Shoemaking device and operating method

A drying device and cooling device technology, which is applied to shoemaking machinery, shoe lasts, footwear, etc., can solve the problem that shoemaking devices and operating methods are difficult to meet production needs, and shoemaking devices are difficult to achieve integrated series connection and drying. Or the combination of cooling devices and other issues, to achieve the effect of reducing labor and production costs, facilitating mass production, and not easy to miss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

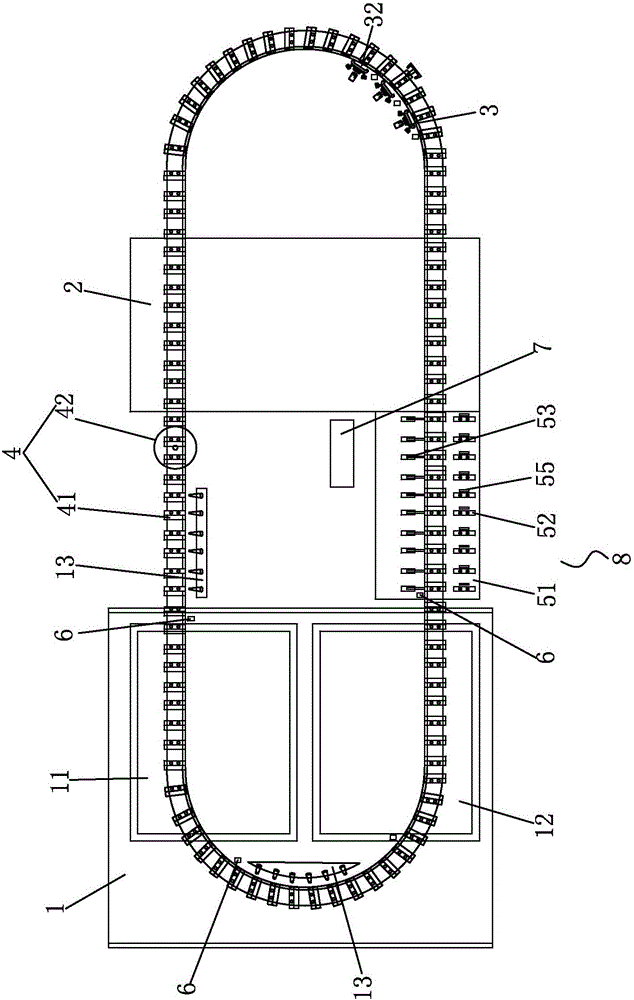

[0050] Specific implementation methods, such as Figure 1 to Figure 4 Shown, a kind of shoe-making device of the present invention mainly comprises the following parts:

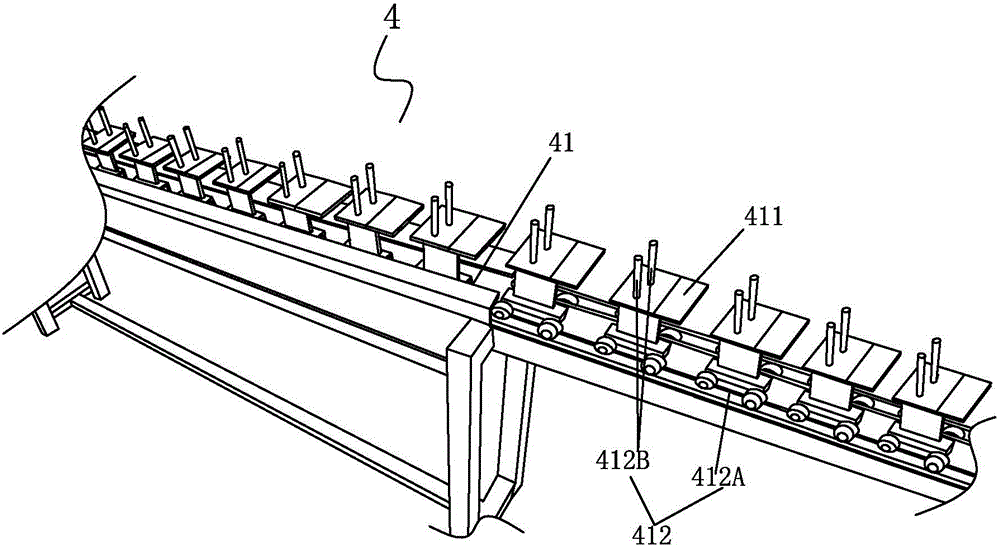

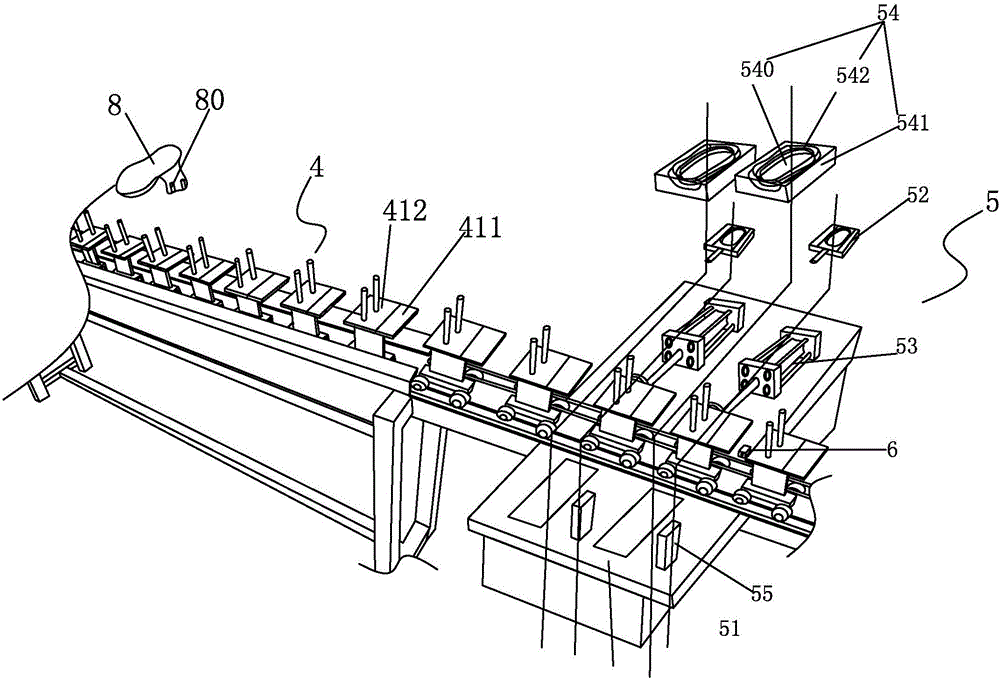

[0051] When assembling: (such as figure 1 , figure 2 As shown), the assembly transmission mechanism 4 includes a track portion 41 and a drive motor 42; a storage platform 411 for placing shoe soles and a sliding seat 412A and a positioning column 412B for positioning and supporting the shoe last 8 are formed on the track portion 41; The platform 411 is connected with the sliding seat 412A;

[0052] Drying device 1, (such as figure 1 As shown) install the drying device 1 on the track part 41 of the conveying mechanism 4, and pass through the first and second drying areas 11 and 12 respectively; The front part of the area 11, 12 (reserved for other equipment or device to place the reserved position here), so that before entering the drying area 11, 12, the glue brushing or glue spraying process is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com