Hydraulic setting/unsetting high-pressure packer

A hydraulic setting and packer technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems that the anti-extrusion force level cannot meet the production of high-pressure wells, so as to ensure safety, The effect of reducing well control risk and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

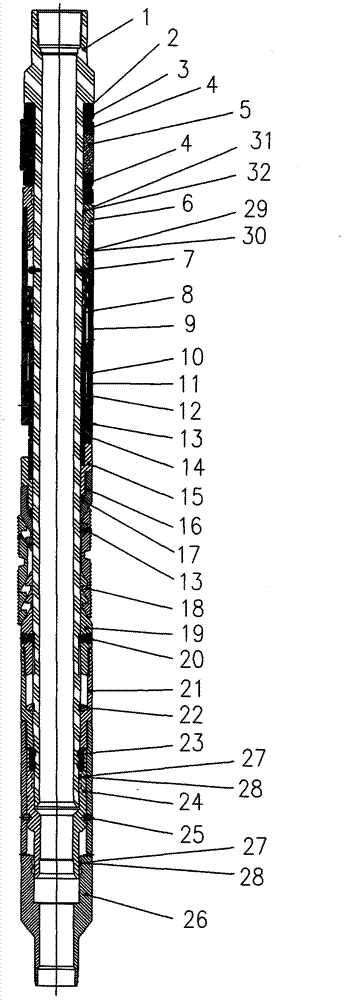

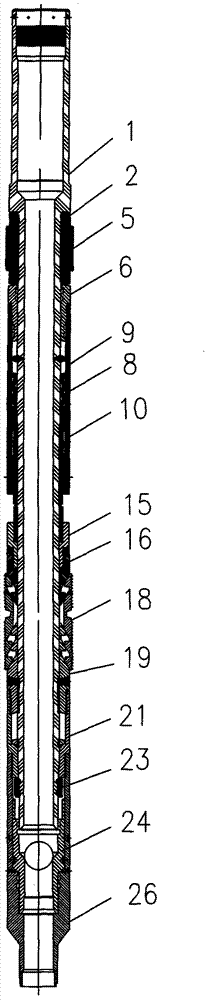

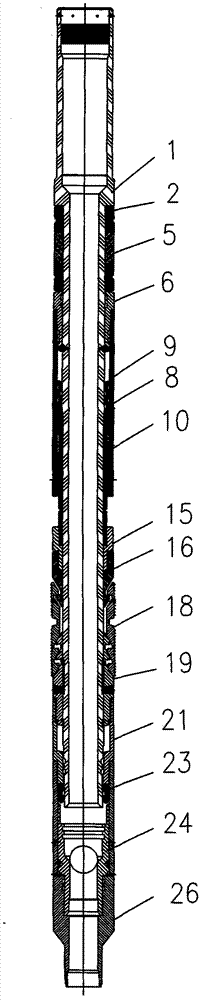

[0024] Such as Figure 1-5 As shown, a hydraulically set and unsealed high-pressure packer of the present invention includes a mandrel 1 and a rubber cartridge seal assembly and a piston that are sequentially fitted on the outer wall of the mandrel 1 from top to bottom along the axial direction of the mandrel. Assembly, slip assembly, unsealing assembly and lower joint 26.

[0025] The mandrel 1 includes a joint connecting the upper part with the oil delivery pipe, the internal thread of the joint is an airtight screw thread, and the lower end of the joint is designed with a step larger than the rubber tube; the middle part of the mandrel 1 is designed with a setting seal The pressure transmission hole of the mandrel 1 is designed with an upper "C"-shaped ring groove; the lower end of the pressure transmission hole of the mandrel 1 is a reduced diameter section, and there are two symmetrical channels in the middle of the reduced diameter section. Guide groove; the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com