Hydraulic switching valve

A technology of hydraulic switch and ball valve, which is applied in the direction of borehole/well valve device, borehole/well parts, earthwork drilling and production, etc. Small risk control, reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to disclose the purpose, technical means and technical effects of the present invention more completely and clearly, the following is a detailed description, and please refer to the accompanying drawings and component numbers.

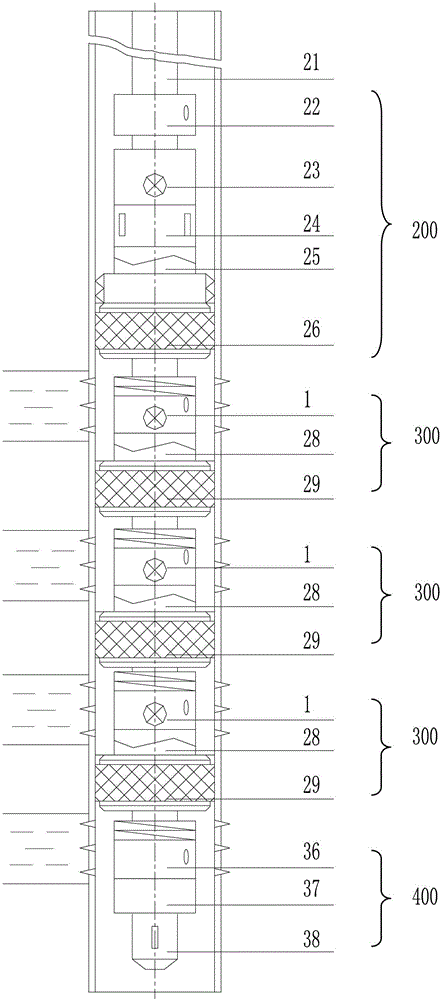

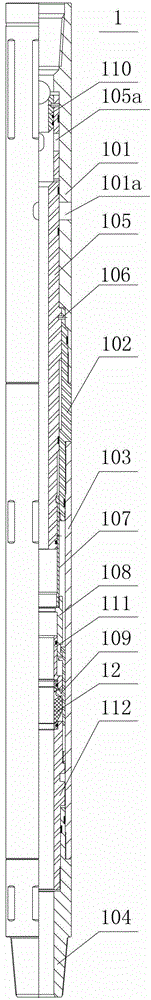

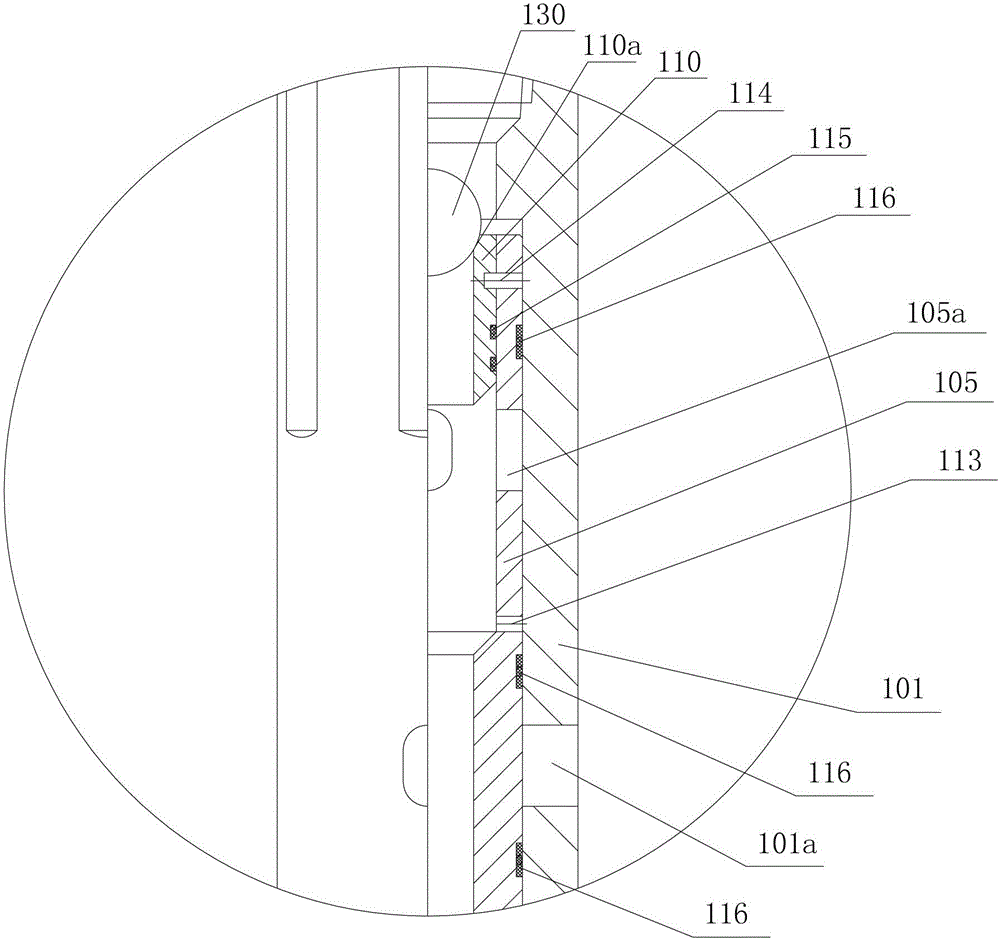

[0039] The invention provides a reasonable and compact hydraulic switch valve, such as figure 2 As shown, because of its long axial dimension, in order to clearly reflect the structure of each part, the figure 2 The part of the ball seat sleeve and the ball valve assembly are respectively enlarged as shown in image 3 and Figure 4 shown. Please refer to the following Figure 2 ~ Figure 4 , the hydraulic switching valve 1 of the present invention is connected to the downhole test pipe string, and is a multi-layer hollow tubular body, which has an outer layer, a middle layer and an inner layer in the radial direction, and the outer layer is connected from top to bottom in the axial direction There are an upper joint 101, an interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com