Method for testing initial position angle of motor rotor

A technology of initial position and motor rotor, applied in the direction of electronic commutator, electrical components, control system, etc., can solve the problems of the influence of the measurement accuracy of the motor load size, high test conditions, wrong values, etc., to achieve online fault diagnosis and The effect of error correction control, low test condition requirements and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, in Embodiment 1 of the present invention, a method for testing the initial position angle of the motor rotor includes the following steps:

[0046] Step 1, first give the motor to be tested a current i to make the motor run; the frequency of the current i is relatively low, and it can be tested as long as the motor rotates. The current frequency determines the speed at which the motor rotates, so the frequency of the current i can be within the rated speed range If the frequency of the current i is 1 / 3 of the rated frequency of the motor.

[0047] Step 2, after the motor is running, make the current i zero;

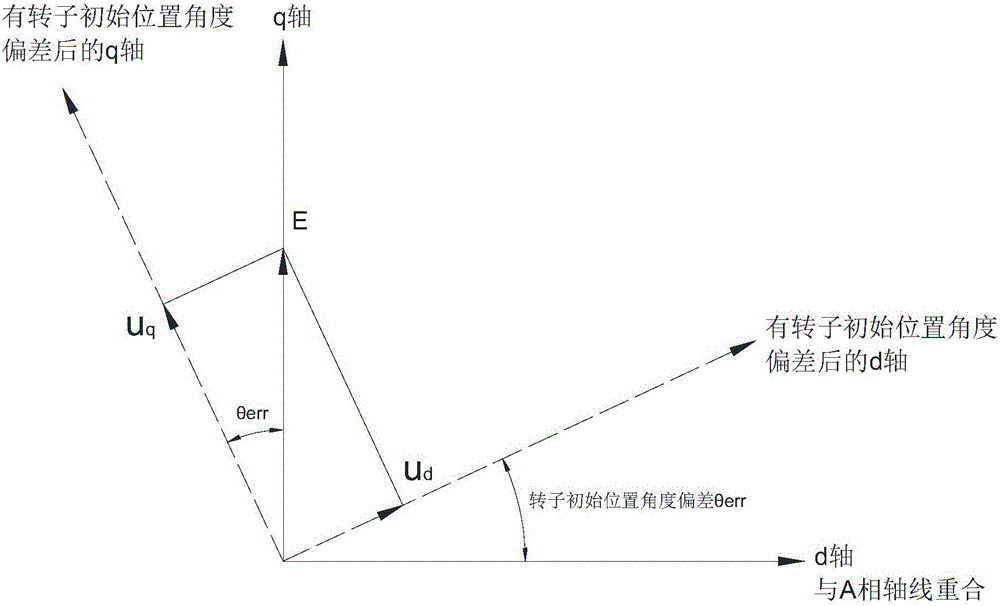

[0048] Step 3, measure the voltage u of the d-axis and q-axis of the motor stator at this time d , uq ;

[0049] Step 4, according to u d , u q The trigonometric function relationship between calculates the initial position angle deviation θ of the motor rotor at this time err .

[0050] The motor tested in this embodiment is a syn...

Embodiment 2

[0080] In Embodiment 2 of the present invention, the initial position angle deviation θ of the motor rotor err The trigonometric function relationship of is expressed as follows:

[0081] When the motor rotates forward, the θ err =arccot2(u q , u d ).

[0082] When the motor rotates in reverse, the θ err =arccot2(-u q ,-u d ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com