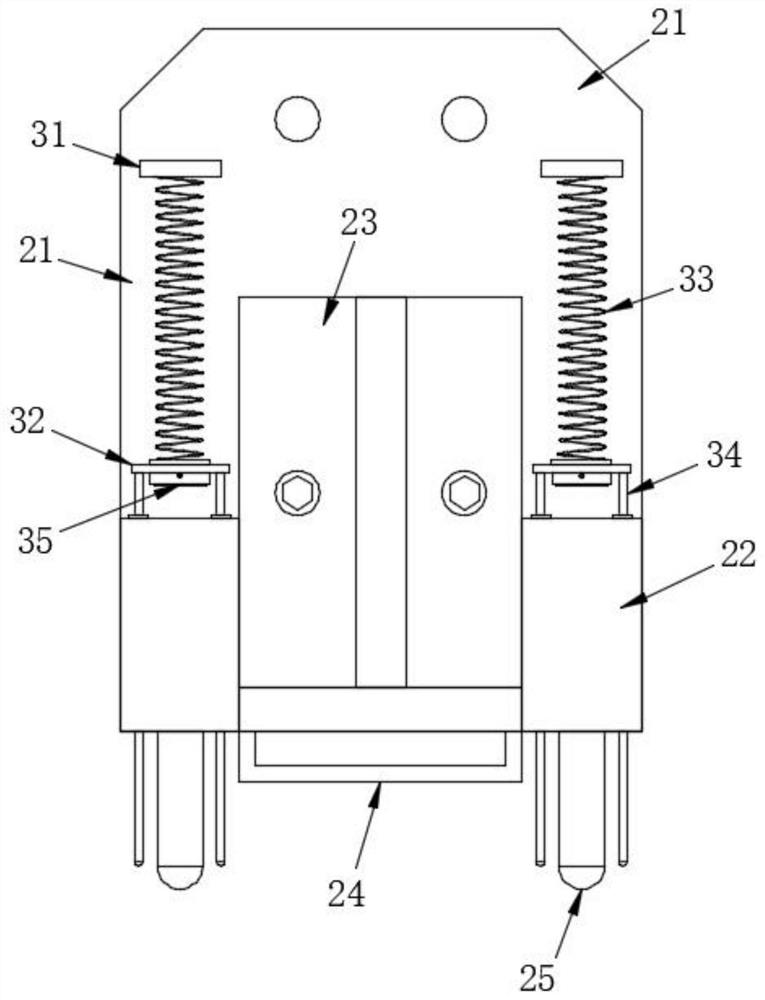

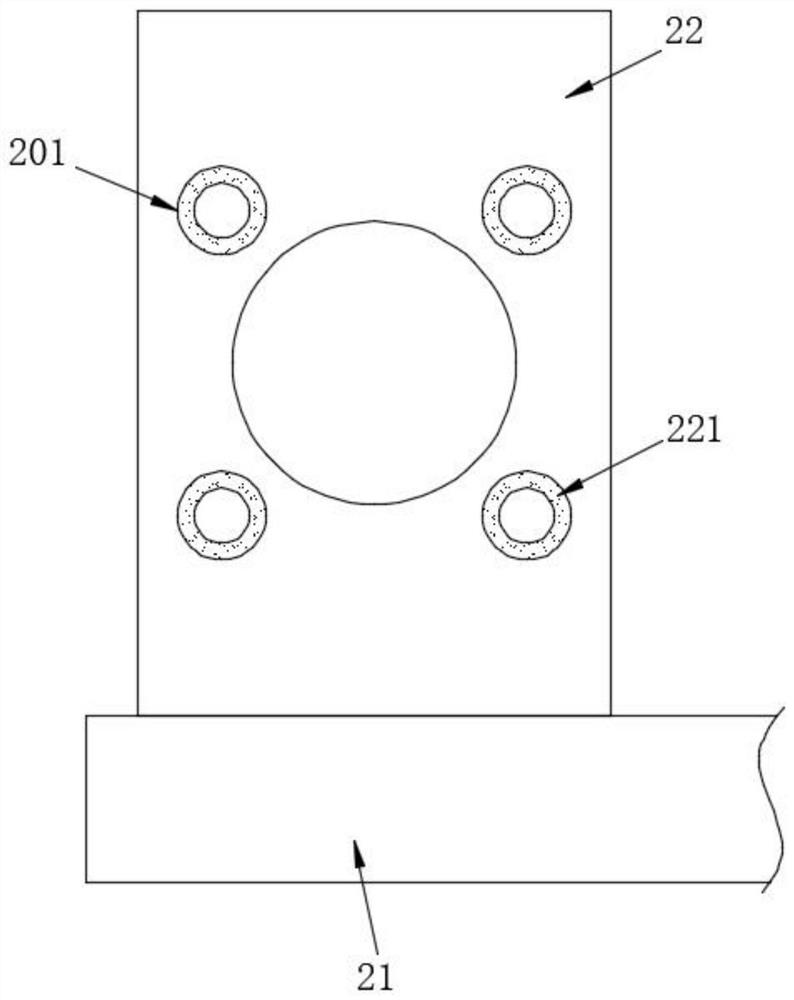

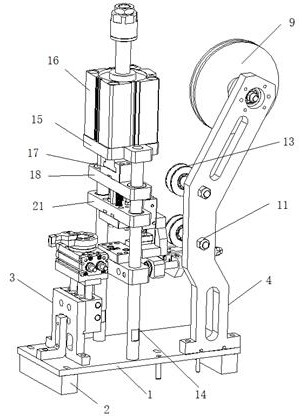

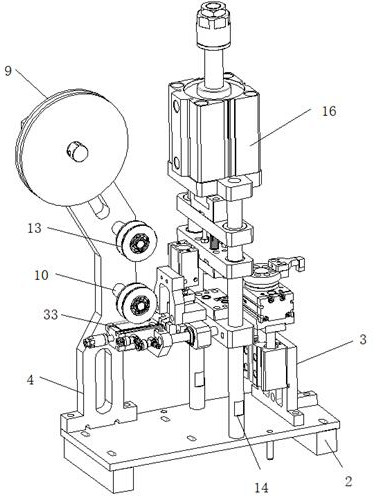

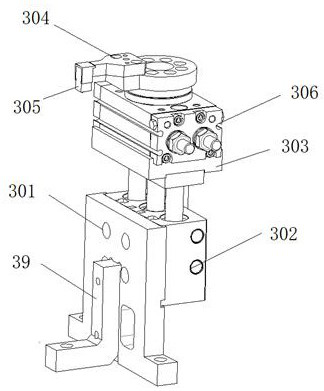

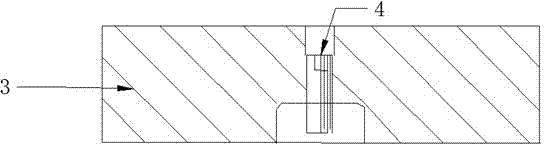

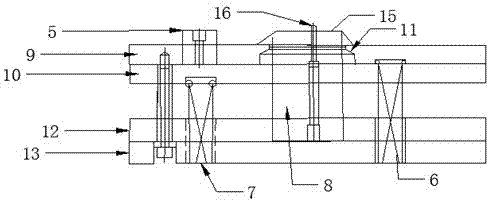

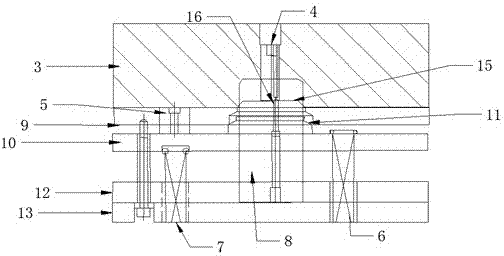

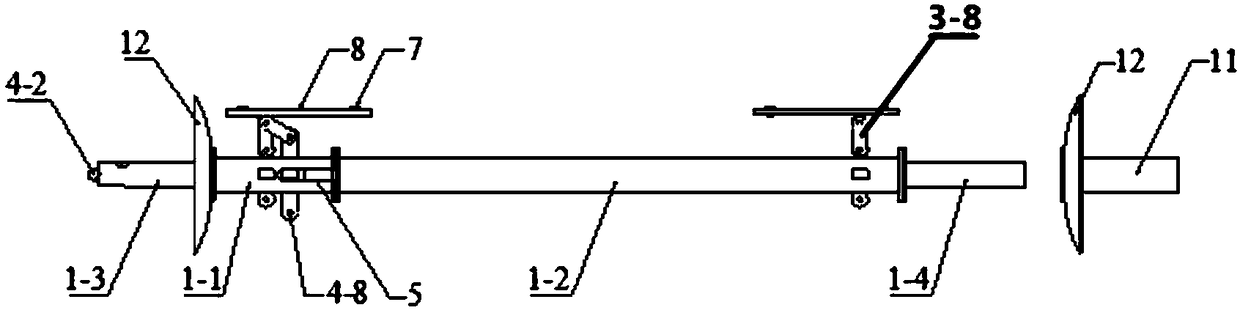

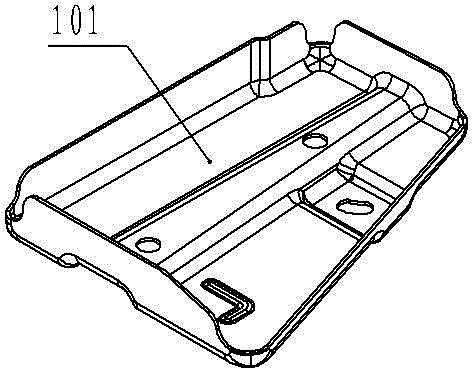

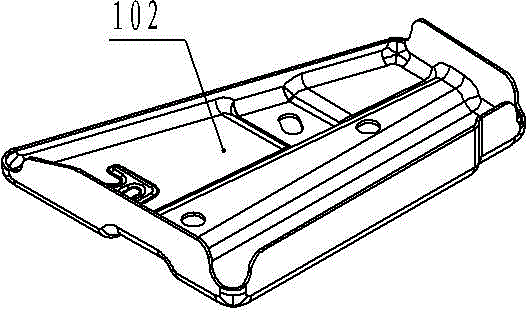

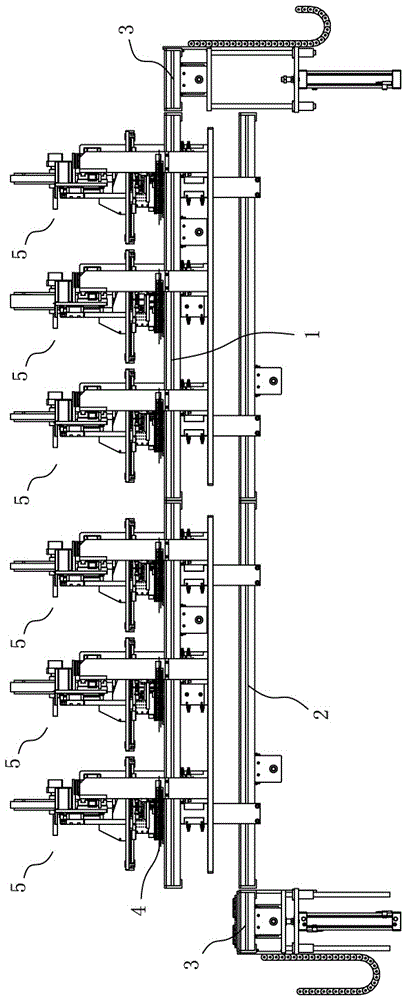

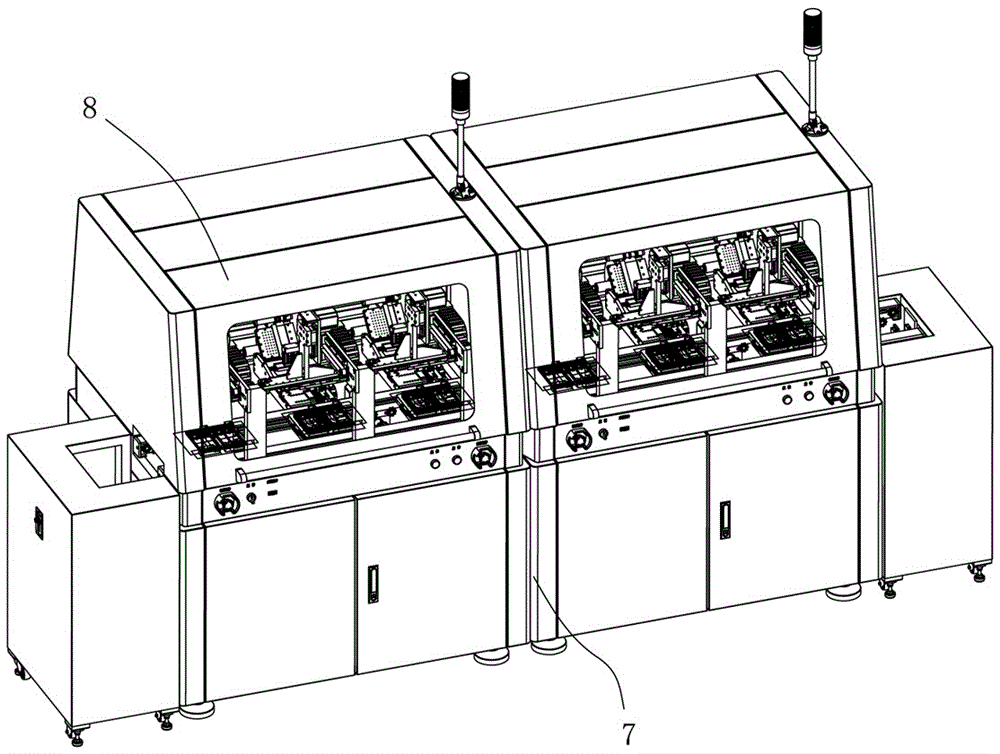

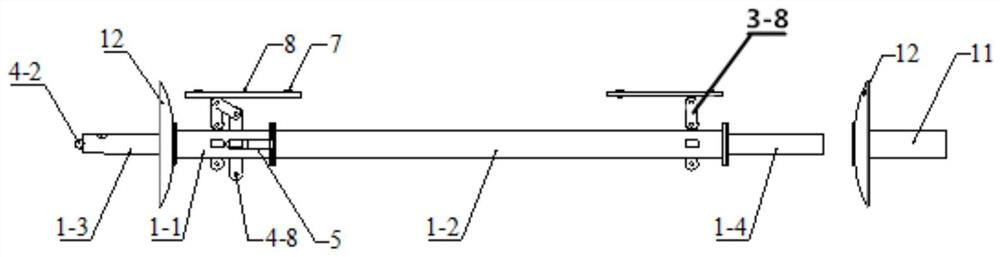

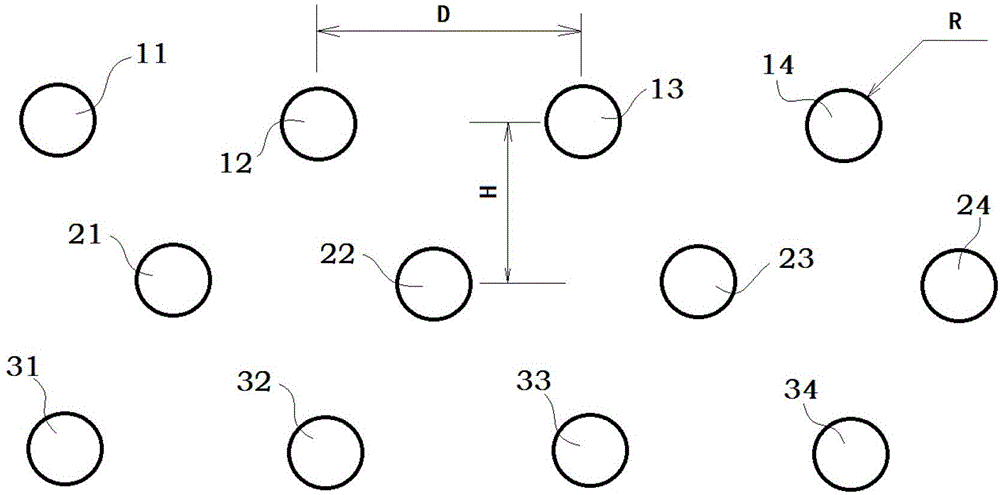

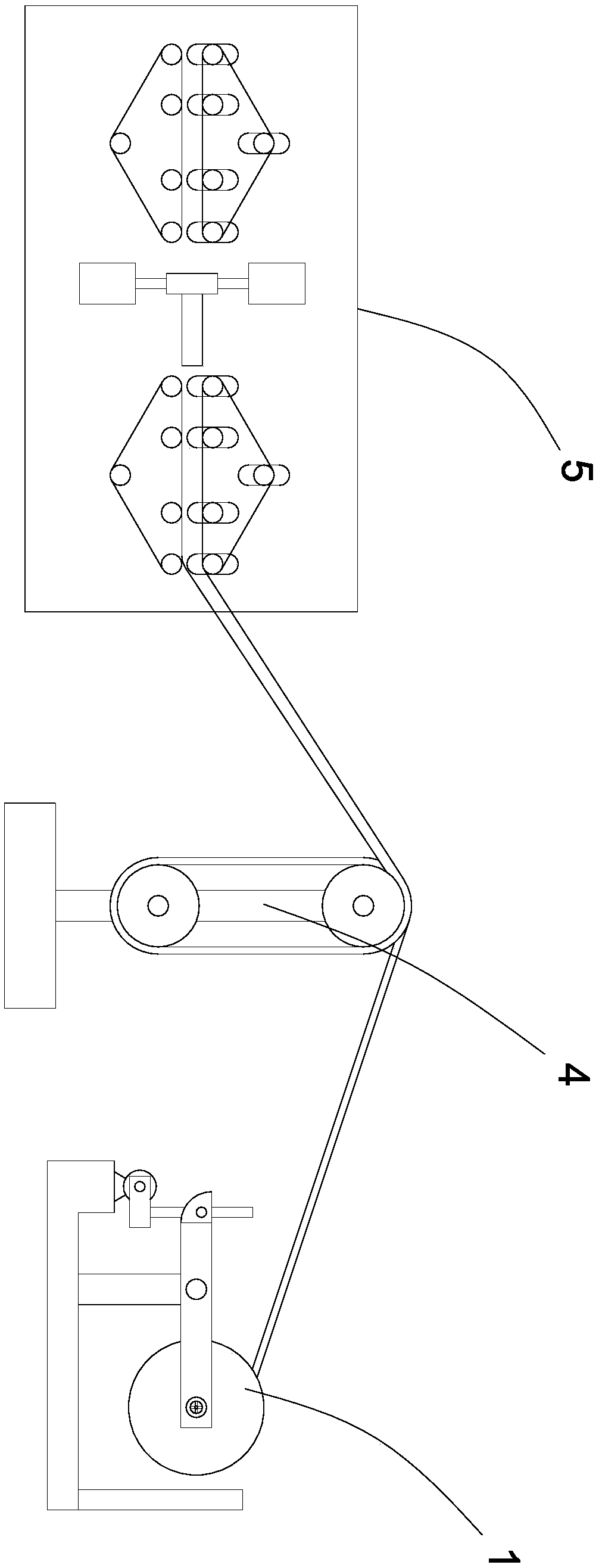

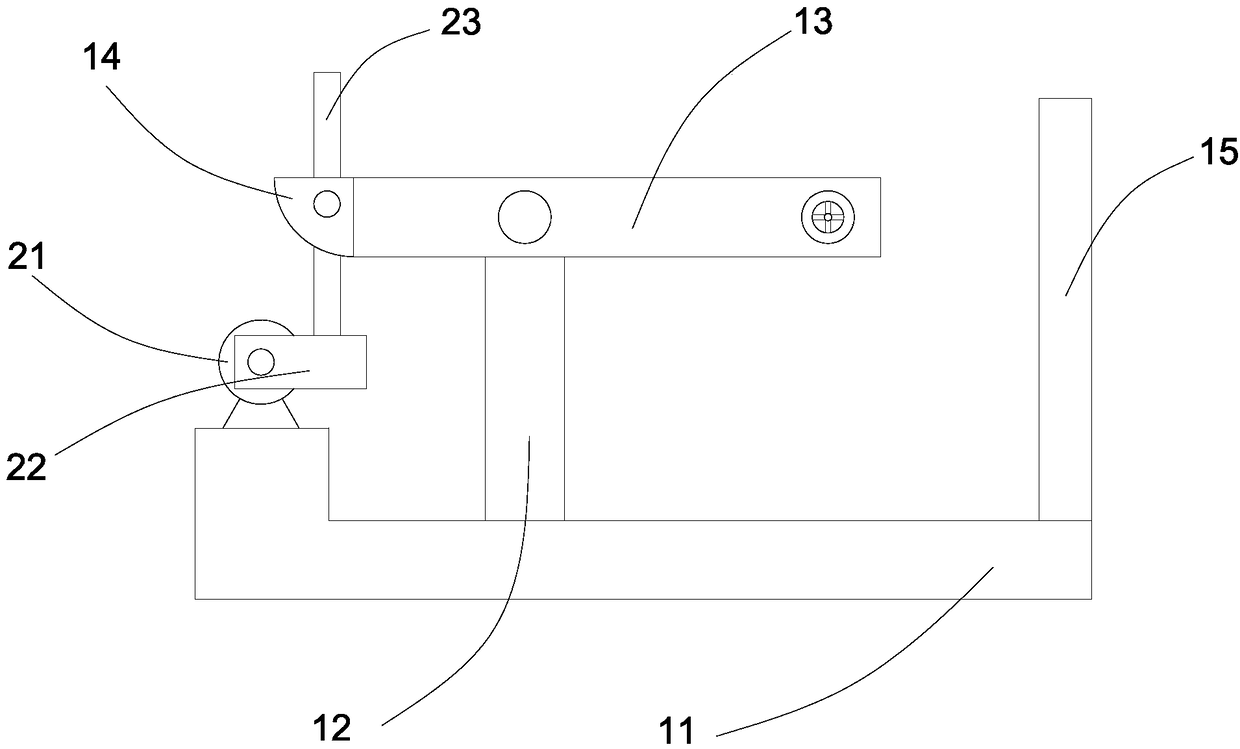

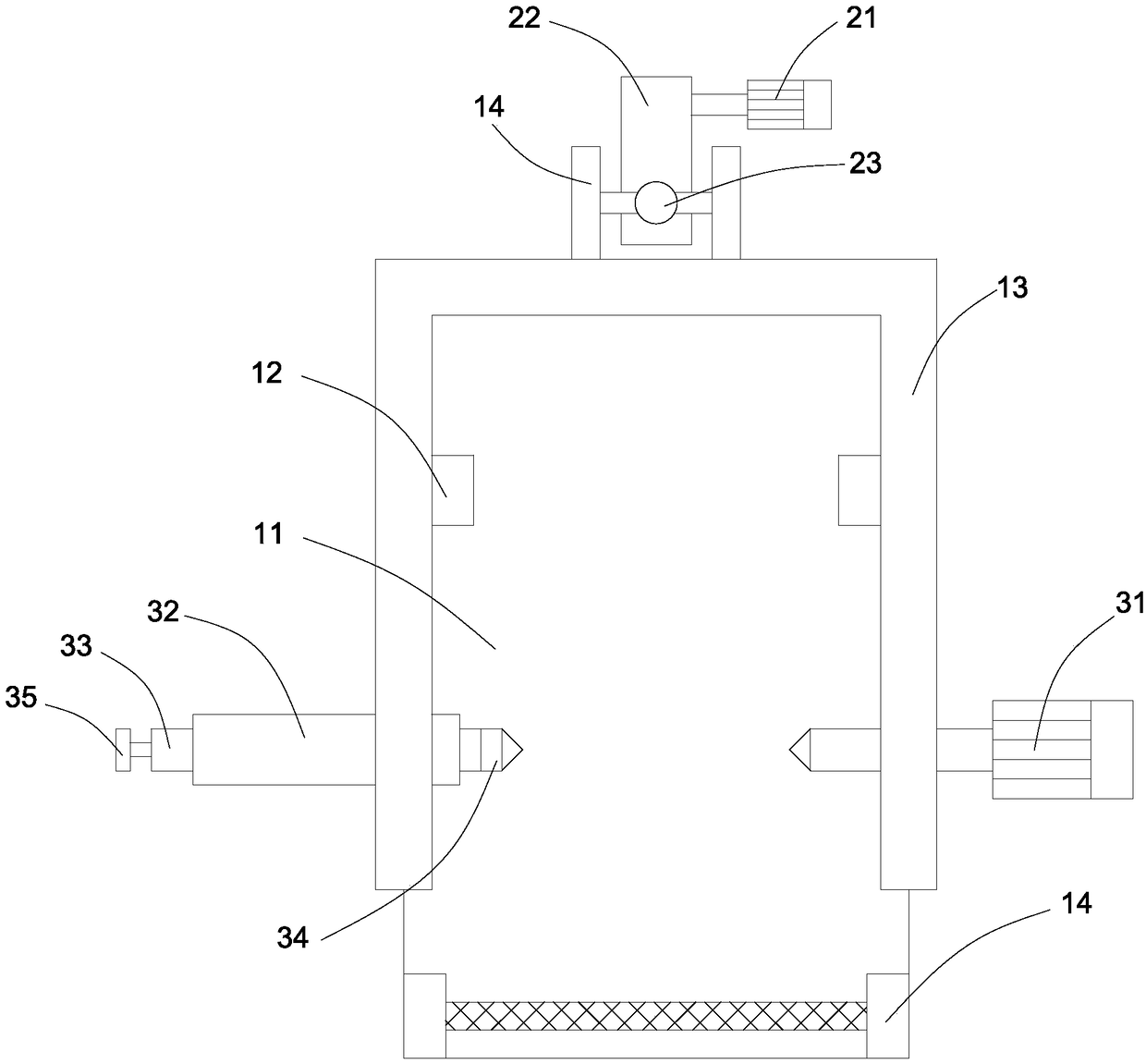

Labeling machine

ActiveCN104528088AGood stabilitySmooth strippingLabelling machinesLabelling machineProcess engineering

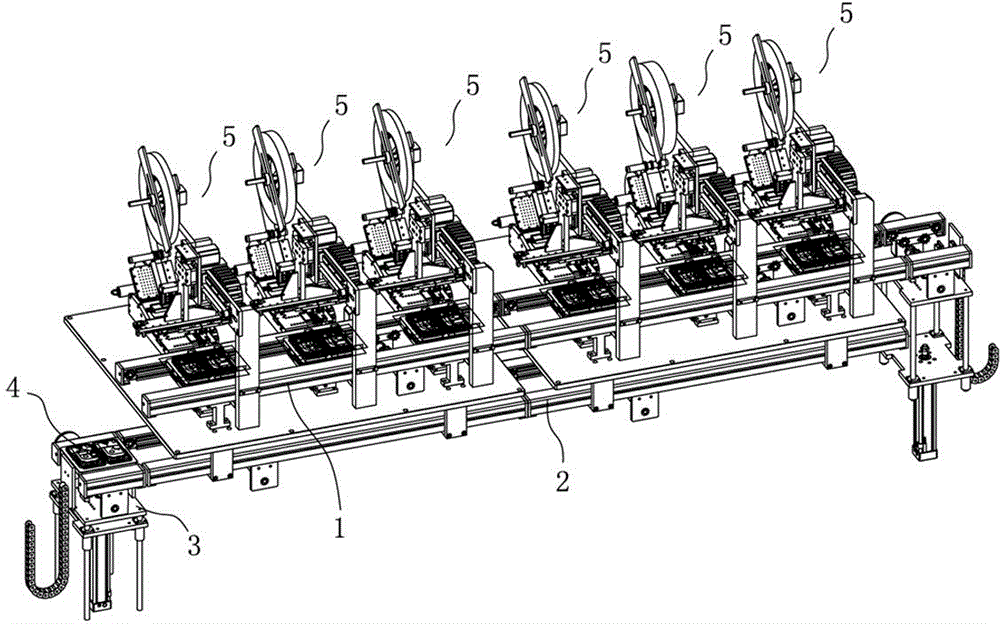

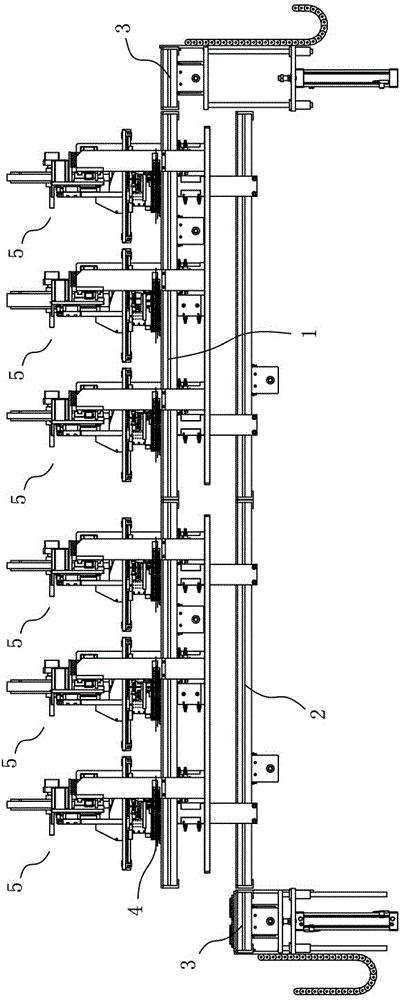

The invention discloses a labeling machine which comprises an attaching production line and a jig return line. The attaching production line and the jig return line are arranged in a two-layer mode, lifting material tables are arranged at the two ends of the attaching production line and the jig return line for transferring conveyed jigs, more than one labeling station is arranged along the attaching production line, labeling devices are installed at all the stations, and all the labeling devices on the production line cooperate to complete the operation of labeling mobile shells. By means of the cooperation of the labeling devices on the production line, and labeling operation of auxiliary materials such as foam gum of the mobile shells can be completed at a time, each labeling device integrates the functions of label stripping and labeling, operation on two products can be conducted at a time, label stripping plates move forwards and backwards through stepping motors, and stability is good. The labeling machine has the advantages of being small in occupied area, high in precision, easy to operate, high in efficiency and the like.

Owner:XIAMEN LIJU AUTOMATION TECH +1

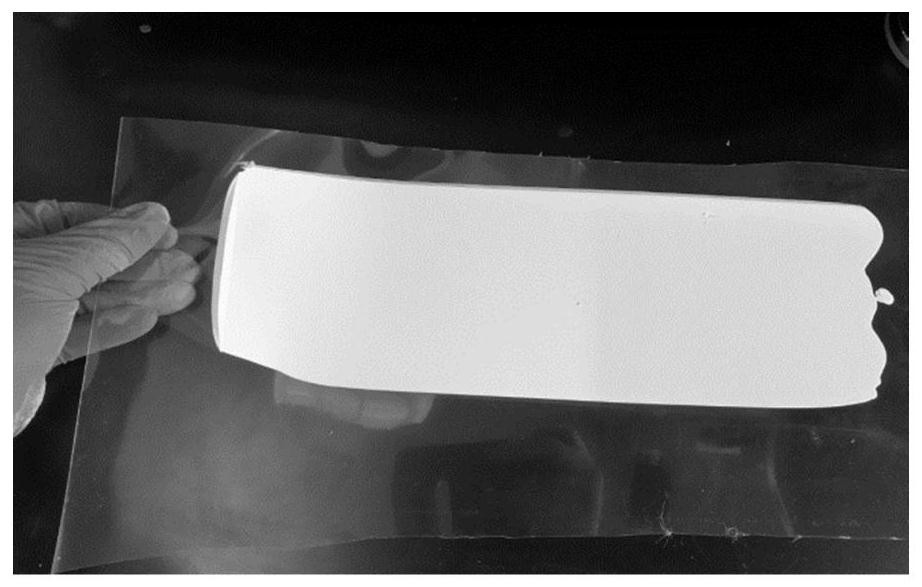

Water transfer printing paper and preparation method thereof

The invention discloses water transfer printing paper and a preparation method thereof. The water transfer printing paper comprises a hydrosol layer, a film-forming adhesive layer, carrier backing paper and an opposite colloid layer sequentially from top to bottom, wherein the opposite colloid layer is a starch layer; the film-forming adhesive layer comprises an activity colloid layer and a white colloid layer sequentially from top to bottom; the activity colloid layer is obtained by coating and drying a mixed aqueous solution of a brightening agent and the starch; the mass fractions of the brightening agent and the starch are respectively 0.5%-1% and 35%-45%; and the white colloid layer is a starch layer. The hydrosol layer is obtained by coating and drying a mixed aqueous solution of kaolin, a butylbenzene emulsion, a dispersing agent and polyvinyl alcohol; and the mass fractions of the kaolin, the butylbenzene emulsion, the dispersing agent and the polyvinyl alcohol are respectively 40%-50%, 10%-15%, 1%-3% and 3%-5%. The water transfer printing paper disclosed by the invention has the advantages of a smooth and flat surface, rational thickness of coated glue layers, higher de-molding speed, uniform water absorbability, and uniform and smooth glue surface.

Owner:杭州飞乐印刷材料有限公司

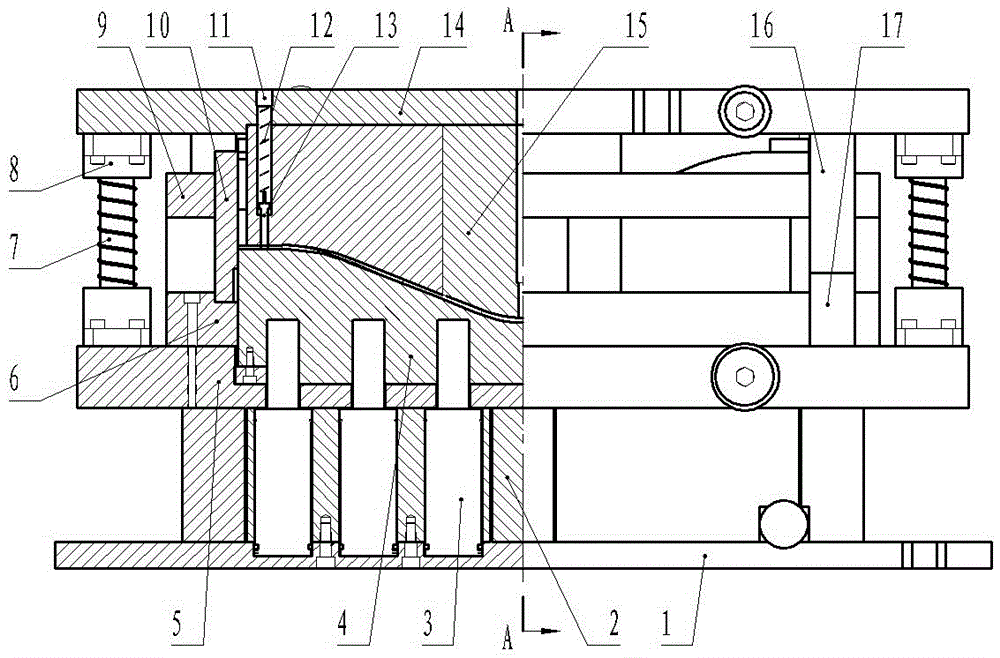

Lateral bending device

InactiveCN107737841AGuarantee product qualitySmooth strippingShaping toolsStripping-off devicesEngineeringLateral bending

The lateral bending device of the present invention relates to a bending device, and its purpose is to provide a lateral bending device in which both the bending die and the bending punch can move horizontally, the bending negative angle is large, and the mold can be demolded smoothly. device. It includes an upper mold, a lower mold, and a lateral bending mechanism. The lateral bending mechanism includes an upper mold wedge, a slider and a lateral die; one end of the slider is fixed with a lateral punch, and the other end is fixed with a push block; The slider can slide along the lower mold by connecting with the first elastic reset mechanism; the lateral die can slide along the slider by connecting with the second elastic reset mechanism; one end of the lateral die cooperates with the lateral punch to In bending, the other end and the push block form a gap; in the split state, there is a gap between the lateral punch and the inner surface of the workpiece side; in the closed state, the upper die wedge is inserted into the gap, so that the slider Sliding drives the lateral punch to abut against the side of the workpiece, and makes the lateral die move in the opposite direction of sliding relative to the slider, and cooperates with the lateral punch to bend the side of the workpiece.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

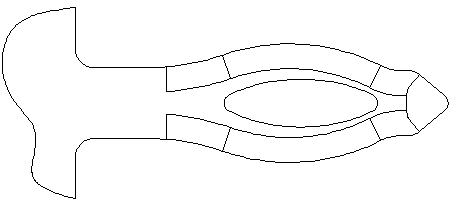

Terminal fisheye contour forming process

InactiveCN103317348AGood workmanshipAccurate shapeOther manufacturing equipments/toolsContour formElectrical and Electronics engineering

The invention relates to a terminal fisheye contour forming process. The process includes the steps of 1, taking a substrate and pre-cutting terminal fisheye contours on the substrate; 2, sending the substrate with the precut fisheye contours to a piercing station for piercing, and allowing the terminal fisheye contours and waste to be incompletely pierced after piercing; 3, sending the pierced substrate to a fisheye waste ejection station to punch off the waste, thus obtaining the terminal fisheye contours; 4, sending the substrate with the waste punched off into a chamfering station for chamfering, and chamfering to obtain four rounded angles of each terminal fisheye contour. The terminal fisheye contours formed by the process are smooth and flat with no bur edge, the formed terminal fisheye contours are precise in size with low fluctuation, chamfers are smooth with small errors, and stripping is easy.

Owner:四川瑞宝电子股份有限公司

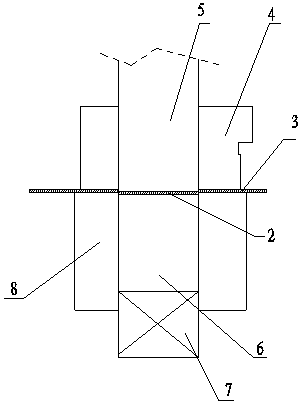

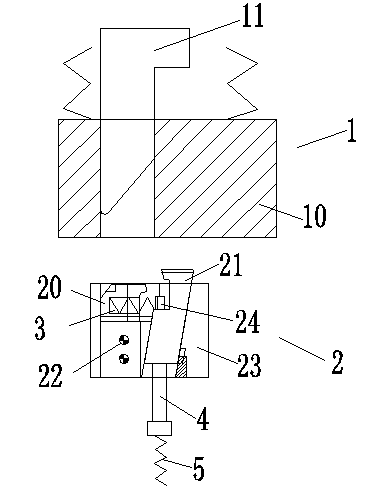

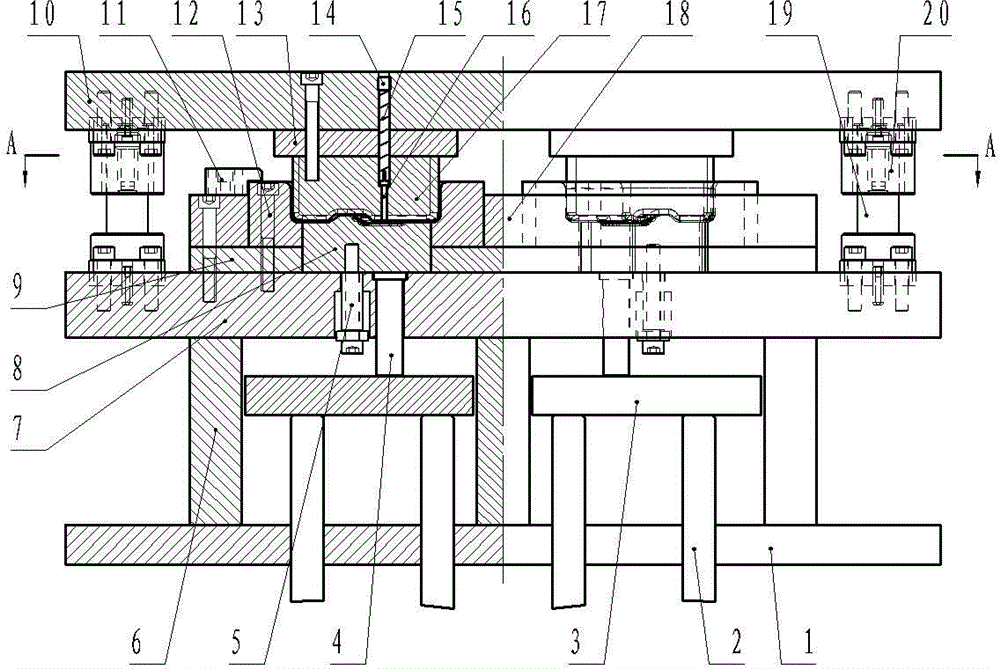

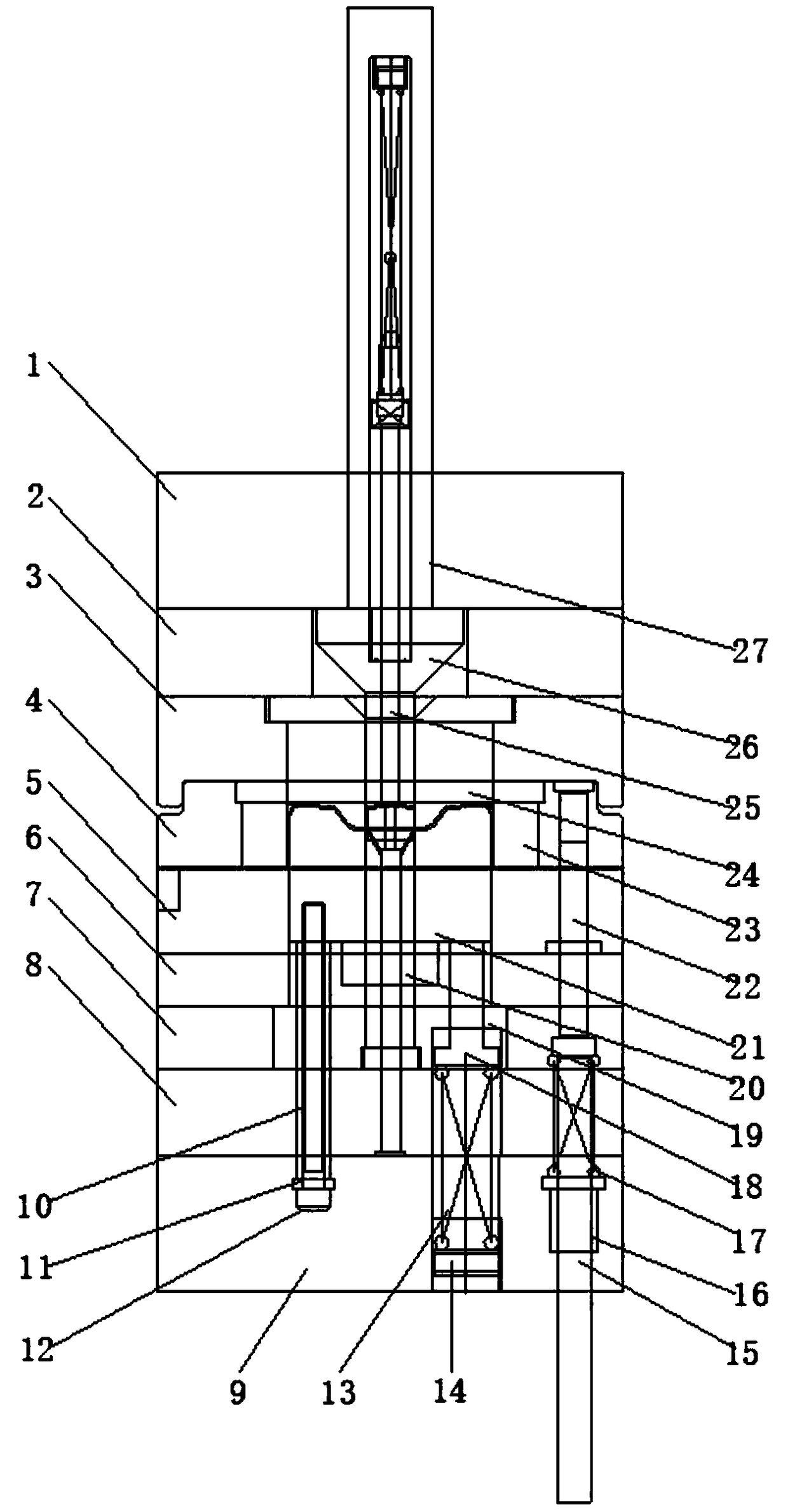

Spring seat plate forming die

InactiveCN104384342ANo offsetSmooth strippingShaping toolsEjection devicesEngineeringMechanical engineering

The invention discloses a spring seat plate forming die, and relates to the technical field of stamping die manufacture. The spring seat plate forming die comprises an upper die holder and a lower die holder, a male die and an upper clamp plate sleeving the male die are mounted at the bottom of the upper die holder, a plurality of limit holes are formed in the male die, a screw plug and an ejector rod extending out of the bottom of the male die are mounted in the limit holes, a spring is mounted between the ejector rod and the screw plug, a lower die plate and a female die plate inserted into the lower die plate are mounted on the upper portion of the lower die holder, a stripper plate is inserted into the female die plate, a plurality of guide holes are formed in the lower die holder and positioned below the stripper plate, a lower pushing post is inserted into the guide holes, the bottom of the lower pushing post is connected with an ejector plate, and guide supporting plates connected with the lower die holder and a lower support plate are mounted on two sides of the ejector plate and abutted to the ejector plate. Compared with the prior art, the spring seat plate forming die has the advantages that the ejector plate moves between the two guide supporting plates in the stripping process of an ejector workpiece, the lower pushing post moves in the guide holes, and the ejector workpiece cannot deviate and is smoothly, simply and rapidly stripped.

Owner:柳州市飞歌汽车配件有限公司

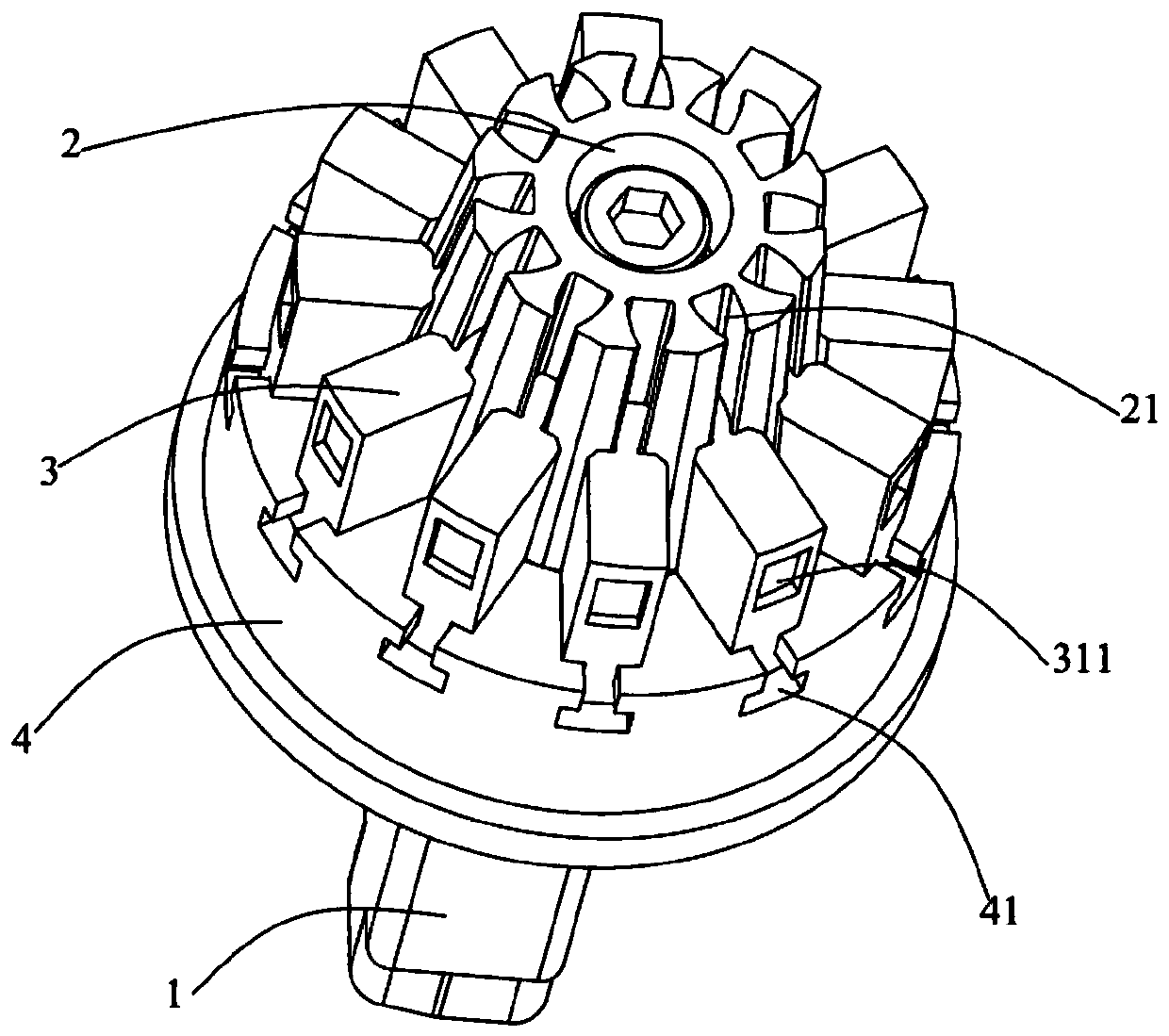

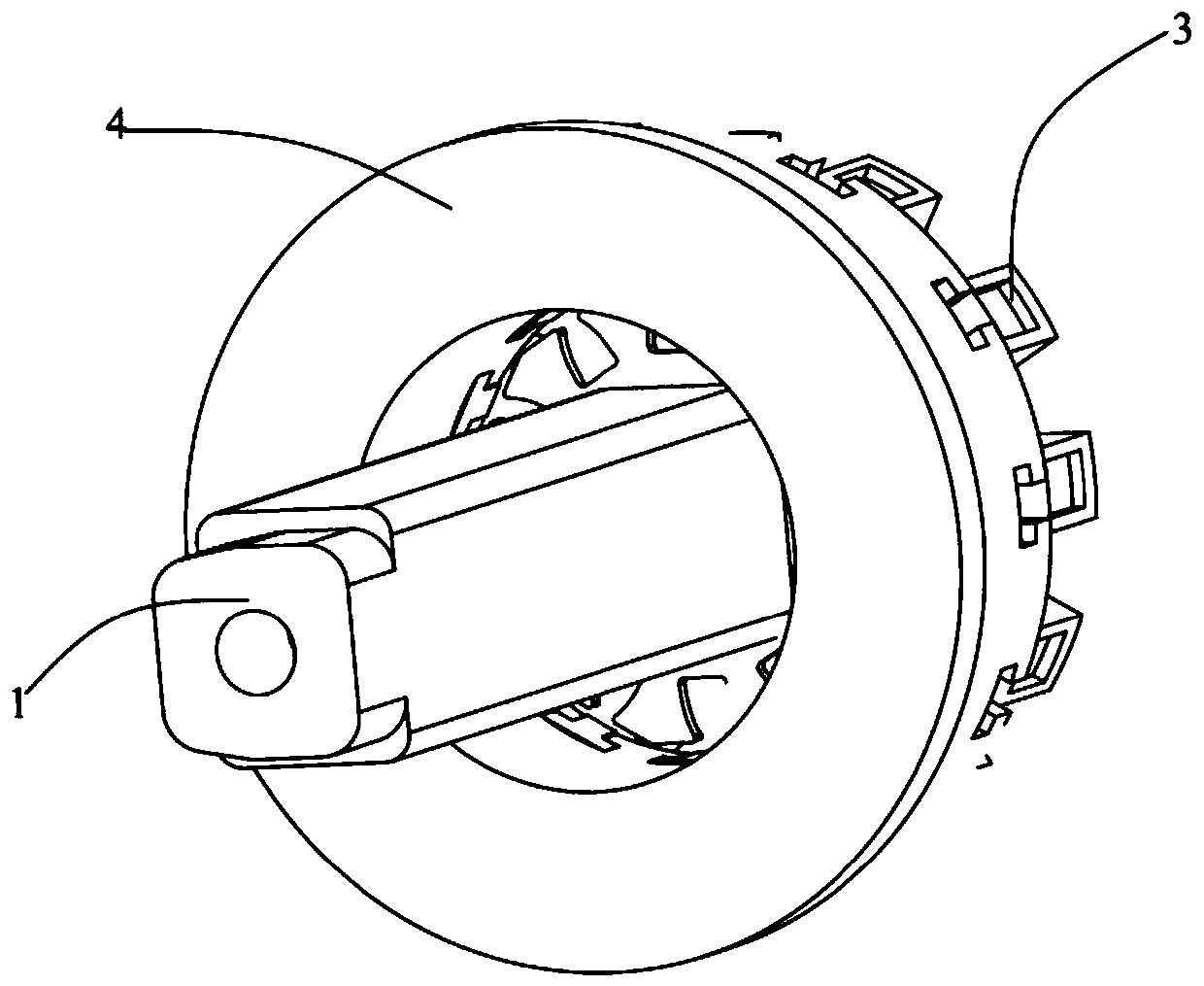

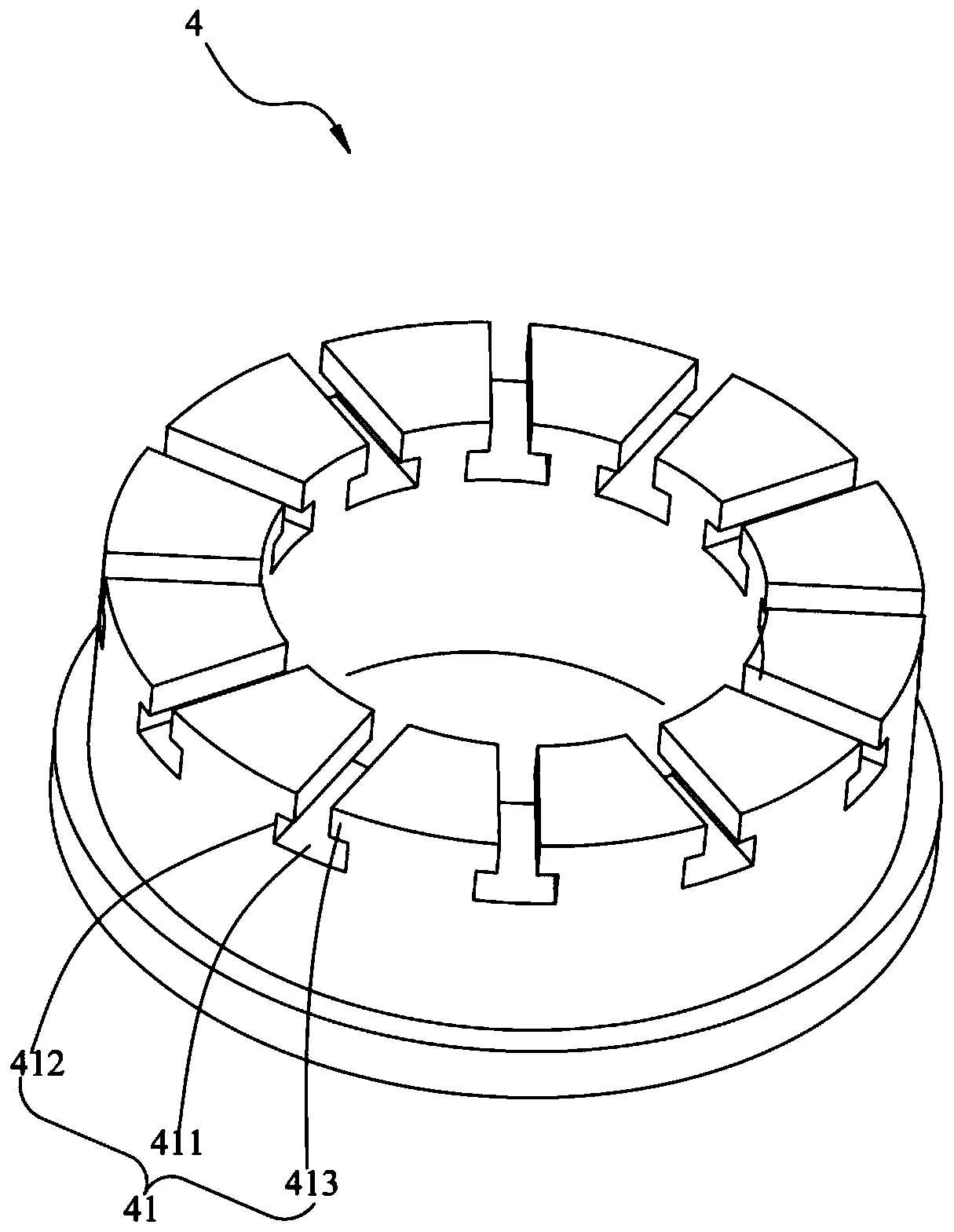

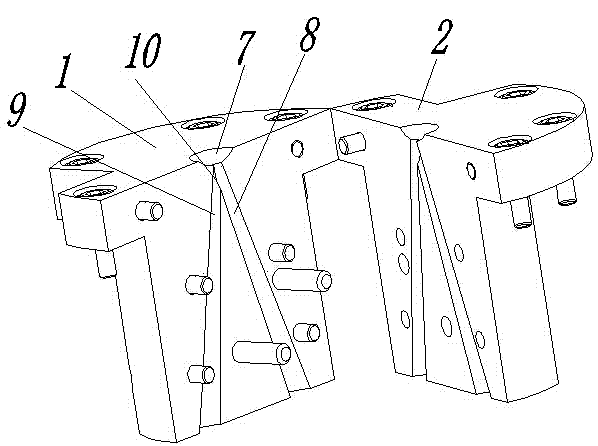

Inner sliding block mechanism, connector demolding device and demolding method

The invention provides an inner sliding block mechanism, a connector demolding device and a demolding method. The inner sliding block mechanism comprises a sliding block seat insert, a plurality of sliding blocks and a sliding block guiding block, wherein one end of the sliding block seat insert is fixedly provided with a sliding block seat, a plurality of sliding grooves are formed in the circumferential direction of the sliding block seat in the vertical direction, and the radial cross section area of the sliding block seat is gradually reduced from the first end to the second end; the sliding block guiding block is disposed on the periphery of the sliding block seat insert in a sleeving mode and provided with a plurality of limiting grooves which are fixedly connected with the pluralityof sliding blocks in the axial direction and slideably connected with the sliding blocks in the radial direction; and the sliding block guiding block reciprocates in the axial direction of the sliding block seat insert under the action of external force so as to drive the plurality of sliding blocks to move from the first position which is in contact with a to-be-separated part to the second position which is not in contact with the to-be-separated part along the sliding grooves along with the sliding block guiding block. By means of the inner sliding block mechanism, a boss on hardware can be successfully separated from a mold without damaging the boss on the hardware, and the subsequent welding effect of the hardware and a conducting wire is guaranteed.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

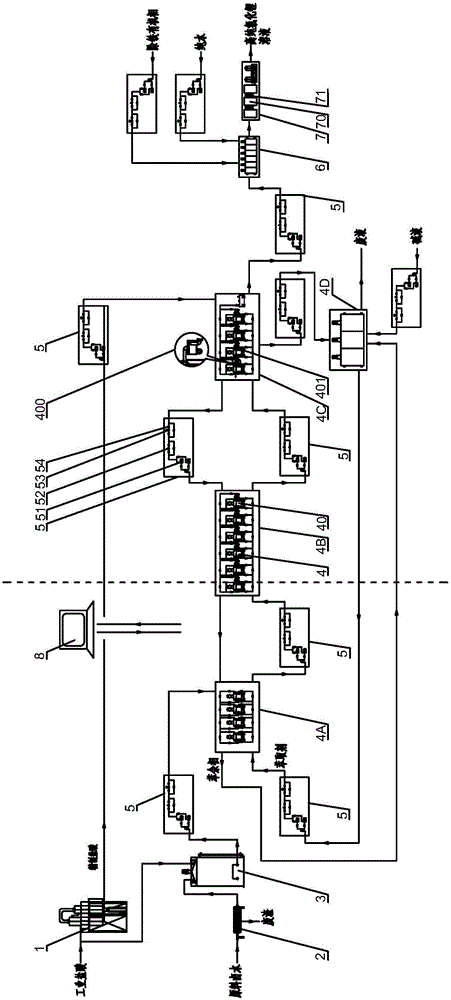

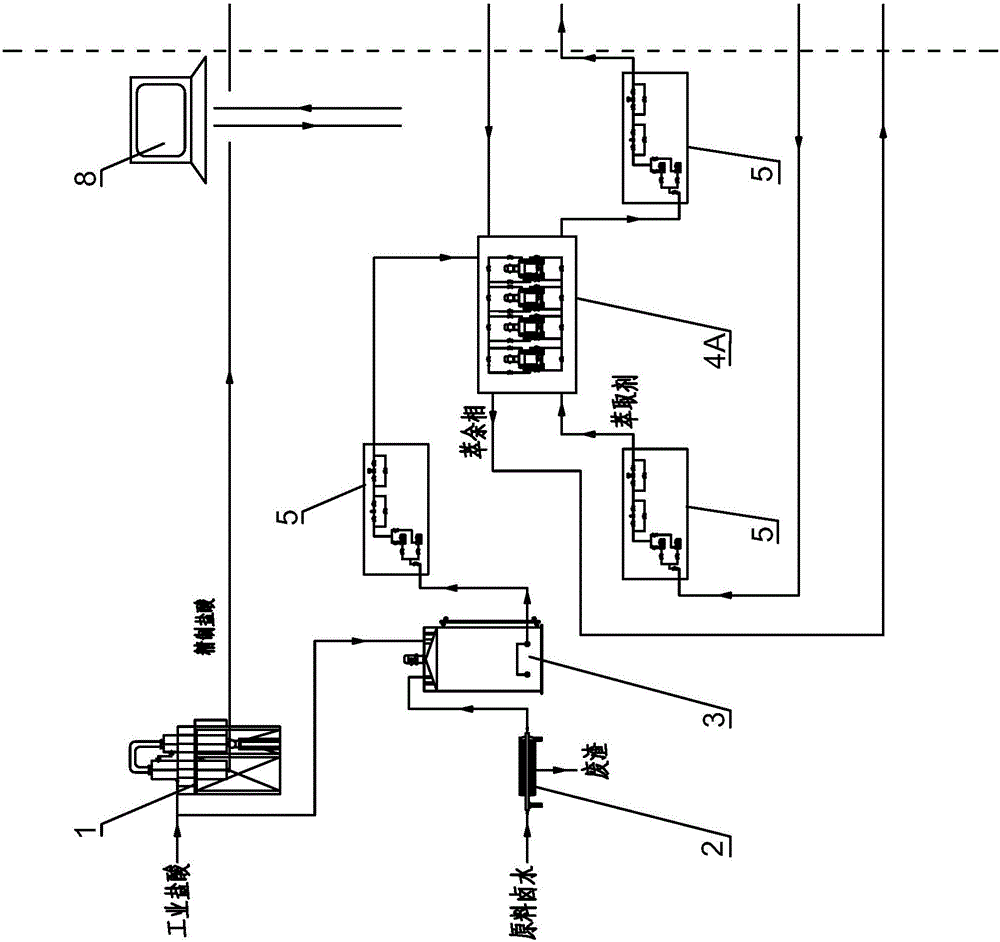

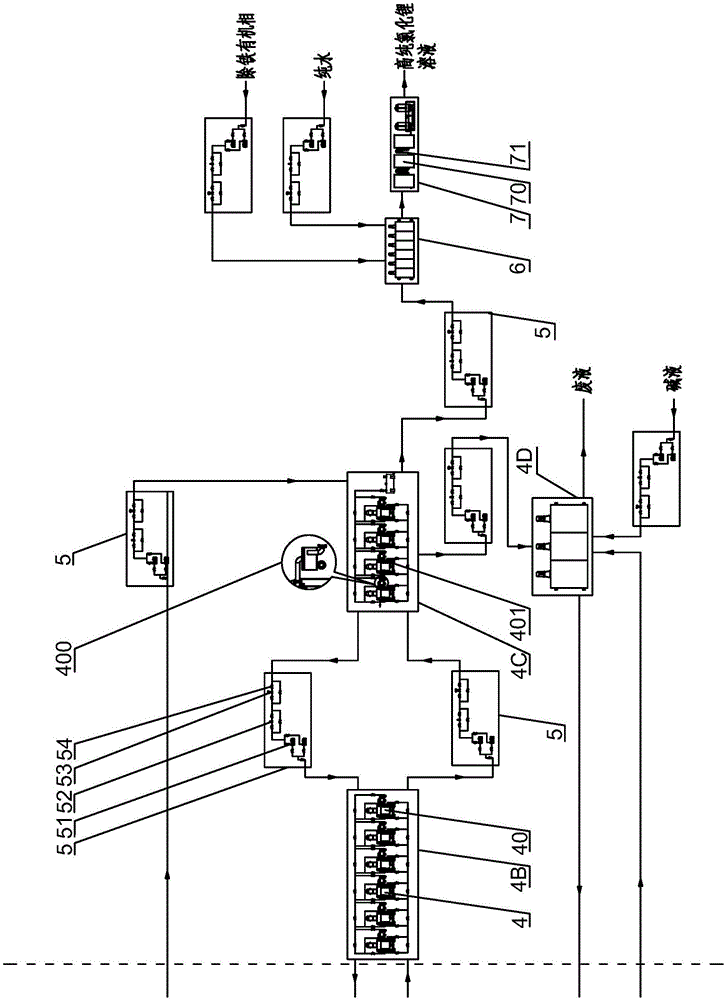

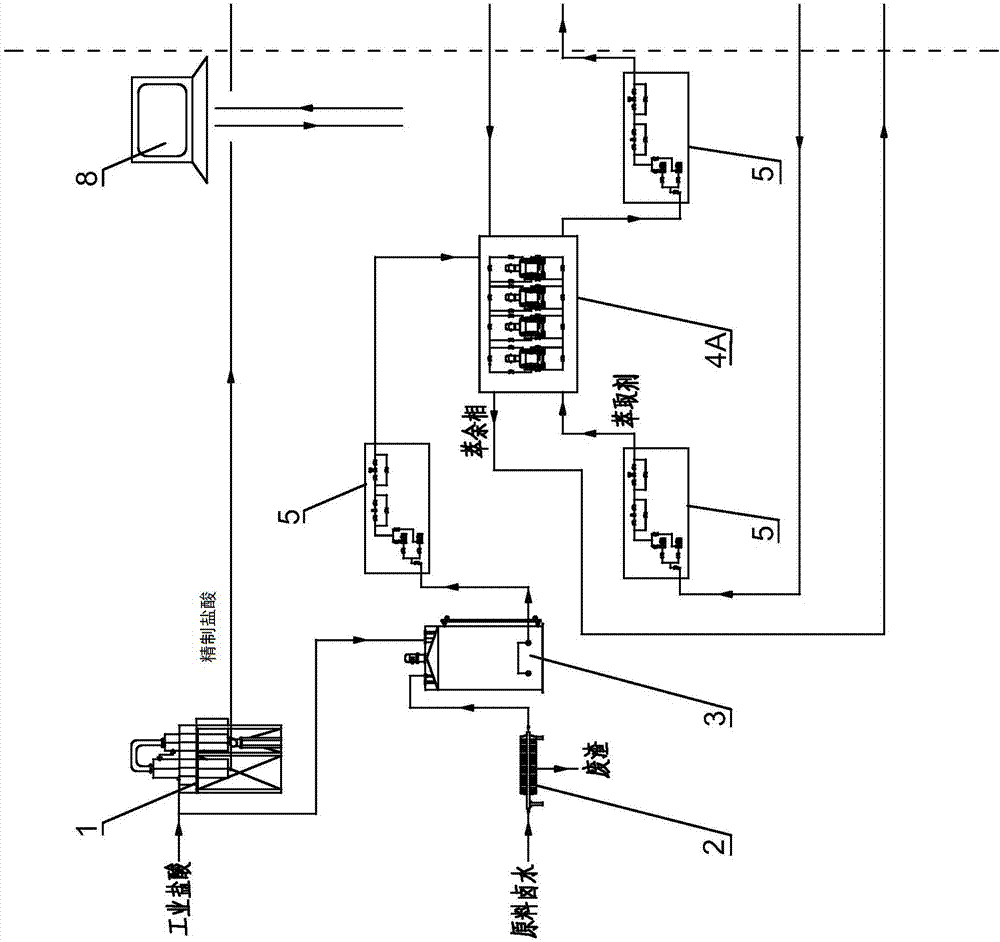

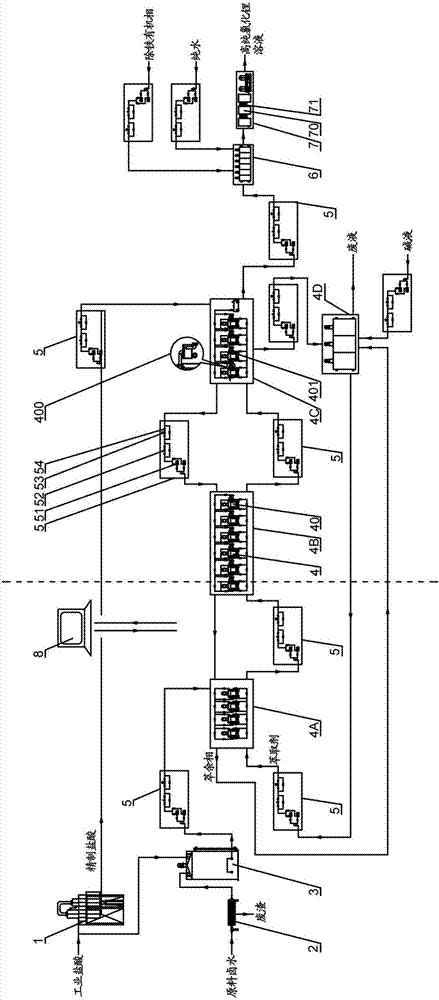

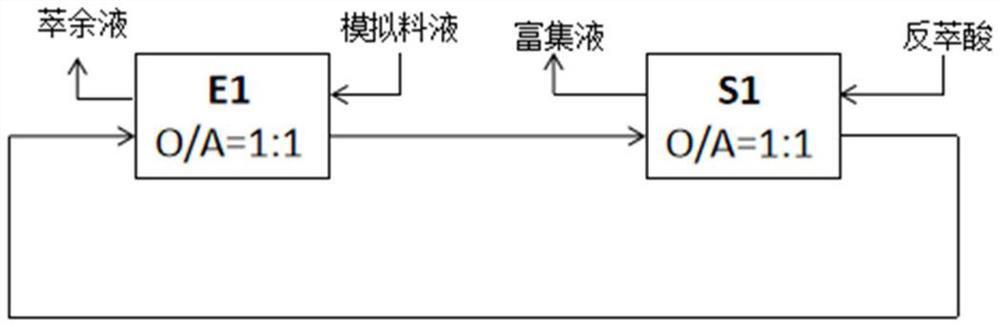

High-purity lithium chloride extraction device

ActiveCN106219579AImprove extraction efficiencyPhase equilibrium establishment time is fastLithium halidesSolventChemistry

The invention discloses a high-purity lithium chloride extraction device. The high-purity lithium chloride extraction device comprises a filter press, a blending tank, an extraction system, a washing system, a reverse extraction system, a deironing system and an oil removal system which are sequentially connected through a pipeline, the blending tank is used for acid regulating treatment, and the extraction system, the washing system and the reverse extraction system are respectively formed by connecting multiple stages of centrifugal extractors in series. The reverse extraction solution outlet end of the reverse extraction system is connected with the washing system, the organic phase output end of the reverse extraction system is connected with a saponification system, and the saponification system is connected with the extraction system. A circulating loop is formed by the extraction system, the washing system, the reverse extraction system and the saponification system. The device is further provided with a data analysis system, and the work positions of the abnormal centrifugal extractors can be automatically switched to a standby centrifugal extractor through the system. Variable-frequency closed-loop flow control systems are arranged at the material input ends of all the systems in the circulating loop for obtaining the precise flow-input phase ratio through timely adjustment. The device is high in extraction efficiency, short in phase balance setting time, small in solvent needing amount, low in solvent consumption and continuous and reliable in process.

Owner:HEFEI GENERAL MACHINERY RES INST

High-purity lithium chloride production technology

The invention discloses a high-purity lithium chloride production technology. An apparatus in the production technology comprises a filter press, a blending pot for acid adjusting treatment, an extraction system, a washing system and a back-extraction system connected by the multistage centrifugation extraction machines in series respectively, an iron-removal system and an oil removing system which are connected in order through the pipelines, wherein, an output terminal of a back extraction solution of the back-extraction system is connected with the washing system, an organic phase output terminal of the back-extraction system is connected with a saponification system, the saponification system is connected with the extraction system; and the extraction system, the washing system, the back-extraction system and the saponification system form a circulation loop. The apparatus also comprises a data analysis system capable of switching an abnormal centrifugation extraction machine station to a backup centrifugation extraction machine. A frequency-conversion closed loop flow control system is arranged at a material input of each system of the circulation loop, and the accurate flowing and input phase ratio can be obtained by appropriate adjusting. The apparatus has the advantages of high extraction efficiency, fast establishing time for phase equilibrium, small solvent required amount, small consumption of a solvent, and continuous and reliable processes.

Owner:HEFEI GENERAL MACHINERY RES INST

Forming mold for Z-shaped product

InactiveCN104826930ARealize automatic strippingSmooth strippingShaping toolsStripping-off devicesMaterials science

Owner:昆山电子羽电业制品有限公司

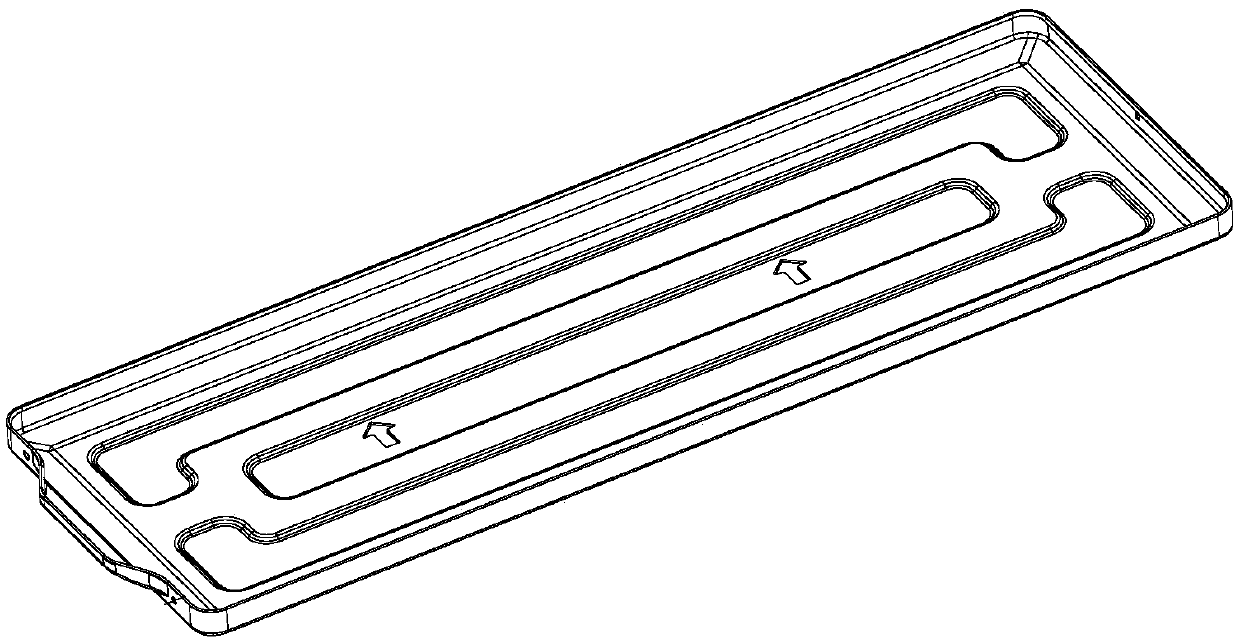

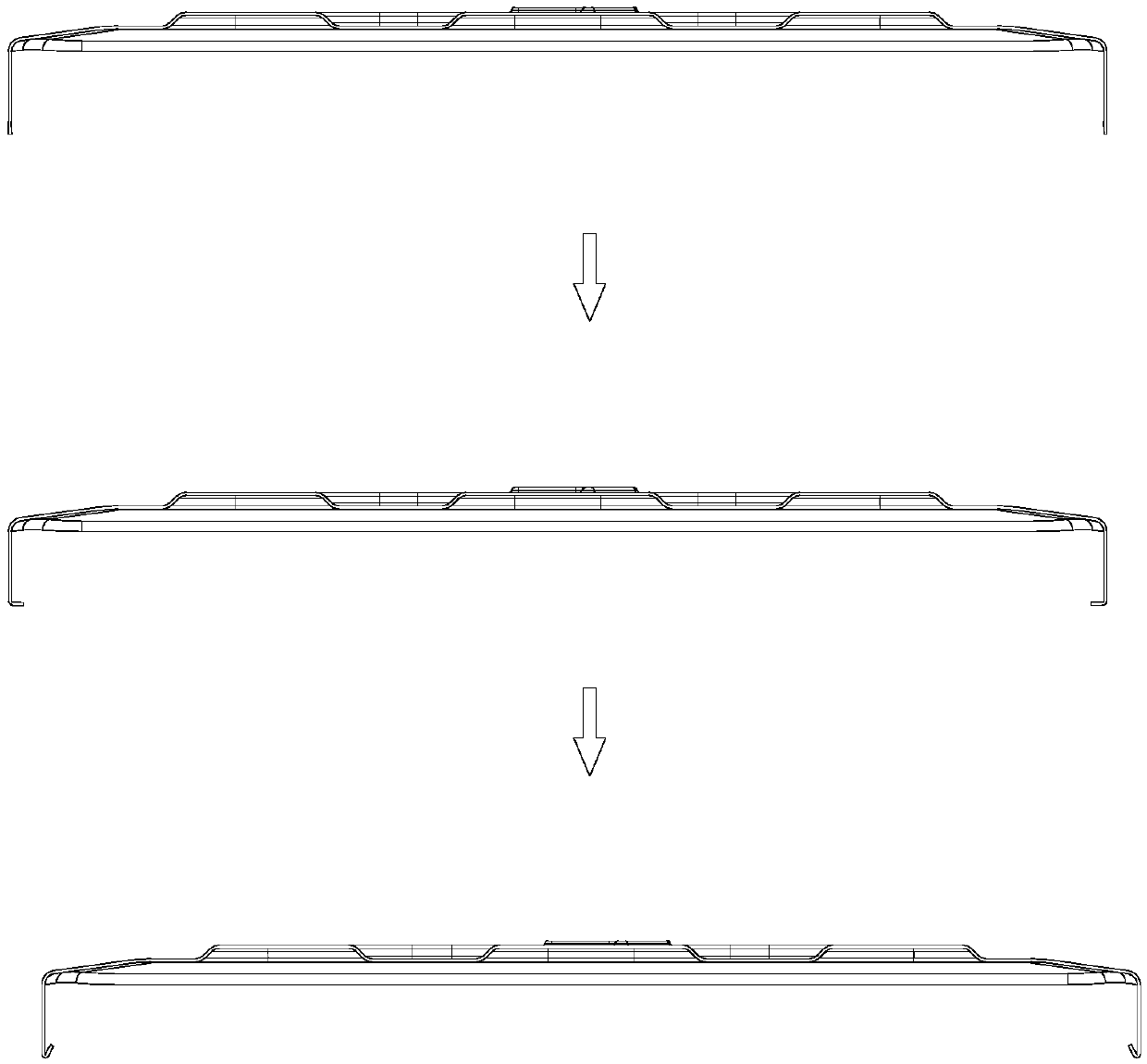

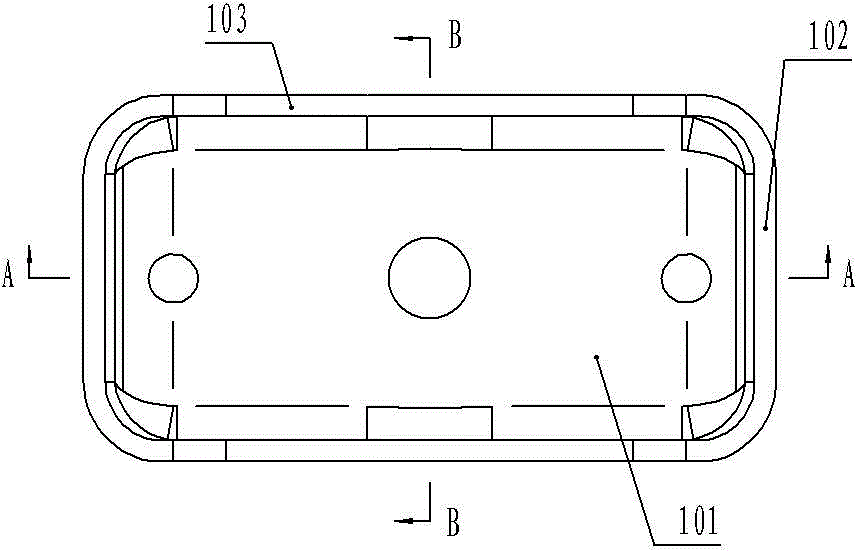

Movable step type located mold

InactiveCN104801616AAvoid frictionSmooth strippingShaping toolsMetal-working feeding devicesPhysicsMechanical engineering

The invention relates to the technical field of display screen back panel mold structures, in particular to a movable step type located mold. A locating ejection mechanism comprises a step type internal locating pin and an ejection mechanism which is connected with the step type internal locating pin and can drive the step type internal locating pin to telescope; the step type internal locating pin comprises a pin main body and a boss arranged at one end of the pin main body, and the diameter of the boss is smaller than that of the pin main body; a locating hole is formed in a material sheet, and the material sheet sleeves the boss through the locating hole. The ejection mechanism directly drives the telescopic motion of the step type internal locating pin, and the step type internal locating pin drives the material sheet to move while telescoping, so that the circumstance in the prior art that the locating hole of the material sheet can be in friction with the internal locating pin and then easily causes the deformation of the locating hole of the material sheet is avoided, thus, the circumstance that the material sheet is easily stuck during demolding can be avoided, and thus, the movable step type located mold has the advantage of smoothness in demolding.

Owner:DONGGUAN HAOSHUN PRECISION TECH CO LTD

Negative angle bending mould

ActiveCN102974693AGet rid of the bends that are not in placeGet rid of productivityShaping toolsEngineering

The invention discloses a negative angle bending mould which comprises an upper mould and a lower mould. The upper mould comprises an upper press plate and a punch. The lower mould comprises a first slide block, a second slide block, a guide rail, a base seat and a baffle, wherein a square hollow cavity is formed in the base seat, the first slide block and the guide rail are placed on the inner left side of the base seat in a stacked mode, the second slide block is placed on the inner right side of the base seat, and the baffle is placed between the first slide block and the second slide block through a first compression spring. Through the method, the negative angle bending mould can improve stability of product size processing and improve processing efficiency.

Owner:SUZHOU XINJIESHUN HARDWARE ELECTROMECHANICAL

Connector cover plate clamping and moving mechanism

InactiveCN112490824AAvoid jammingEasy to disengageContact member assembly/disassemblyForward slidingClassical mechanics

The invention belongs to the technical field of connector cover plate clamping devices, and particularly relates to a connector cover plate clamping and moving mechanism which comprises a supporting mechanism. The supporting mechanism comprises a supporting column and a top plate fixed to the top face of the supporting column, a first air cylinder is fixedly connected to one side of the top face of the top plate, and the first air cylinder is in transmission connection with an external air source. A guide rail is fixedly connected to the side, away from the first air cylinder, of the top surface of the top plate, and a sliding table is slidably connected to the guide rail. After machining is completed, the first air cylinder pushes the sliding table to slide forwards along the guide rail,a sliding table air cylinder on a mounting plate pushes the supporting plate to move downwards, and a second air cylinder drives a clamping jaw to loosen the cover plate; a sliding plate drives an ejector rod to slide downwards under the action of a spring so as to push away the cover plate, and meanwhile a patch vibration motor drives the sliding plate and the ejector rod to vibrate. Therefore, the cover plate can be better separated from a positioning pin, the phenomenon that the cover plate is clamped is effectively prevented, and the cover plate can be stripped more smoothly.

Owner:嘉兴晨翔智能装备有限公司

Structure for automatically and continuously cutting and feeding brazing sheets

PendingCN111673481APush smoothEliminate fine burrsOther manufacturing equipments/toolsMetal working apparatusPunchingWelding

The invention relates to the technical field of brazing sheet cutting and feeding, in particular to a structure for automatically and continuously cutting and feeding brazing sheets. The structure comprises an underframe, wherein the bottom end of the underframe is provided with a pair of feeding pads; a brazing sheet feeding assembly and a feeding frame are installed at the upper end of the underframe; the brazing sheet feeding assembly comprises a brazing sheet feeding support, a three-column cylinder, a brazing sheet feeding swinging cylinder seat, a rotary feeding swinging block and a feeding sucker; the brazing sheet feeding support is fixedly installed on the underframe through pins; the three-column cylinder is fixedly installed on the right side wall of the brazing sheet feeding support; the brazing sheet feeding swinging cylinder seat is fixedly installed at the telescopic end of the three-column cylinder; a rotary cylinder is installed at the upper end of the brazing sheet feeding swinging cylinder seat; the rotary feeding swinging block is fixed at the top output end of the rotary cylinder; and the feeding sucker is fixed on the outer wall of the rotary feeding swingingblock. According to the structure for automatically and continuously cutting and feeding the brazing sheets, the feeding, punching, cutting and feeding of the sheets of 0.05 mm are finished through the automatic continuous die structure, so that the difficulty in the manual cutting and taking is reduced, and the achievement of the automatic welding is realized.

Owner:安徽奥维斯智能设备科技有限公司

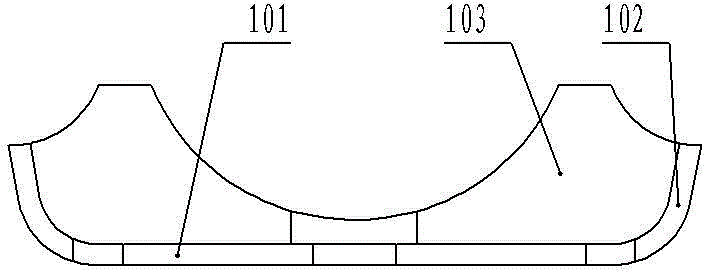

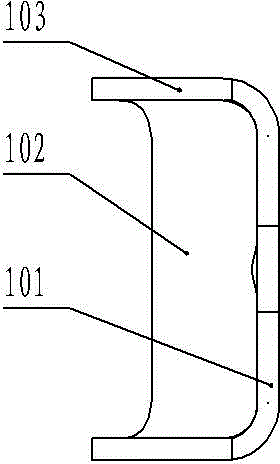

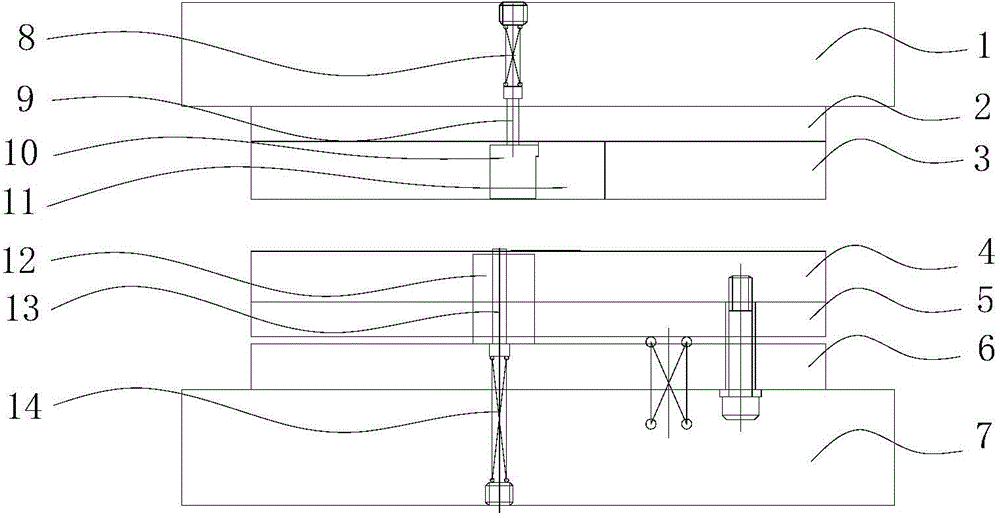

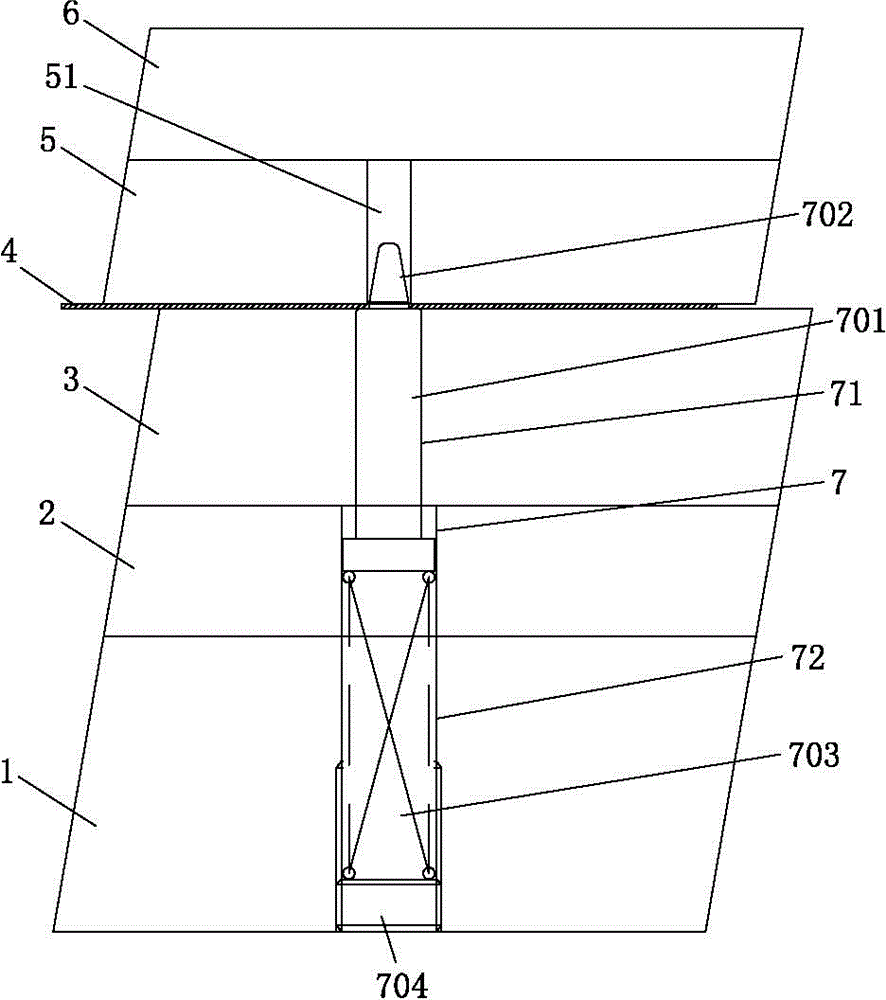

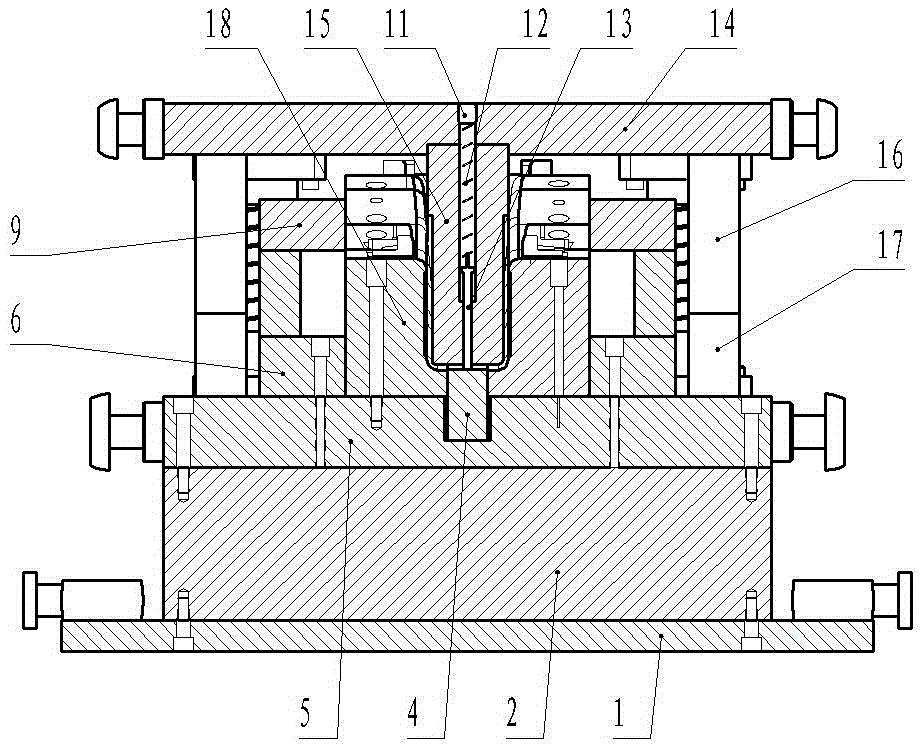

Double-layer stripping mechanism of ironware drawing die

ActiveCN104117591AGuaranteed appearance qualityPrecise positioningShaping toolsStripping-off devicesEngineeringMechanical engineering

The invention discloses a double-layer stripping mechanism of an ironware drawing die. The double-layer stripping mechanism comprises an upper die assembly and a lower die assembly, the upper die assembly comprises a die sleeve and a stripping block in the die sleeve, the lower die assembly comprises an inner limiting column, a lower stripping plate I spring, a lower stripping plate II spring, a male punch, a lower stripping plate I, a lower stripping plate II, an inner stripping block in the lower stripping plate, a lower clamping plate, a lower backing plate and a lower die base. The double-layer stripping mechanism is easy to position, stripping is smooth, the lower stripping plate I takes charge of material pressing, and the lower stripping plate II takes charge of stripping. The appearance quality of drawn products is ensured, dimensional stability of the products is ensured, the die repairing time is shortened, die repairing cost is reduced, and the production yield is increased.

Owner:TIANJIN DEV ZONE JINGRUI PRECISION MOLD

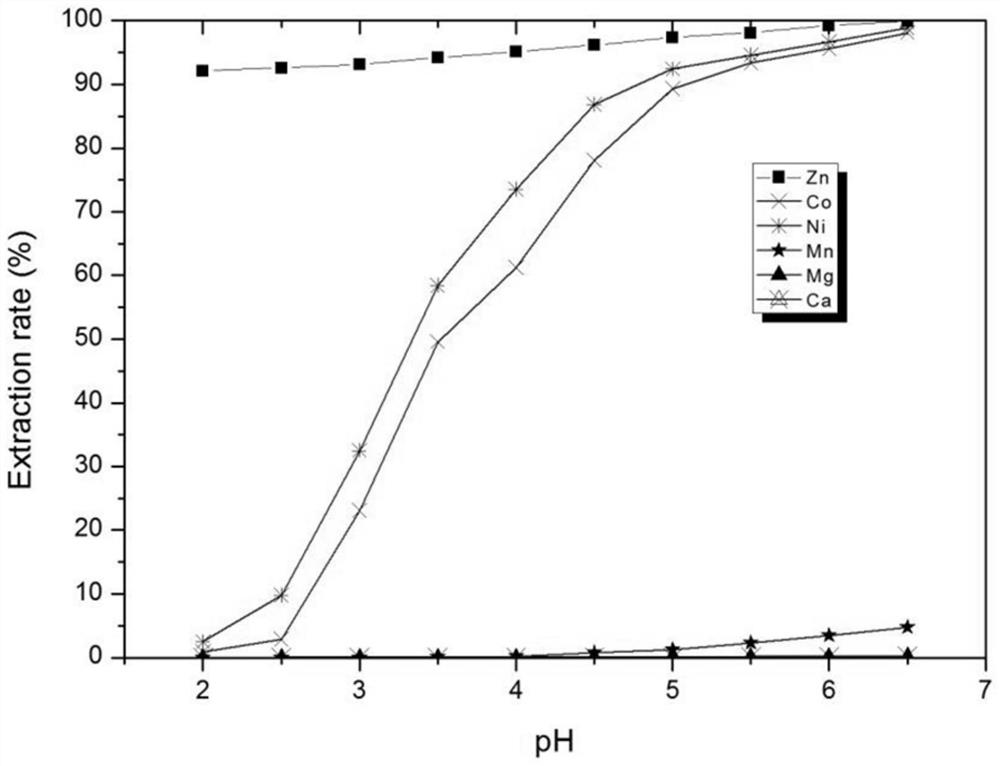

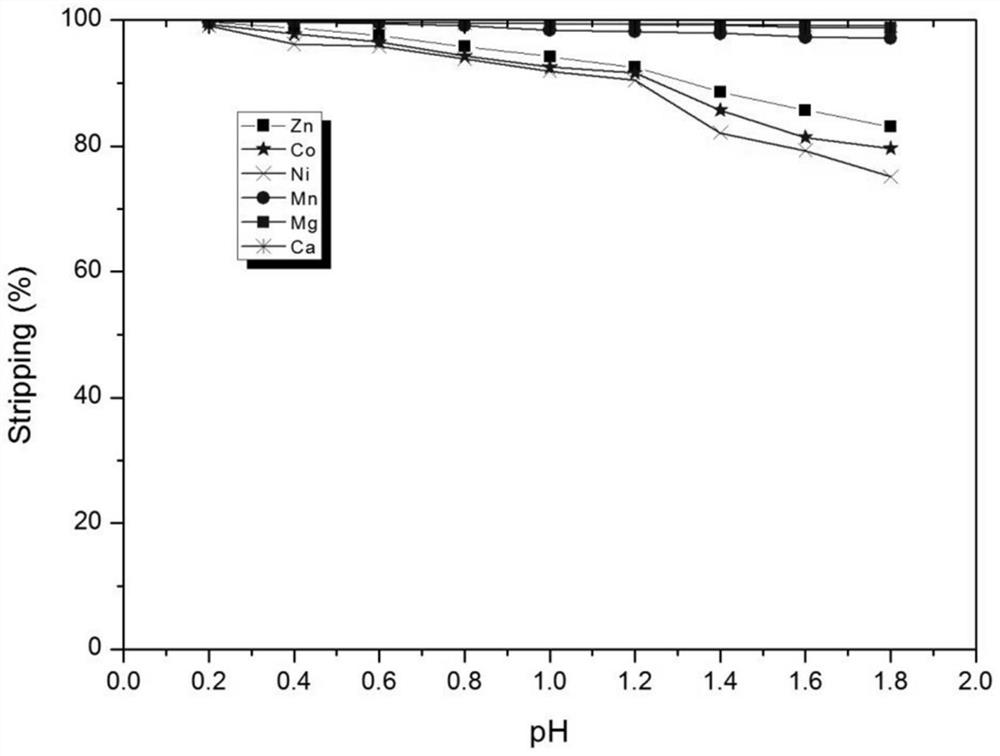

Synergistic extraction system for co-extraction of nickel and cobalt and co-extraction method of co-extraction system

PendingCN114317961ASmooth strippingEfficient separationProcess efficiency improvementSeparation processMagnesium

The invention relates to the technical field of metal ion extraction systems and methods, in particular to a co-extraction system for co-extraction of nickel and cobalt and a co-extraction method of the co-extraction system. The co-extraction system for nickel-cobalt co-extraction comprises alkyl hydroxyl oxime, carboxylic acid and a modified extraction agent according to a molar ratio of (1.0-2.0): (1.0-3.0): (1.0-3.0), and the structural formula of the modified extraction agent is shown as a formula (1) or a formula (2). According to the scheme, the technical problem that a co-extraction system in the prior art is difficult to realize high-efficiency separation of nickel and cobalt from other interfering metal ions and high-efficiency reverse extraction of co-extracted nickel and cobalt at the same time can be solved. The co-extraction system not only can realize efficient separation of nickel and cobalt from zinc, manganese, magnesium and calcium, but also can enable co-extracted nickel and cobalt to be smoothly reversely extracted at room temperature, so that the extraction separation process is simplified, carbon emission is reduced, the operation cost is reduced, and the co-extraction system has a wide application prospect.

Owner:CHONGQING KOOPPER CHEM IND

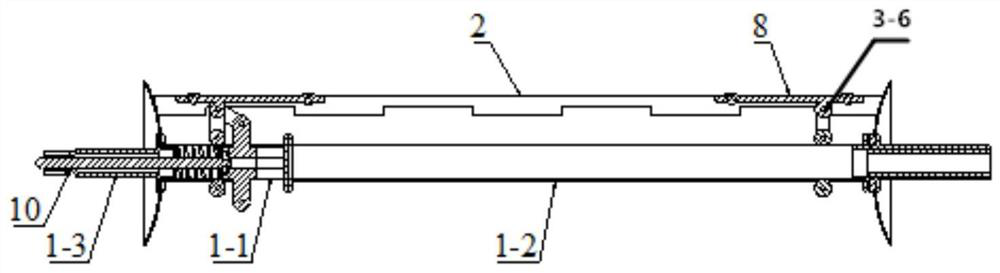

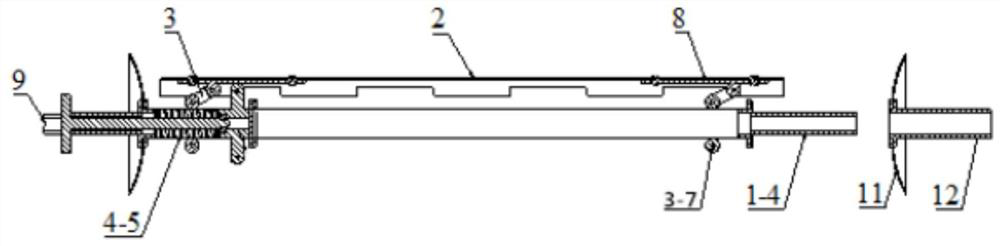

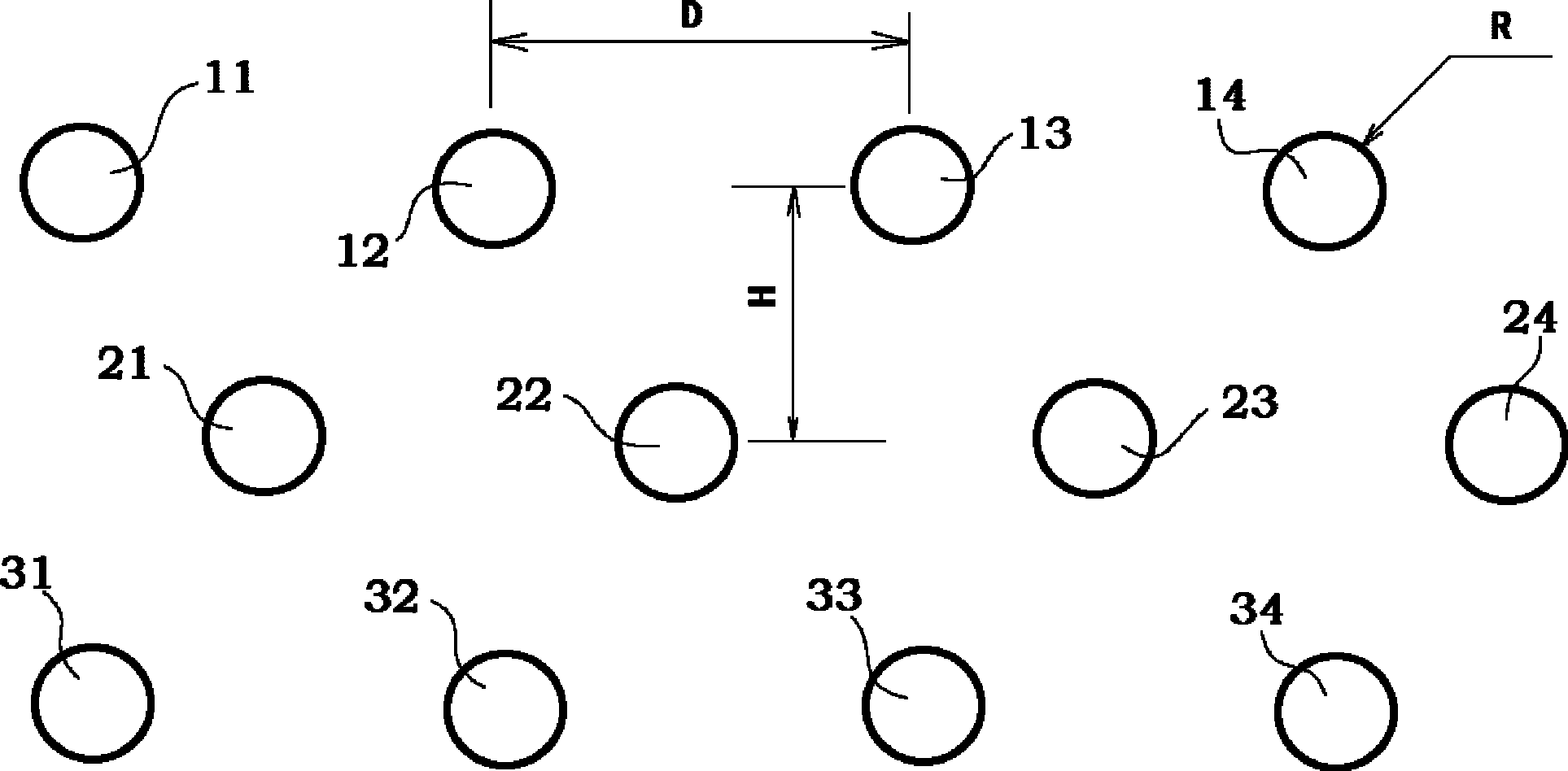

Film winding roller of mulching film picking-up device

InactiveCN108147171ALarge outer circle radiusOuter circle radius reductionGatherer machinesWebs handlingEngineeringFlange

The invention discloses a film winding roller of a mulching film picking-up device. The film winding roller comprises a center shaft, a connection assembly and a blade; the center shaft comprises a left half shaft, a short half shaft and a long half shaft; one end of the left half shaft and one end of the long half shaft are connected with flange plates through bolts and fixed to the two ends of the short half shaft; the left half shaft is a hollow pipe, and the other end of the left half shaft is provided with two opposite notches; a pull rod is arranged in the left half shaft, and one end ofthe pull rod is located at the end, provided with the notches, of the left half shaft and provided with a gear lever; the other end of the pull rod penetrates through the flange plate, connected withthe short half shaft, of the left half shaft and enters the short half shaft; the short half shaft is a hollow pipe, and the flange plate, connected with the long half shaft, of one end of the shorthalf shaft is provided with an opening slide groove leading to the middle of the short half shaft; one end of the pull rod penetrates through an elastic piece arranged in the short half shaft and is connected with a bearing; a gasket is arranged between the elastic piece and the bearing and fixedly connected with a slide sleeve arranged in the short half shaft; and a connection lug is welded to the slide sleeve and penetrates through the opening slide groove formed in the short half shaft to be connected with a connection assembly.

Owner:GANSU AGRI UNIV

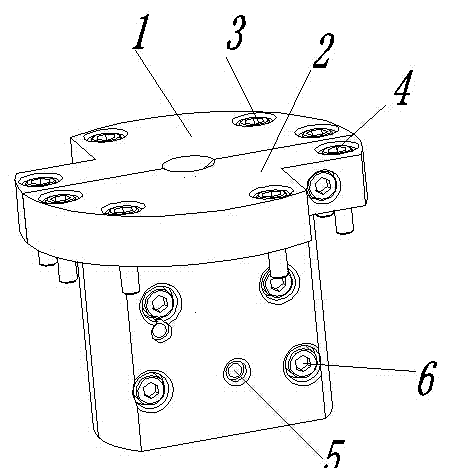

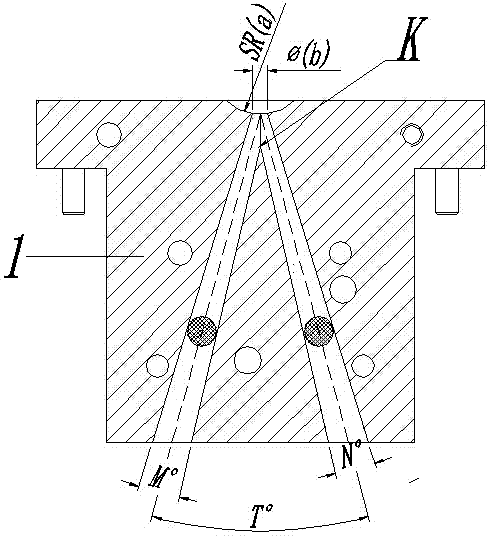

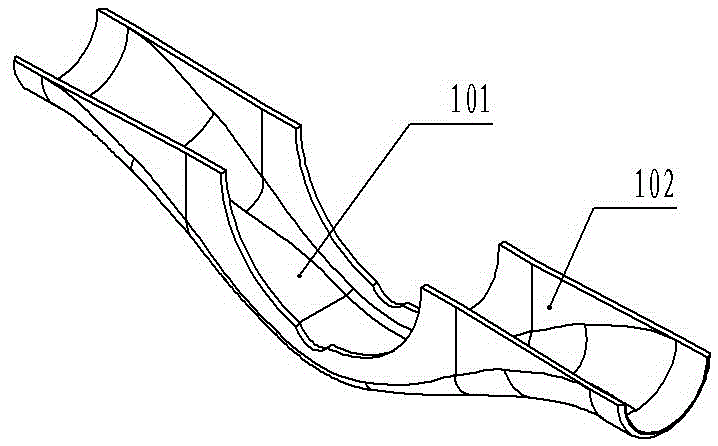

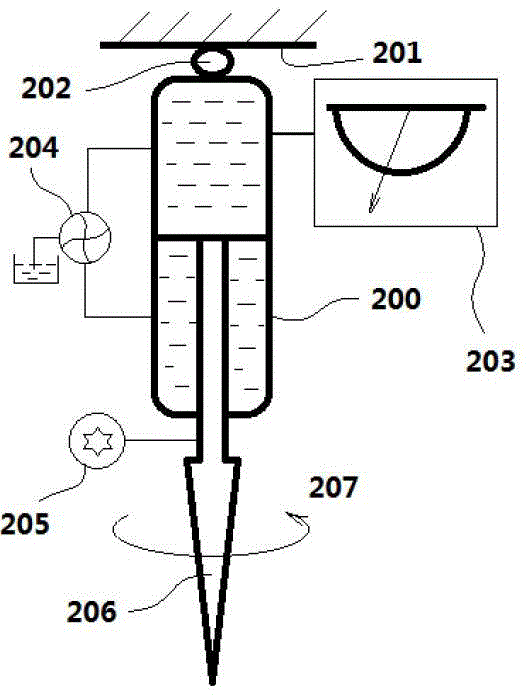

Double-cone-shaped main runner sprue bushing

The invention provides a double-cone-shaped main runner sprue bushing. The double-cone-shaped main runner sprue bushing comprises a first runner splice block, a second runner splice block, a first splice block screw, a second splice block screw, positioning pins, plywood fastening screws, a spherical crown nozzle surface, a first cone-shaped main pouring runner, a second cone-shaped main pouring runner and an injection molding inlet. A single edge of the first runner splice block of the sprue bushing is composed of the first cone-shaped main pouring runner, the second cone-shaped main pouring runner and the injection molding inlet, and the spherical crown nozzle surface is used for being in butt joint with a spray pipe nozzle ball of an injection molding machine. By the adoption of the double-cone-shaped main runner sprue bushing, the requirement for forming an eccentric pouring main runner on a mould is met; compared with a traditional oblique sprue bushing, materials can flow more smoothly when injection molding is conducted in the main runner, the requirements for pouring of two independent runners can be met at the same time, pressure losses are small, machining is easy, material discharging is smooth, and mould production cost and product injection molding cost are reduced; the structural design is reasonable, working is stable, both safety and reliability are guaranteed, and using is convenient.

Owner:陈伟娅

Left rear supporting plate and right rear supporting plate shape pressing die

InactiveCN104785635AIncrease productivityReduce labor intensityShaping toolsMaterial resourcesEngineering

The invention discloses a left rear supporting plate and right rear supporting plate shape pressing die, and relates to the technical field of stamping dies. The shape pressing die comprises an upper die base and a lower die base. The lower die base is connected with a lower support plate through a plurality of die feet. The lower end of the upper die base is provided with two symmetrical forming male die bodies. The forming male die bodies and the upper die base are provided with a plurality of limiting holes communicated with one another. The limiting holes are provided with unloading jacking rods and plug screws stretching out of the lower ends of the forming male die bodies. Springs are arranged between the unloading jacking rods and the plug screws. The upper end of the lower die base is provided with a reinforcing plate and two forming female bodies inserted into the reinforcing plate. The forming female die bodies are provided with a plurality of workpiece positioning plates. Stripper plates are inserted into the forming female die bodies. The lower ends of the stripper plates are provided with a plurality of lower jacking rods penetrating through the lower die base to be connected with strike-out plates. The strike-out plates are connected with a plurality of jacking-out rods inserted into the lower support plate. Compared with the prior art, forming machining of a left rear supporting plate and a right rear supporting plate can be finished at the same time, production efficiency is high, labor intensity is low, and human and material resources are saved.

Owner:柳州市飞歌汽车配件有限公司

A kind of oxide solid electrolyte sheet and its preparation method and application

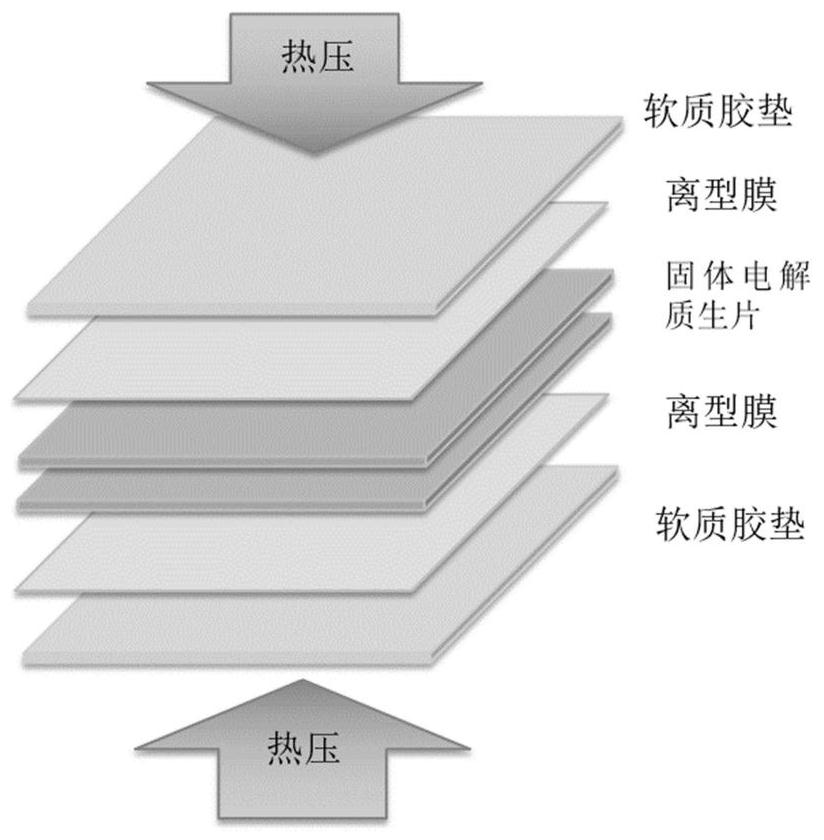

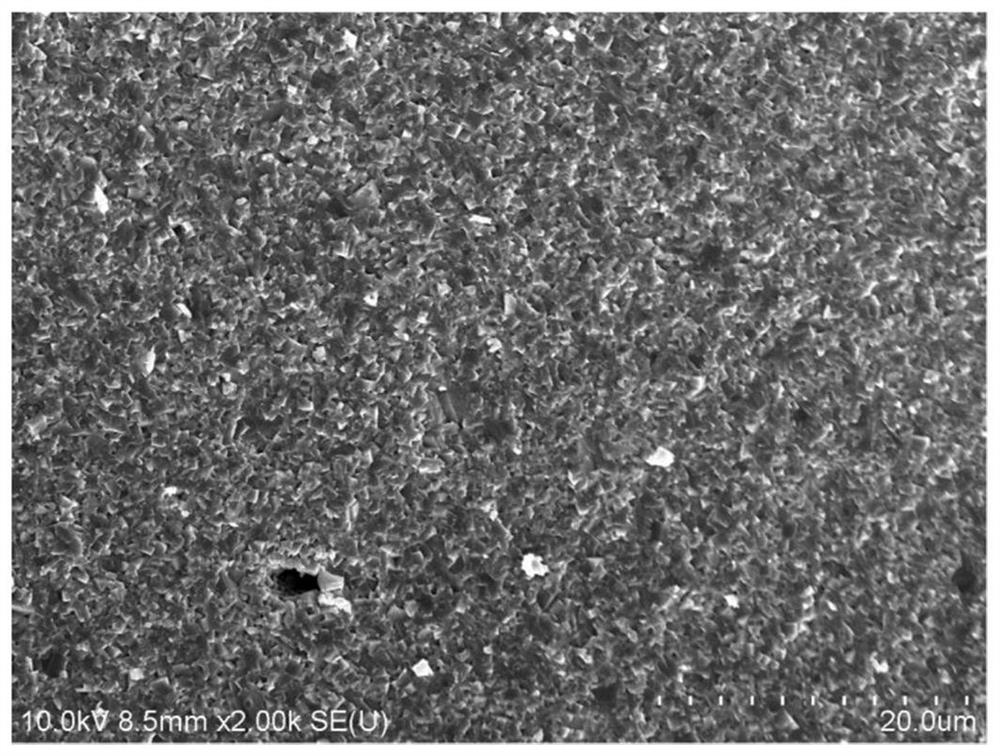

ActiveCN111129560BImprove gas barrier sealing effectLarge area spanFuel and primary cellsFuel and secondary cellsPhysical chemistryEngineering

The invention belongs to the technical field of solid electrolytes, and in particular relates to an oxide solid electrolyte sheet and its preparation method and application. The method of the present invention comprises the following steps: bonding two or more layers of oxide solid electrolyte green sheets into one layer by means of thermal compression bonding. The present invention adopts a double-layer or multi-layer hot-compression composite method to obtain a dense oxide solid electrolyte sheet without through holes, which can effectively improve the gas-blocking and sealing effect of the dense solid electrolyte sheet.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

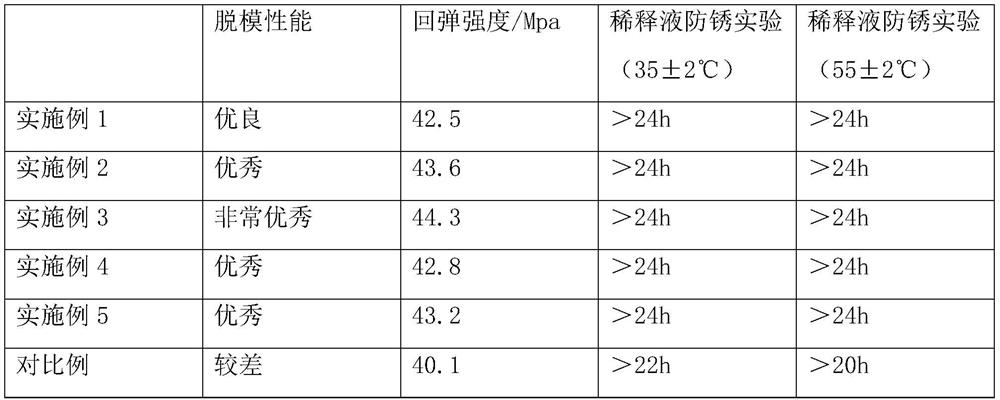

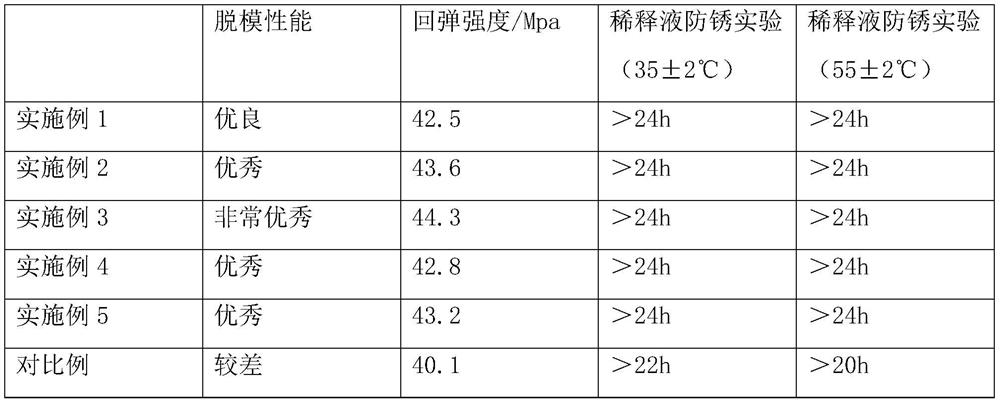

A kind of environment-friendly styrene butadiene polymer permeable concrete release agent and preparation method thereof

ActiveCN113773898BImprove liquidityImprove adhesionCeramic shaping apparatusLubricant compositionCalcium formateStearic acid

The invention belongs to the field of concrete release agents, and specifically discloses an environment-friendly styrene butadiene polymer permeable concrete release agent and a preparation method thereof. The release agent is calculated in parts by weight and is made from the following raw materials: 40-60 parts of water-soluble styrene butadiene polymer, 20-30 parts of calcium formate, 8-15 parts of 100-200# solvent oil, white 20-30 parts of oil, 25-40 parts of mineral oil, 25-50 parts of emulsified silicone oil, 40-100 parts of waste motor oil, 200-500 parts of glycerin, 1-5 parts of petroleum ether, 10 parts of dodecyl diethanolamide -35 parts, 1-5 parts of lauryl stearate, 1-2 parts of butyl stearate, 80-150 parts of deionized water, 0.5-2 parts of film-forming aid, 3-10 parts of rust inhibitor, Activated powder 30-60 parts. The mold release agent of the invention can prolong the service life of the mold, is convenient for cleaning, has good surface finish, good dispersibility, good anti-corrosion and anti-rust functions, is easy to demould and clean, the coating is resistant to water erosion, and can increase the amount of permeable concrete. The strength, the greater reduces the cost and improves the performance.

Owner:绍兴职业技术学院

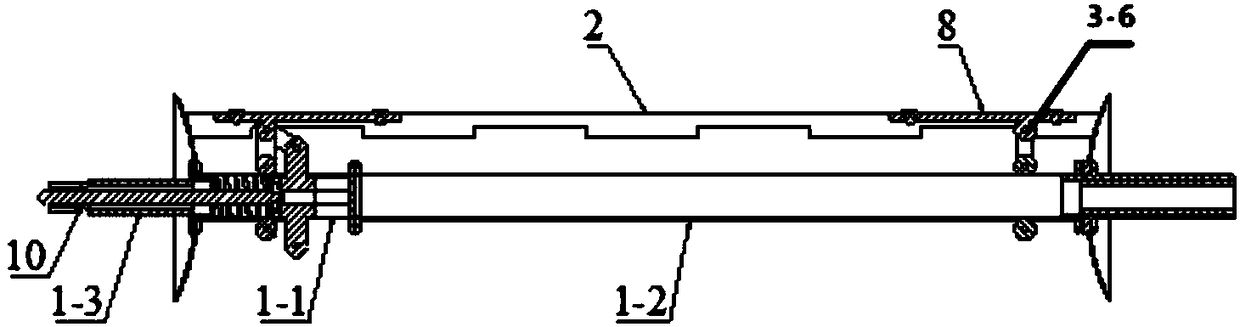

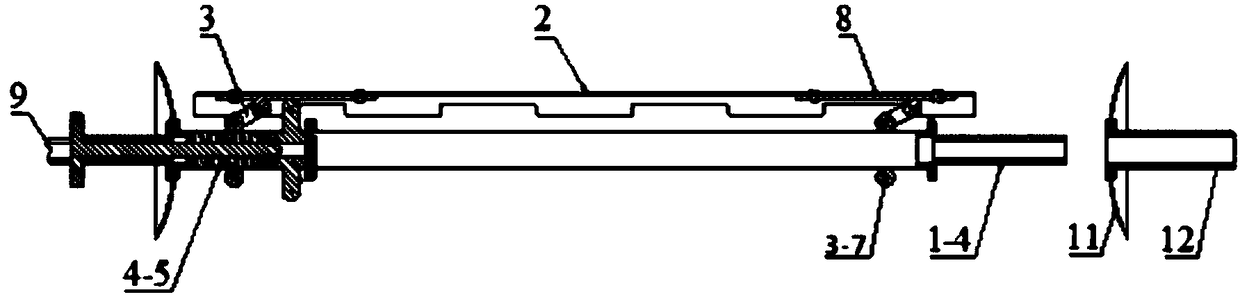

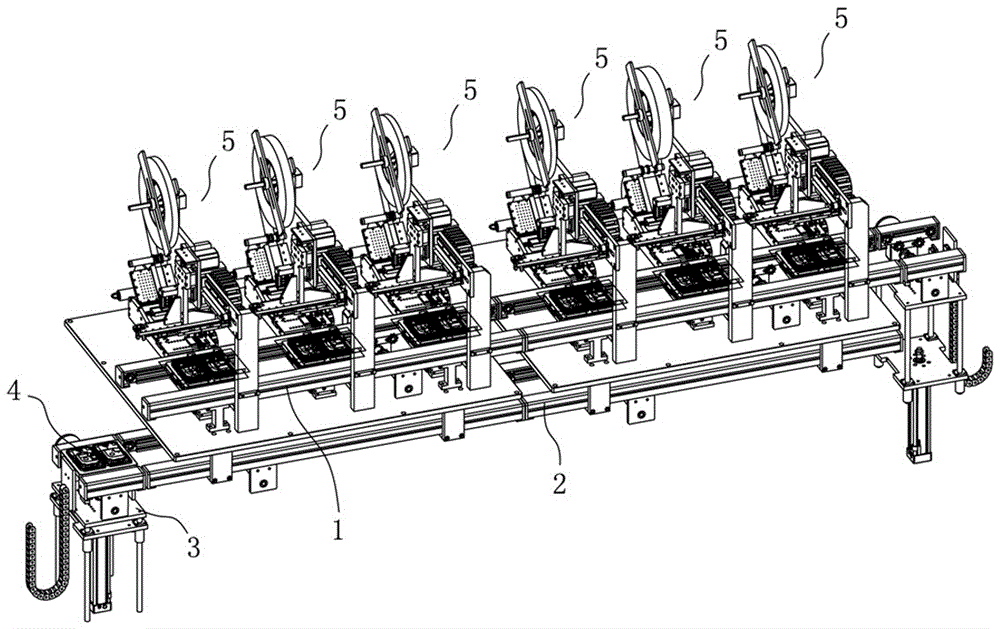

Labeling Machine

ActiveCN104528088BImprove stabilitySmooth strippingLabelling machinesProduction lineProcess engineering

The invention discloses a labeling machine which comprises an attaching production line and a jig return line. The attaching production line and the jig return line are arranged in a two-layer mode, lifting material tables are arranged at the two ends of the attaching production line and the jig return line for transferring conveyed jigs, more than one labeling station is arranged along the attaching production line, labeling devices are installed at all the stations, and all the labeling devices on the production line cooperate to complete the operation of labeling mobile shells. By means of the cooperation of the labeling devices on the production line, and labeling operation of auxiliary materials such as foam gum of the mobile shells can be completed at a time, each labeling device integrates the functions of label stripping and labeling, operation on two products can be conducted at a time, label stripping plates move forwards and backwards through stepping motors, and stability is good. The labeling machine has the advantages of being small in occupied area, high in precision, easy to operate, high in efficiency and the like.

Owner:XIAMEN LIJU AUTOMATION TECH +1

A film roll of a mulch pick-up machine

InactiveCN108147171BLarge outer circle radiusOuter circle radius reductionGatherer machinesWebs handlingLeft halfClassical mechanics

The invention discloses a film roll for a mulch picker, which comprises a central shaft, a connecting component, and blades; the central shaft includes a left half shaft, a short half shaft, and a long half shaft; one end of the left half shaft and one end of the long half shaft pass through a bolt The connecting flange is fixed at both ends of the short half shaft; the left half shaft is a hollow tube and the other end of the left half shaft is provided with gaps opposite to each other, and a pull rod is arranged inside the left half shaft, and one end of the pull rod has a gap on the left half shaft One end is provided with a gear rod; the other end of the pull rod passes through the flange connected to the left half shaft and the short half shaft and enters into the short half shaft; the short half shaft is a hollow tube and connected to the long half shaft at one end The flange is provided with an open chute leading to the middle of the short half-shaft; one end of the tie rod is connected to the bearing through the elastic part arranged in the short half-shaft; a gasket is arranged between the elastic part and the bearing, and the gasket is fixedly connected. The sliding sleeve in the short semi-shaft is welded with connecting ears, and the connecting ears pass through the opening chute on the short semi-shaft to connect with the connecting assembly.

Owner:GANSU AGRI UNIV

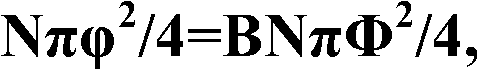

Process and system for striping and mining solid ore rock masses of surface mine

The invention relates to a process for striping and mining solid ore rock masses of a surface mine, which comprises a step of drilling a blast hole array, wherein the blasthole array comprises a plurality of rows of blast holes; adjacent rows of blast holes are mutually staggered along the directions of the rows; each blast hole corresponds to a non-blast hole of the adjacent row of blast holes; on each row, the distance between each two adjacent blast holes serves as a hole pitch; and the distance between each two adjacent blast hole rows serves as a row pitch. The process is characterized in that a small-aperture drill bit and a small hole network spacing are selected to drill the holes; the rock drilling speed is improved for more A times than before; the construction operation is carried out according to the small hole network spacing; the number of the drilled holes is increased to B times that of the original drilled holes; the area of each drilled hole is equivalent to one Bth of the area of the original drilled hole; and both A and B are natural numbers greater than 1. According to the invention, the boulder frequency and the blast root residual ratio can be greatly reduced, the striping and mining operations are continuously carried out, the process is convenient to operate, other investment is not required, the explosive load is unchanged, the drilling time is shortened, and the secondary blast quantity is greatly reduced.

Owner:江西分宜珠江矿业有限公司

Air conditioner motor end cover deep drawing finishing die

InactiveCN109290447AGood tolerance requirementsReduce dezincificationShaping toolsStripping-off devicesEngineeringManipulator

The invention discloses an air conditioner motor end cover deep drawing finishing die, and relates to the technical field of air conditioner motor end cover dies. The air conditioner motor end cover deep drawing finishing die comprises a lower die seat. The middle position in a lower convex die seat is fixedly connected with a bearing chamber forming convex die, and a large convex die is fixedly connected to the middle position in a stripper plate and is located above the bearing chamber forming convex die. A forming convex die is fixedly connected to the top of a concave die plate and locatedabove a concave die, and a pre-pressing rod is arranged at the middle position in a fixing plate in a penetrating mode. The middle position in an upper pad plate is fixedly connected with a piece returning device, and the bottom end of the piece returning device is fixedly connected with the top of the pre-pressing rod. A material beating rod is arranged at the middle position of the inner portion of the upper die plate in a penetrating mode. The air conditioner motor end cover deep drawing finishing die facilitates the smooth grasping of a mechanical claw on manipulator equipment, reduces the abnormal downtime, improves the production capacity, greatly reduces the scrapping of defective products and reduces the cost of manufacturing, so that effective working hours of an enterprise are greatly increased.

Owner:芜湖弘迪机电有限公司

Rear axle housing stamping die

ActiveCN104325023BEasy to fixFacilitate strippingShaping toolsEjection devicesManufacturing technologyEngineering

The invention discloses a rear axle housing stamping die, and relates to the technical field of stamping die manufacturing. The rear axle housing stamping die comprises an upper die base and a lower die base, wherein the lower die base is fixed on a lower support plate through a die foot; a convex die is mounted at the lower end of the upper die base; a plurality of limiting holes are formed in the convex die; discharge rods and plug screws which stretch outside the lower end of the convex die are mounted inside the limiting holes; discharge springs are mounted between the plug screws and the discharge rods; a concave die and a concave die bottom plate which sleeves the concave die are mounted at the upper end of the lower die base; a concave die reinforcing plate is mounted above the concave die bottom plate through a support plate; baffles are mounted between two sides of the concave die and the concave die reinforcing plate; the lower ends of the baffles stretch into the concave die bottom plate; a discharge plate is inserted into the concave die; a plurality of guide holes are formed in the bottom of the discharge plate; a plurality of nitrogen springs are mounted on the lower support plate; the plunger rods of the nitrogen springs penetrate through the lower die base and stretch into the guide holes of the discharge plate. Compared with the prior art, the rear axle housing stamping die can form a rear axle housing in a stamping manner at once, thus alleviating the working intensity and improving the production efficiency.

Owner:柳州市福牛科技有限公司

Environment-friendly styrene butadiene polymer pervious concrete release agent and preparation method thereof

ActiveCN113773898AImprove liquidityImprove adhesionCeramic shaping apparatusLubricant compositionCalcium formateGlycerol

The invention belongs to the field of concrete release agents, and particularly discloses an environment-friendly styrene butadiene polymer pervious concrete release agent and a preparation method thereof. The release agent is prepared from the following raw materials in parts by weight: 40 to 60 parts of water-soluble styrene butadiene polymer, 20 to 30 parts of calcium formate, 8 to 15 parts of 100 # to 200 # solvent oil, 20 to 30 parts of white oil, 25 to 40 parts of mineral oil, 25 to 50 parts of emulsified silicone oil, 40 to 100 parts of waste engine oil, 200 to 500 parts of glycerol, 1 to 5 parts of petroleum ether, 10 to 35 parts of dodecyl diethanolamide, 1 to 5 parts of lauryl stearate, 1 to 2 parts of butyl stearate, 80 to 150 parts of deionized water, 0.5 to 2 parts of a coalescing agent, 3 to 10 parts of an antirust agent and 30 to 60 parts of activated powder. The release agent disclosed by the invention can prolong the service life of a mold, is convenient to clean, good in surface smoothness, good in dispersity, relatively good in anti-corrosion and anti-rust functions and easy to demold and clean, a coating is resistant to water washing, the strength of pervious concrete can be improved, the cost is greatly reduced, and the performance is improved.

Owner:绍兴职业技术学院

Hard ore rock stripping technology and system of open-pit mine

Owner:江西分宜珠江矿业有限公司

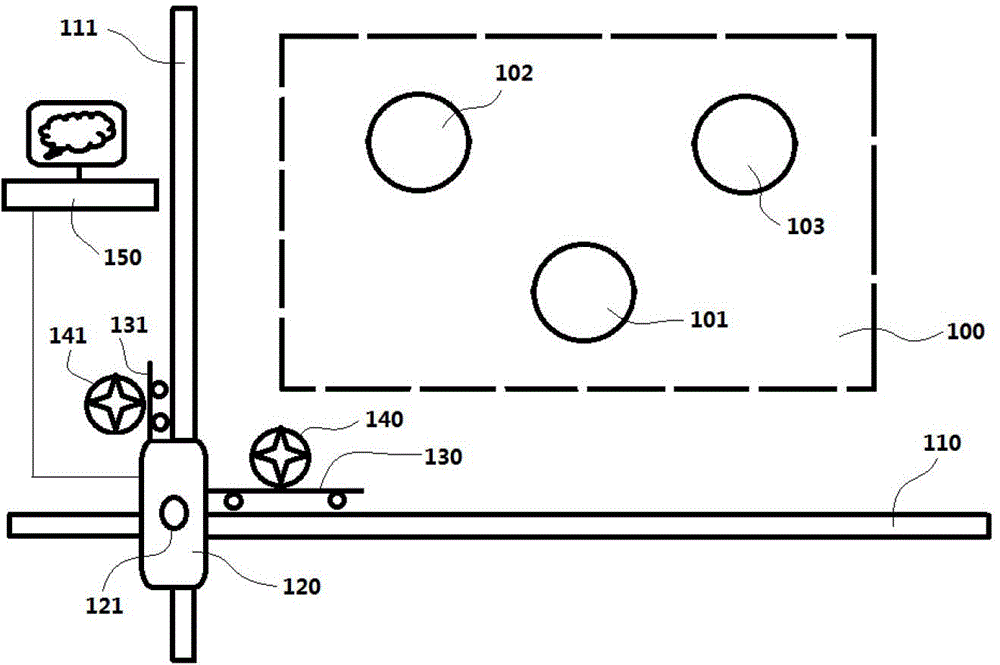

Stripping system

ActiveCN109274039ASmooth strippingApparatus for removing/armouring cablesElectronic waste recyclingBlock and tackleEngineering

The embodiment of the invention discloses a wire stripping system, comprising: a wire stripping mechanism, comprising a frame body and a clamping wire stripping assembly, wherein the frame body comprises a U-shaped frame, and the clamping wire stripping assembly comprises a wire stripping motor, a sleeve, a clamping shaft and a rotating head; A thread stripping mechanism comprising a plate frame,two feeding mechanisms and a shearing assembly; The transition mechanism is arranged between the setting-out mechanism and the stripping mechanism, and comprises a transition frame, a certain pulley and a movable pulley, wherein the fixed pulley is rotatably connected with the transition frame, and the fixed pulley and the movable pulley form a pulley set. A thread stripping mechanism includes a transition mechanism, the transition mechanism mainly comprises a pulley block, when the feeding rate is higher than the stripping rate, the excess cables are stored in the pulley block, when the feeding rate is lower than the stripping rate, the cables stored in the pulley block are supplemented, so that the stripping motor only needs to provide an average rate to ensure smooth stripping.

Owner:格林美(武汉)新能源汽车服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com