Walking control method of container cover opening machine

A walking control and container technology, which is applied in the direction of packaging, conveyors, lifting devices, etc., can solve the problems of frequent movement of containers, large volume and weight of containers, and high labor intensity of manual lifting, so as to facilitate the transfer of the car body and ensure The effect of manual operation safety, reduction of manual intervention and control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

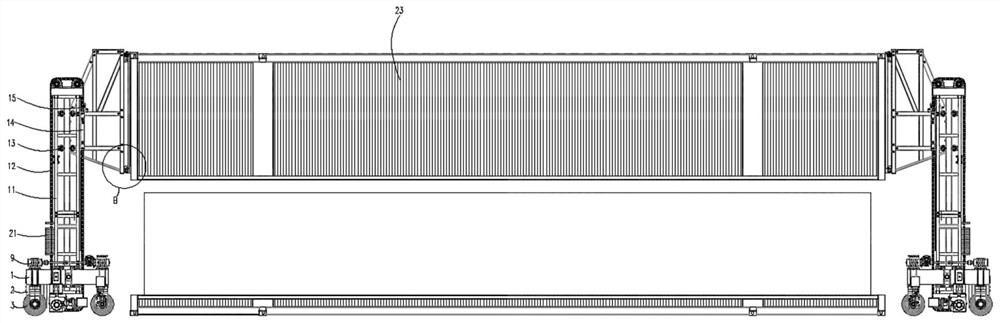

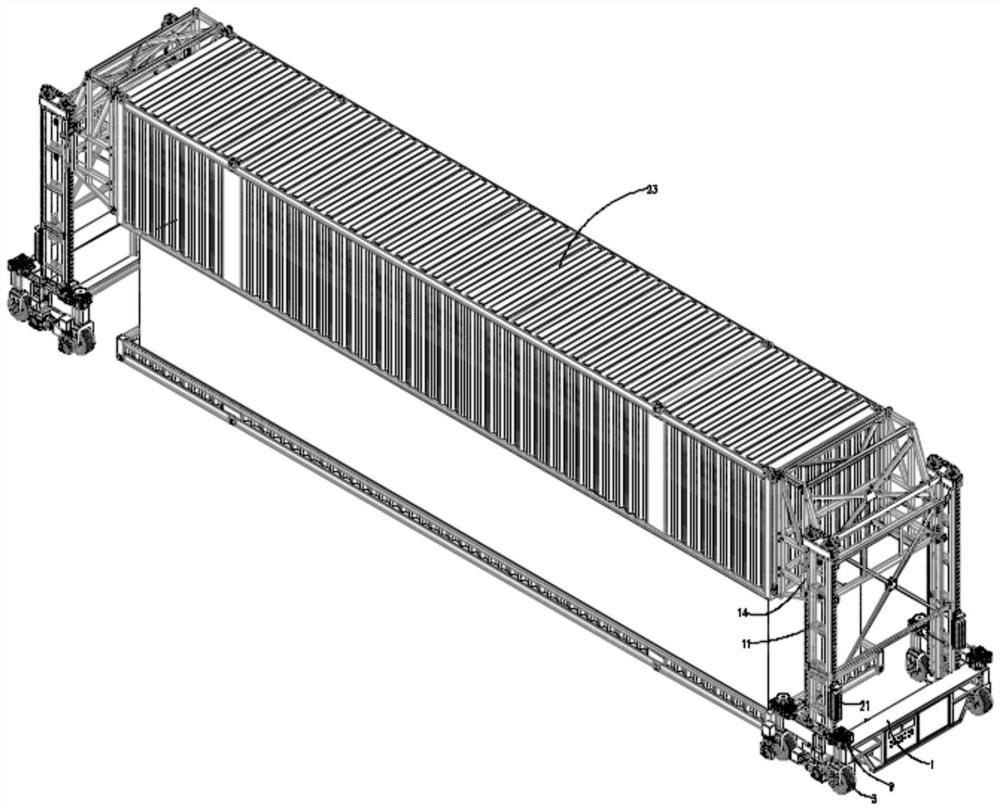

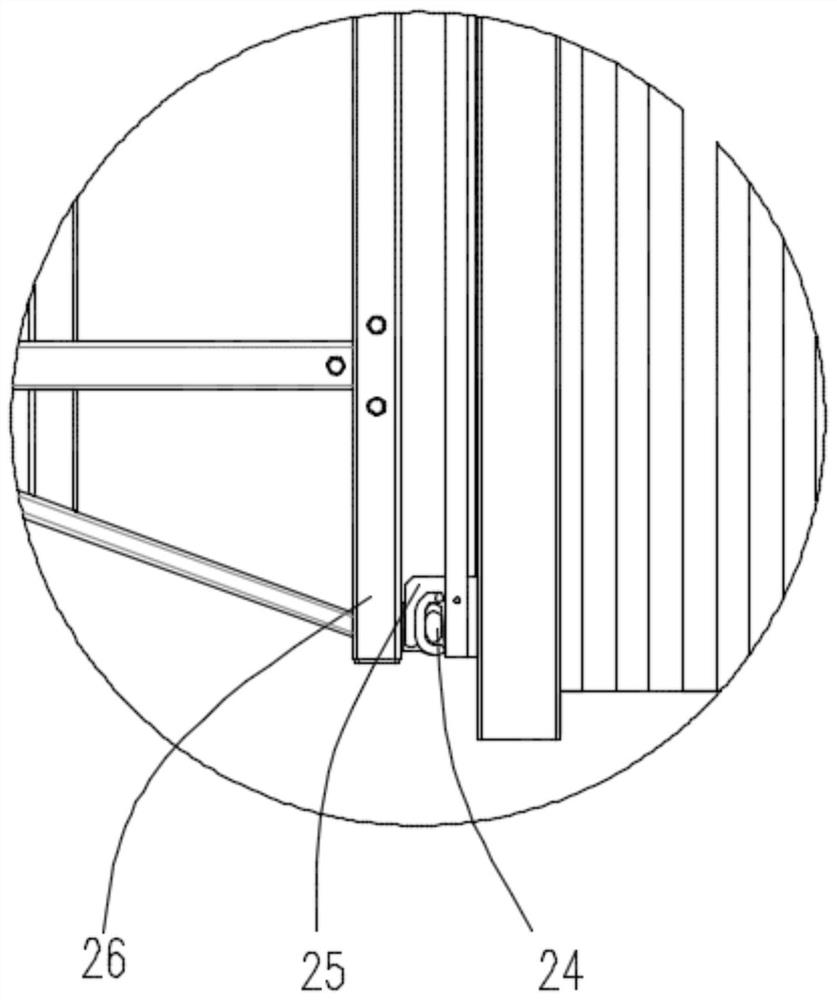

[0038] Such as Figure 1 to Figure 8As shown, a method for controlling the movement of a container lifting machine, the container lifting machine includes two carrying trolleys, and a lifting mechanism is provided on the two carrying trolleys, and the lifting mechanism includes a lifting platform 16 and a driving lifting platform 16 lifting drive mechanism that moves up and down. The lifting platform 16 is provided with a pick-and-place material claw, and the pick-and-place material claw includes a pick-and-place plate 26 that is fixedly connected with the lift platform 16. The upper and lower sides of the upper and lower sides of the container cover 23 are respectively provided with lifting rods 24 corresponding to the hooks 25 on the upper and lower edges of the container cover 23; 2 is provided with a transport wheel 3 for rotation, at least two transport wheels 3 located on the same side of the vehicle frame 1 are connected with a first drive motor 10 that drives the trans...

Embodiment 2

[0062] Such as figure 1 and figure 2 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0063] The steps of controlling the movement or turning of the carrier vehicle by the control processor include:

[0064] (1) When it is necessary to control the carrying trolley to walk in a straight line, the control processor starts the second drive motor 9, and the second drive motor 9 drives the connecting column 2 to rotate, so that the four transport wheels 3 are consistent with the direction of travel, and then the first drive motor 9 is started. Drive the motor 10 to drive the transport wheel 3 to rotate to realize the straight-line walking of the carrying trolley;

[0065] (2) When controlling the steering of the carrier trolley, the second drive motor 9 is controlled by the control processor to rotate the four transport wheels 3 to the target steering angle, and then the transport wheels 3 are driven to rotate by the first drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com