High-temperature flue gas waste heat utilization device

A high-temperature flue gas and waste heat technology, which is applied in the direction of heat exchangers, heat exchanger types, heat recovery systems, etc., can solve the problem of reduced heat exchange efficiency between heat exchange components and heat exchange media, affecting heat recovery effects, air particle pollution, etc. problem, to achieve the effect of conveniently and smoothly driving the drive rod, improving the shielding effect, and ensuring the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

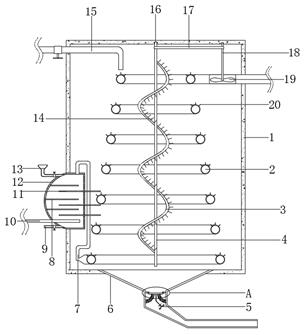

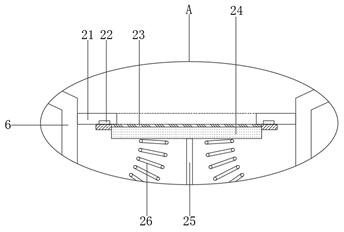

[0029] refer to Figure 1-4 , a high-temperature flue gas waste heat utilization device, comprising a heat exchange tank 1, a water outlet is opened at the bottom of the heat exchange tank 1, and a water outlet bucket 6 is welded on the inner wall of the water outlet, and a heat exchange tank 1 is fixedly installed inside the heat exchange tank 1 The conical spiral air duct 2, and the top outer wall of the heat exchange conical spiral air duct 2 are fixed with equidistantly distributed water guide fins 20, and one side of the heat exchange tank 1 is equipped with a water washing heat exchange mechanism, and the water washing heat exchange The mechanism includes a water washing heat exchange box 12 arranged on one side of the heat exchange tank 1. An air intake pipe 10 is fixedly installed on one side of the bottom end of the water washing heat exchange box 12, and one end of the air intake pipe 10 is provided with a check valve. The inner wall of one side of 12 is fixedly inst...

Embodiment 2

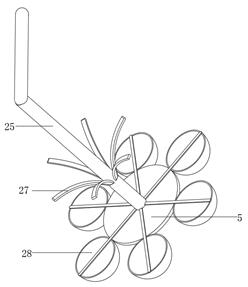

[0038] refer to figure 1 and Figure 5 , a high-temperature flue gas waste heat utilization device. Compared with Embodiment 1, this embodiment also includes an extended hemispherical end 30 fixedly installed on the top side of the heat exchange conical spiral air duct 2, and the extended hemispherical end 30 is connected to the heat exchange tank. The opposite side of 1 is rotatably connected with drive rod 18 by bearing.

[0039] In the present invention, the bottom end of the driving rod 18 is fixedly connected with fan blades 19 distributed equidistantly, and the middle end of the heat exchange tank 1 is fixed with a bearing seat 16 by bolts, and one side of the fan blade 19 is fixedly installed with fan blades 19 distributed equidistantly. The arc plate 29; the fan blade 19 arranged inside the extended hemispherical end 30 can blow the fan blade 19 in the process of letting out the smoke, thereby driving the driving rod 18 and the rotating rod 4 to rotate; The plate 29 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com