Self-supporting vertical structure LED chip and preparation method thereof

An LED chip, vertical structure technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor heat dissipation performance of sapphire substrate, expensive equipment and solder, and reduced luminous efficiency, etc., to achieve high luminous efficiency LED, reduce Production cost, the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

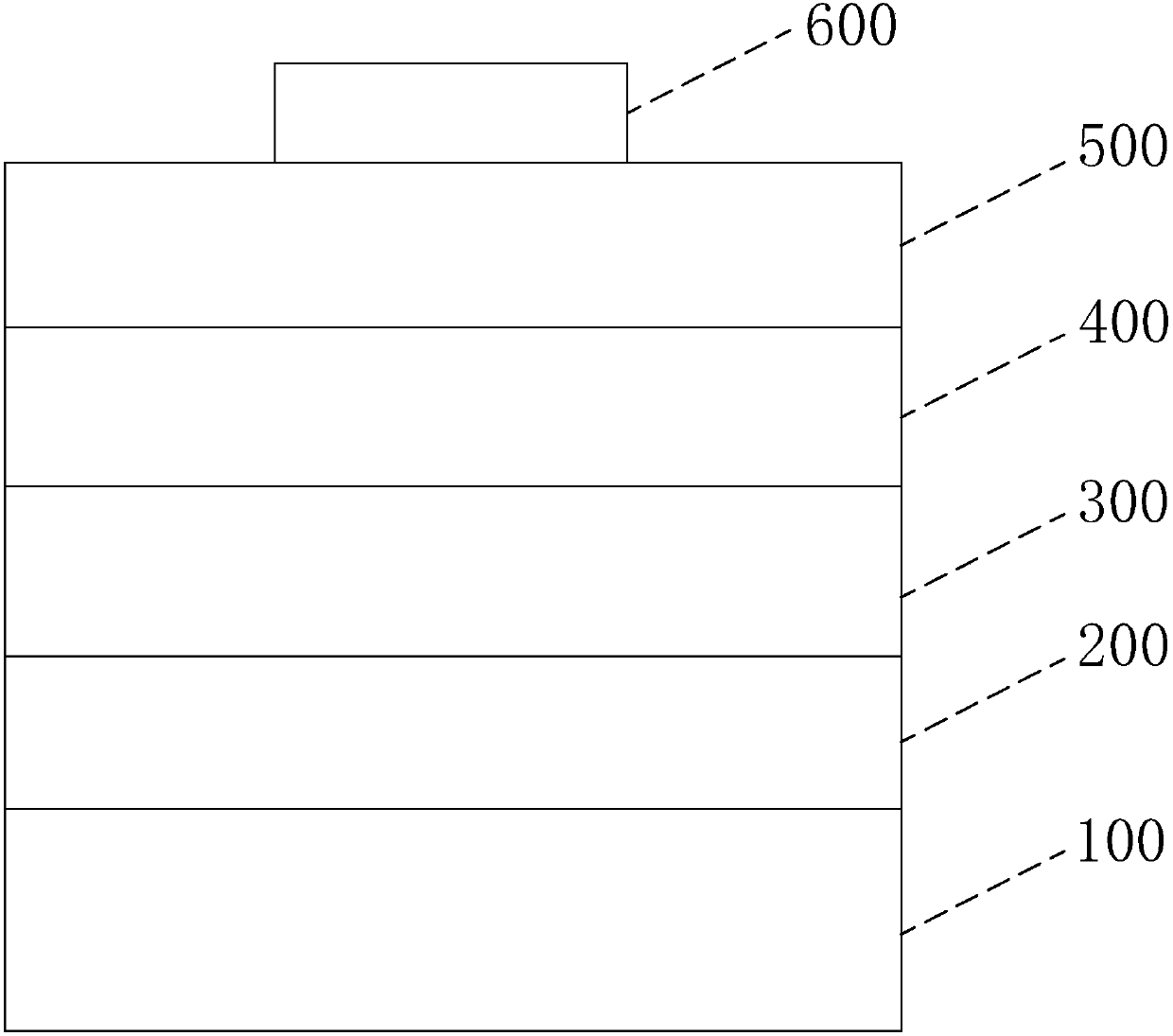

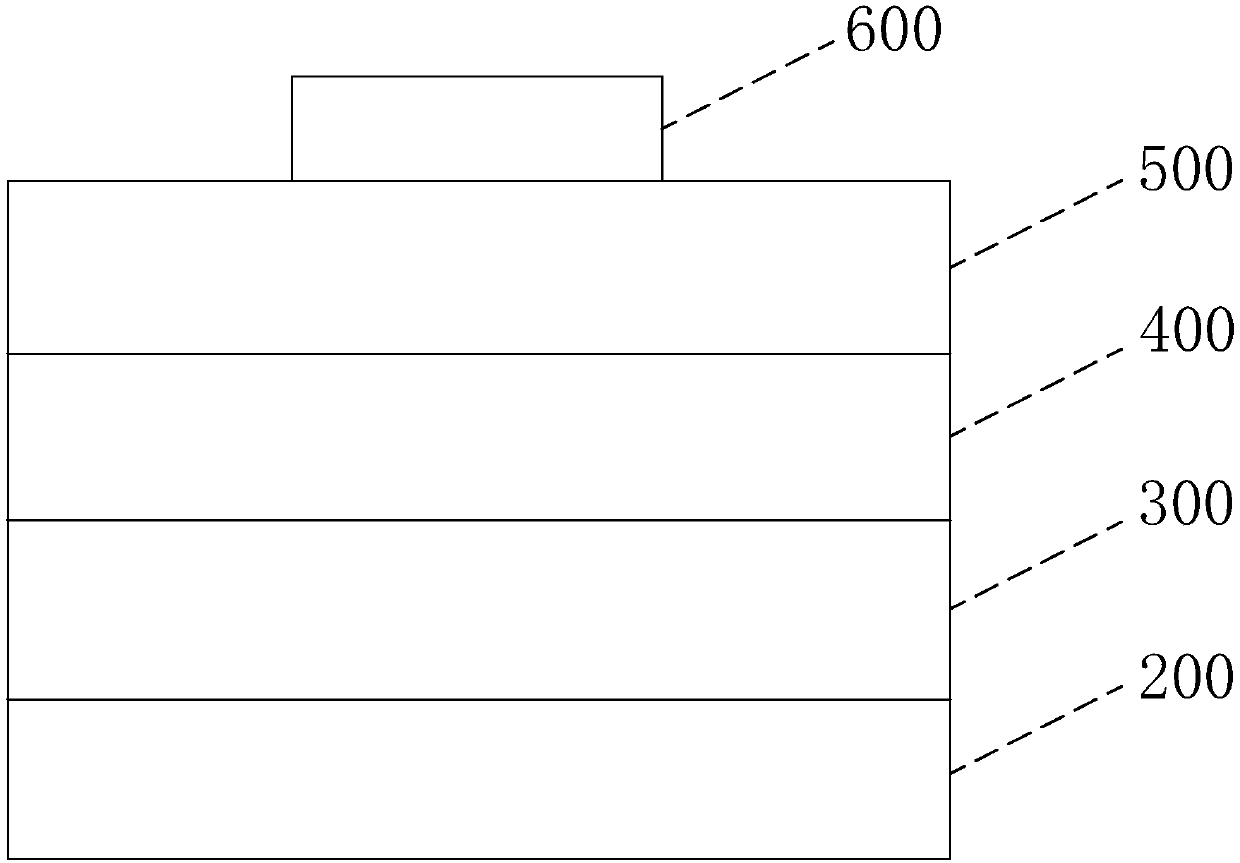

[0027] refer to figure 1 , a specific structural diagram of the first embodiment of a self-supporting vertical structure LED chip of the present invention before peeling off the substrate, which is a structural diagram before peeling off the substrate in the LED chip manufacturing process, including LiGaO 2 Substrate 100, metal thin film 200, N-GaN layer 300, InGaN / GaN quantum well 400, P-GaN layer 500 and p-electrode 600, the metal thin film 200, N-GaN layer 300, InGaN / GaN quantum well 400, The p-GaN layer 500 and the p-electrode 600 are sequentially arranged on the LiGaO 2 on the substrate 100. The thickness of the metal film 200 is 30-200 microns, and the metal film 200 is an Al single crystal film or a Cu single crystal film.

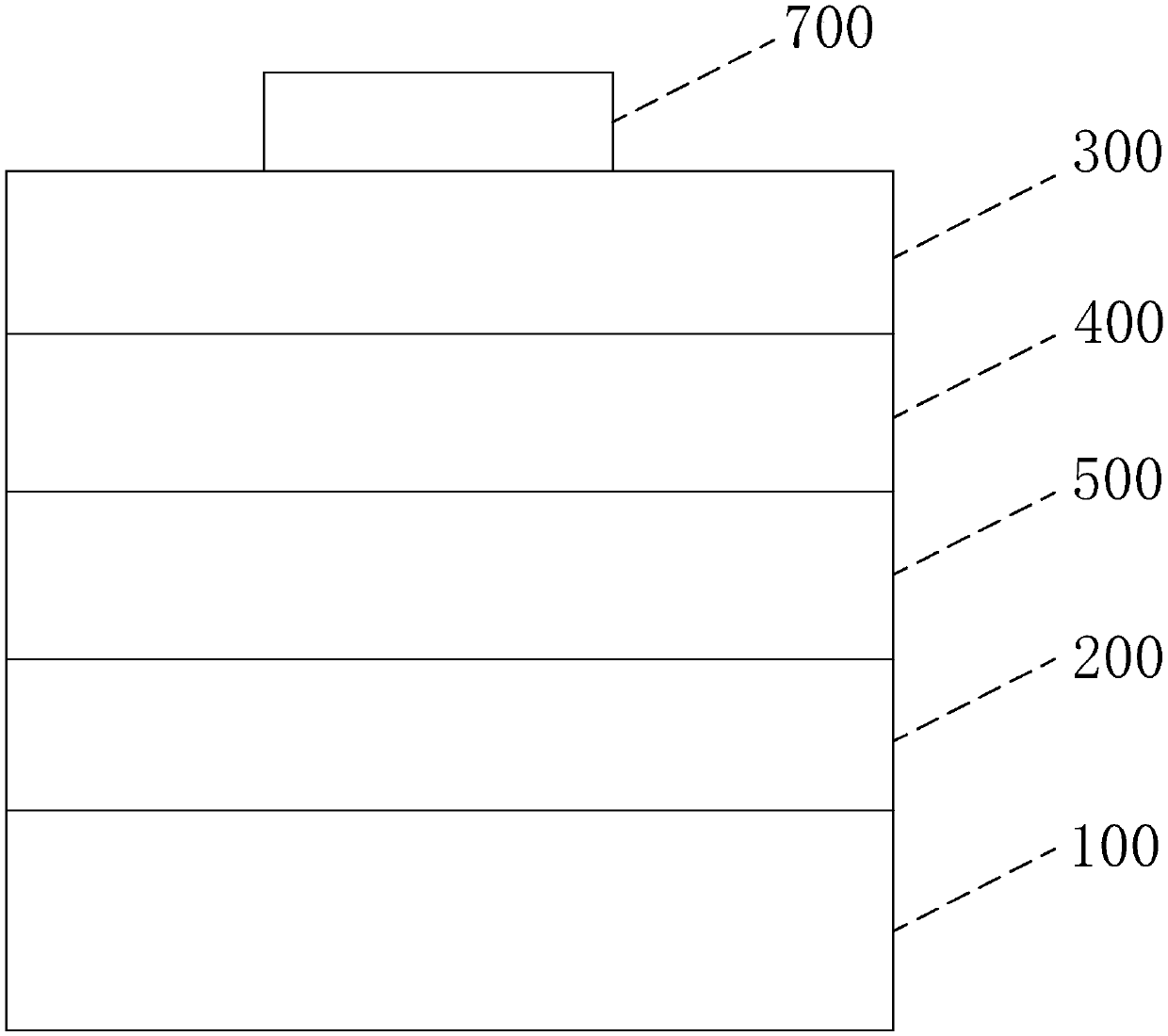

[0028] refer to figure 2 , a specific structural diagram of the second embodiment of a self-supporting vertical structure LED chip of the present invention before peeling off the substrate, which is a structural diagram before peeling off the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com