Drilling fluid leakage determining instrument

A drilling fluid and instrument technology, which is applied in the field of instruments for judging leakage horizons, can solve the problems of cumbersomeness, poor accuracy of the leakage horizons, and increased well control risks, so as to eliminate interference factors and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

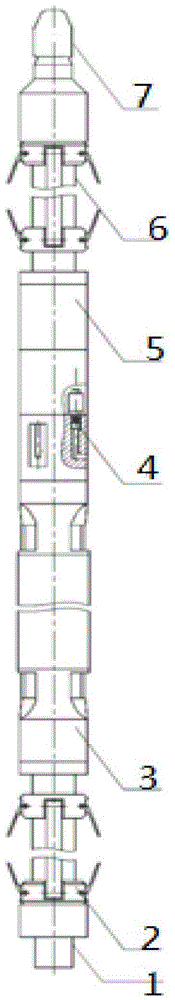

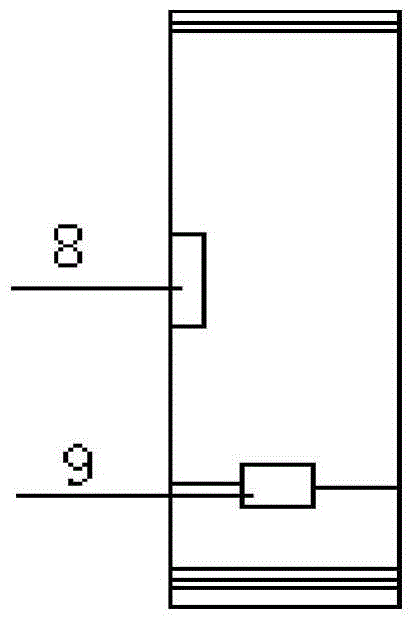

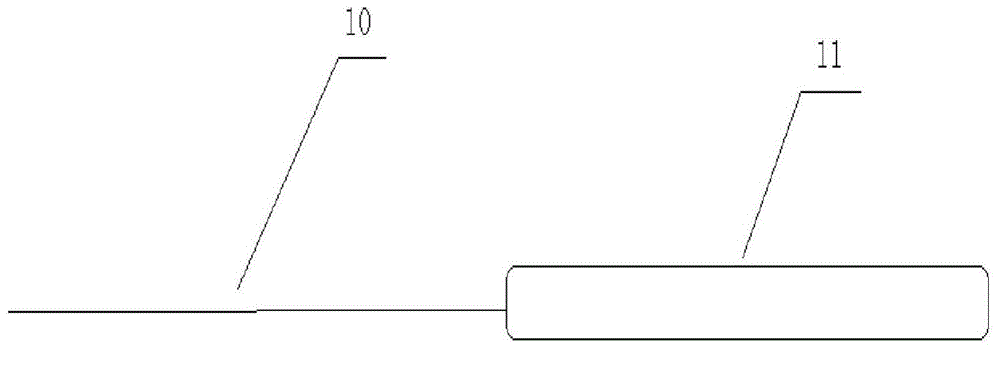

[0020] The drilling fluid loss determination instrument is composed of three parts: measuring instrument, outer cylinder pup joint, and cable transmission equipment. The measuring instrument assembly is mainly composed of an upper positioning joint 1, a lower centralizer 2, a draft pipe assembly 3, a pressure temperature measurement assembly 4, a measurement and control electronic assembly 5 (including batteries), an upper centralizer 6, and a male gun head 7; the outer cylinder is mainly It is composed of a short section with a bypass valve 8 and a lower positioning joint 9; the cable transmission device is mainly composed of a cable 10 and a female gun head 11.

[0021] Refer to attached figure 1 , the upper positioning joint 1 of the measuring instrument is connected with the lower centralizer 2, the lower centralizer 2 is connected with the draft tube assembly 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com