Labeling device of FOSB packaging assembly line

A packaging line and labeling technology, which is applied in the field of labeling devices of FOSB packaging lines, can solve the problems of high labeling efficiency and inability to meet various needs of wafer packaging box labeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below with reference to the accompanying drawings:

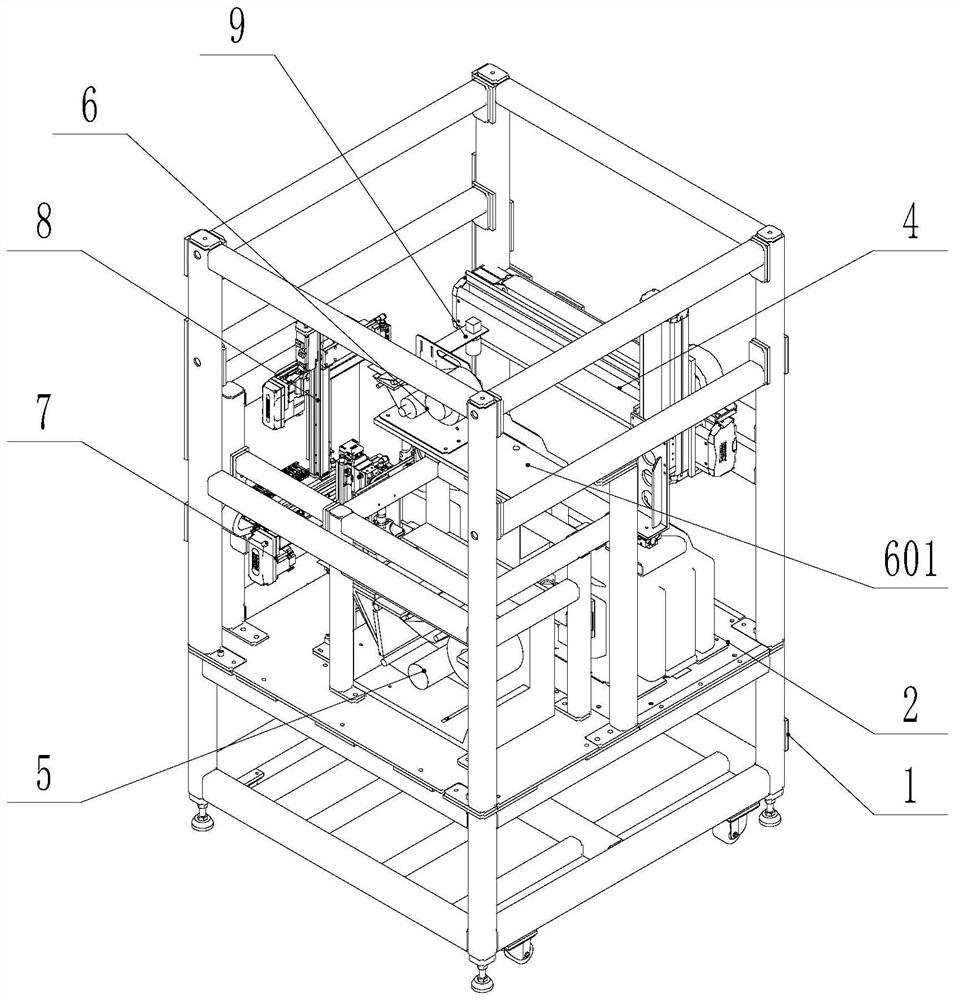

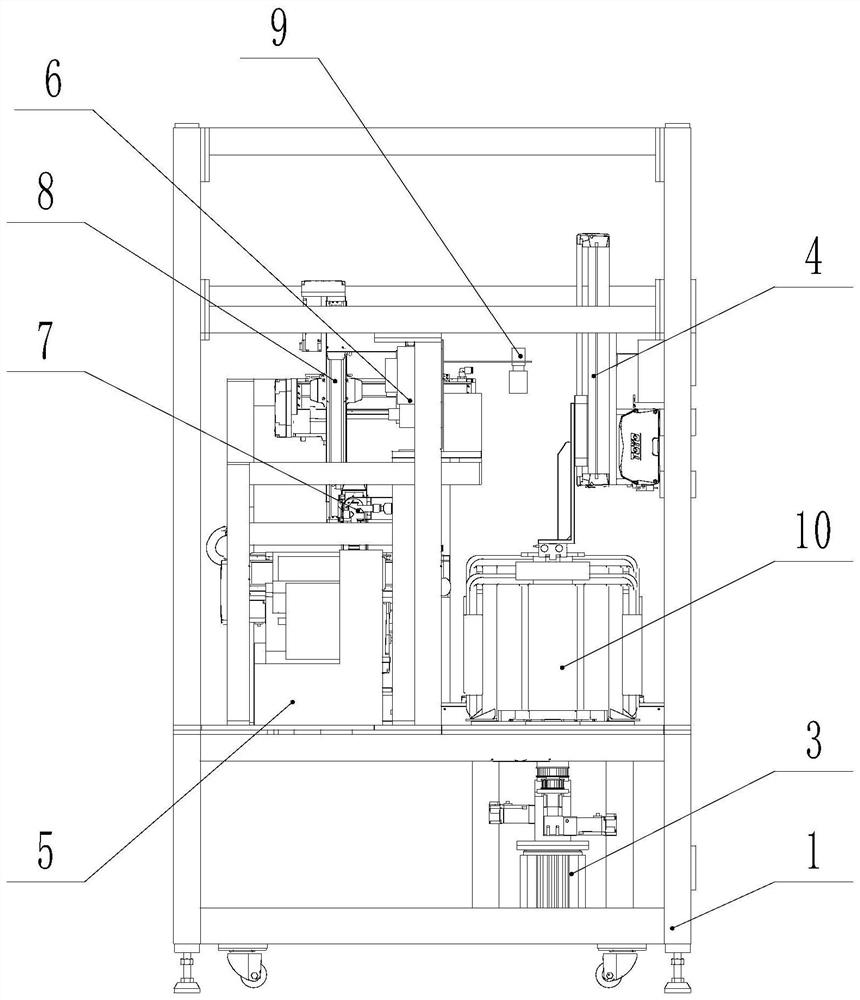

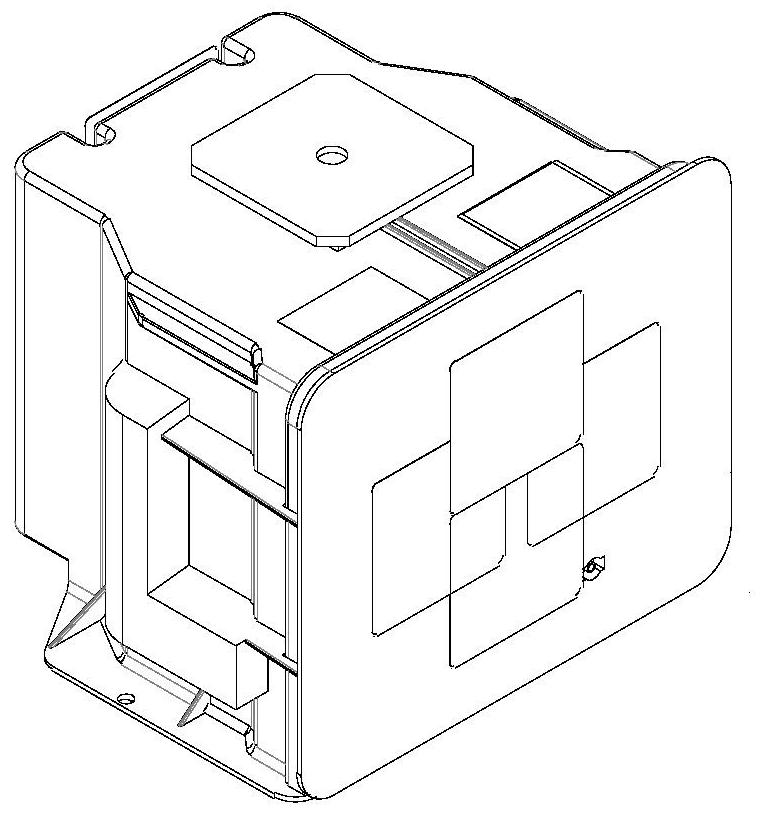

[0069] Such as Figure 1 ~ 19 As shown, a labeling device of a FOSB packaging pipeline includes a fixing frame 1, a rotatable conveyor belt 3, an ID tag marking, alert strip device 6, an ID tag label device 7, alert label sticker The labeling device 8 and the label test shooting device 9 are provided with four roller 2 and four support legs 4 at the bottom of the fixed frame 1. When moving, four support legs 4 are colliled and passed through four roller wheels. 2 Push the movement of the fixing rack 1; After the movement is completed, the four support pin 4 is put down, and the four support legs 4 are supported by knob adjusting the height of the height.

[0070] The rotatable conveyor belt 3 capable of rotating the wafer package 10 is fixed to the fixing frame 1; ID tag marking destnerator 5, alert tag stripper device 6, alert label label device 8 and ID label label device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com