Hard ore rock stripping technology and system of open-pit mine

A kind of mining and hard technology, applied in the field of mining and stripping technology and system of hard ore rock mass in open-pit mines, can solve the problems of doubting the rationality and economy of parameters, secondary changes in mining operations, and increased perforation operations. The effect of reducing the amount of secondary blasting, improving the drilling process, and reducing the amount of secondary blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

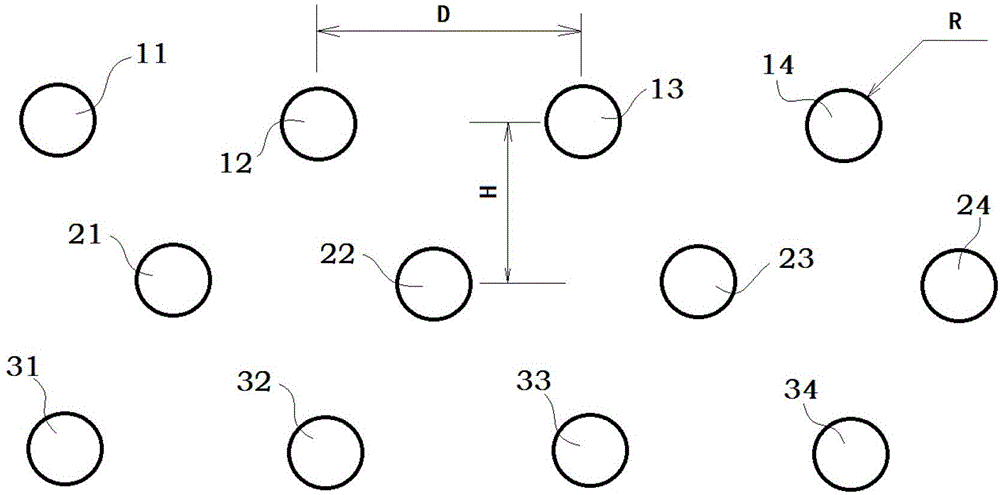

[0024] According to an embodiment of the present invention, such as figure 1 The stripping process shown for a hard ore mass in an open pit mine involves drilling an array of blastholes:

[0025] Blasting hole 11, blasting hole 12, blasting hole 13, blasting hole 14, ...;

[0026] Blast hole 21, blast hole 22, blast hole 23, blast hole 24, ...;

[0027] Blast hole 31, blast hole 32, blast hole 33, blast hole 34, ...;

[0028] ........., ... ..., ... ..., ... ..., ....

[0029] The gunhole array includes several rows of gunholes, such as:

[0030] The first row of blastholes: blasthole 11, blasthole 12, blasthole 13, blasthole 14, ...;

[0031] The blast hole of the second row: blast hole 21, blast hole 22, blast hole 23, blast hole 24, ...;

[0032] The blast hole of the 3rd row: blast hole 31, blast hole 32, blast hole 33, blast hole 34,...;

[0033] The blastholes of adjacent rows (such as between the first row and the second row, between the second row and the third r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com