Straddle perforating and testing combining string capable of firstly testing lower layer and operation method thereof

A technology that straddles the lower layer and is applied in the field of testing joint operation strings and oil and gas wells spanning perforation. It can solve the problems that cannot be realized, and achieve the effect of increasing the speed and efficiency of oil testing and optimizing the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical means and technical effect of the present invention more completely and clearly disclosed, the following detailed description is given, and please refer to the accompanying drawings and component numbers together.

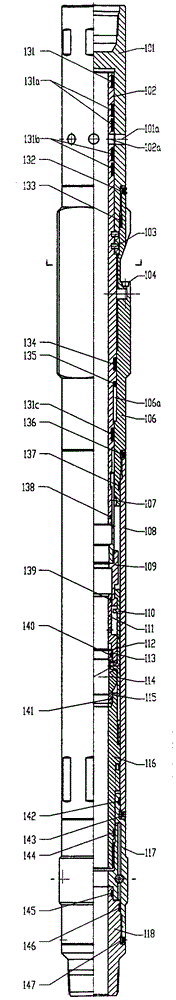

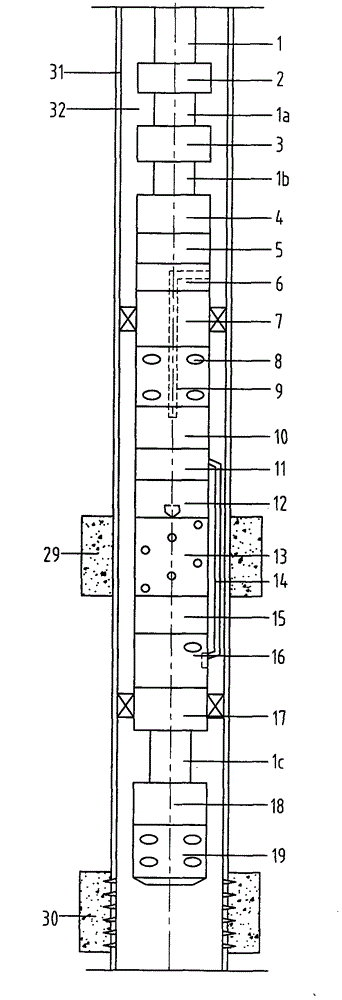

[0041] The present invention provides a well-sealing shut-in valve with reasonable and compact structure, such as figure 2 shown. Please see below Figure 2-4 , the sealing layer shut-in valve 16 of the present invention can be connected to the two-layer layered perforation-layered test combined pipe string, and is a multi-layer tubular body, and the sealing layer shut-in valve has an outer diameter in the radial direction. layer, middle layer and inner layer, the outer layer is connected with the upper joint 101, the air cavity joint 106, the ball valve outer cylinder 108, the stakeout valve joint 117 and the lower joint 118 from top to bottom along the axial direction, and the outer wall of the air cavity joint 106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com