Stripping system

A technology of wire stripping and wire stripping mechanism, which is applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of reduced feeding rate, poor matching of wire stripping mechanism, and reduced radius of cable coil, etc., to achieve smooth and smooth wire stripping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

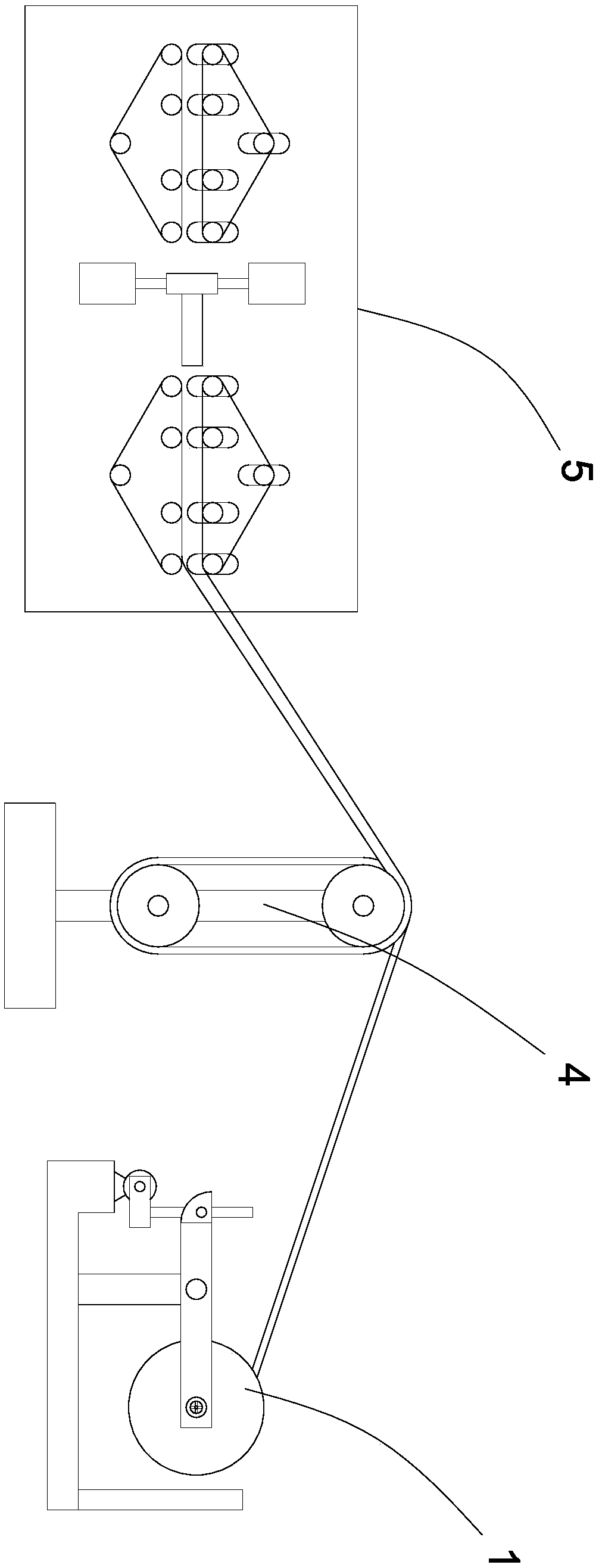

[0022] See figure 1 , figure 1 It is a structural schematic diagram of the wire stripping system provided by the present invention.

[0023] The wire stripping system includes: a wire pay-off mechanism 1 , a transition mechanism 4 and a wire stripping mechanism 5 .

[0024] The transition mechanism 4 is arranged between the pay-off mechanism 1 and the wire-stripping mechanism 5, the cable roll to be processed is placed on the pay-off mechanism 1, the cable protrudes from the pay-off mechanism 1, and is wound on the transition mechanism 4 once Afterwards, enter in the stripping mechanism 5 and carry out stripping, cutting process.

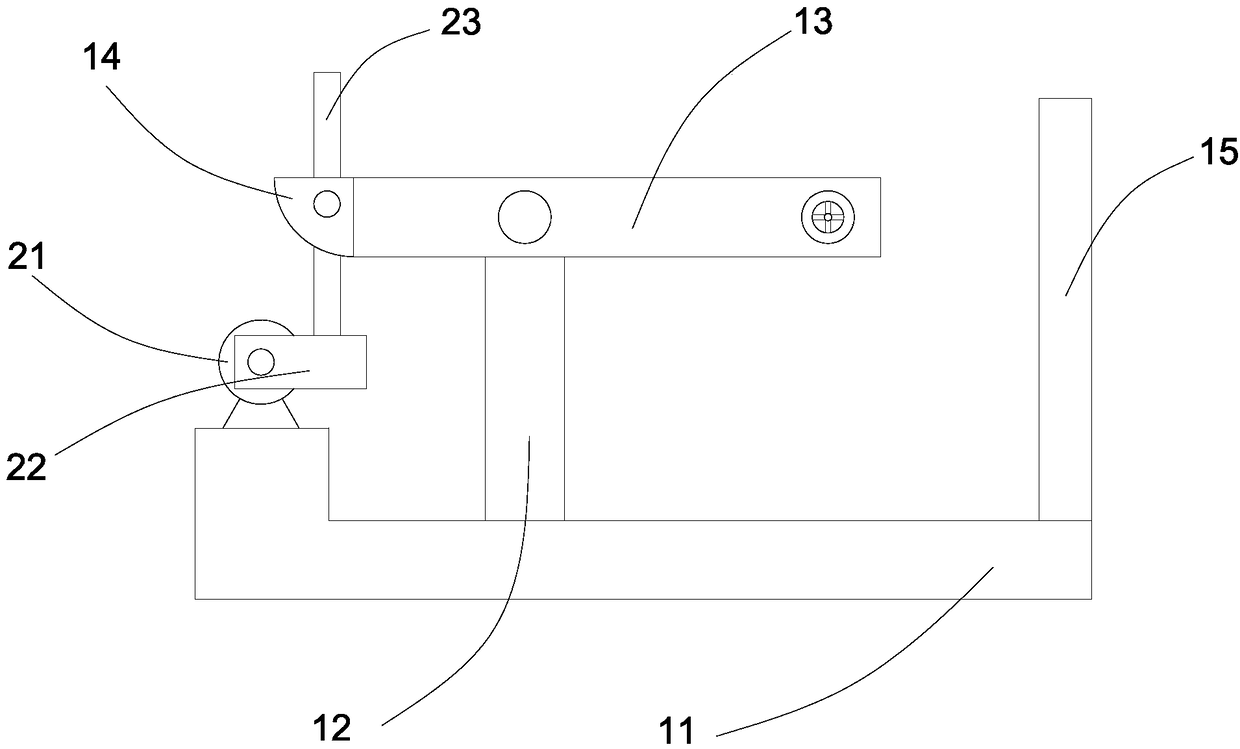

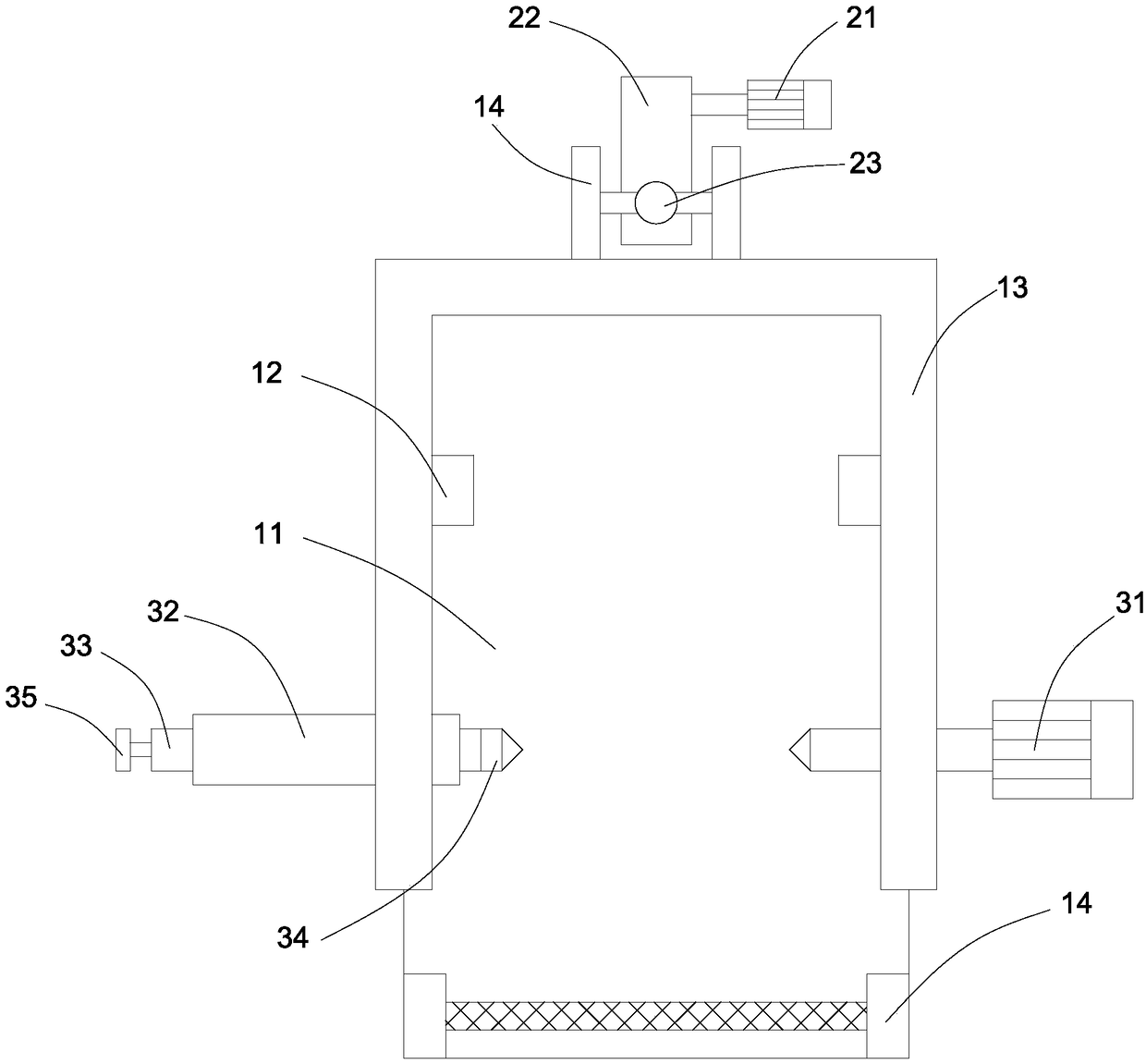

[0025] See Figure 2 to Figure 4 , figure 2 yes figure 1 Side view of the middle pay-off mechanism; image 3 yes figure 1 Top view of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com