Thermal wire stripping apparatus

A technology of stripping device and rotating device, used in cable installation device, cable installation, equipment for dismantling/armored cable, etc., can solve the problems of difficult application, fused or cut fiber braided net, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

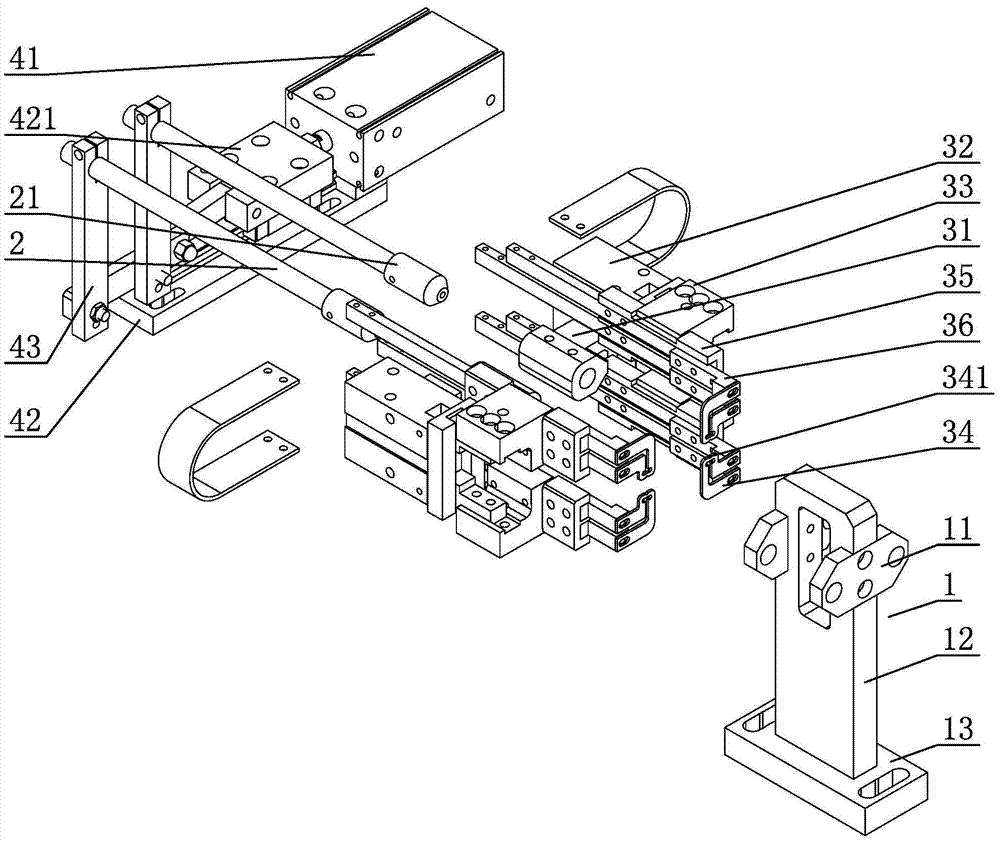

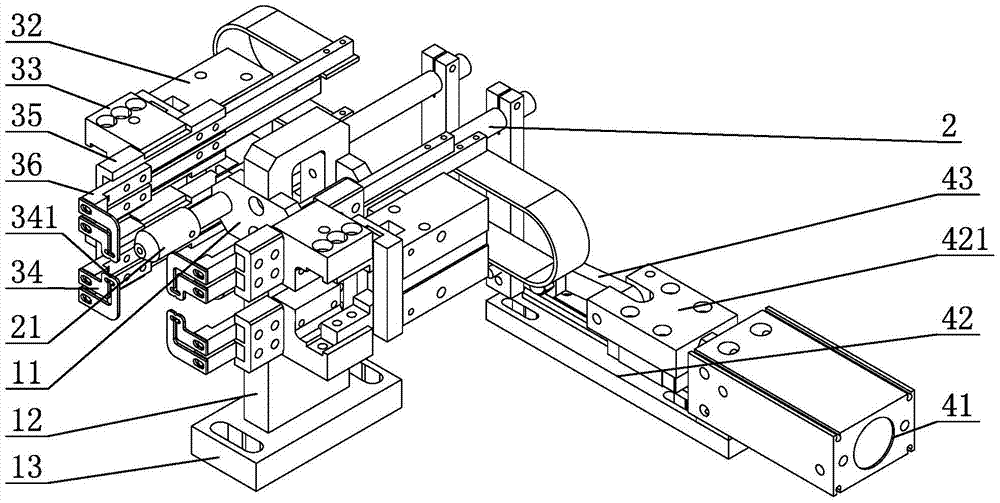

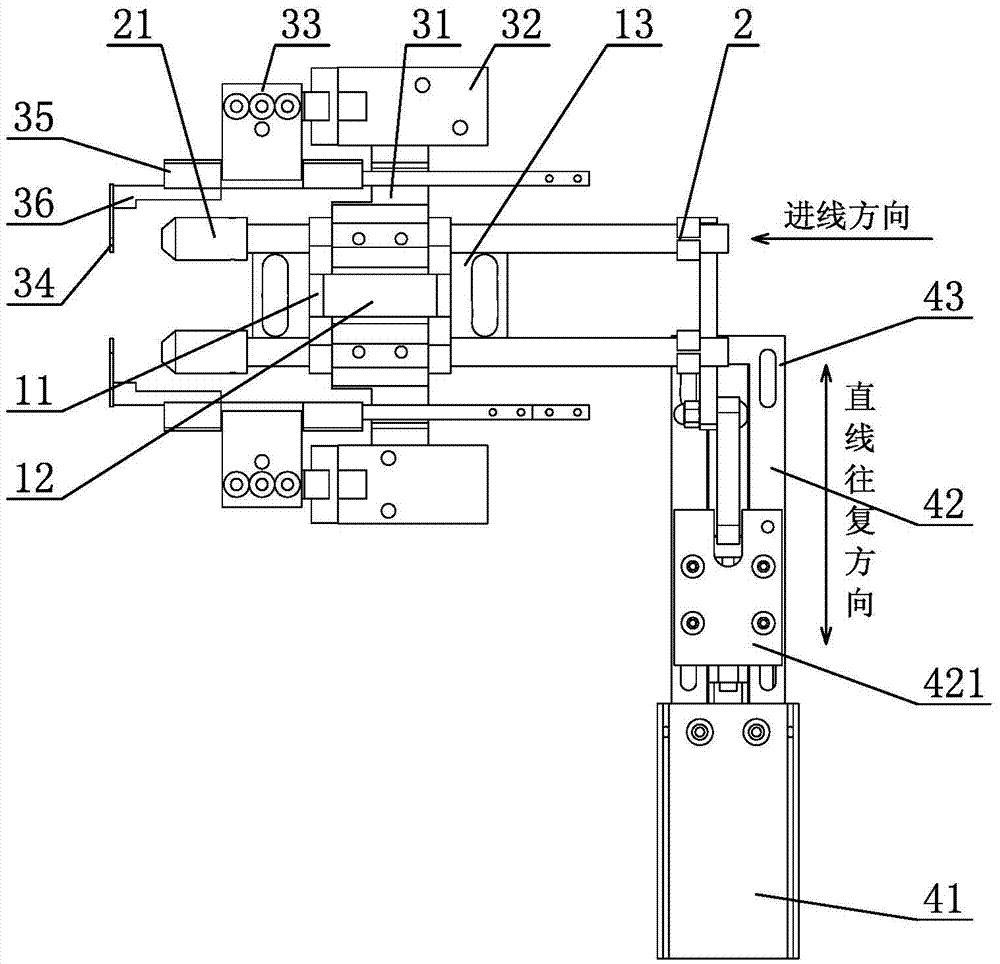

[0021] see Figure 1-Figure 3 , the thermal wire stripping device includes a support base 1, the support base 1 is provided with a wire mechanism 2 for conveying electric wires, and the head end of the corresponding wire mechanism 2 is provided with a wire ironing mechanism for clamping the wire skin of the wire and scalding, and the wire The tail end of the mechanism 2 is connected with a rotating device that drives the wire to rotate back and forth. The head end of the wire mechanism 2 is the wire transmission end, and the tail end is the wire delivery end; the head end of the wire mechanism 2 outputs the wire, and the ironing mechanism clamps the wire And when scalding, the rotating device drives the wire mechanism 2 to drive the electric wire to rotate back and forth, so that the wire skin of the electric wire is evenly heated and fused at 360 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com