Drilling anomaly detection method, device and equipment, drilling well and storage medium

A detection method and anomaly technology, applied in the field of oil and gas exploration, can solve the problems of low reliability of anomaly detection, achieve the effect of reducing false alarm rate, reducing well control risk and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

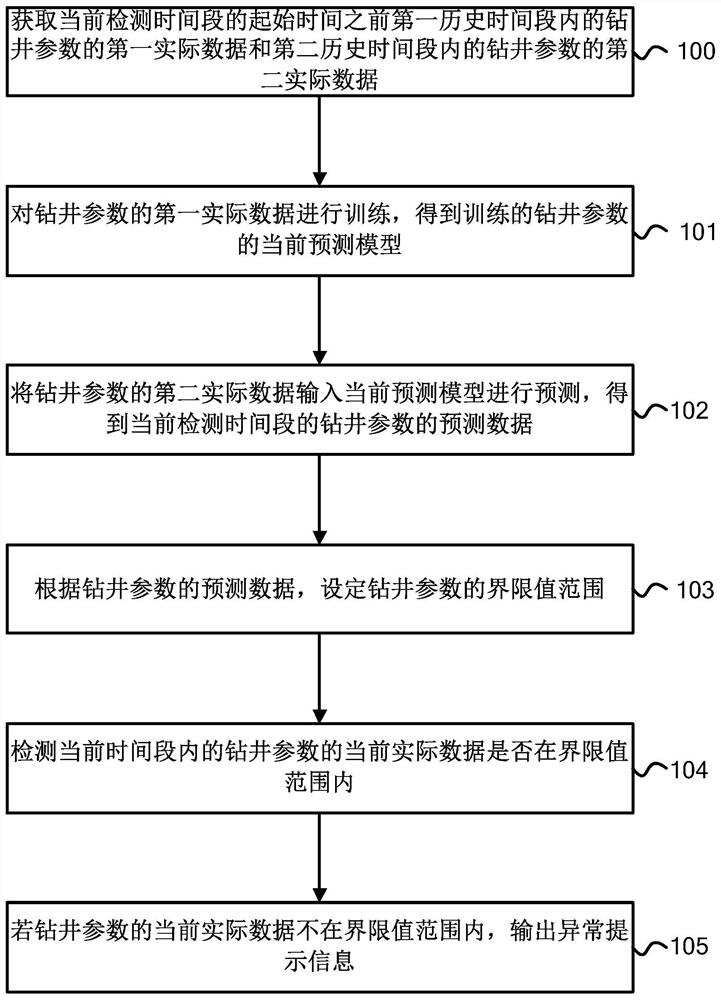

[0055] specifically, figure 1 It is a flow chart of Embodiment 1 of the detection method for drilling abnormality of the present invention, as figure 1 As shown, the abnormal drilling method of the present embodiment may specifically include the following steps:

[0056] 100. Acquire the first actual data of the drilling parameters in the first historical time period before the start time of the current detection time period and the second actual data of the drilling parameters in the second historical time period;

[0057] In this embodiment, multiple dynamic time slices may be set according to actual requirements. Wherein, each dynamic time slice includes the time period in which drilling has been carried out and the time period in which drilling anomalies need to be detected, and the time period in which drilling anomalies need to be detected is used as the time sliding step, so that after moving sequentially according to the time sliding step, each The drilling parameter...

Embodiment 2

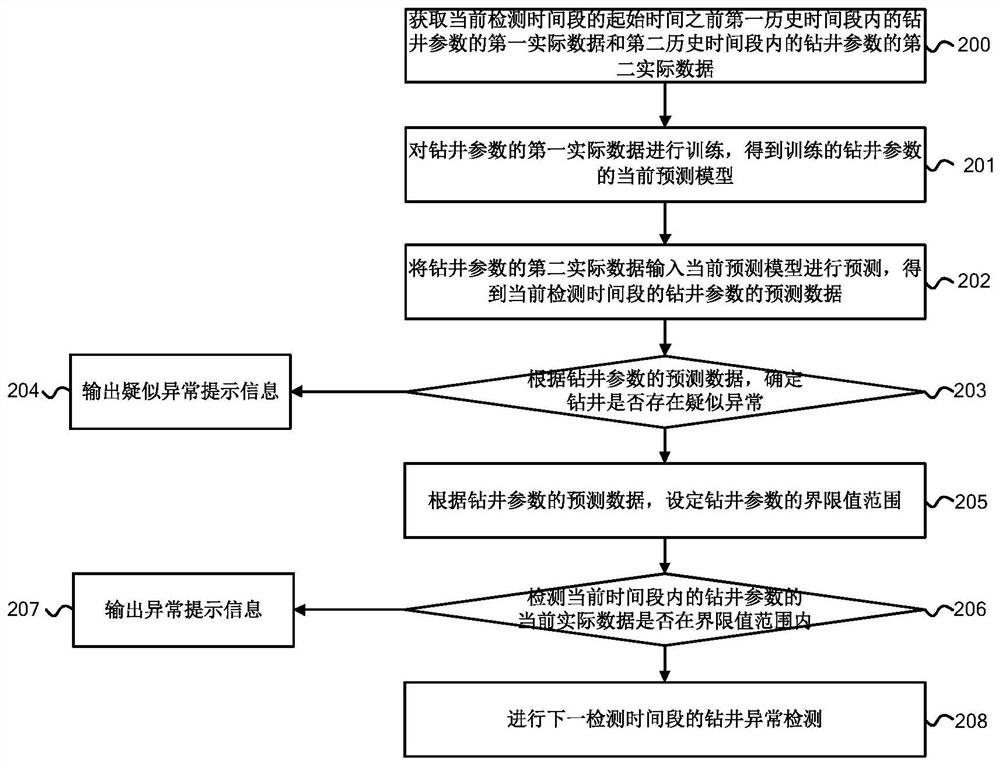

[0075] figure 2 It is the flow chart of Embodiment 2 of the detection method for abnormal drilling of the present invention, as figure 2 As shown, the drilling abnormality detection method of this embodiment is based on the above embodiments, and further describes the technical solution of the present invention in more detail.

[0076] like figure 2 As shown, the abnormal drilling method of this embodiment may specifically include the following steps:

[0077] 200. Acquire the first actual data of the drilling parameters in the first historical time period before the start time of the current detection time period and the second actual data of the drilling parameters in the second historical time period;

[0078] The implementation process of this embodiment is the same as the implementation process of step 100 in the above-mentioned embodiment, please refer to the relevant records above for details, and details are not repeated here.

[0079] 201. Perform training on th...

Embodiment 3

[0106] Image 6 It is a structural schematic diagram of an embodiment of the abnormal drilling detection device of the present invention, such as Image 6 As shown, the drilling abnormality detection device of this embodiment includes an acquisition module 60 , a training module 61 , a prediction module 62 , a setting module 63 , a detection module 64 and an output module 65 .

[0107] The obtaining module 60 is used to obtain the first actual data of the drilling parameters in the first historical time period before the start time of the current detection time period and the second actual data of the drilling parameters in the second historical time period; wherein, the first The start time of the historical time period is earlier than the start time of the second historical time period; the end time of the first historical time period is earlier than or equal to the end time of the second historical time period;

[0108] The training module 61 is used to train the first act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com