High-purity lithium chloride production technology

A production process, lithium chloride technology, applied in lithium halide and other directions, can solve the problems of unstable extraction process, large solvent demand, high labor intensity, and achieve fast phase equilibrium establishment time, continuous and reliable process, and small solvent demand. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

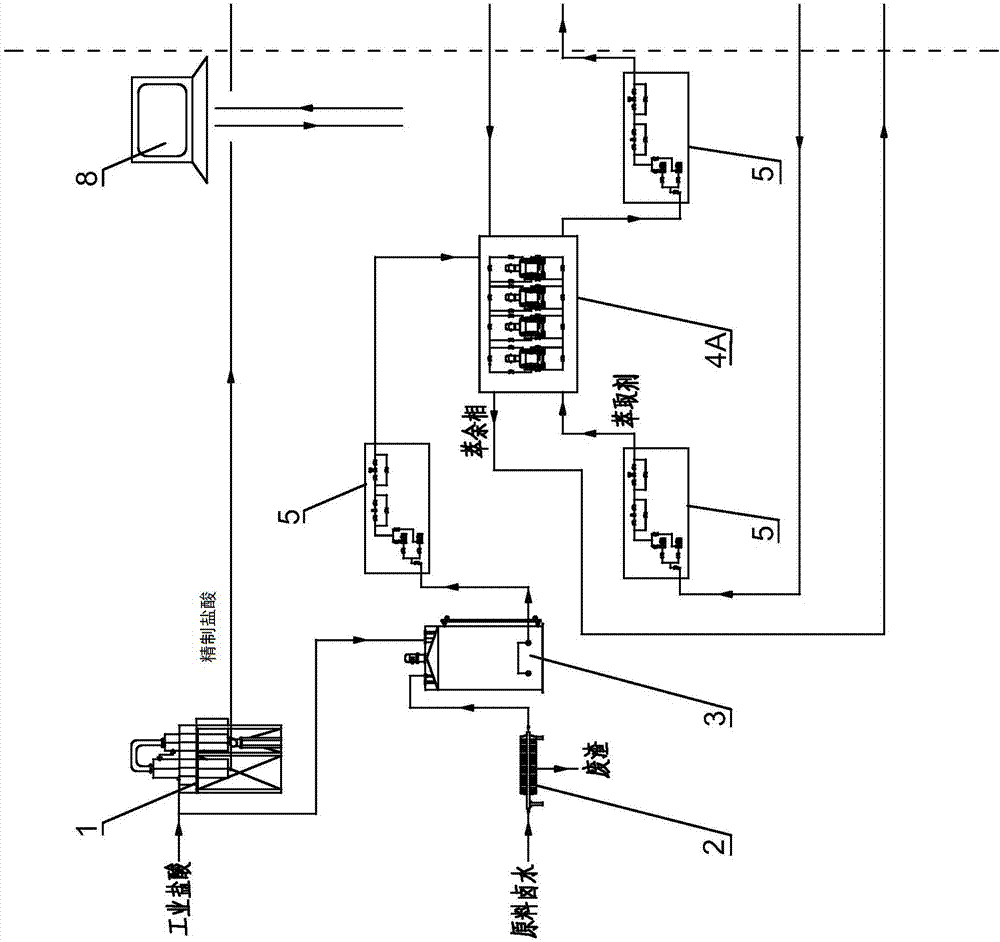

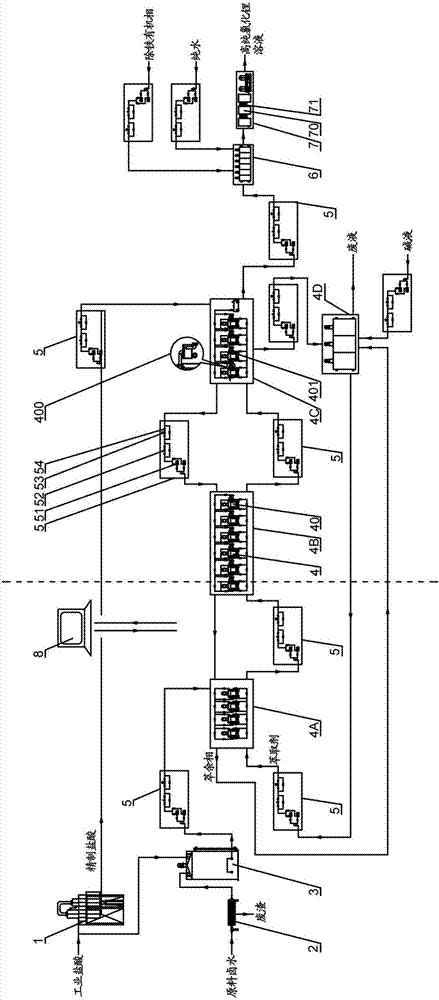

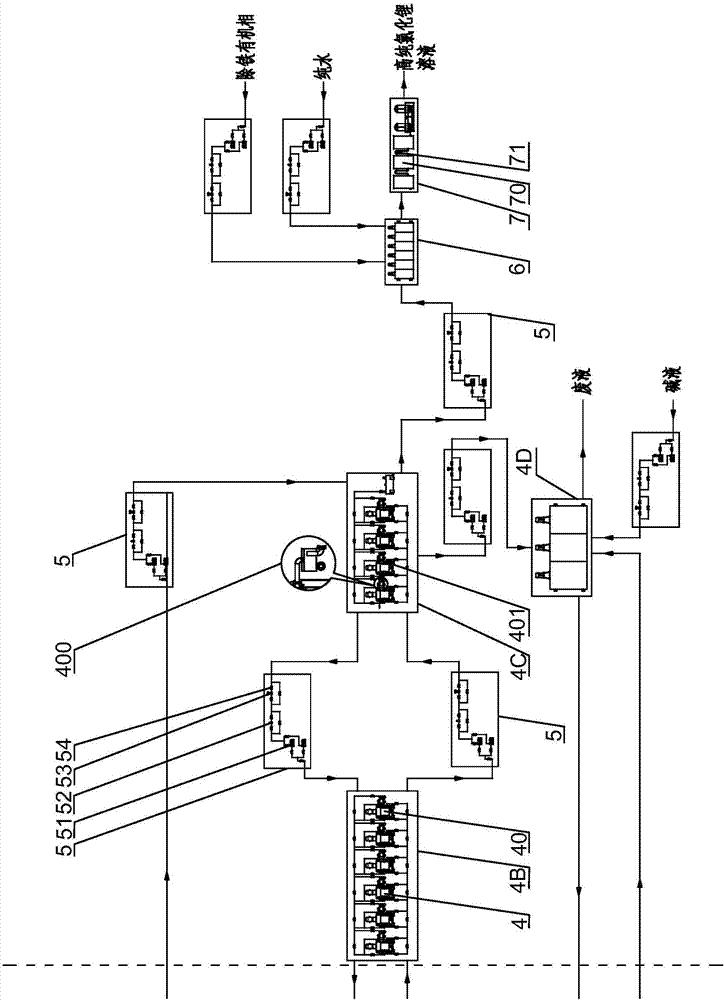

[0059] like figure 1 As shown, it is a high-purity lithium chloride extraction device, which includes a filter press 2 that is sequentially connected through pipelines to pretreat the brine material, and a mixing tank 3 that performs acid adjustment treatment on the pretreated material, Extraction system 4A, washing system 4B and stripping system 4C formed by multi-stage centrifugal extractor 4 connected in series respectively, subsequent iron removal system 6 and oil removal system 7; wherein, the stripping solution output end of stripping system 4C is also Connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com