Patents

Literature

45 results about "Hierarchical test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hierarchical Testing. One simple but novel feature of Agar that has not been explicitly described in other CAA systems is the notion of hierarchical testing: if a given test fails, run one or more secondary tests and return the sum of their outputs instead.

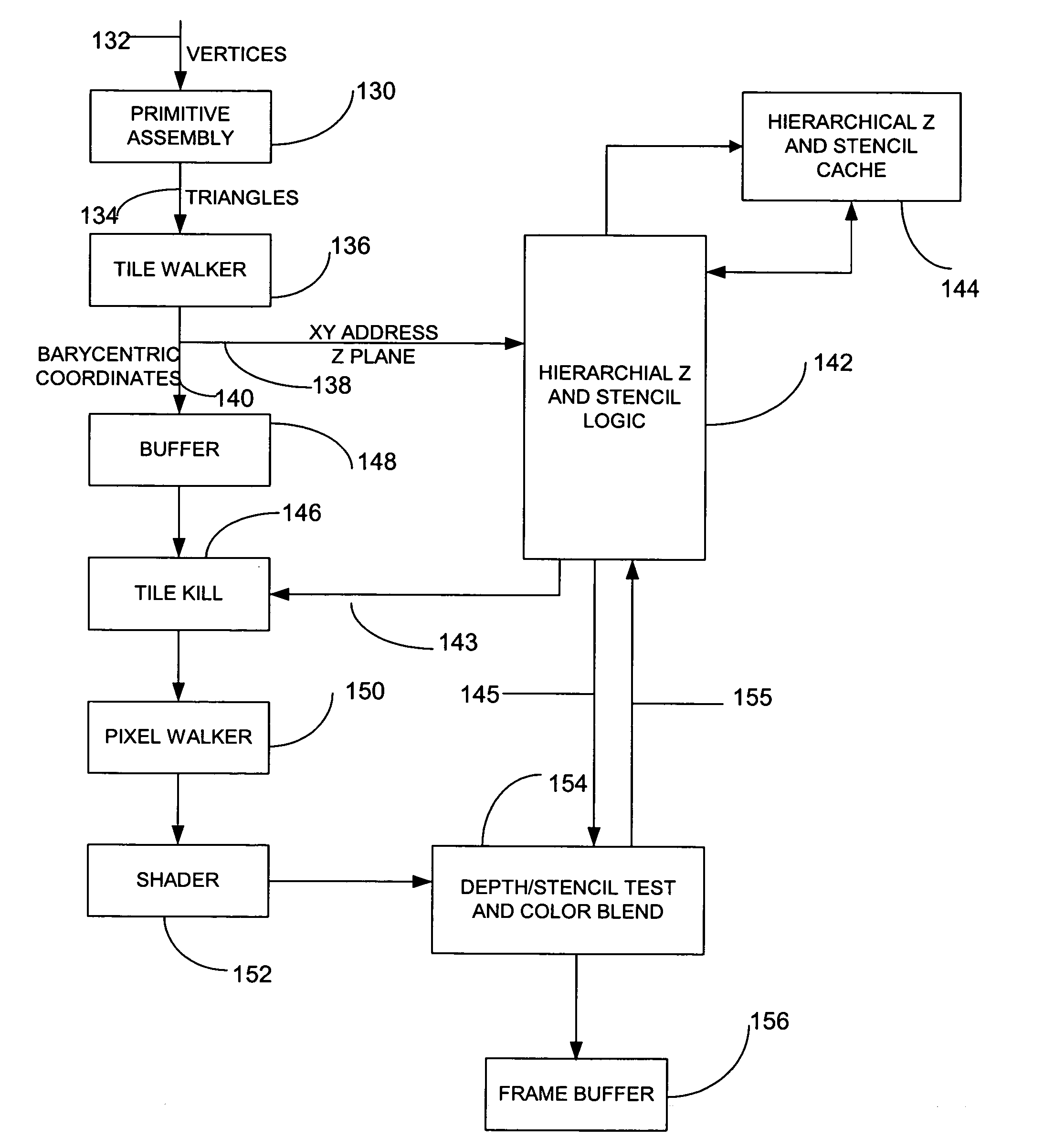

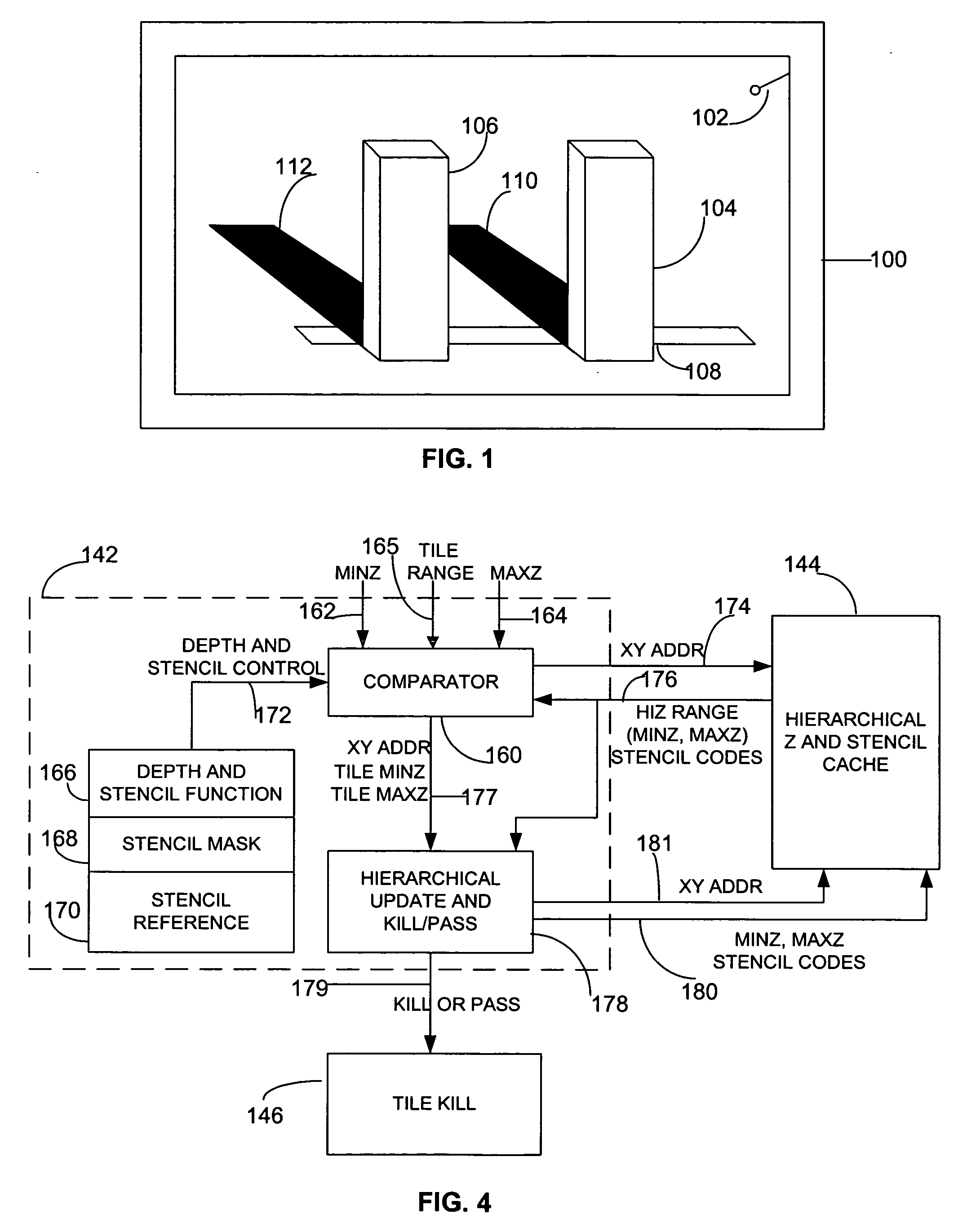

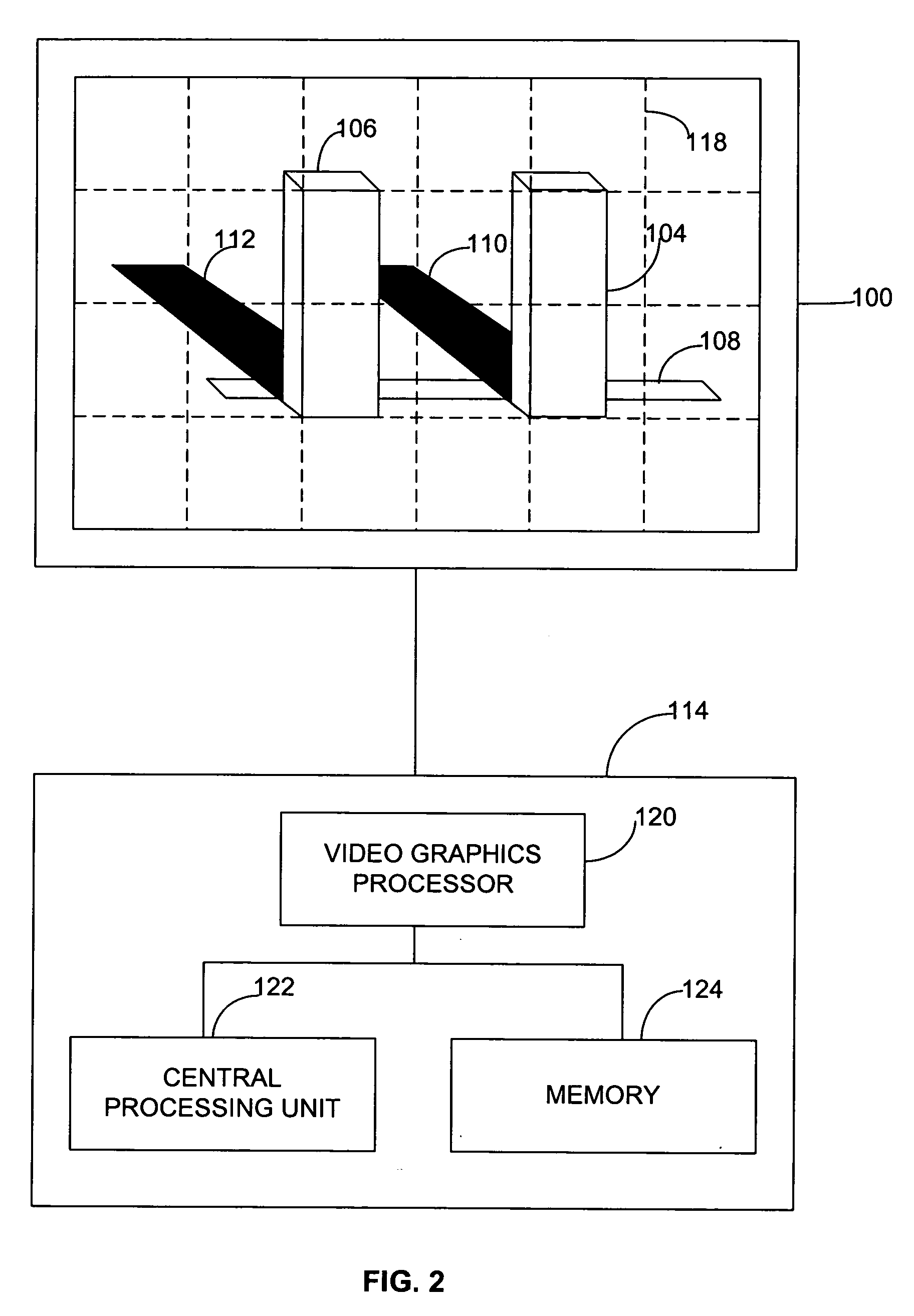

Method and apparatus for hierarchical Z buffering and stenciling

ActiveUS20050195187A1Digital computer detailsCathode-ray tube indicatorsComputational scienceGraphics

A method and apparatus for hierarchical Z buffering stenciling includes comparing an input tile Z value range with a hierarchical Z value range and a stencil code. The method and apparatus also updates the hierarchical Z value range and stencil code in response the comparison and determines whether to render a plurality of pixels within the input tile based on the comparison of the input tile Z value range with the hierarchical Z value range and stencil code. In determining whether to render the tile, a stencil test and a hierarchical Z value test is performed. If one of the test fails, the tile is killed as it is determined that the pixels are not visible in the graphical output. If the stencil test passes and the hierarchical Z test passes, the pixels within the tile are rendered, as it is determined that the pixels may be visible.

Owner:ATI TECH INC

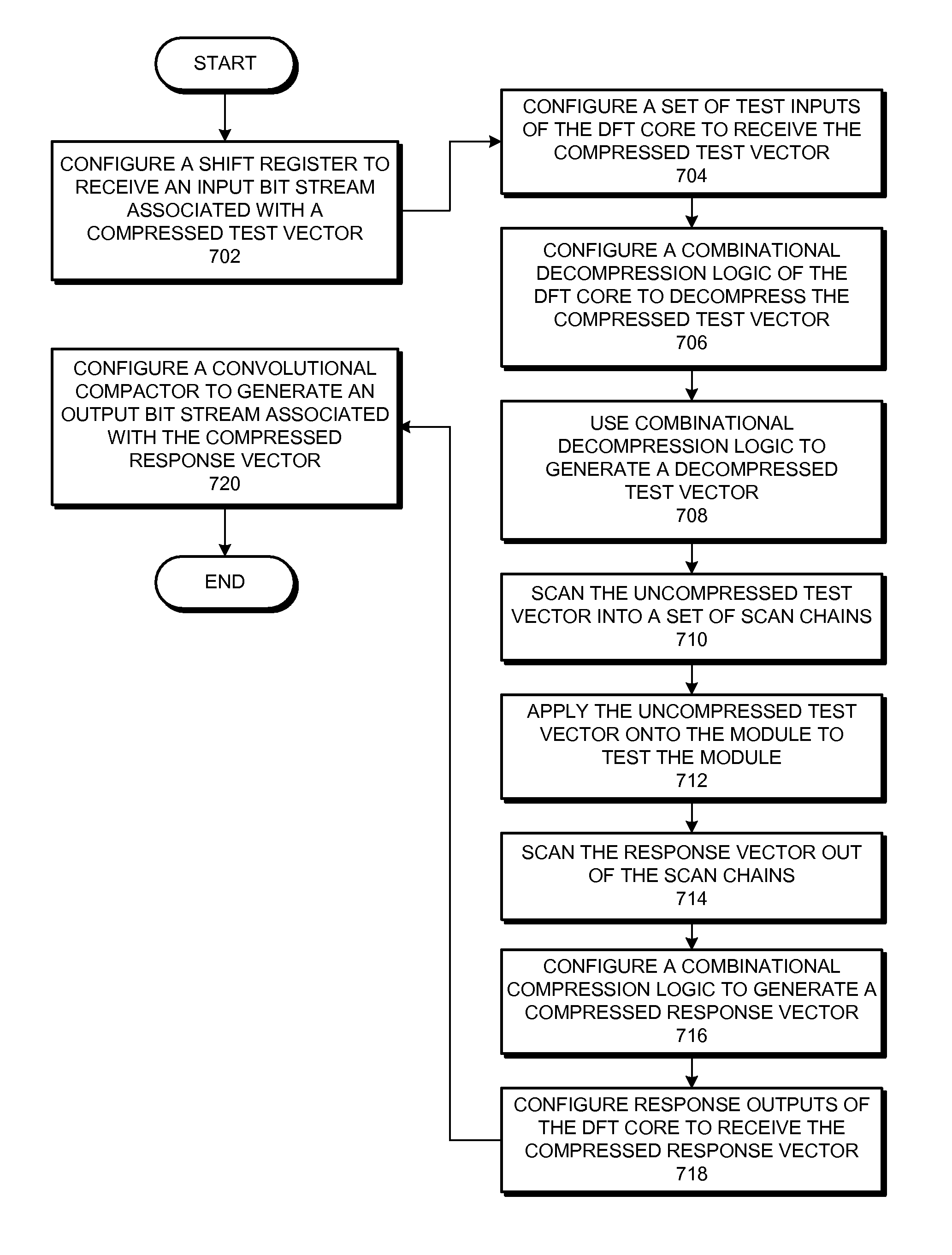

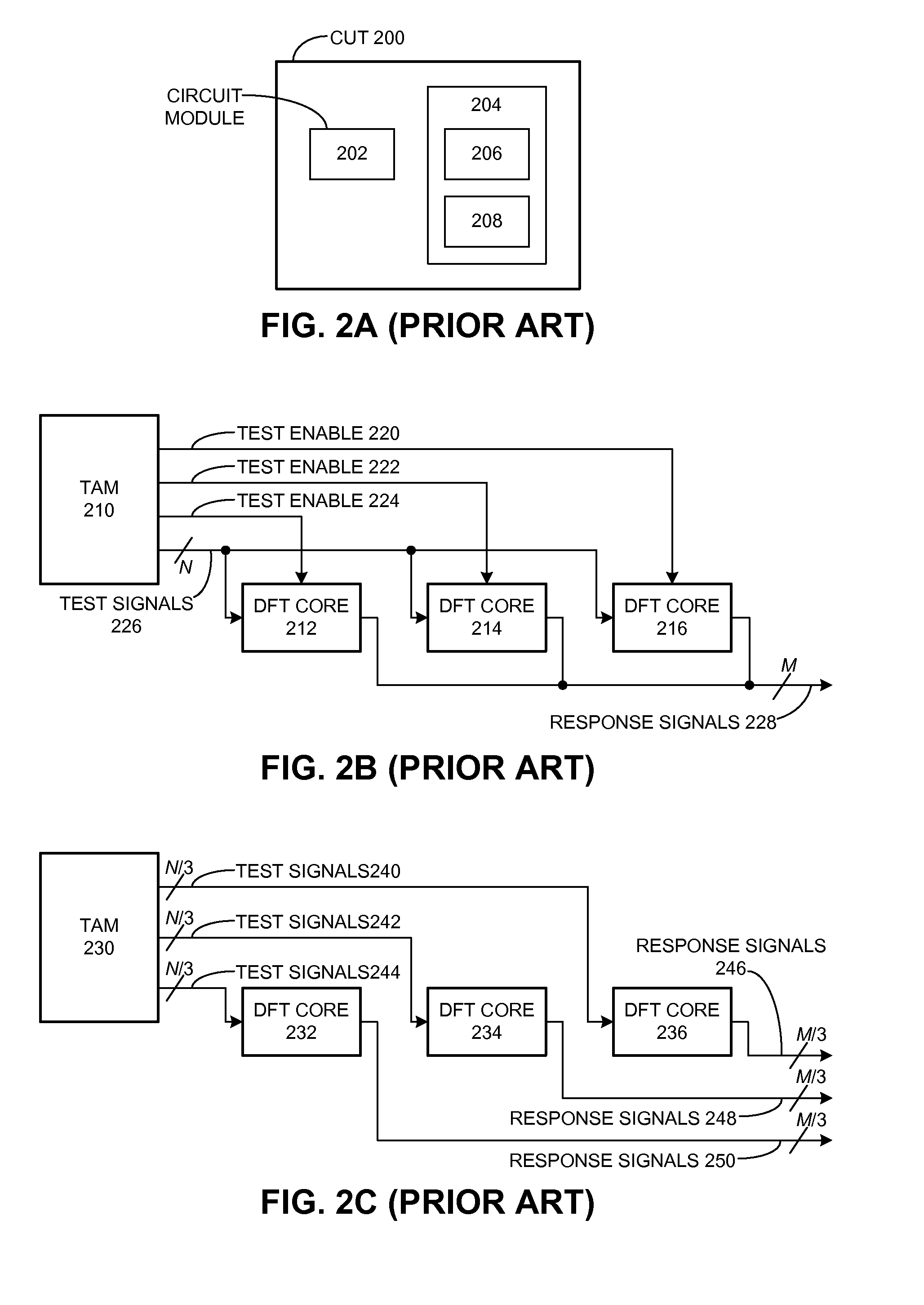

Implementing hierarchical design-for-test logic for modular circuit design

ActiveUS8065651B2Reduce dataReduce testingElectronic circuit testingDetecting faulty computer hardwareDesign testingControl signal

Embodiments of the present invention provide methods and apparatuses for implementing hierarchical design-for-test (DFT) logic on a circuit. The hierarchical DFT logic implements DFT circuitry that can be dedicated to a module, and which can configure DFT circuitry for multiple modules to share a sequential input signal and / or to share a sequential output signal. During operation, the DFT circuitry for a first module can propagate a bit sequence from the sequential input signal to the DFT circuitry of a second module, such that the bit sequence can include a set of control signal values for controlling the DFT circuitry, and can include compressed test vectors for testing the modules. Furthermore, the DFT circuitry for the second module can generate a sequential response signal, which combines the compressed response vectors from the second module and a sequential response signal from the DFT circuitry of the first module.

Owner:SYNOPSYS INC

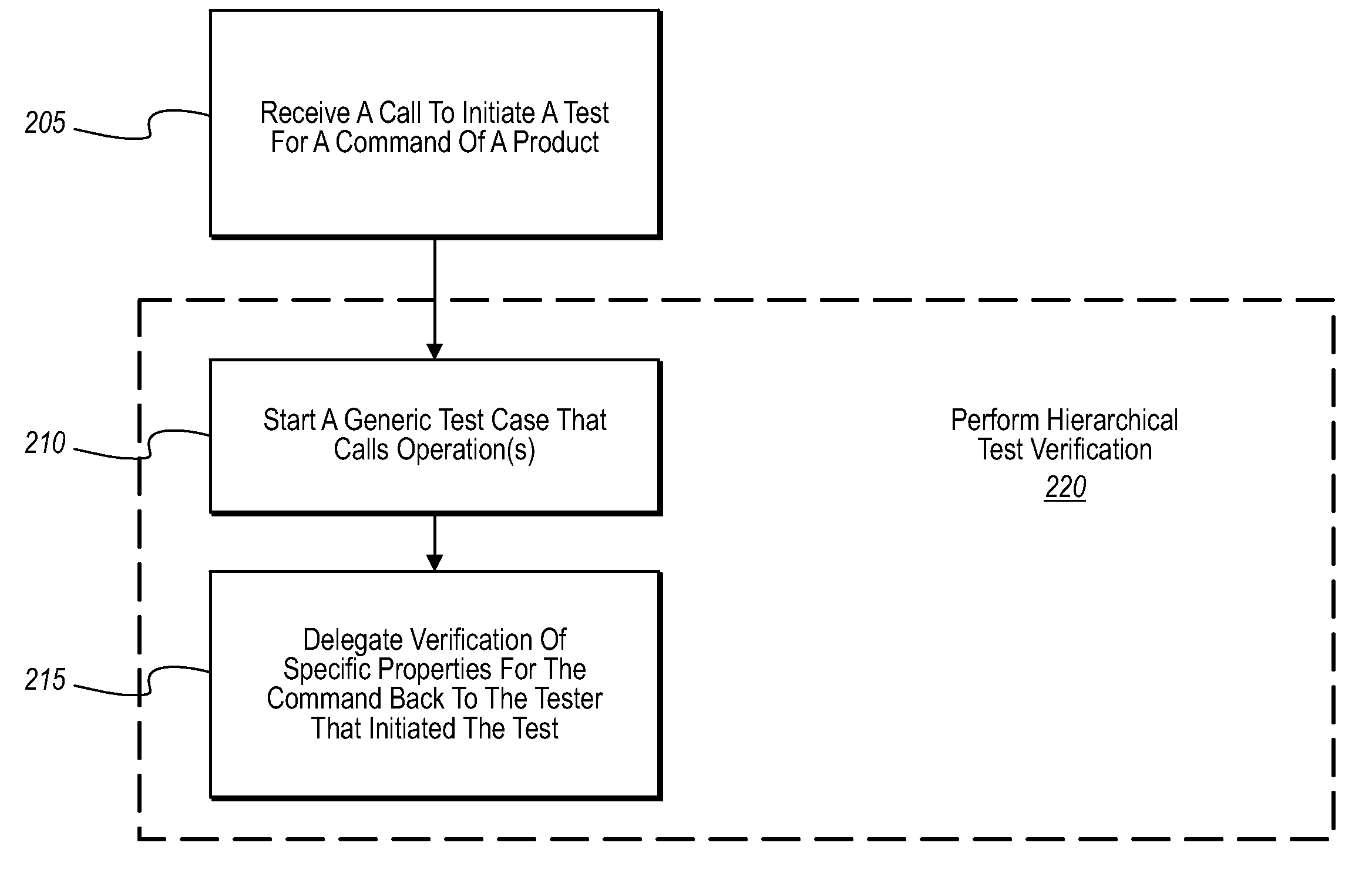

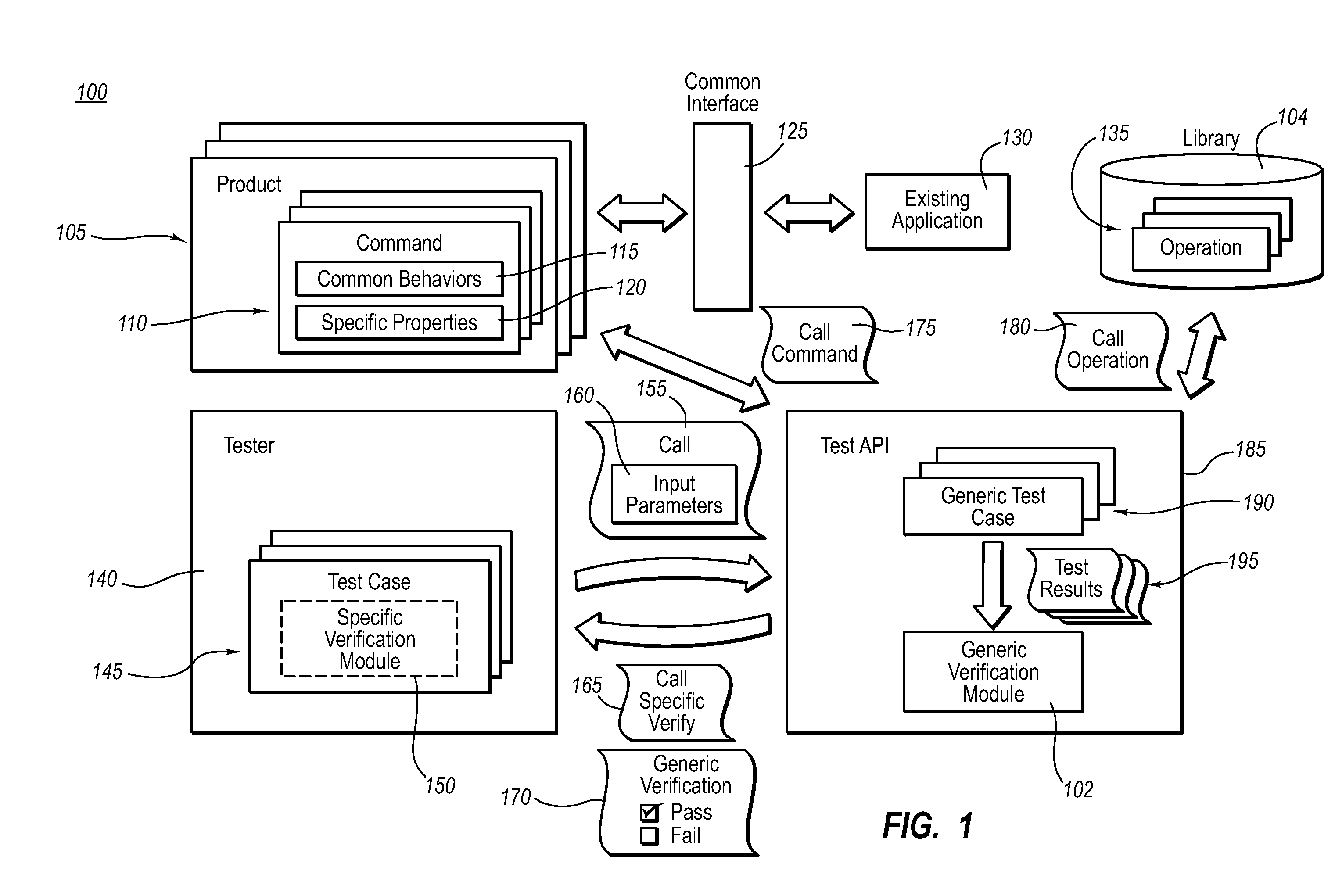

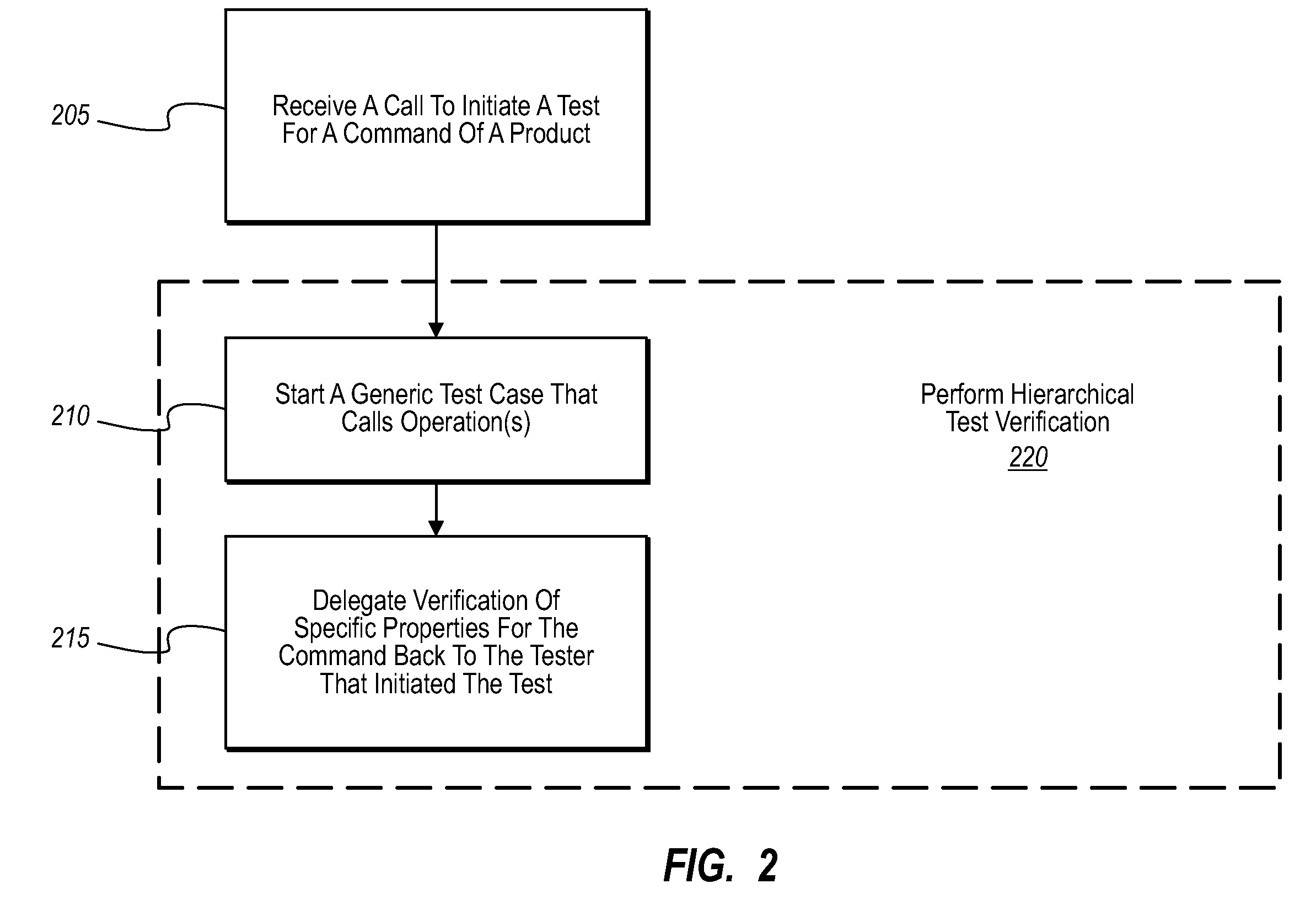

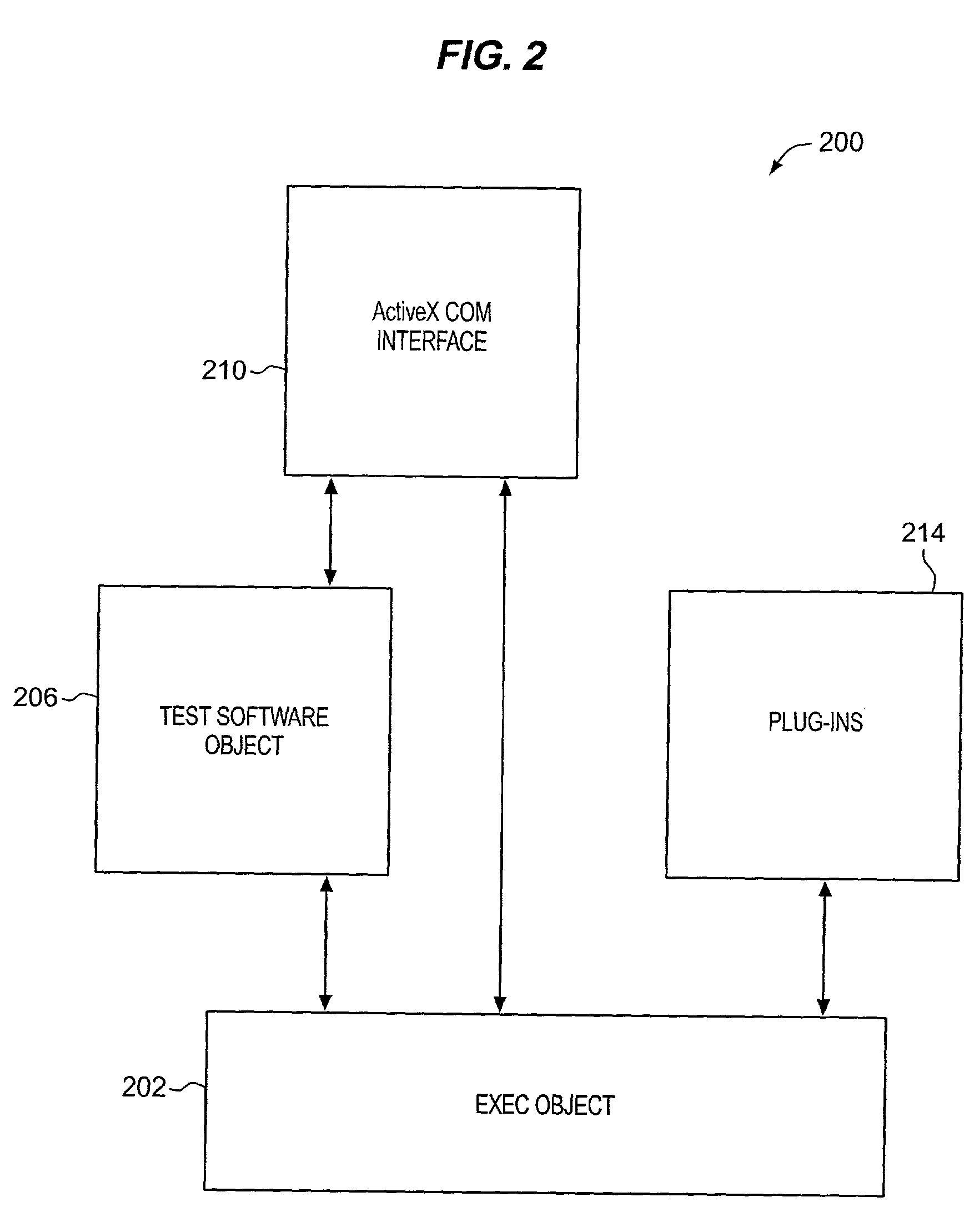

Hierarchical test verification using an extendable interface

InactiveUS20070283327A1Well formedError detection/correctionSpecific program execution arrangementsHierarchical testCoding quality

Embodiments provide for a pluggable framework for testing a product by creating a command test application program interface (API) layer that supports hierarchical verification. These test APIs provide well written wrappers around commands so that a product tester can start writing test cases quickly and at good code quality. Verification of command execution is broken into two parts. The high level first stage verification is handled by an embodied framework; the detailed second stage is delegated back to the pluggable tester that initiated the test. This final stage of verification verifies that the specific properties of the item are valid. It is up to the tester to decide how granular the second stage should be. Accordingly, other embodiments provide for progressive development, which indicates that the specific verifications do not need to be enforced by the framework and can be added over time in the development process.

Owner:MICROSOFT TECH LICENSING LLC

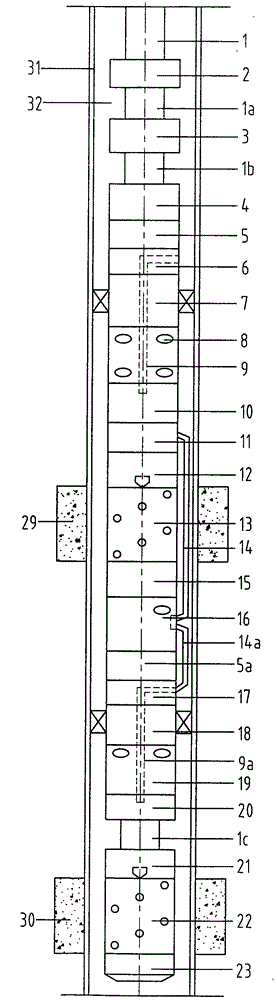

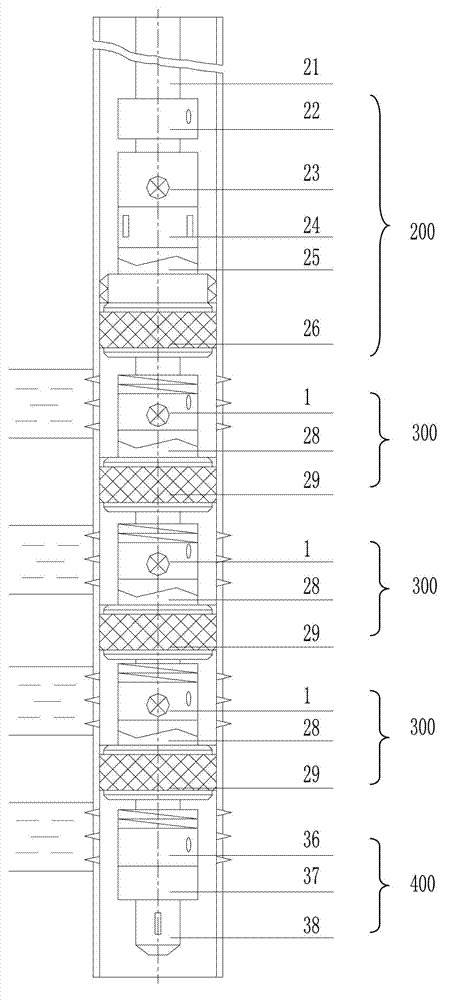

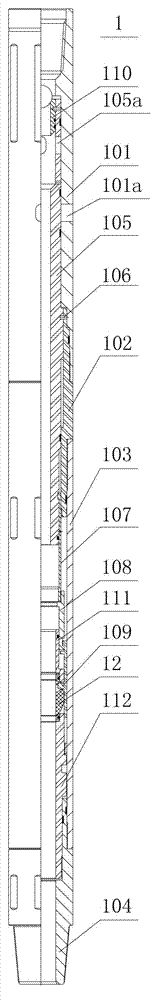

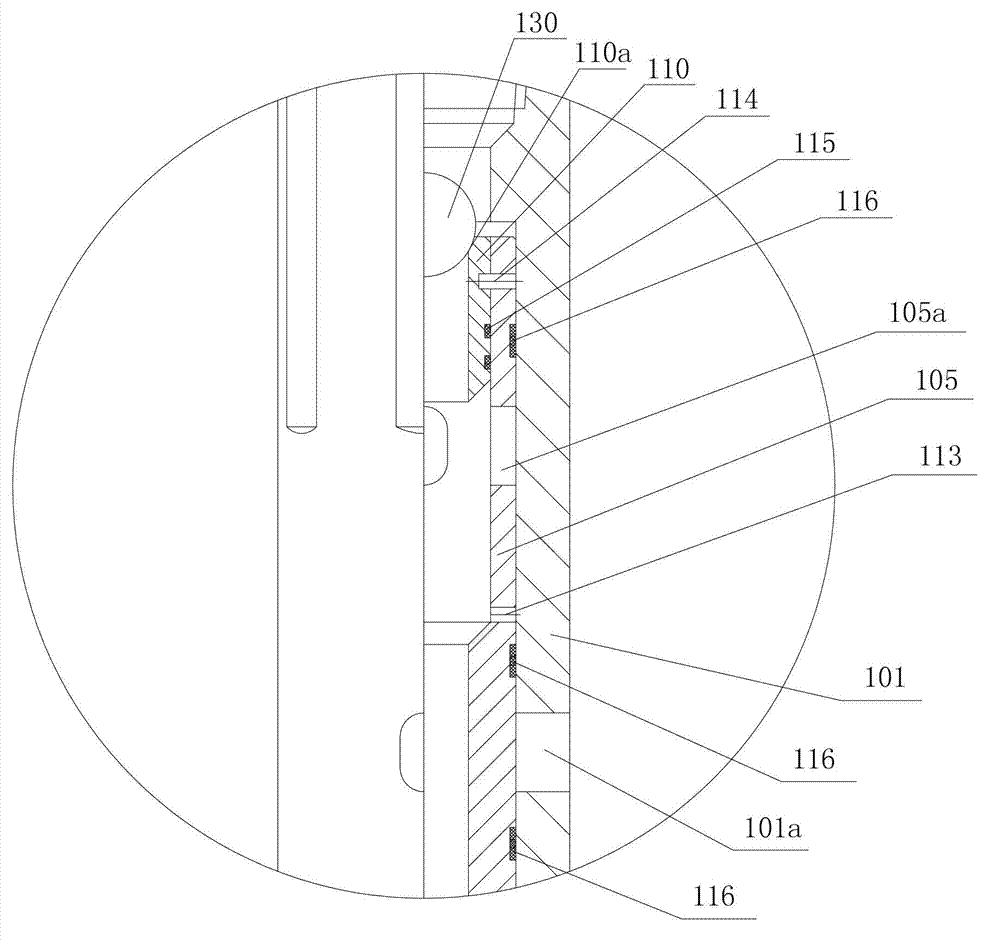

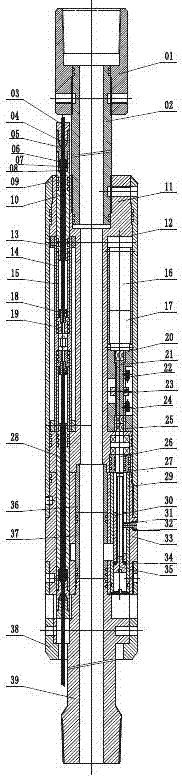

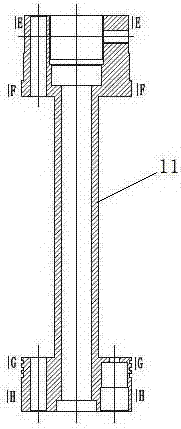

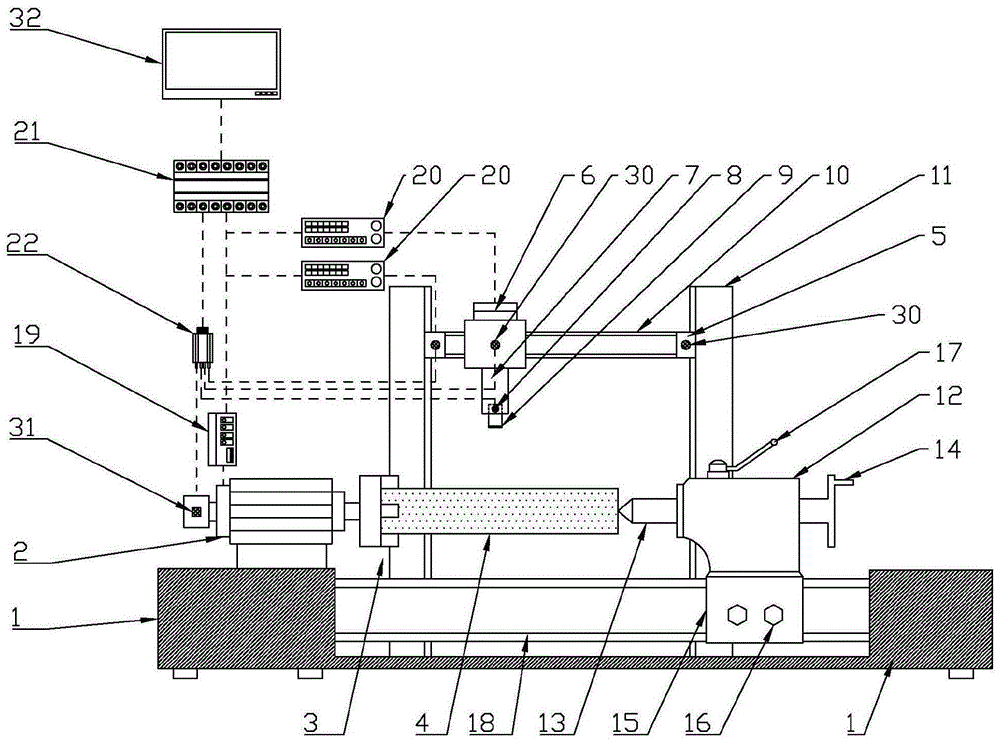

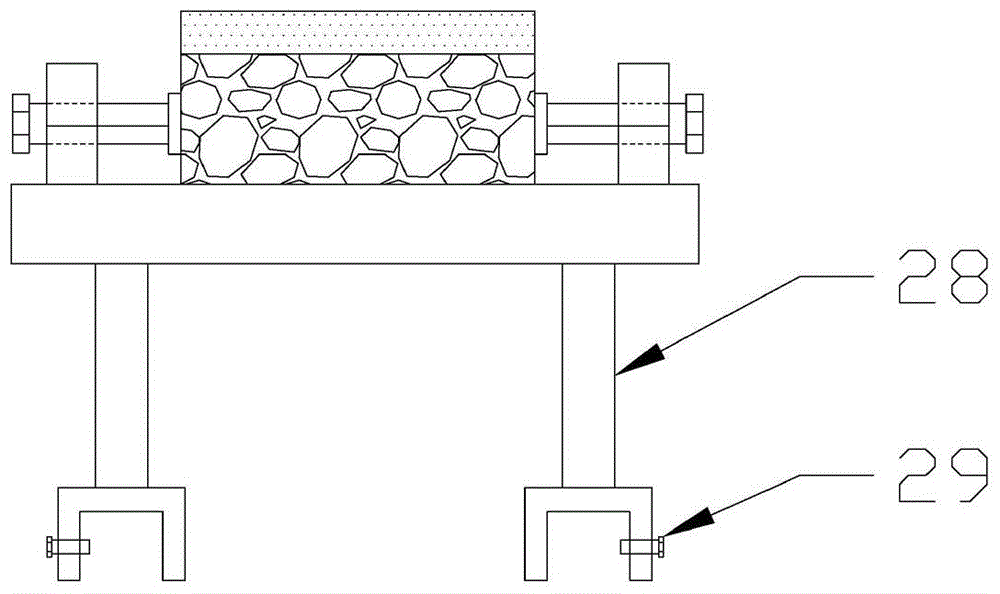

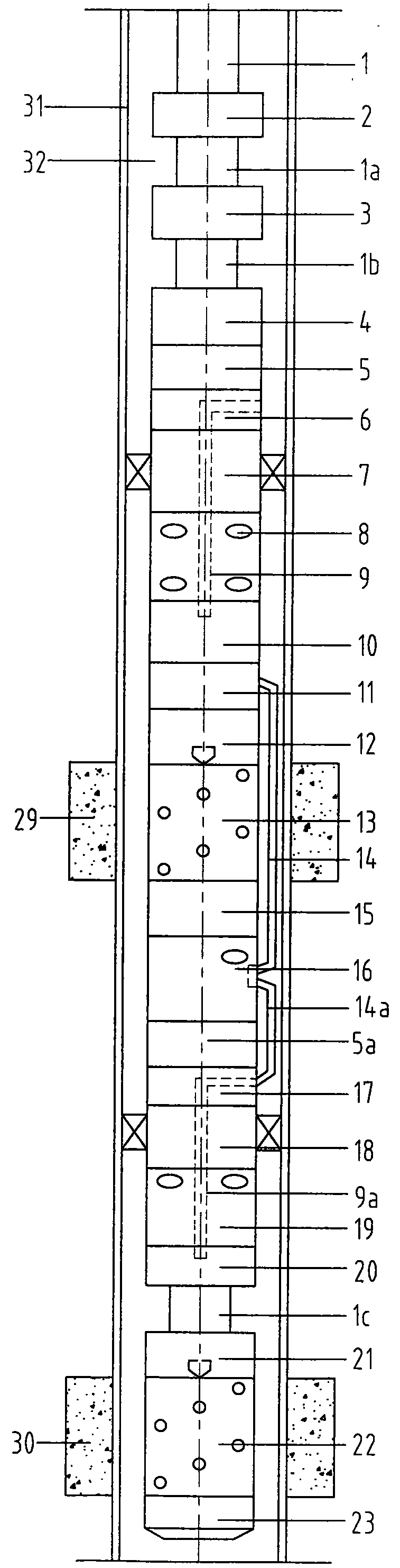

One-trip string two-layer layering perforation-layering testing combining tubular column and operation method thereof

ActiveCN106150445AImprove admission qualityIncrease the proportion of stratified oil testingFluid removalWell/borehole valve arrangementsHierarchical testInternal pressure

The invention relates to a one-trip string two-layer layering perforation-layering testing combining tubular column and an operation method. The tubular column comprises a first oil tube, a depth correction short joint, a second oil tube, a circulating valve, a third oil tube, a testing valve assembly, a second pressure gauge supporting cylinder, a second pressure transfer joint, a straddle packer, a second sieve tube, a spacer tube, a pressure guiding joint, a second ignition head, a second perforating gun, a pressure release device, sealing layer well shut-in sampling valve, a damping pressure gauge supporting cylinder, a first pressure transfer joint, an anchor packer, a first sieve tube, a shock absorber, a fourth oil tube, a first ignition head, a first perforating gun, a pressure relieving device, a second inner pressure transfer tube, a first pressure transfer tube and a first outer pressure transfer tube. The sealing layer well shut-in sampling valve is located between the second perforating gun and the anchor packer. The damping pressure gauge supporting cylinder is located below the sealing layer well shut-in sampling valve. by adopting the tubular column, two-layer layering perforation and layering testing combination can be completed, final well shut-in of the first layer does not need to occupy the operation machine time independently, down-hole sampling is convenient, and the tubular column has the advantages of being short in period, low in cost and the like.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

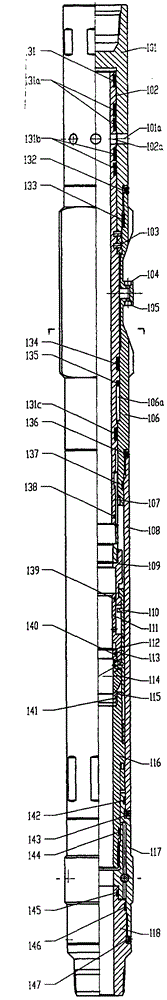

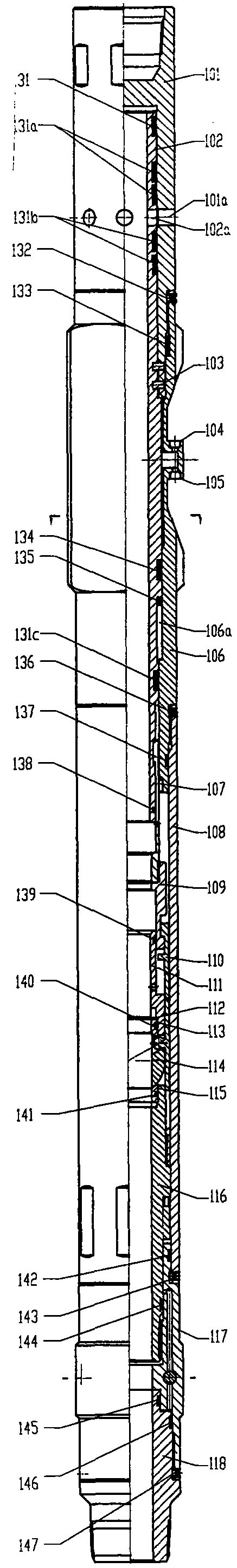

Multi-layer multi-section continuous oil testing system without lifting tubular column and operation method thereof

ActiveCN103114843ACompact and reasonable structureShort cycleSurveyFluid removalHierarchical testEngineering

The invention relates to a multi-layer multi-section continuous oil testing system without lifting a tubular column. The system is connected on the downhole testing tubular column in series and comprises an upper sub-system, a plurality of layered testing systems and a lower sub-system which are sequentially connected in series along the axial direction of the tubular column, wherein the upper sub-system comprises a manifold circulating valve, a main testing valve, a full-bore pressure gage support barrel, a safe connector and a top hydraulic packer which are sequentially connected in series along the axial direction of the tubular column. The plurality of layered testing systems are sequentially connected on the tubular column in series along the axial direction of the tubular column, each layered testing system corresponds to one oil layer, and each layered testing system comprises a hydraulic switching valve, a safe connector and a layered hydraulic packer. The lower sub-system comprises a hydraulic sliding sleeve, a pressure transmitting connector and a monitoring pressure gage which are sequentially connected in series along the axial direction of the tubular column. By means of the system, multi-layer and multi-section continuous testing, capacity increasing revamp, liquid discharging and a series of downhole operation processes can be completed without lifting the tubular column, and the system has the advantages of being simple in construction operation, convenient to assemble, short in construction period and the like.

Owner:PETROCHINA CO LTD

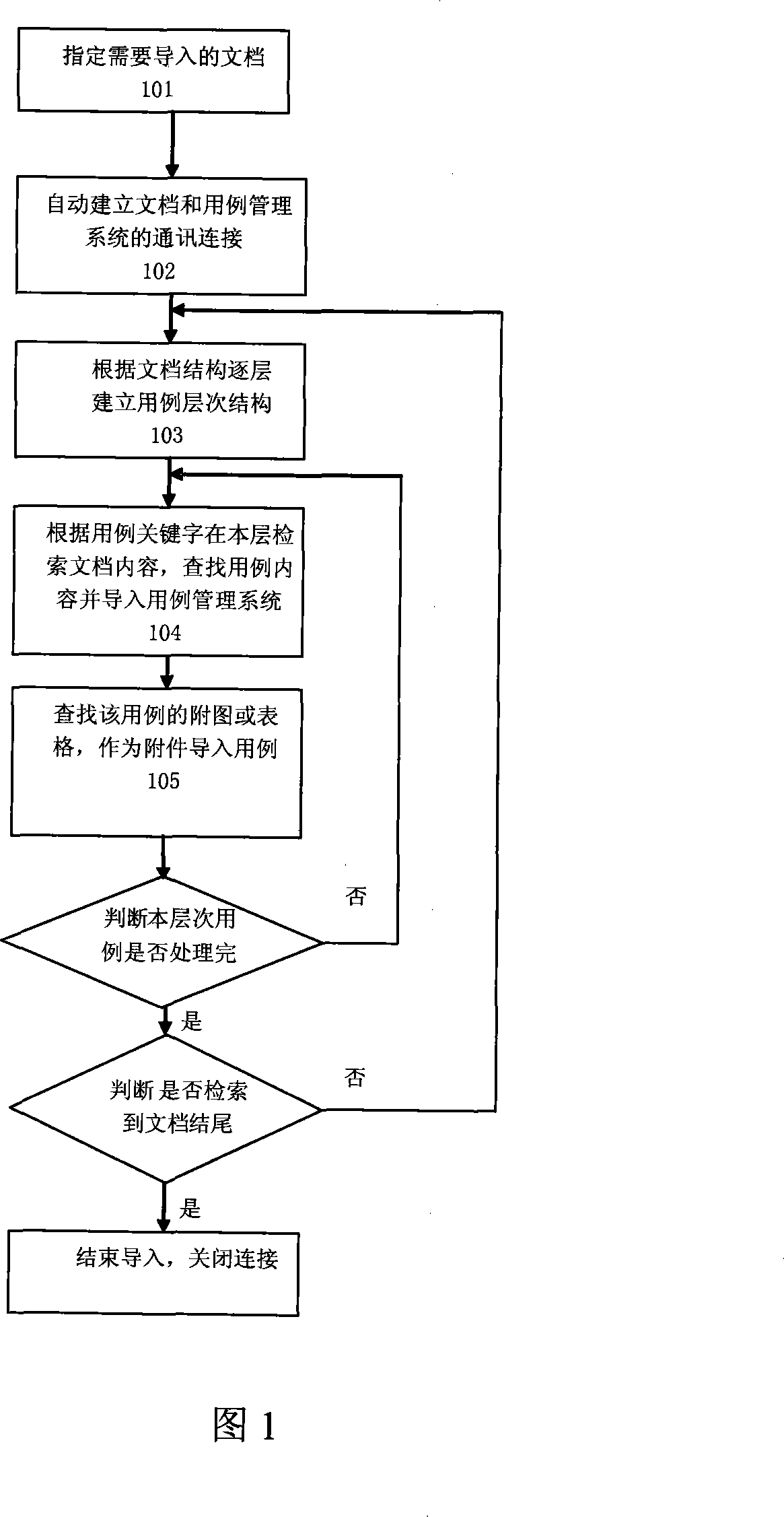

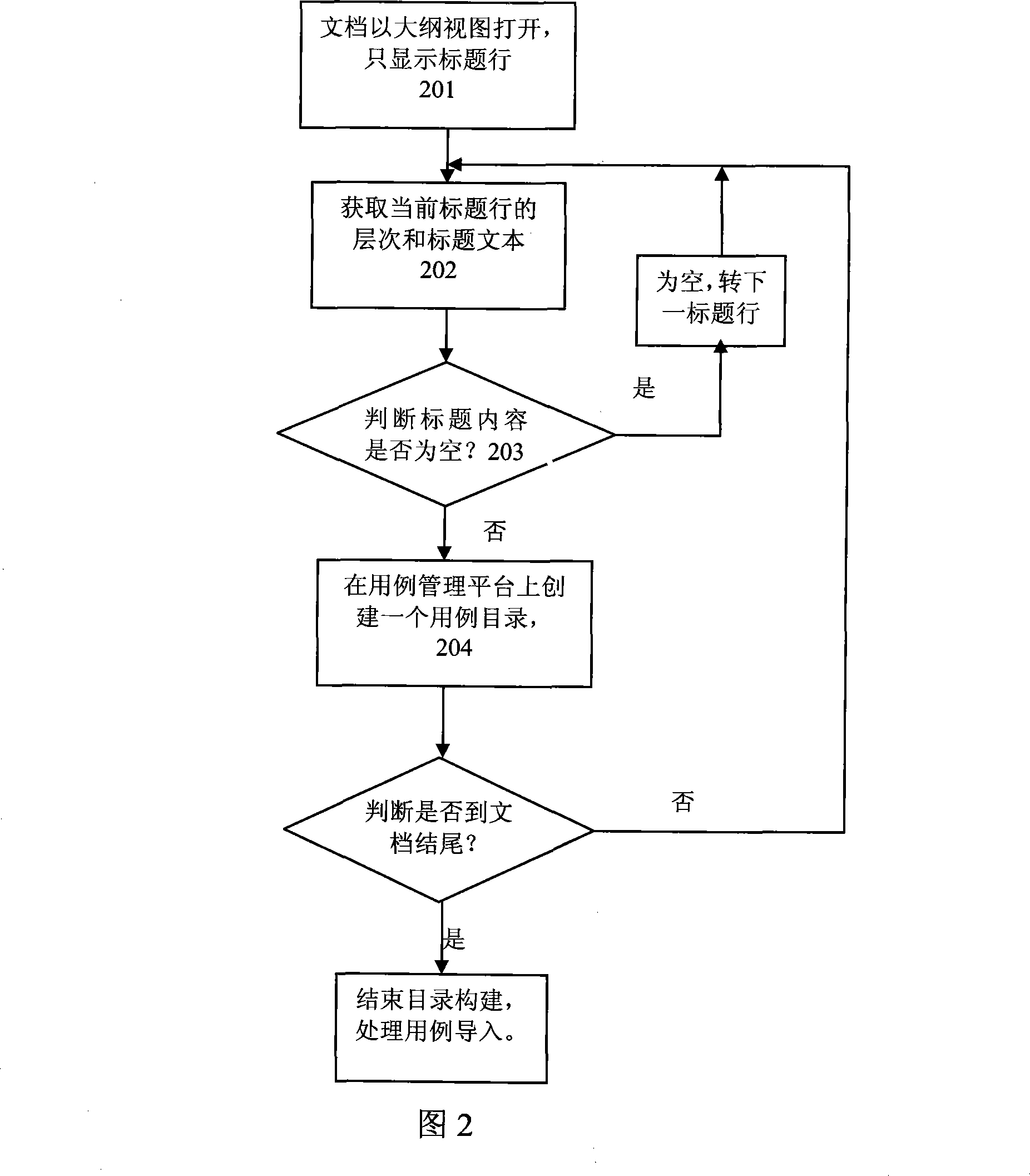

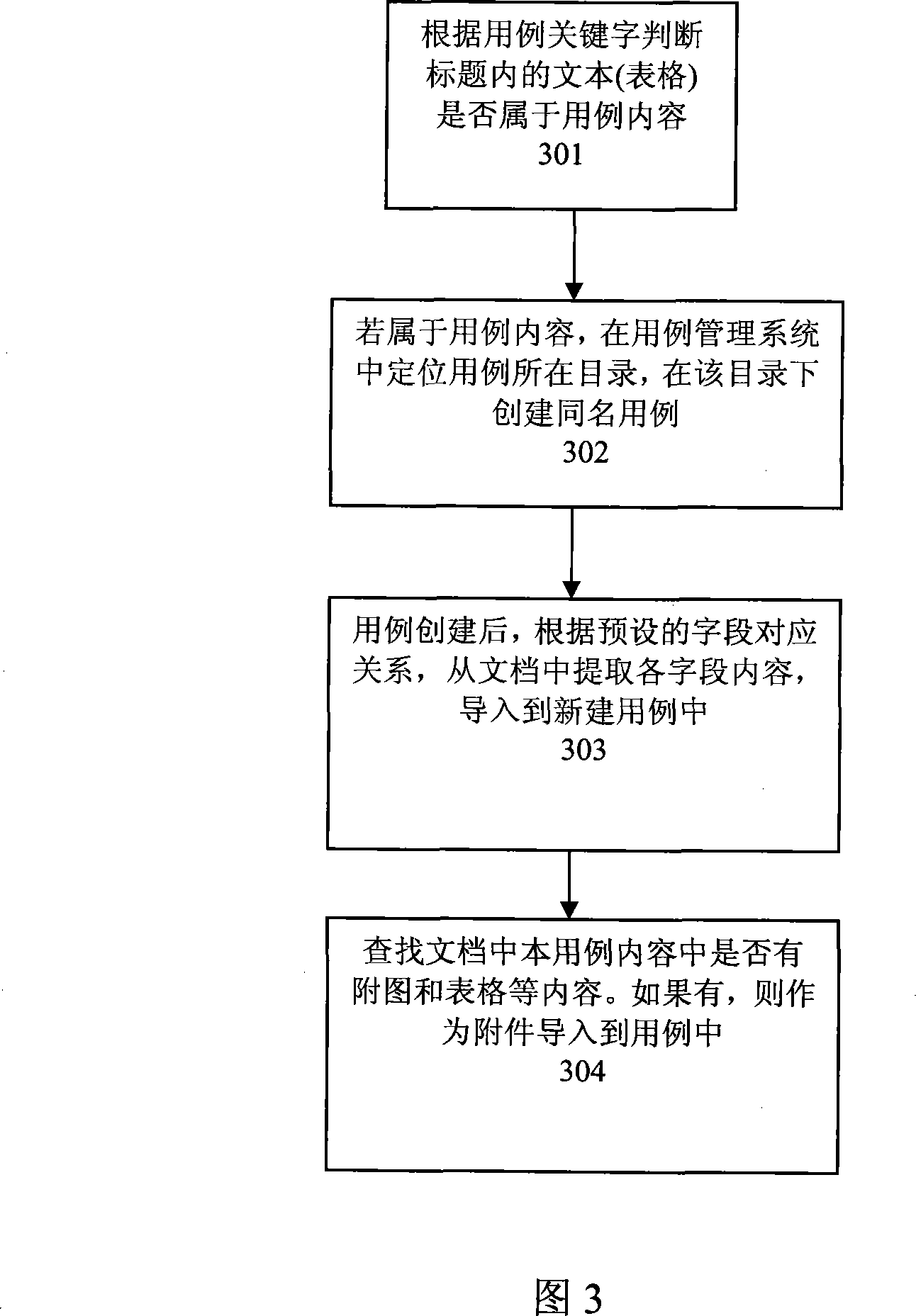

Method for automatically leading in test cases

InactiveCN101221530AAutomatic import implementationImprove import efficiencySoftware testing/debuggingHierarchical testGraphics

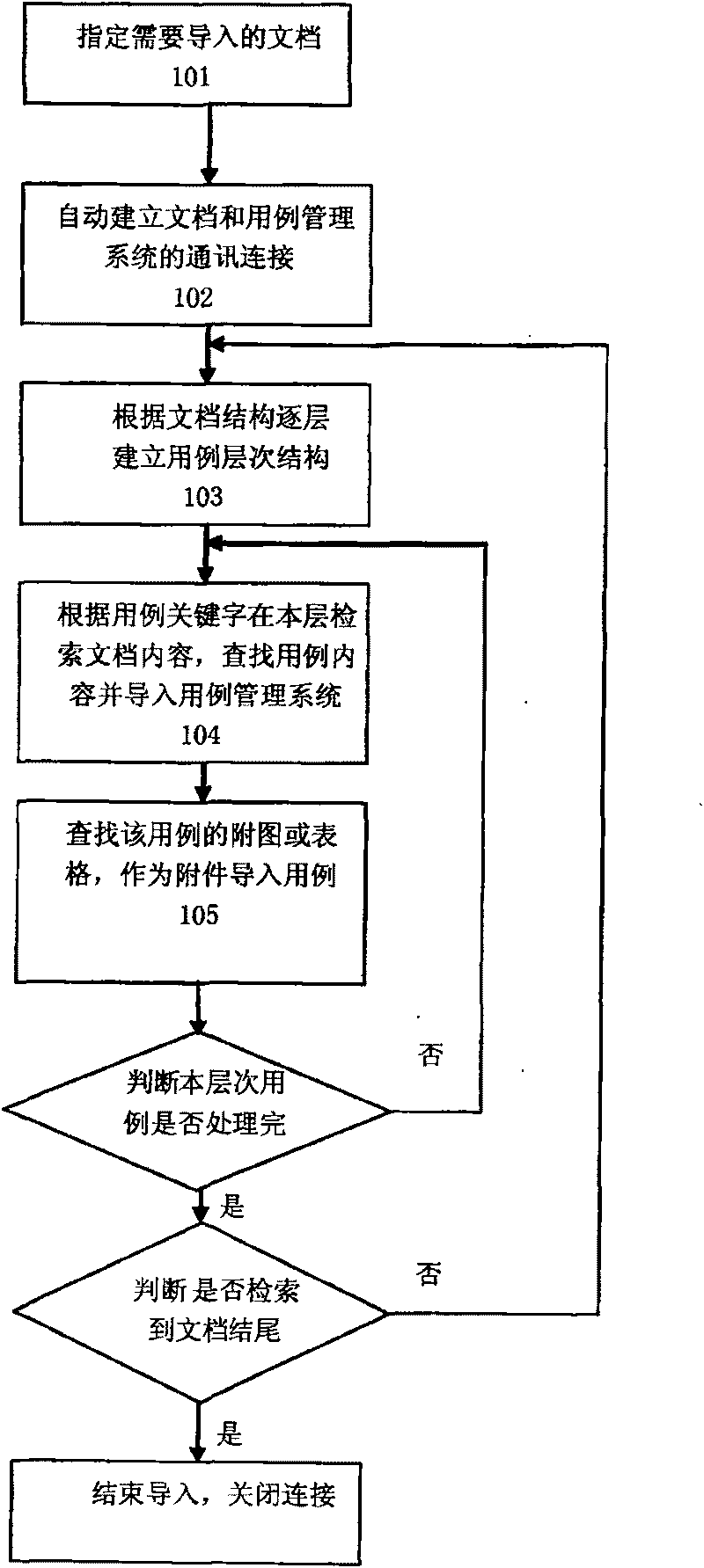

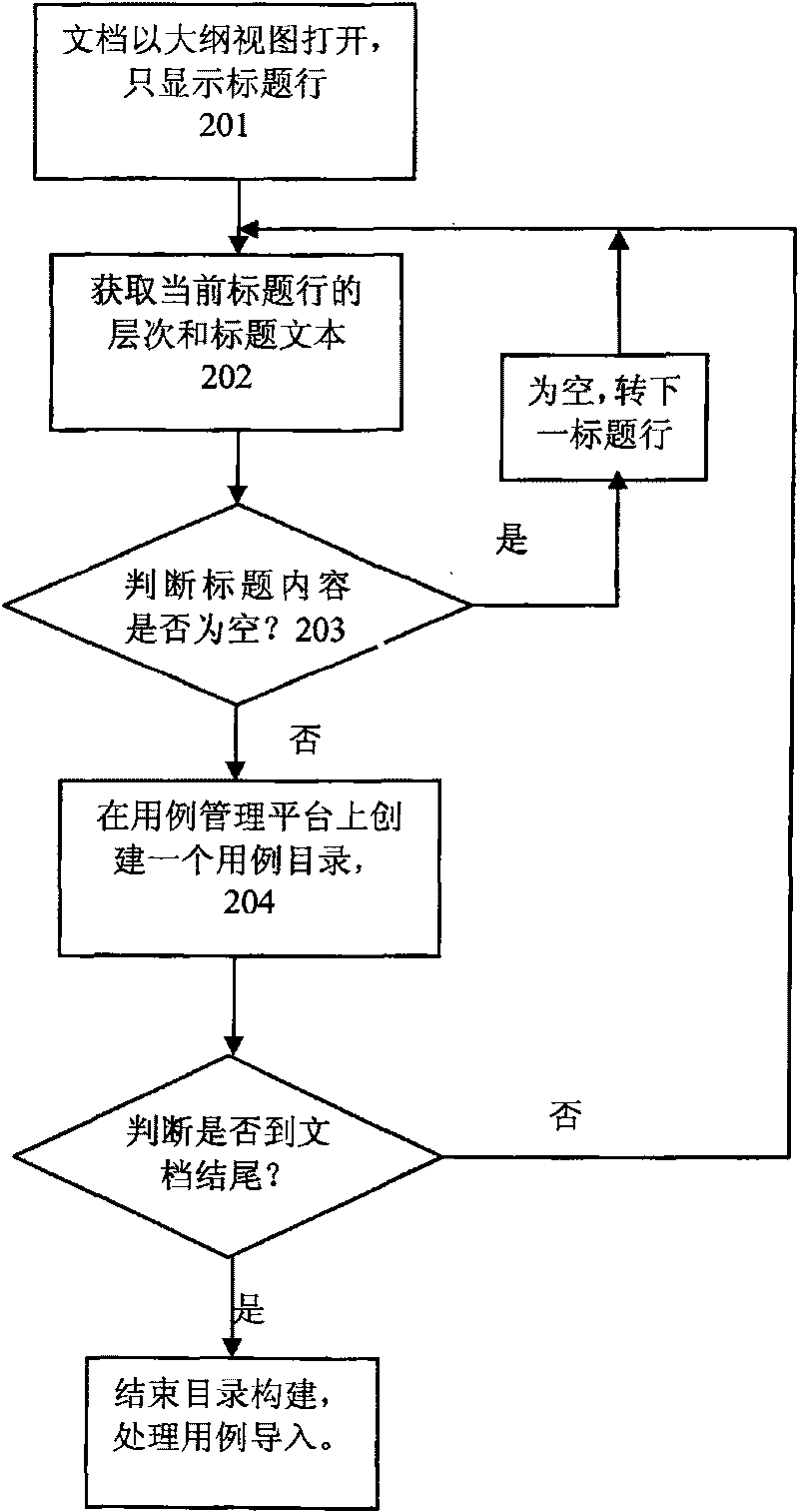

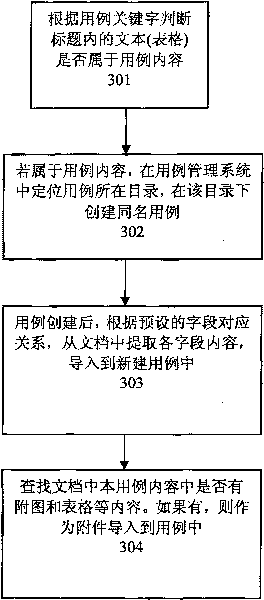

The invention relates to a test case automatic leading-in method, wherein, test case keywords and corresponding relations of test case fields are set in advance. The invention comprises the following steps: a hierarchical test case organization structure is created in a test case management system according to document hierarchy; test case contents required for introduction are searched layer by layer on the current hierarchy by adoption of a test case keyword recognition method; different field contents of test cases in the current hierarchy and test case fields of the test case management system are automatically and correspondingly led in layer by layer by adoption of a test case field corresponding strategy; graphics and tables in the current hierarchy are automatically recognized layer by layer and taken as enclosures to be led in together according to user requirements. The method of the invention can flexibly realize automatic introduction of documents with different formats according to the user requirements.

Owner:ZTE CORP

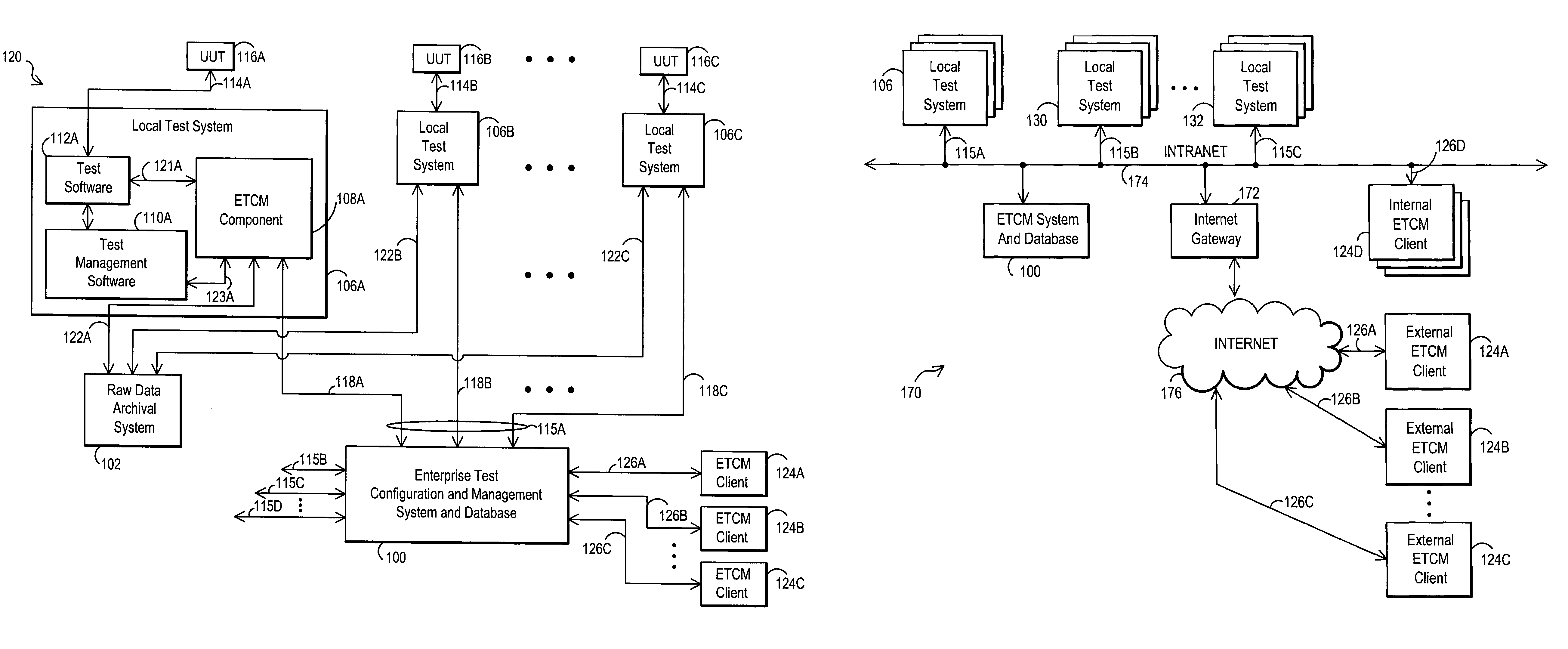

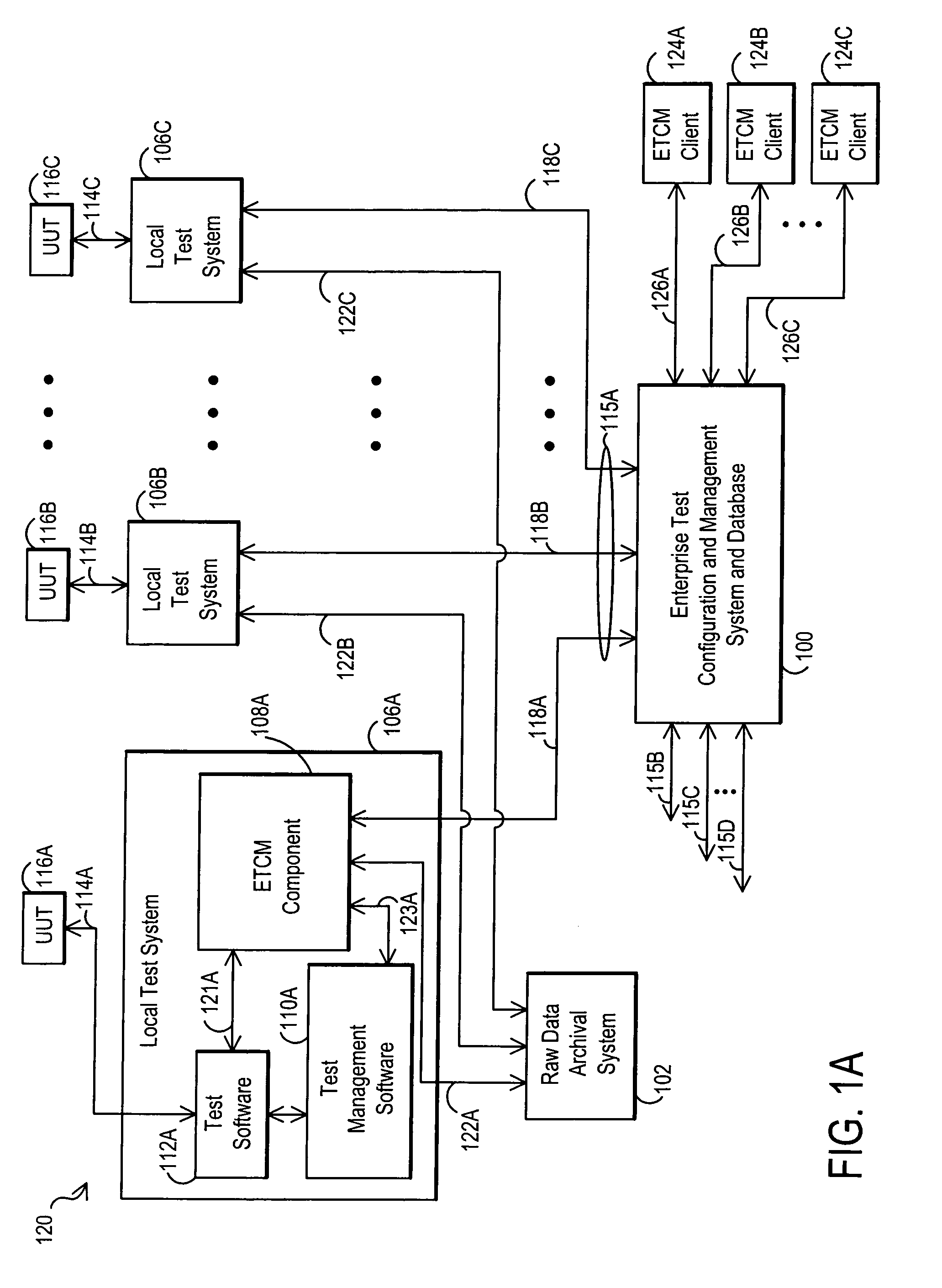

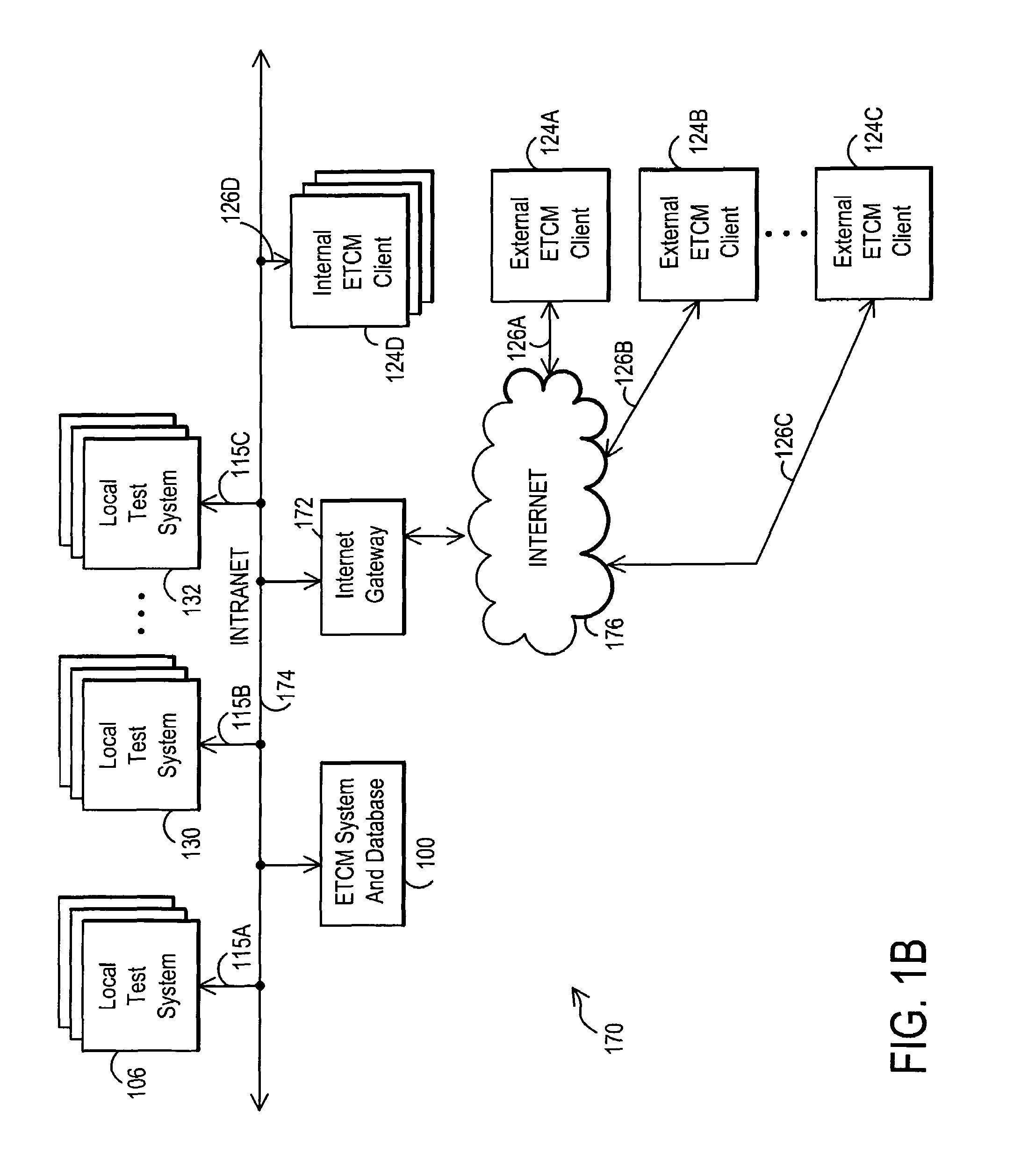

Enterprise test data management system utilizing hierarchical test data models and related methods

InactiveUS7539591B2Faulty hardware testing methodsSpecial data processing applicationsMethod testUser interface

Test data model and test data structure creation improvements are disclosed for enterprise test data management systems in the test, measurement and automation environment. A hierarchical test data model for a plurality of test systems includes hierarchical data objects configured to store test data related information. In addition, one or more data objects within the test data model are linked such that data entered into one object can be used by another object or can be automatically propagated to linked objects. And default data object properties are defined such that each new data object includes the default properties. Still further, a graphical user interface (GUI) can be provided through which information can be input to the database where the GUI includes a first frame showing a structure for the hierarchical test data model and a second frame automatically showing one or more data input fields related to an object selected within the first frame. Related systems and methods are also disclosed.

Owner:AEROFLEX SYST GRP

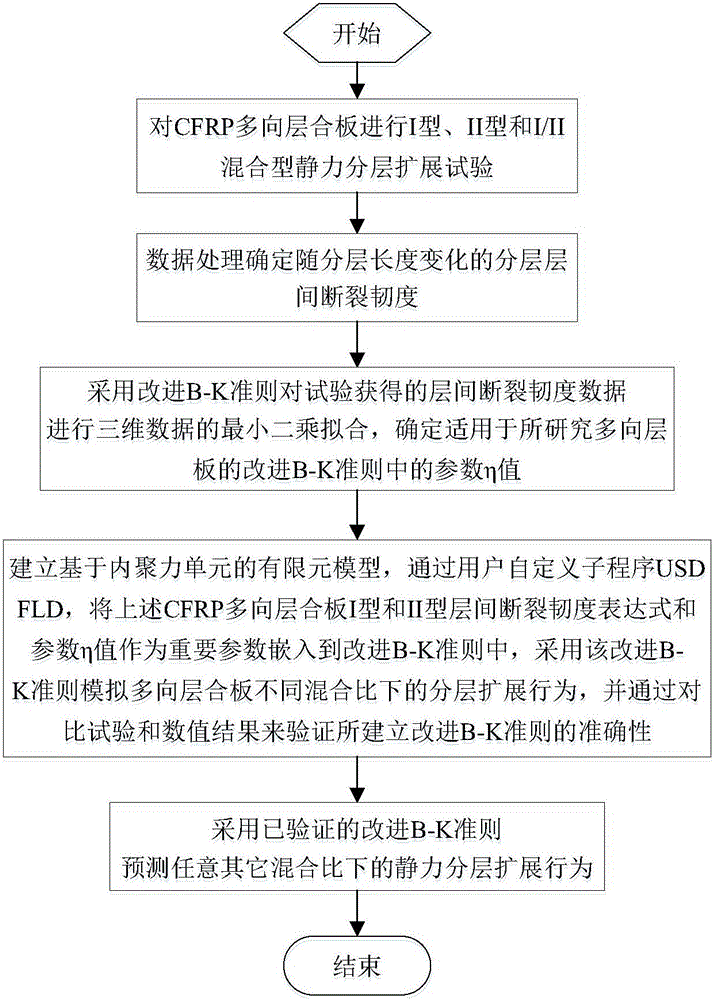

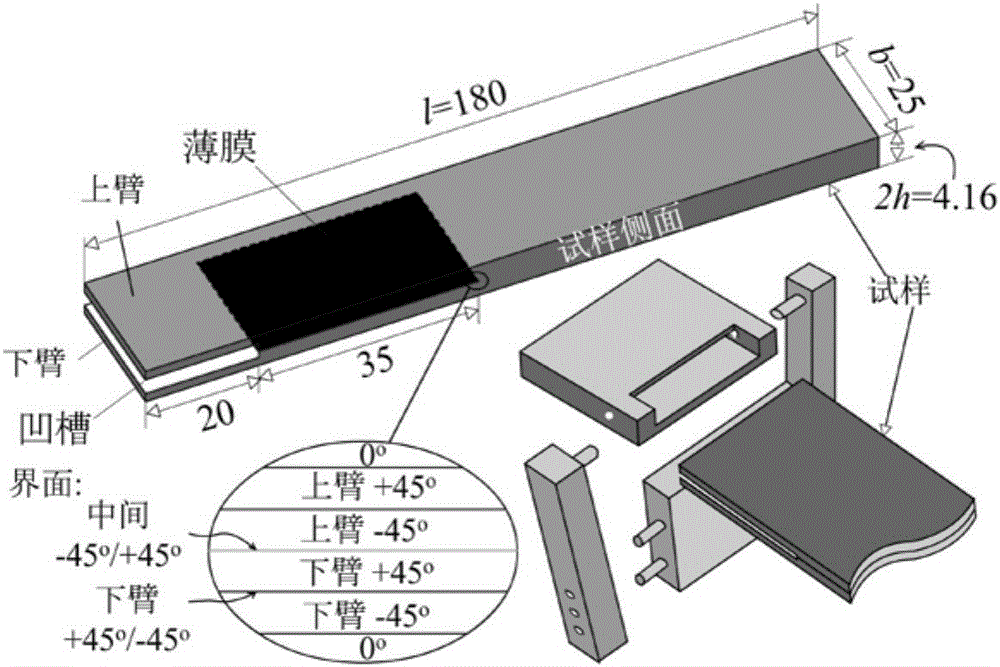

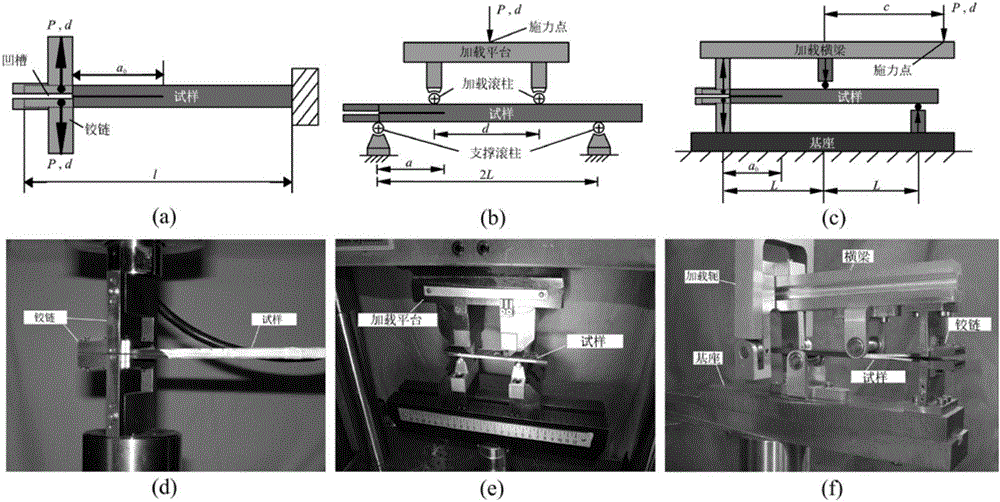

Hierarchical prediction method for composite material multi-direction lamination board by considering fiber bridge connection influence based on improved B-K criterion

ActiveCN106599507AReduce testing workloadReduce testing costsDesign optimisation/simulationSpecial data processing applicationsFiberHierarchical test

The invention discloses a hierarchical prediction method for a composite material multi-direction lamination board by considering fiber bridge connection influence based on improved B-K criterion. By performing a static force hierarchical test on I type, II type and I / II mixed type of different mixed ratios of CFRP multi-direction lamination board, I type interlayer fracture toughness GIC (a), II type interlayer fracture toughness GIIC (a) and interlayer fracture toughness GC (a) of different mixed ratios which are changed along with hierarchical lengths are determined; least square fitting on three-dimensional data is performed to obtain a parameter <eta> in the improved B-K criterion considering the fiber bridge connection influence; next, by taking the GIC (a), the GIIC (a) and the fitting parameter <eta> as important parameters in the improved B-K criterion, a finite element model based on a cohesion unit is established, and hierarchical expansion behaviors of different mixed ratios are simulated by applying the improved criterion; and the accuracy and the applicability of the disclosed improved criterion are verified by contrast tests and numerical value results, so that hierarchical expansion behaviors of any other mixed ratios can be further predicted by applying the improved criterion, thereby greatly shortening the experimental period and lowering experimental cost.

Owner:BEIHANG UNIV +1

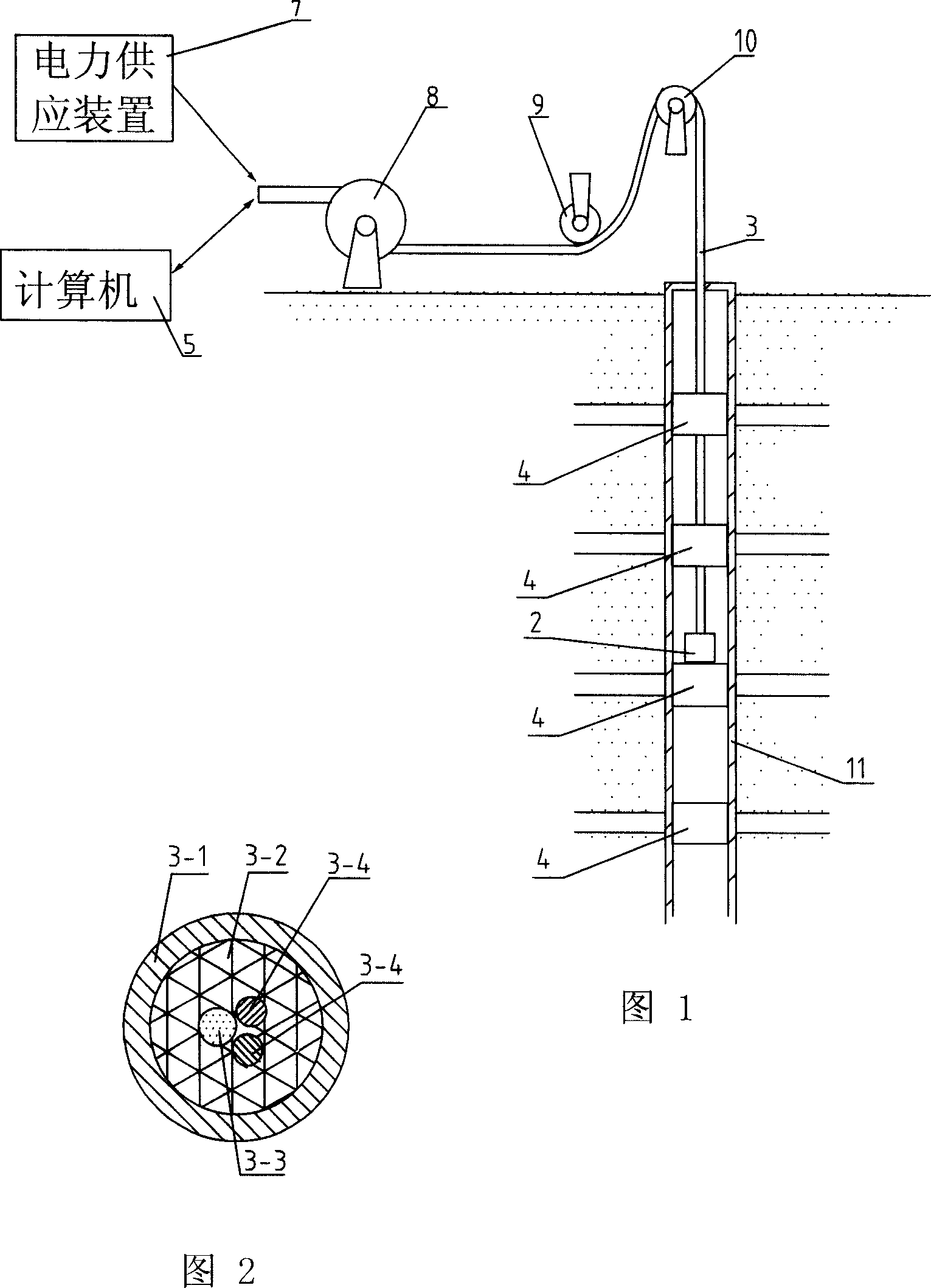

Water injection well layered electric testing method employing metallic sheath detective cable

InactiveCN101082274AProtectSolve the sealing problemSurveyConstructionsHierarchical testControl signal

The invention relates to an electric test method for flooding well lamination by using the metal jacket detecting cable. It relates to the separate injection and separate test method of oil production technology in the oil field. It overcomes the defect of wasting human and object power in the existing multiple throwing and fetching method. It contains the following steps: the silo testing instrument is hung to the rearranged section by the testing cable for locating and sealing. The regulating arm of the silo testing instrument is butted to the preinstalled adjustable eccentric flooding blocking device. It floods to the rearranged section in the oil well and tests the water-flow, the water pressure of this section and the temperature. A computer is used to monitor the data detected by the silo testing instrument and transmit the control signal depending on the deviation of the real-time flow and the preinstalled fluence, which adjusts the flooding flow of the blocking device until it reaches the desired flow. The computer deblocks the silo testing instrument through the testing cable and hangs it to the other rearranged sections in the oil well.

Owner:DAQING OILFIELD CO LTD

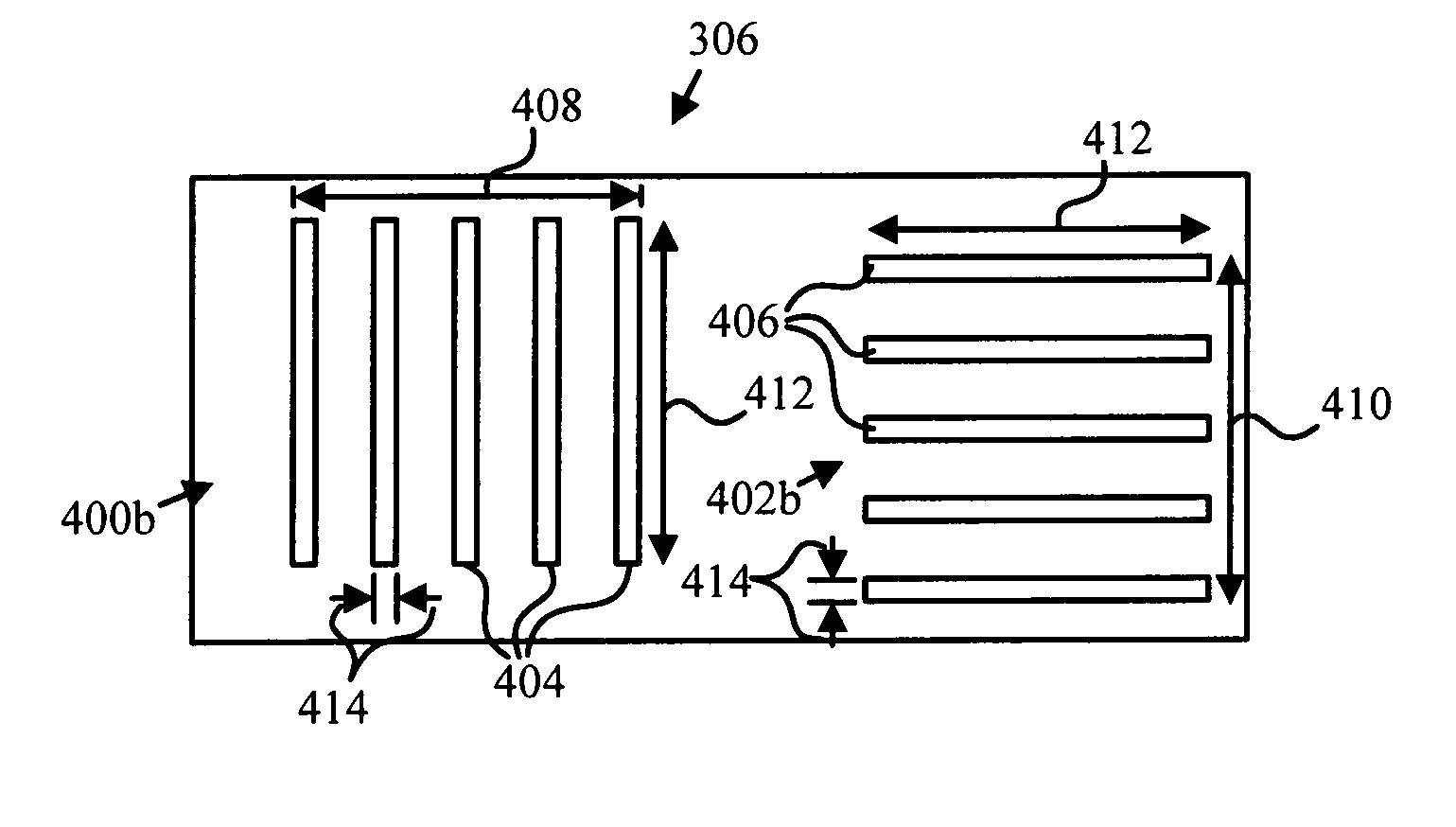

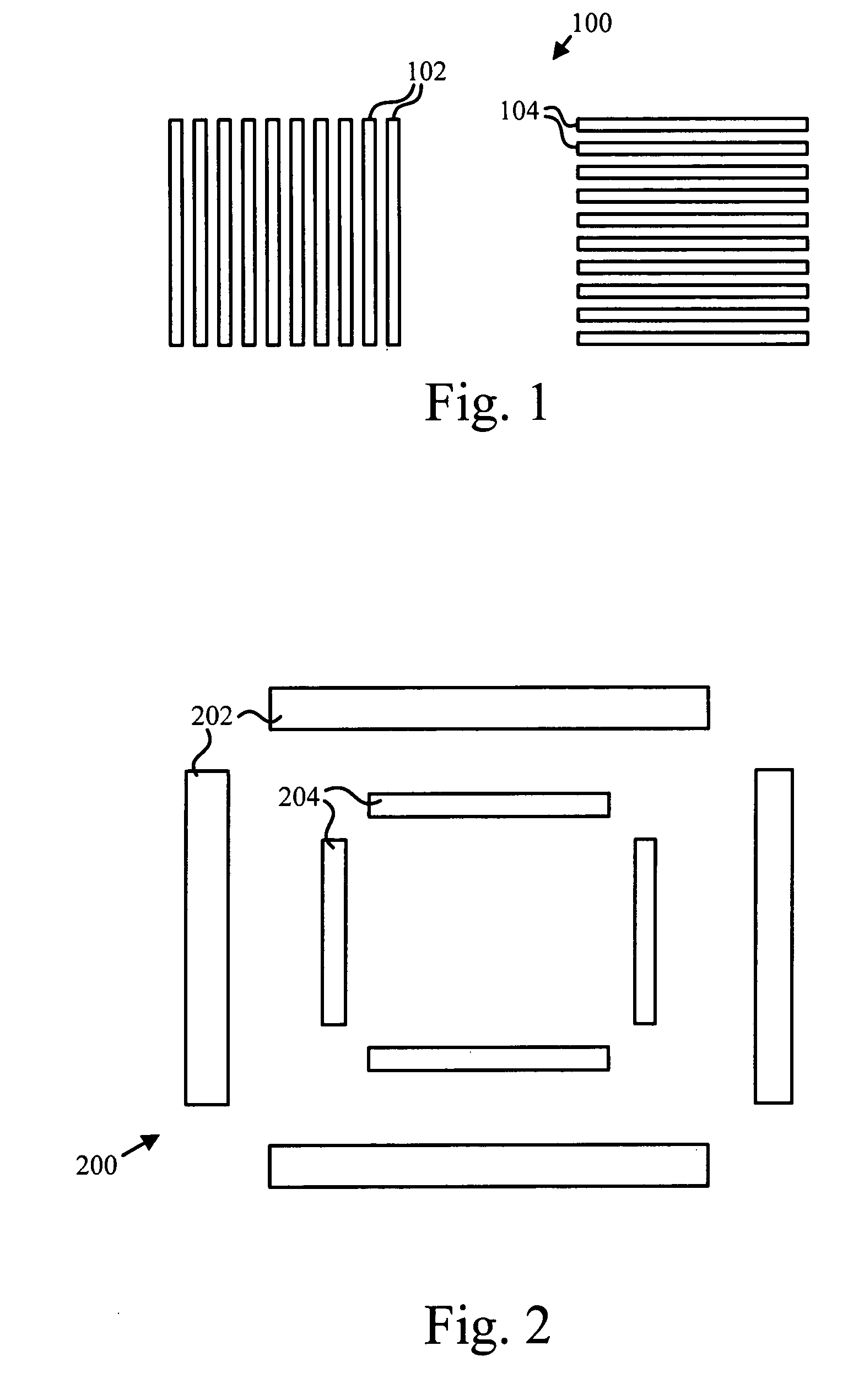

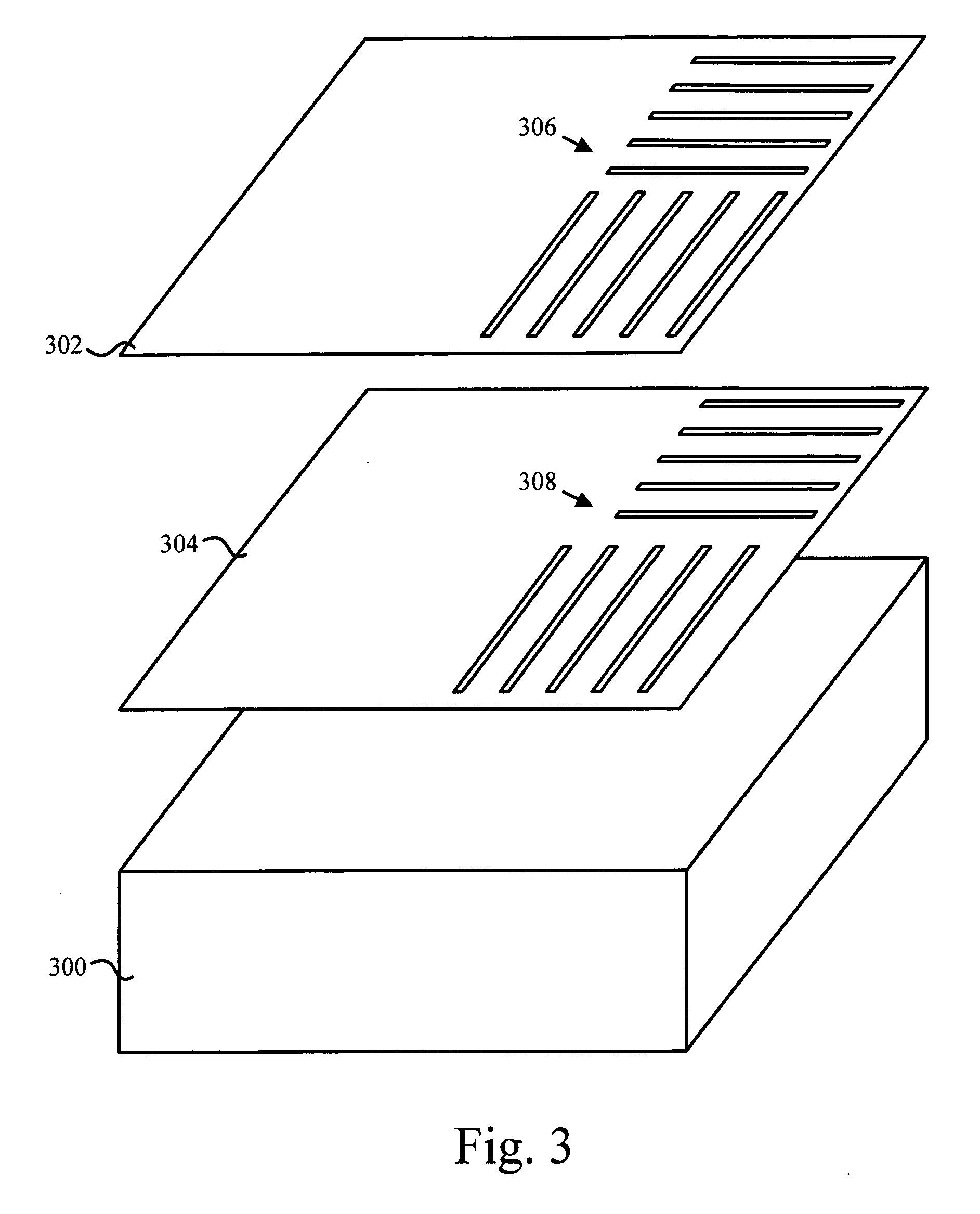

Multi-layer registration and dimensional test mark for scatterometrical measurement

InactiveUS20060172447A1Semiconductor/solid-state device detailsSolid-state devicesHierarchical testPhase shifted

A layered test pattern for measuring registration and critical dimension (CD) for multi-layer semiconductor integrated circuits is disclosed. A first layer includes a first pattern having vertical and horizontal portions. A second layer is formed over the first layer and includes a second pattern having vertical and horizontal portions having nominal vertical and horizontal phase shifts with respect to the vertical and horizontal portions, respectively, of the first pattern. The vertical and horizontal portions include periodically repeating vertical lines and horizontal lines, respectively. The nominal phase shifts may be half of the period of the vertical and horizontal lines. A scatterometry tool measures the width of the lines and the phase shift of the first pattern relative to the second pattern. The width of the lines corresponds to CD, whereas the difference between the measured phase shift and the nominal phase shift indicates variation in registration.

Owner:BELL SEMICON LLC

Method and device for layered simultaneous determination and long-term monitoring of foundation compactness

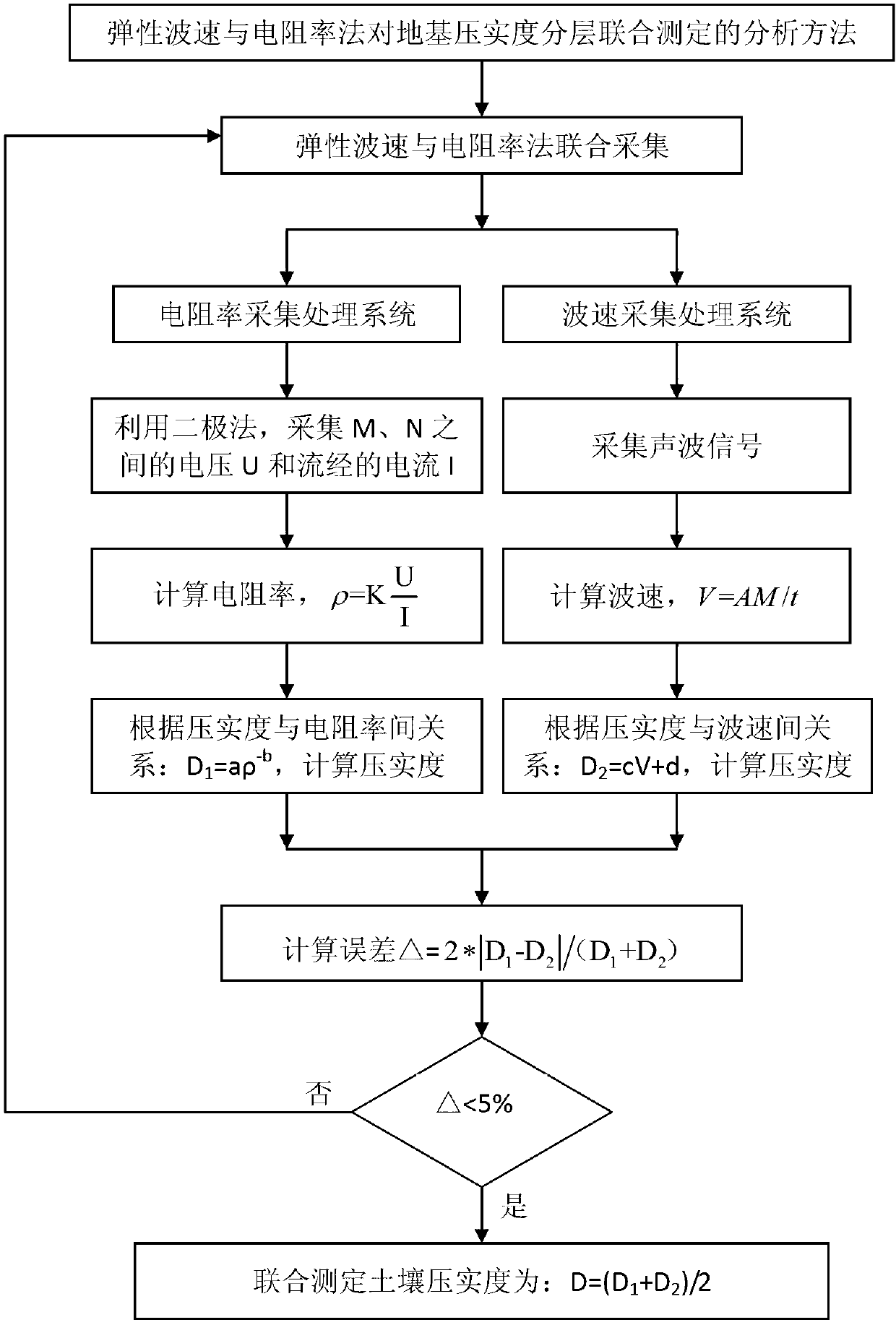

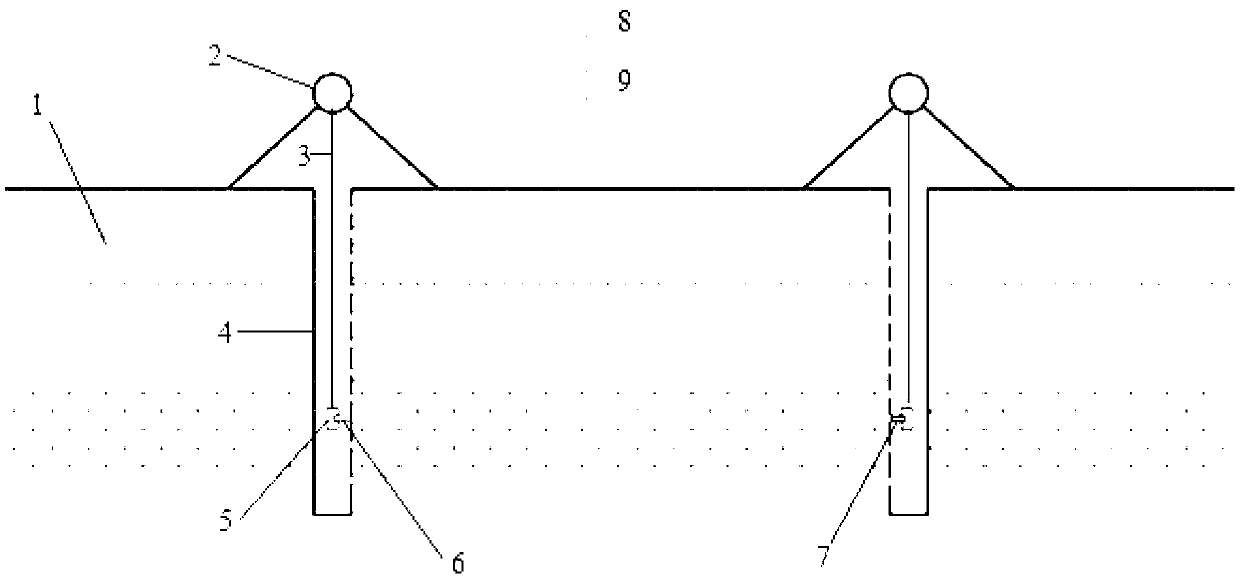

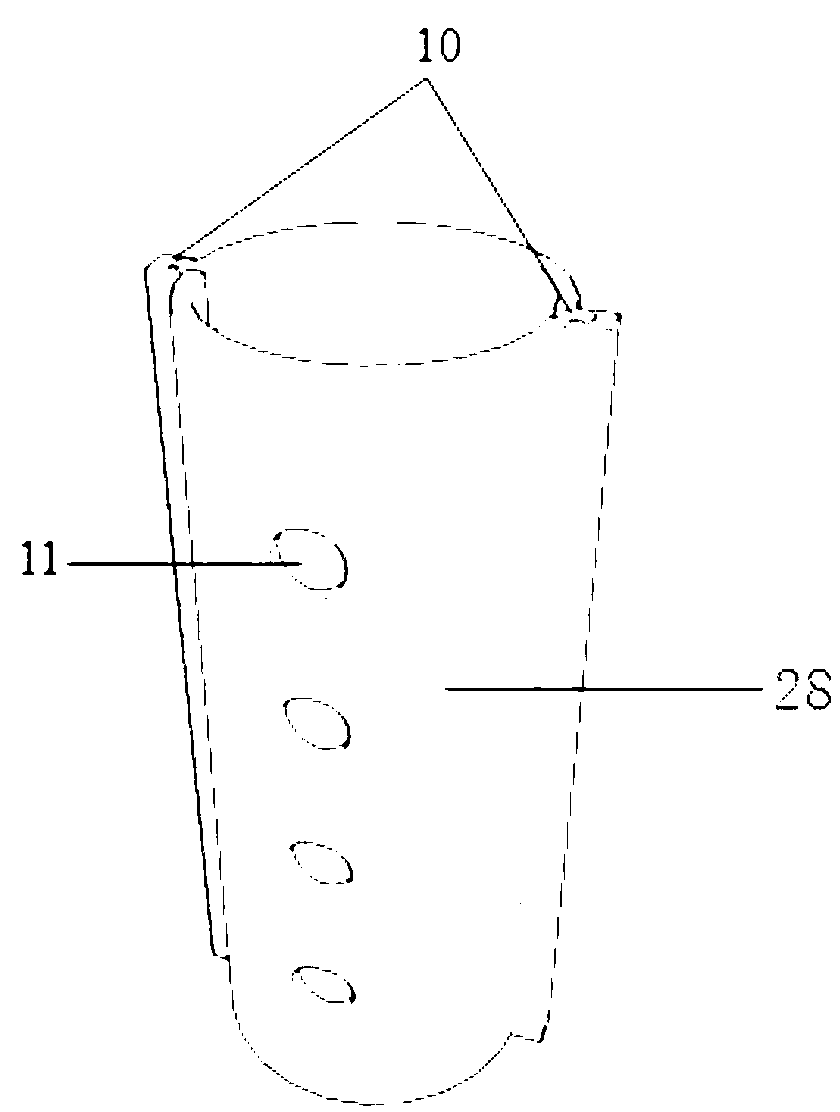

InactiveCN103015390AIncrease credibilityImprove efficiencyRoadwaysIn situ soil foundationHierarchical testClassical mechanics

The invention particularly discloses a method and a device for layered simultaneous determination and long-term monitoring of foundation compactness, provides the quantitative relationship between resistivity and compactness, as well as between elastic wave velocity and compactness, for the first time through research, and designs a resistivity and wave velocity integrated parallel sensor, a simultaneous determination transmitting and guiding device and a simultaneous determination permanent protection device for field compactness determination and long-term observation. The method can be used for simultaneously determining the resistivity and the elastic wave velocity of a foundation, solves the problems that a single test method is poor in adaptability and undesirable in result through mutual corroboration norm of two methods, realizes layered measurement of different positions of the foundation, as well as long-term monitoring of the foundation compactness in the service period, and solves the problem that a conventional method can realize neither layered compactness testing nor long-term compactness monitoring.

Owner:SHANDONG UNIV

Intelligent control device and control method of layer mining, control and testing of gas well

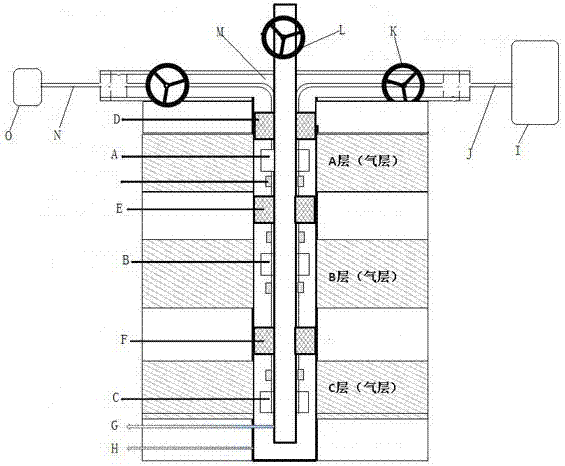

ActiveCN107227945AEfficient power supplyEasy to controlSurveyConstructionsHierarchical testProcess engineering

The invention discloses a control method layer mining, control and testing of gas well. The method comprises the following steps: setting three production gas layers of a natural gas well as a gas layer A, a gas layer B and a gas layer C, mounting a direct reading intelligent gas well underground layering zonal pressure measuring device on each layer, packing the three production gas layers through a gas control underground packer, and ensuring that a ground intelligent control box gives an instruction to enable the direct reading intelligent gas well underground layering zonal pressure measuring devices of the gas layers A and C to be closed, open a communicating hole of the direct reading intelligent gas well underground layering zonal pressure measuring device of the gas layer B when the gas layer A is required to be closed, the gas layer B is required to perform production and the gas layer C is required to be closed, so as to enable natural gas of the gas layer B to be output to the ground through an oil pipe and to realize layer control; ensuring that a ground metering station can timely measure the gas output of a layer, so as to realize layer gas production; ensuring that the direct reading intelligent gas well underground layering zonal pressure measuring devices can record the production pressure difference and underground temperature at the same time, so as to realize layer testing. The gas layer A, the gas layer B and the gas layer C can be subjected to simultaneously gas production and testing.

Owner:DONGYING XINJI PETROLEUM TECH

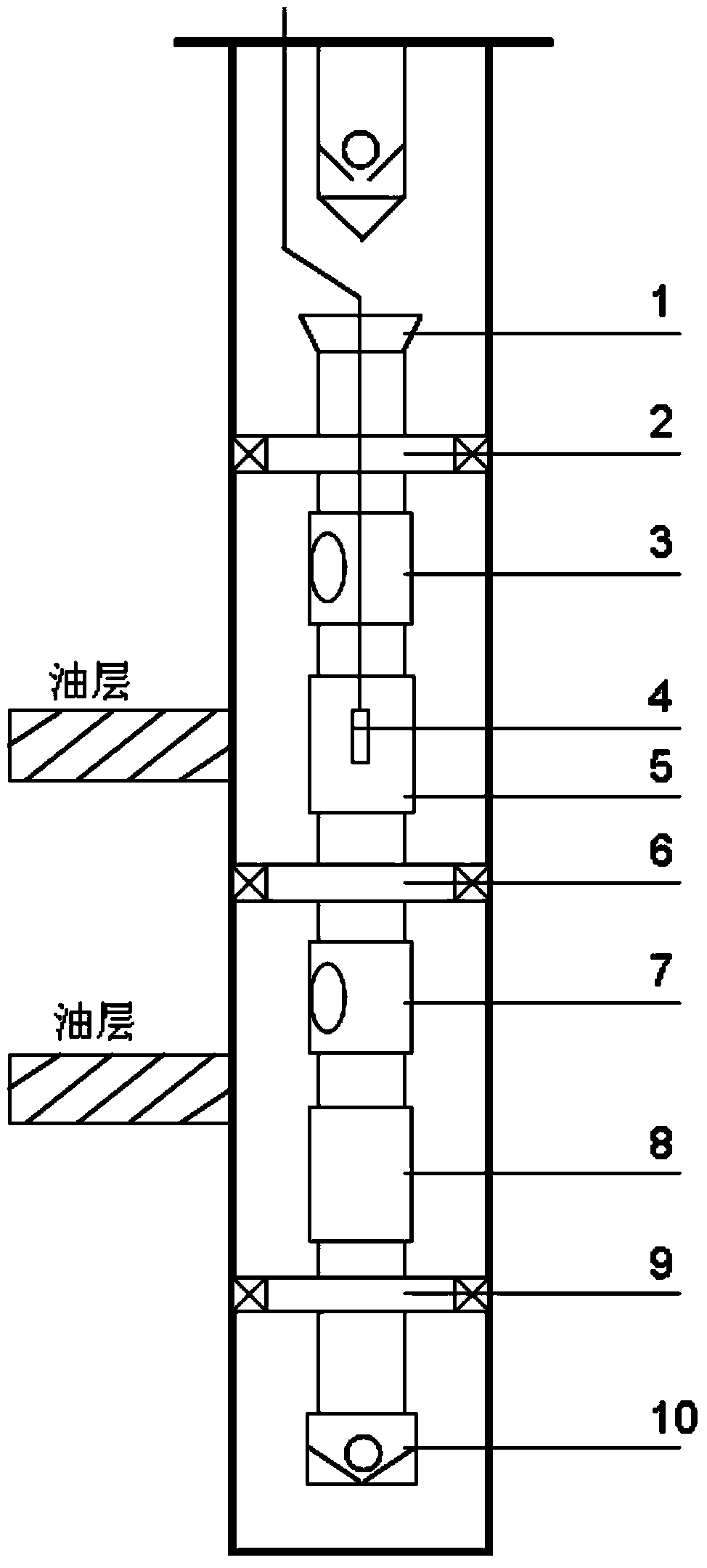

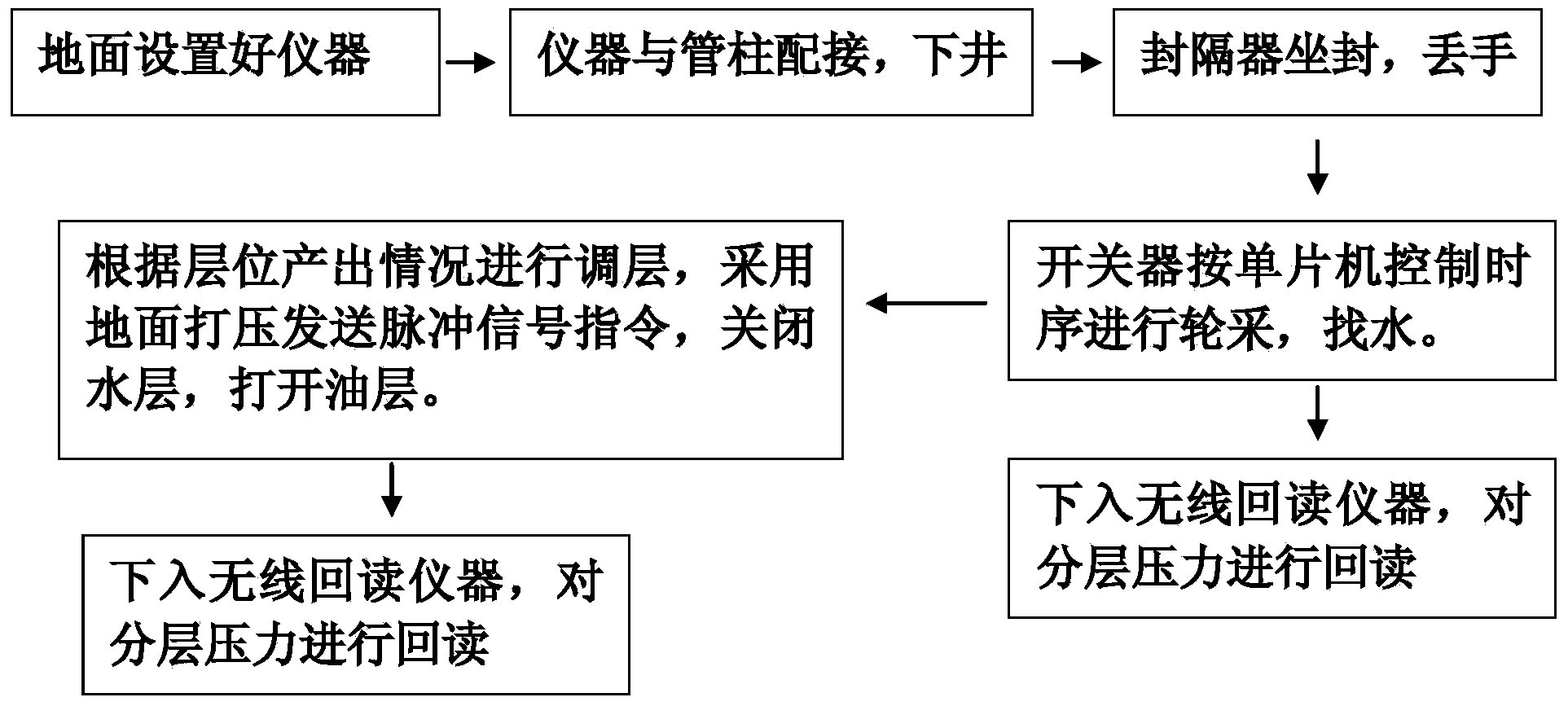

Zonation testing method used for downhole intelligent well shutdown

InactiveCN104018824AShorten the test cycleFormation pressure recovery data is trueSurveyConstructionsMicrocontrollerHierarchical test

The invention provides a zonation testing method used for downhole intelligent well shutdown and belongs to the field of petrochemical engineering. According to the method, a control motor of a single-chip microcomputer is adopted to push and control opening or closing of a liquid outlet channel, then switchgears can automatically switch opening or closing horizons according to programs set on the ground, and zonation mining is carried out on an oil well, or the mode that pulse signals are sent from a well mouth at any time is adopted to control the switchgears; pressure measurement short sections uninterruptedly measure pressure and temperature data for storage; wireless readback meters are placed from the well mouth to the pressure measurement short sections, and read the data stored by the pressure measurement short sections in a wireless mode. By the utilization of the method, the purposes that the testing cycle is shortened and tested stratum pressure recovery data are more real and accurate are achieved, and testing cost is saved at the same time.

Owner:PETROLEUM ENG TECH RES INST OF JIANGHAN OILFIELD BRANCH OF

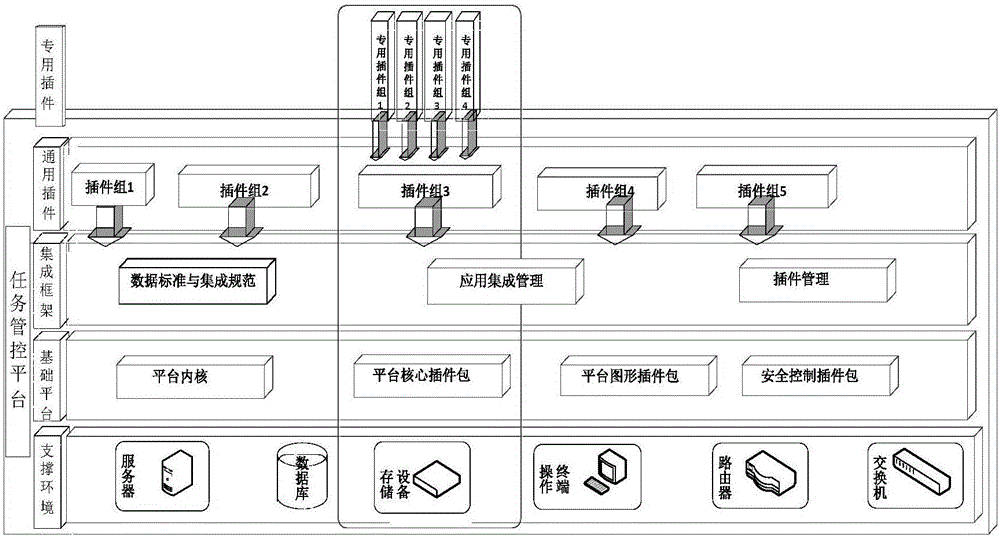

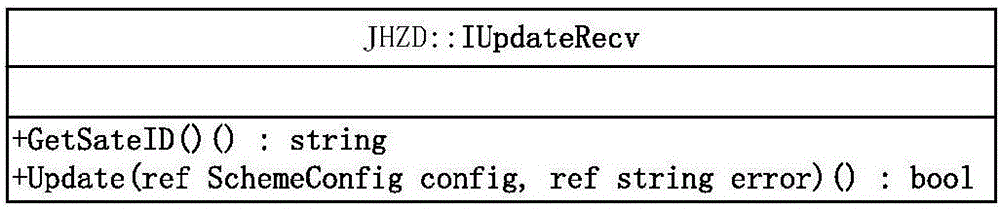

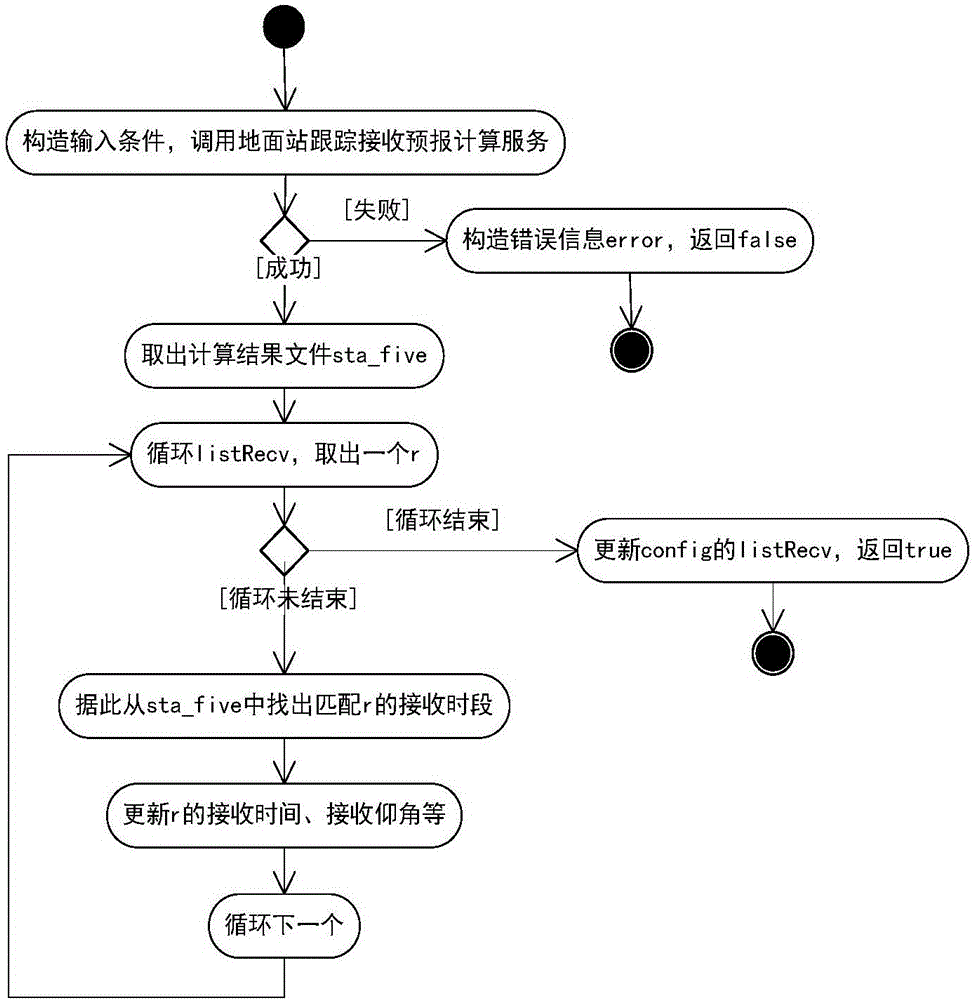

Platform plug-in technology oriented testing method

ActiveCN106649112AAvoid expansionSolve development problemsSoftware testing/debuggingTest designHierarchical test

The invention discloses a platform plug-in technology oriented testing method and relates to the field of software testing. The method specifically includes the steps of testing model establishment, testing strategy making, testing design, testing implementation and the like. On the basis of plug-in oriented software testing theory and method research, the method is combined with thinking of traditional software testing and different plug-in characteristics in project engineering, and a layered testing strategy for plug-in testing, a set of universal new integration testing case design thoughts based on UML pluggability, and a new testing method of a new system composed of plug-ins based on scene testing are put forward. By means of the layered testing strategy, plug-in testing can be carried out in time after newly developed basic plug-ins or core plug-ins are coded. By means of a new integration testing method, the collaboration ability between the plug-ins is verified through plug-in cluster testing, and interface problems between the plug-ins are found and effectively positioned. By means of system testing based on scenes, consistency of the service implementation capacity of a system and user requirements is guaranteed.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

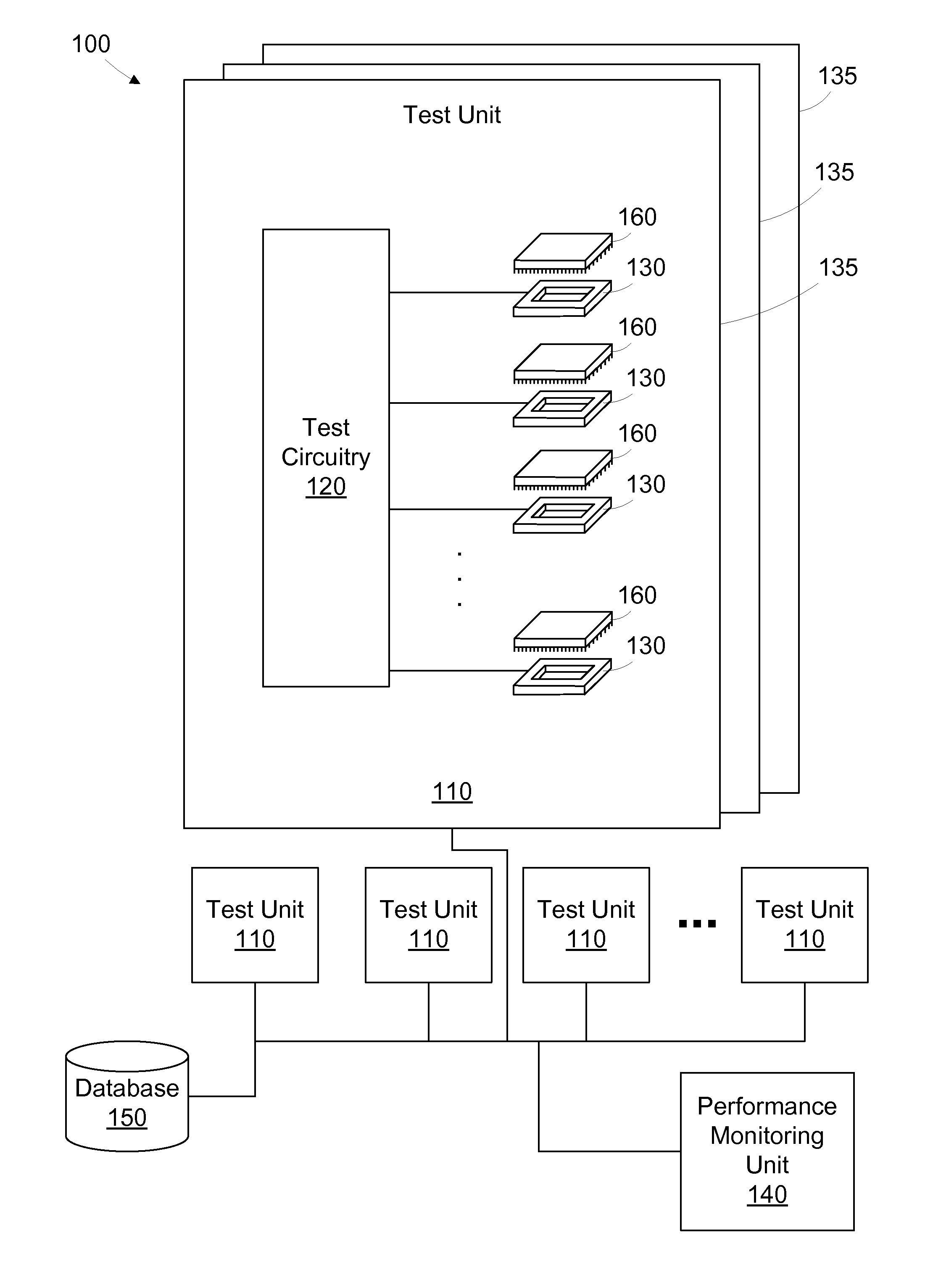

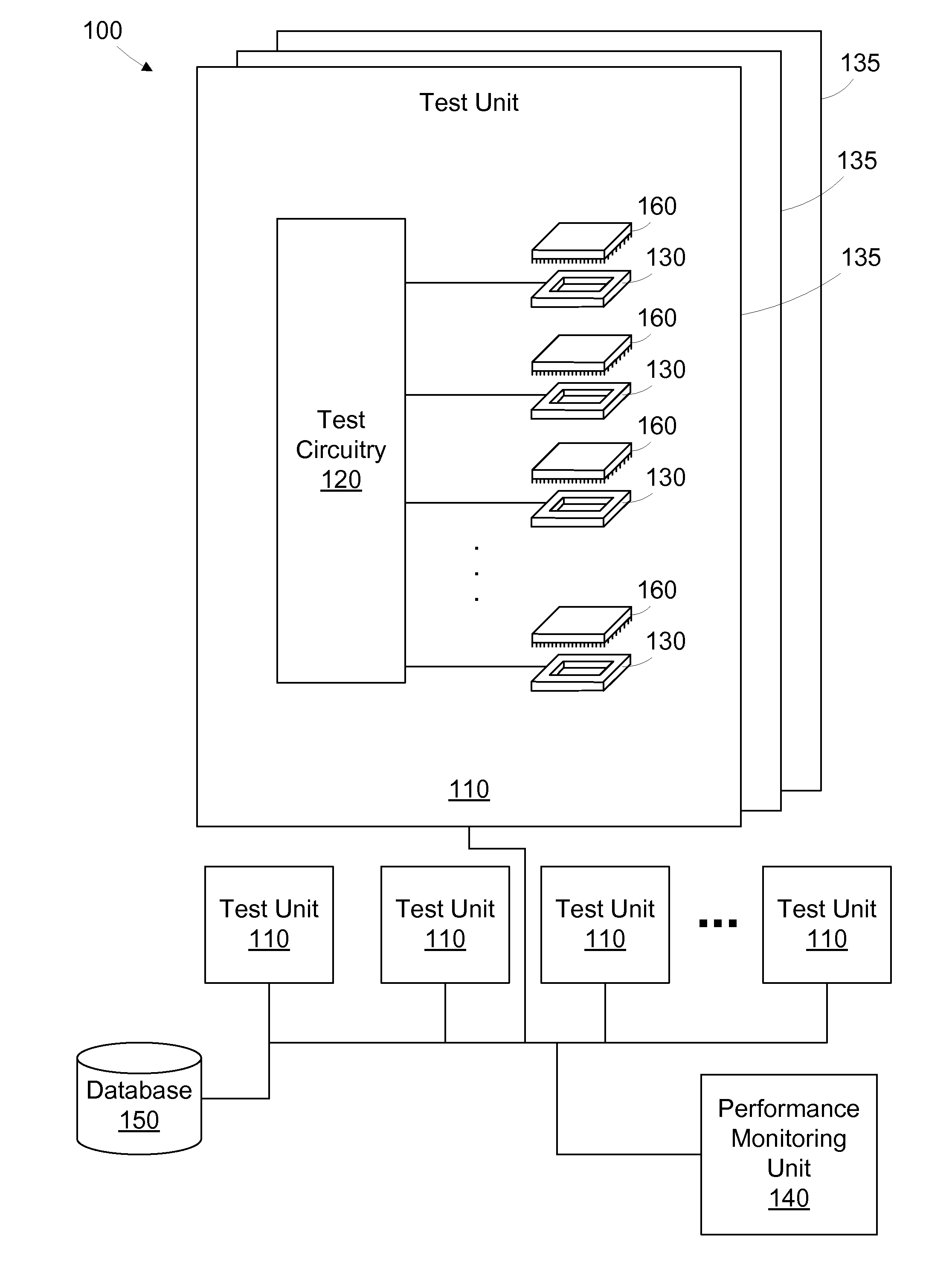

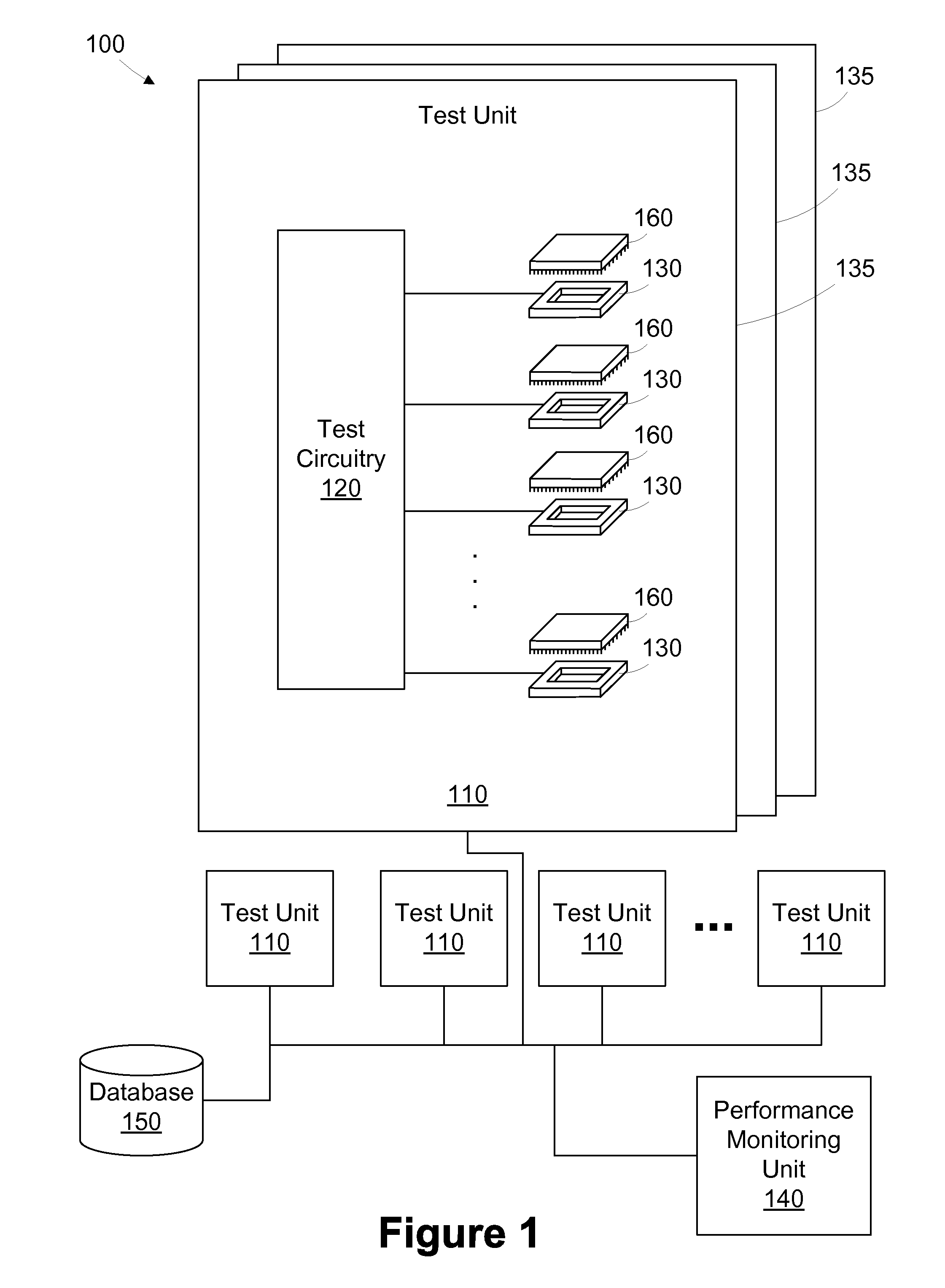

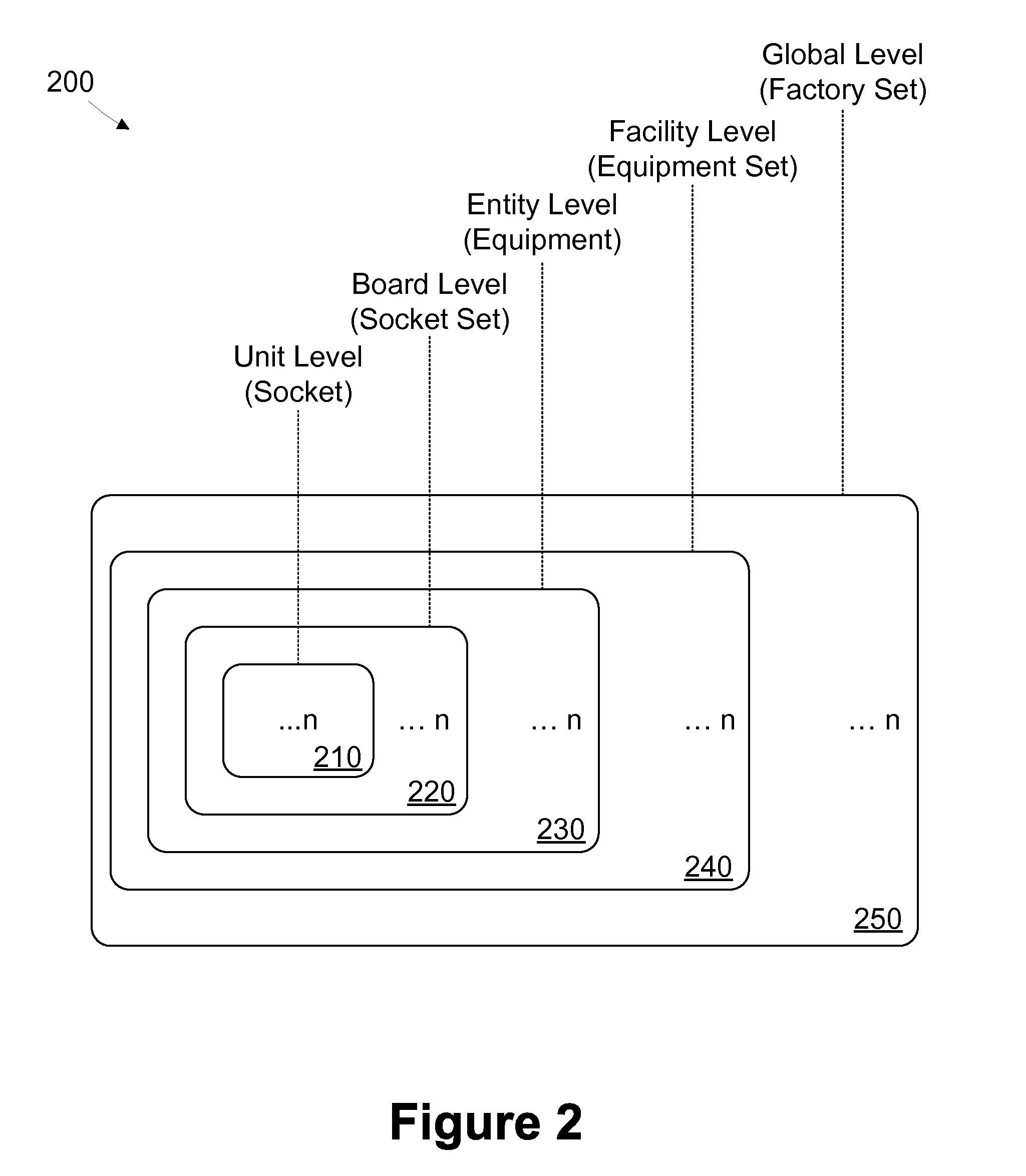

Method and apparatus for measuring performance of hierarchical test equipment

Owner:GLOBALFOUNDRIES INC

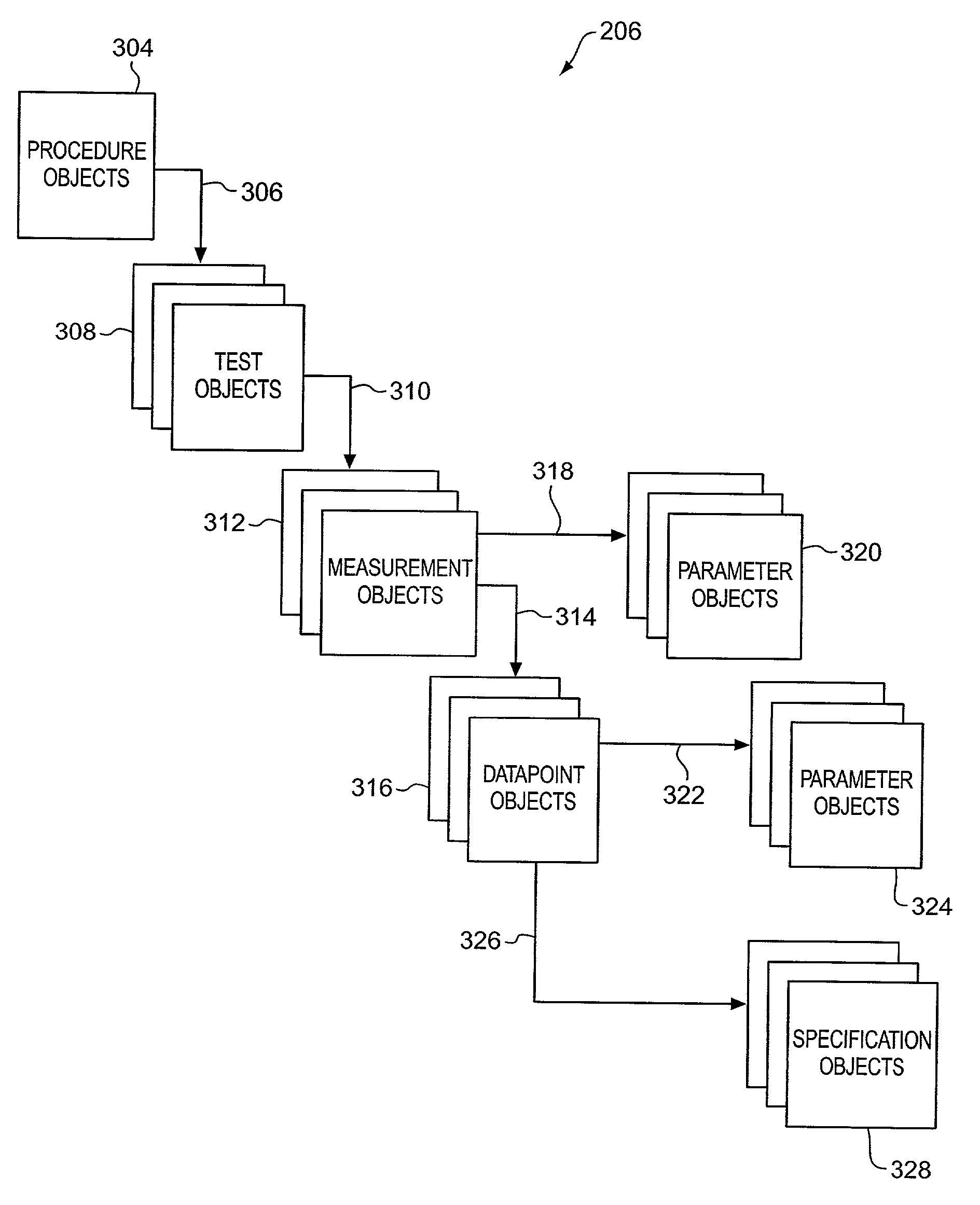

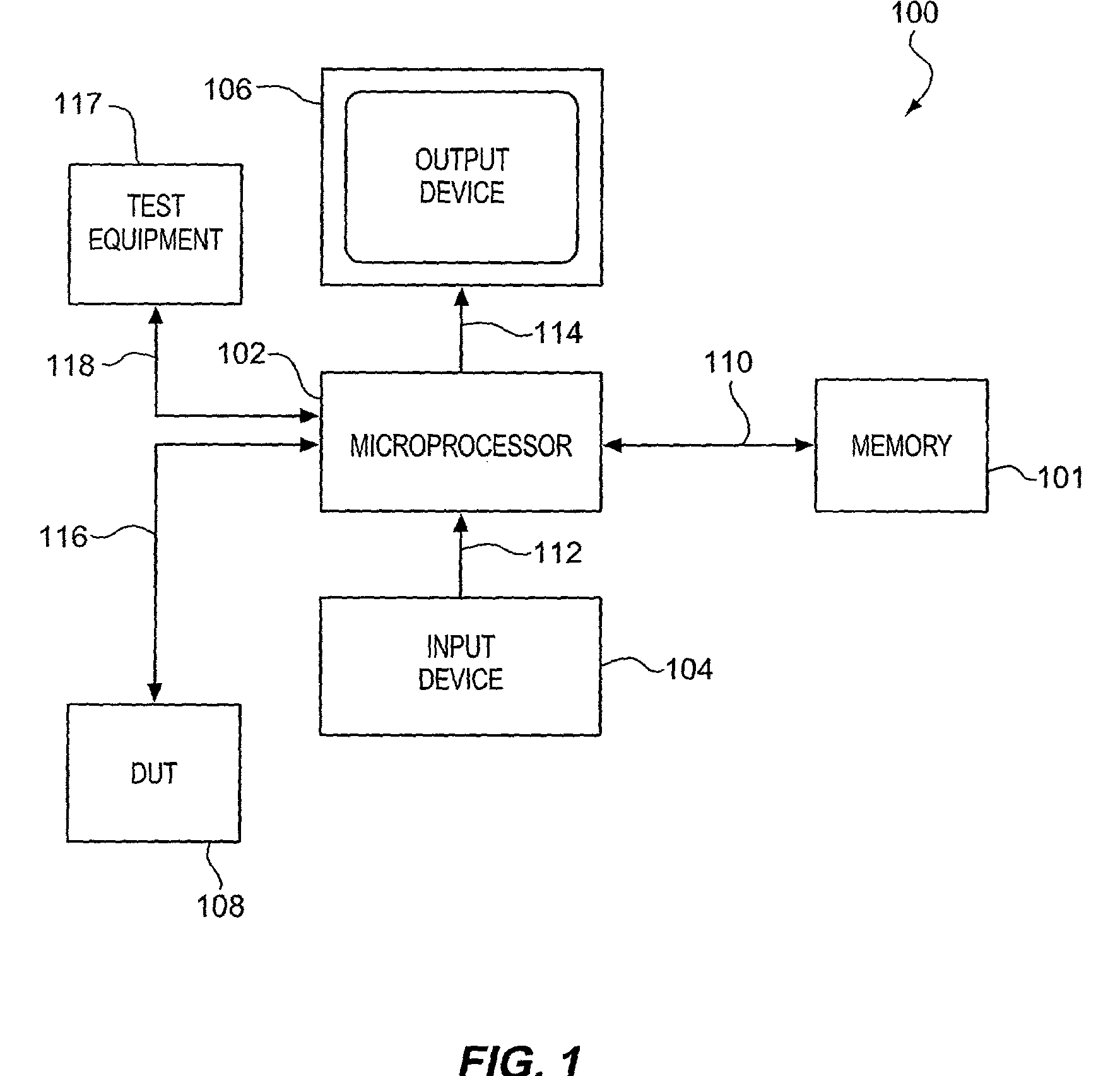

Method and apparatus for generating electronic test and data structure

InactiveUS8225152B2Digital circuit testingDetecting faulty computer hardwareHierarchical testTest algorithm

A hierarchical test executive system comprising and including Procedure, Test, Measurement and Datapoint levels. A Procedure is an ordered list of Tests; a Test is a group of Measurements in a Procedure that share the same test algorithm, and thus the same software code; a Measurement is a configuration or setup for a Test, and provides parameters to a Test; and a Datapoint is a subset of a Measurement containing additional parameters that select a result when one Measurement generates multiple results. When initiated, the test executive system presents a list of models and the user selects a model to be tested. The program then uploads the test software corresponding to the selected model and presents a list and descriptions of Procedures to the user. The user selects one of the Procedures, and the program retrieves the selected procedure from the test software and expands it into Tests, Measurements and Datapoints as determined by the Procedure. The test executive system then loops through the Tests, Measurements and Datapoints, generating the results and a corresponding data structure on the fly.

Owner:KEYSIGHT TECH

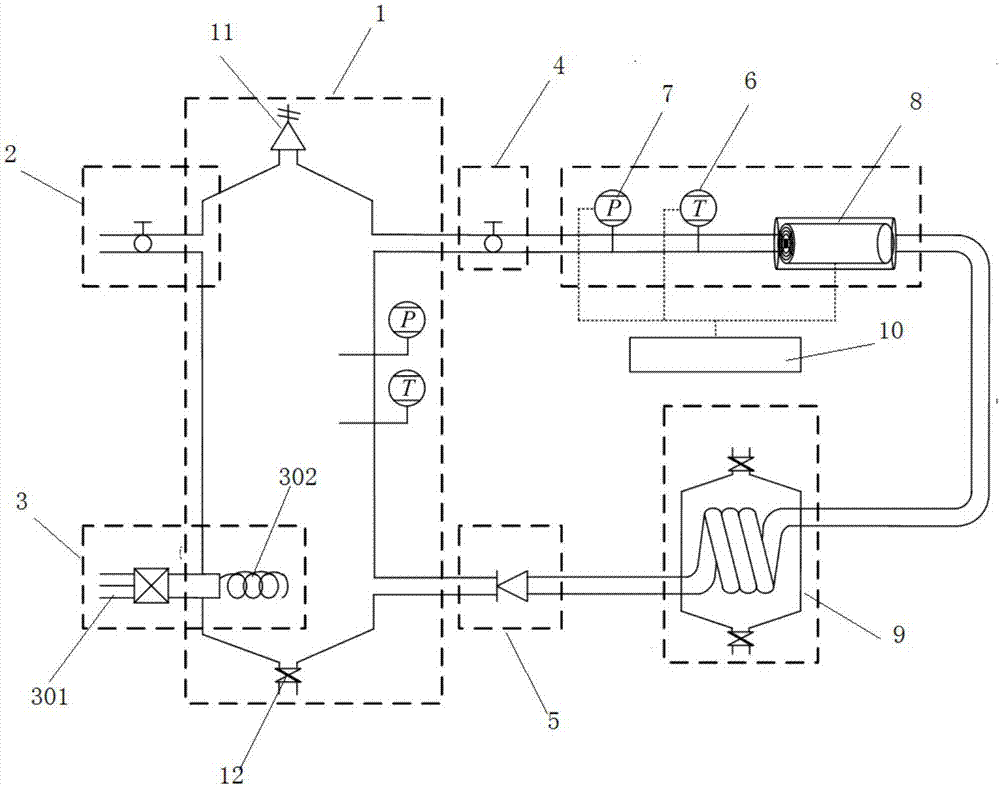

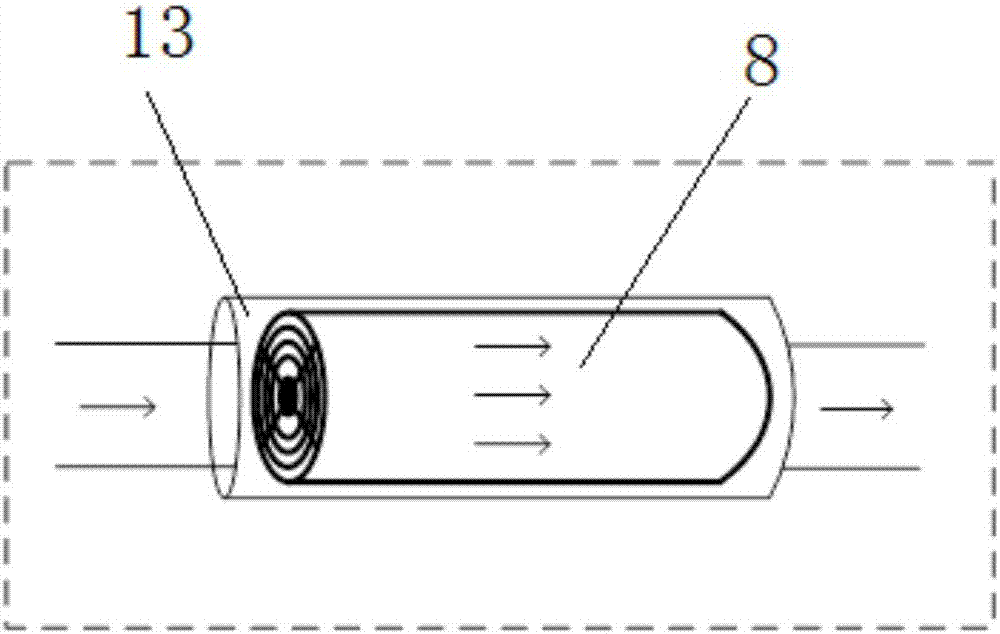

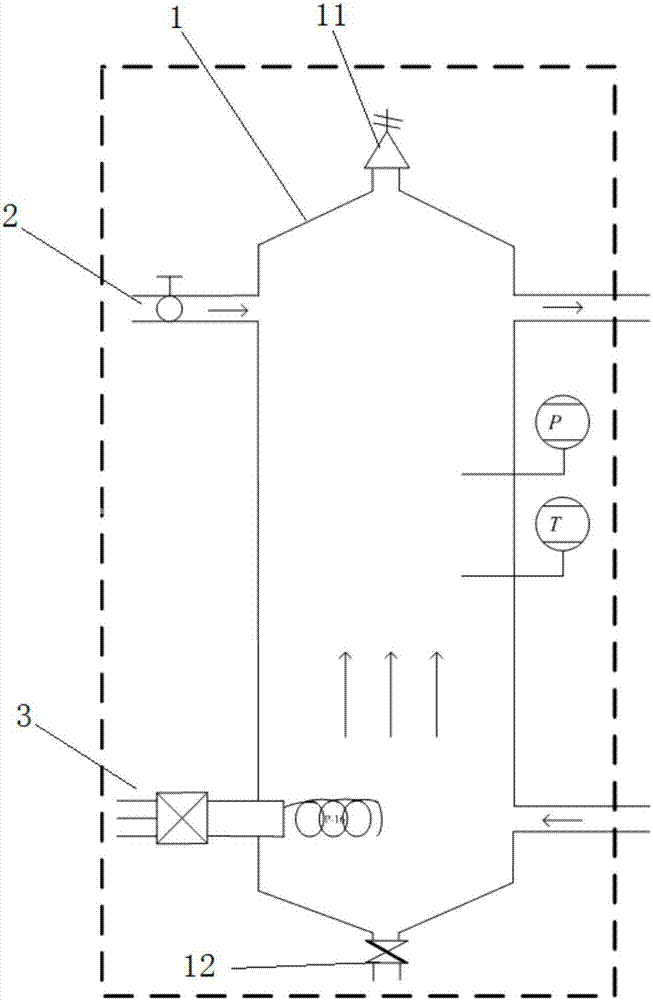

Gas and liquid two-phase dryness measuring system

ActiveCN107389747AReal-time accurate detectionReal-time accurate measurementMaterial capacitanceHierarchical testEngineering

The invention provides a gas and liquid two-phase dryness measuring system. The gas and liquid two-phase dryness measuring system comprises a gas and liquid two-phase heating furnace, a water injection cutoff valve, a three-phase heating power source, a voltage stabilizing valve, a unidirectional cutoff valve, a temperature transmitter, a pressure transmitter, a multi-layer drum-shaped capacitance sensor, a condensing tank, a data processing unit and the like. The gas and liquid two-phase dryness measuring system has the advantages that the dryness of steam can be accurately detected and measured in real time at high temperature and high pressure; by utilizing an experiment device to test the precise feature structure of the sensor, the system can be widely applied to the fields of real-time detection of steam injection boilers, downhole detection of steam injection wells in stratification testing, and the like.

Owner:NORTHEAST GASOLINEEUM UNIV

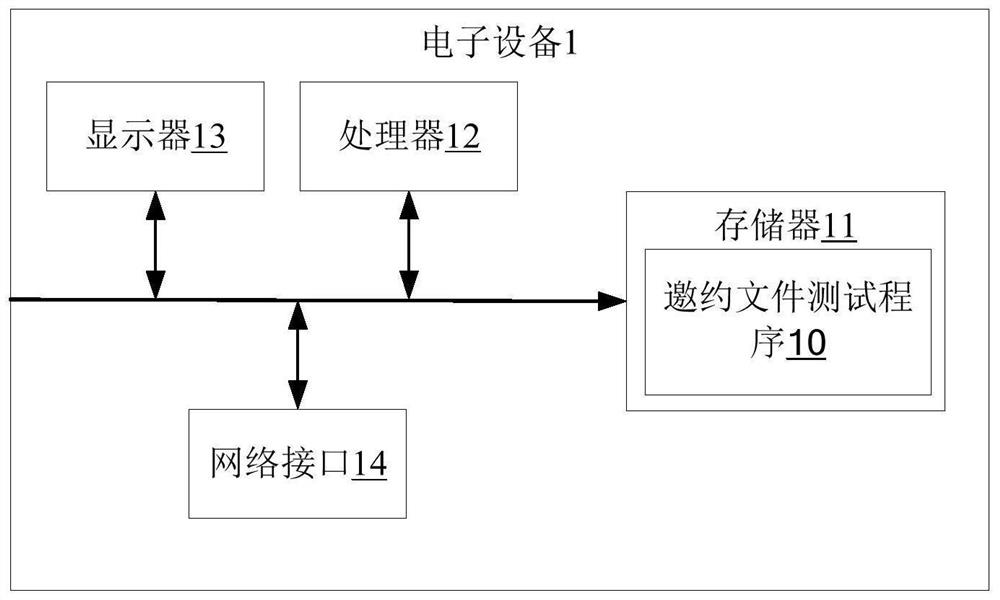

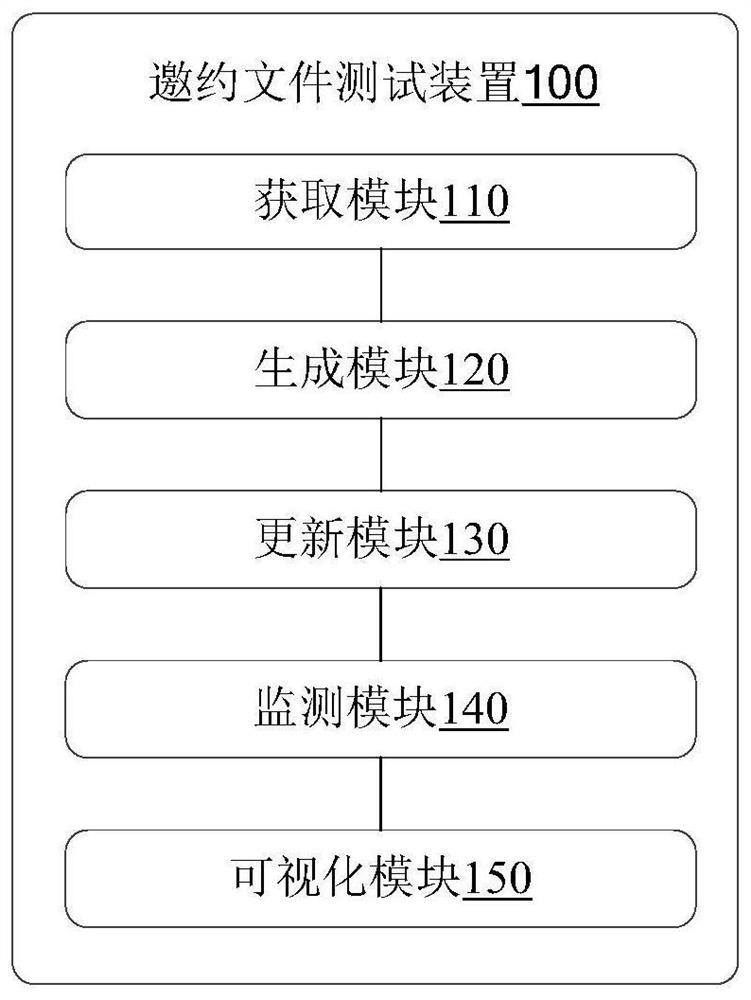

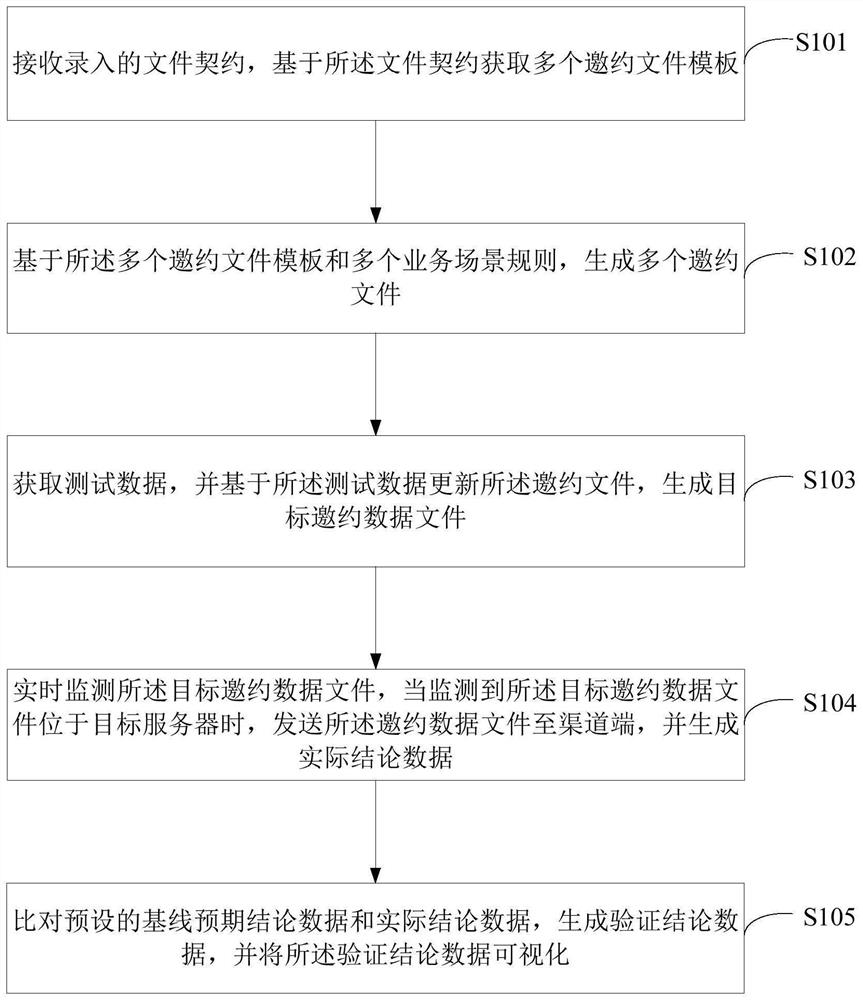

Invitation file testing method and device, equipment and storage medium

PendingCN113986730AShorten the timeImprove efficiencySoftware testing/debuggingHierarchical testData file

The invention relates to the technical field of research and development testing, and discloses an invitation file testing method which comprises the following steps: receiving an input file contract, and obtaining a plurality of invitation file templates based on the file contract; generating a plurality of invitation files based on the plurality of invitation file templates and the plurality of business scene rules; obtaining test data, updating the invitation file based on the test data, and generating a target invitation data file; monitoring the target invitation data file in real time, when it is monitored that the target invitation data file is located in a target server, sending the invitation data file to a channel end, and generating actual conclusion data; and comparing the preset baseline expected conclusion data with the actual conclusion data, generating verification conclusion data, and visualizing the verification conclusion data. According to the file generation tool of the configuration method provided by the invention, hierarchical testing is efficiently carried out, so that batch file task class testing can be carried out in a platformization and sustainable manner.

Owner:深圳平安智慧医健科技有限公司

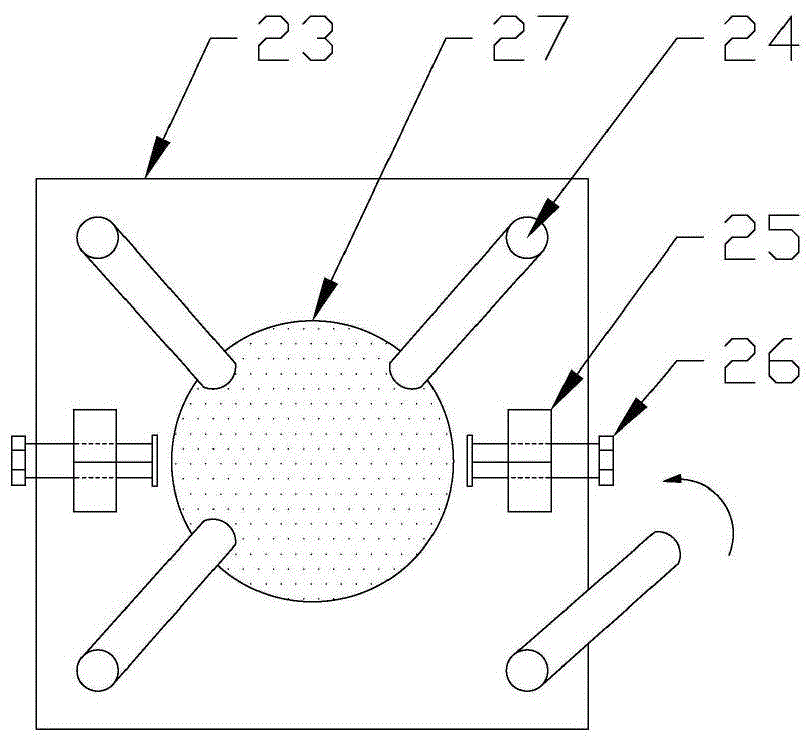

Filter cake strength layered testing device and method

InactiveCN105675407AContribute to researchMaterial strength using steady shearing forcesWall shearHuman–machine interface

The invention discloses a device and method for testing filter cake strength stratification. The motor drives the scraper assembly to move horizontally along the horizontal beam, and to move up and down vertically along the longitudinal beam. The stepper motor is connected to the core clamping assembly. The sensor assembly is composed of a pressure sensor, a displacement sensor, and a rotation angle sensor. The control assembly is composed of It is composed of programming logic controller, servo driver and stepping driver, and the data acquisition and output component is composed of data collector and man-machine interface. The device can test two types of filter cake samples of different shapes: filter cake samples attached to cylindrical rock cores, and filter cake samples attached to flat filter media such as filter paper screens. The invention can provide a more accurate filter cake strength quantification method, provide a basis for establishing the relationship between interlayer strength and wall shear stress, and guide the filter cake removal before cementing.

Owner:SOUTHWEST PETROLEUM UNIV

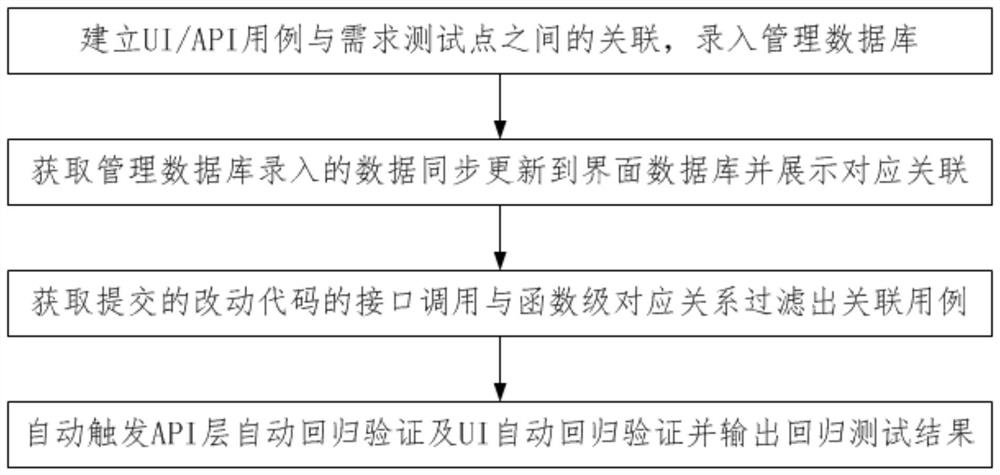

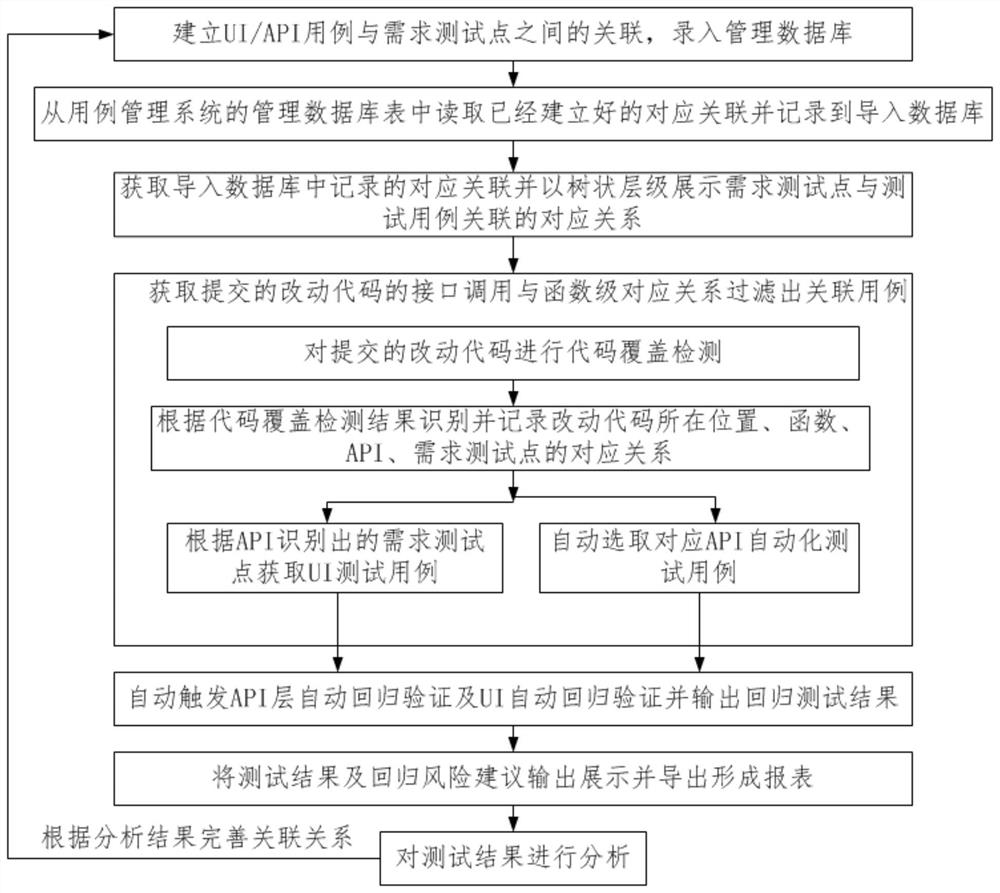

Method and device for selecting regression test case based on hierarchical test model

PendingCN114138628ASolve imperfectionsSolve the costSoftware testing/debuggingRegression testingTable (database)

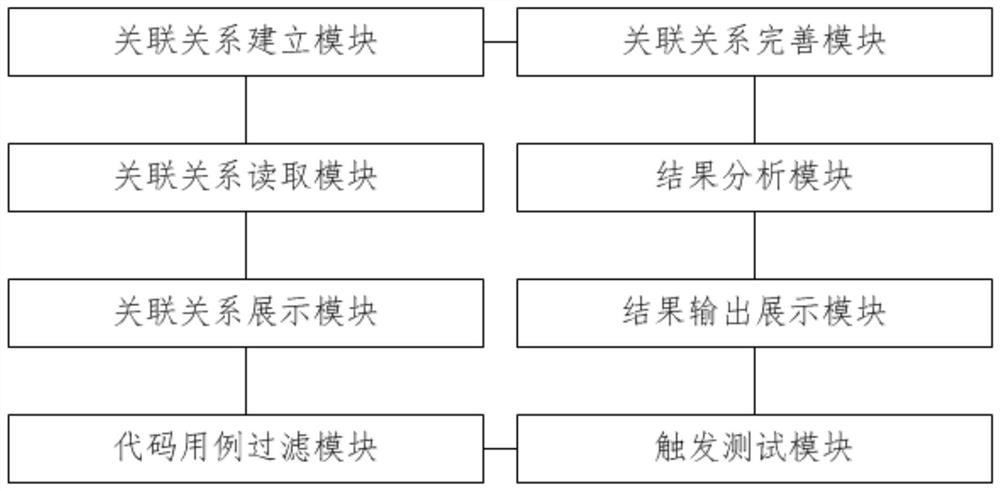

The invention belongs to the technical field of software testing, and particularly provides a method and device for selecting regression test cases based on a hierarchical test model.The method comprises the following steps that association between UI / API cases and demand test points is established and input into a management database; reading the established corresponding association from a management database table of the use case management system and recording the corresponding association into an import database; obtaining corresponding association recorded in the import database, and displaying a corresponding relationship between the demand test point and the test case association in a tree hierarchy manner; obtaining a corresponding relationship between interface calling of the submitted modified code and a function level, and filtering out an associated case; and automatically triggering API layer automatic regression verification and UI automatic regression verification, and outputting a regression test result. The corresponding relation between the use case and the code can be quickly and conveniently established on the existing automation framework, and the cost is greatly saved.

Owner:济南浪潮数据技术有限公司

Method for automatically leading in test cases

InactiveCN101221530BAutomatic import implementationImprove import efficiencySoftware testing/debuggingGraphicsHierarchical test

The invention relates to a test case automatic leading-in method, wherein, test case keywords and corresponding relations of test case fields are set in advance. The invention comprises the followingsteps: a hierarchical test case organization structure is created in a test case management system according to document hierarchy; test case contents required for introduction are searched layer by layer on the current hierarchy by adoption of a test case keyword recognition method; different field contents of test cases in the current hierarchy and test case fields of the test case management system are automatically and correspondingly led in layer by layer by adoption of a test case field corresponding strategy; graphics and tables in the current hierarchy are automatically recognized layer by layer and taken as enclosures to be led in together according to user requirements. The method of the invention can flexibly realize automatic introduction of documents with different formats according to the user requirements.

Owner:ZTE CORP

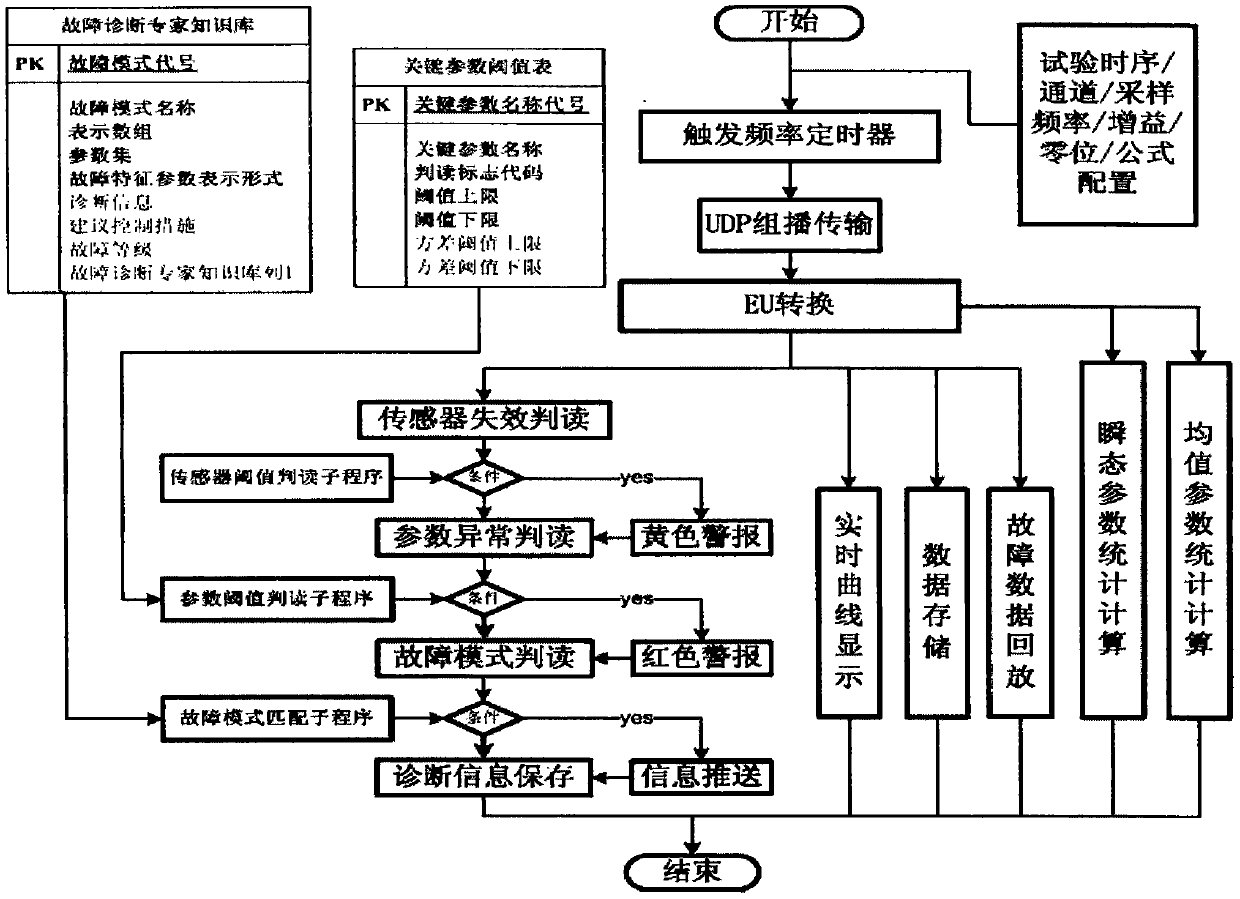

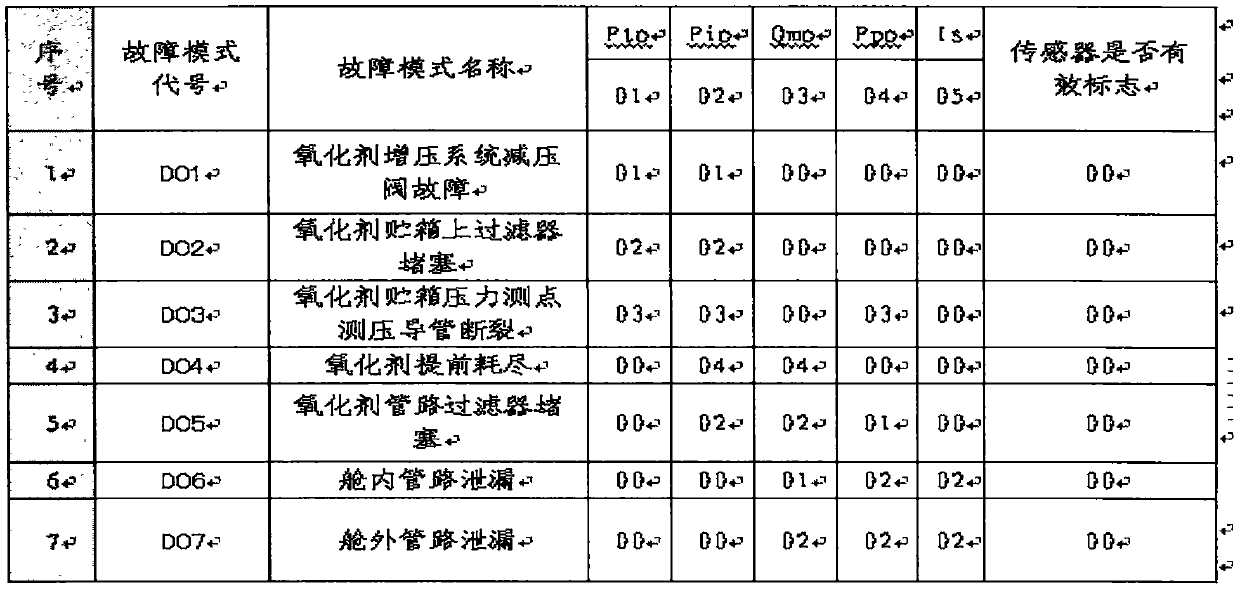

Liquid rocket engine test real-time data diagnosis strategy

InactiveCN110879152AEnsuring Safety and ReliabilityIncrease profitGas-turbine engine testingJet-propulsion engine testingHierarchical testReal-time data

The invention provides a liquid rocket engine test data diagnosis strategy which has good universality and feasibility. A hierarchical test data real-time interpretation method can be provided for testers, more test data information can be integrated, a quantified fault mode can be identified, a coping strategy can be pushed, and the safety of human and property in the test process can be guaranteed. The method comprises the following steps: S1, establishing a quantitative fault mode standardization library; S2, executing a sensor and converter failure detection logic; S3, executing an engineparameter anomaly detection logic; and S4, executing an engine fault mode detection logic.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

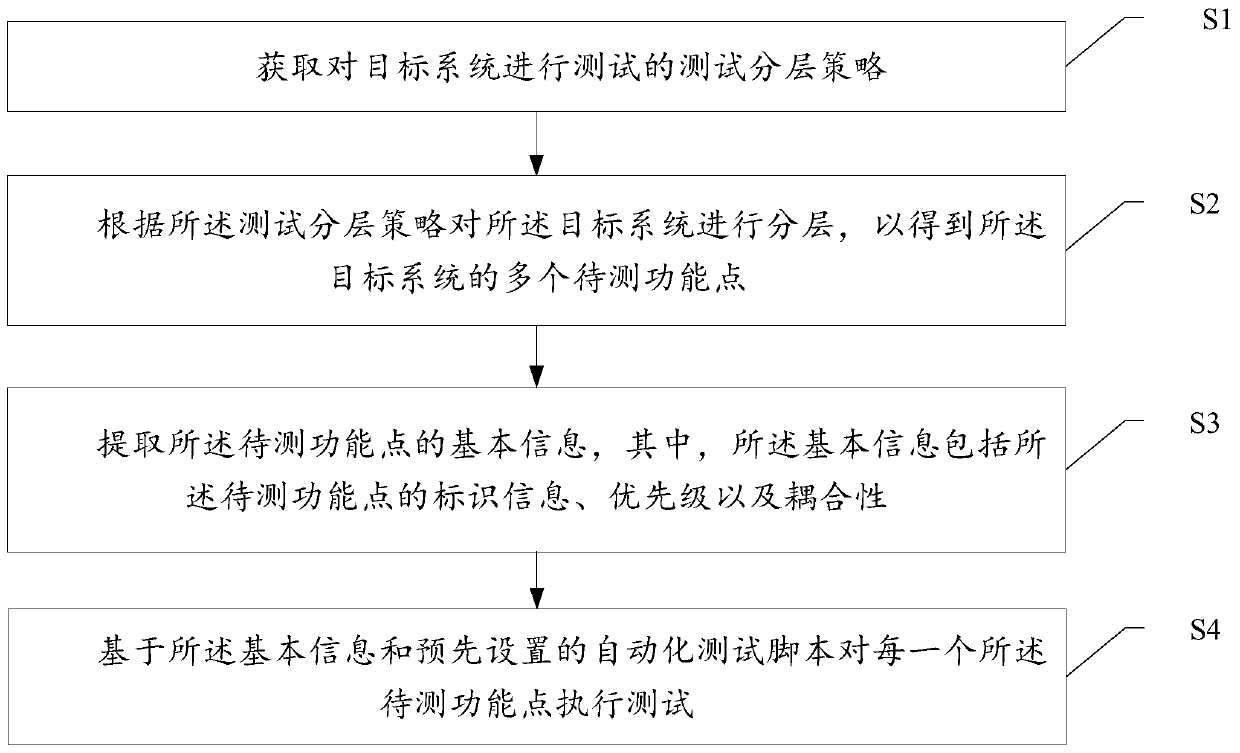

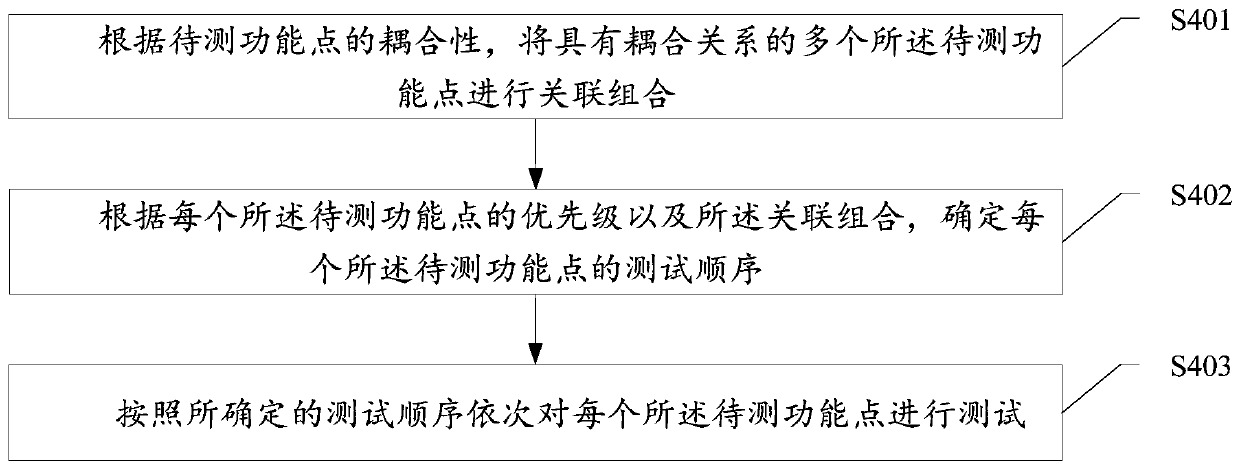

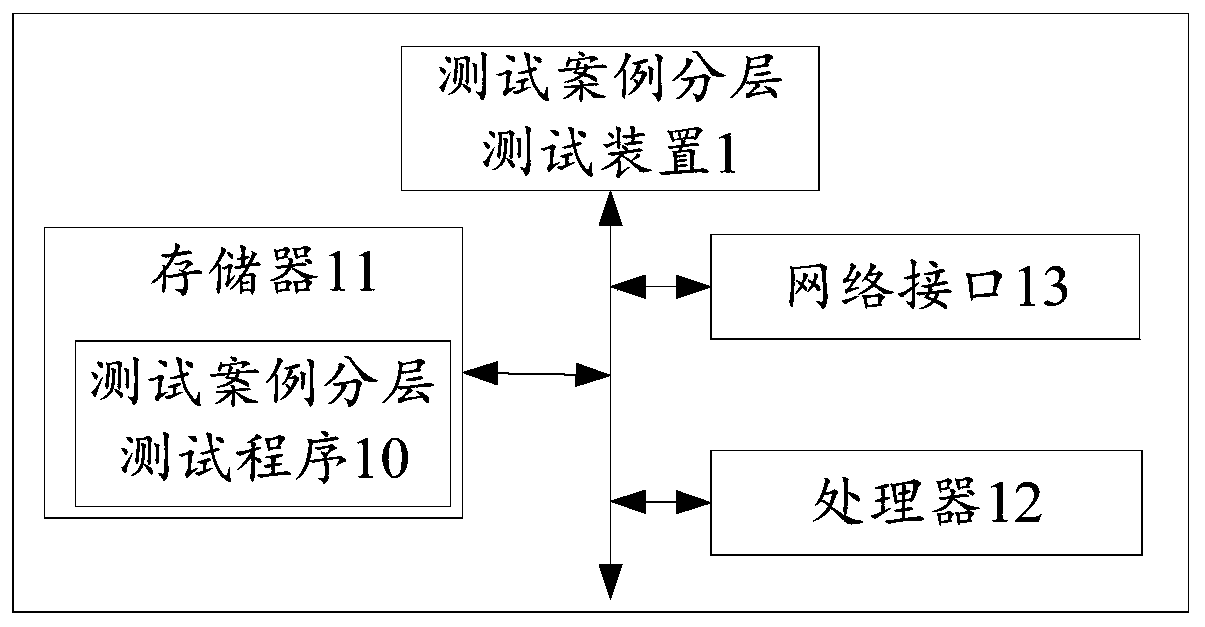

Test case hierarchical test method, computer equipment and computer readable storage medium

PendingCN111538672ASolve the problem of data dependenceSoftware testing/debuggingHierarchical testTest script

The invention relates to the technical field of testing, and discloses a test case layering test method, which comprises the following steps of: obtaining a test layering strategy for testing a targetsystem; layering the target system according to the test layering strategy to obtain a plurality of function points to be tested of the target system; extracting basic information of the to-be-testedfunction point, the basic information including identification information, priority and coupling of the to-be-tested function point; and executing a test on each function point to be tested based onthe basic information and a preset automatic test script. The invention further provides computer equipment and a computer readable storage medium. By applying the method and the device, layering ofthe target system can be realized, the coupling between the to-be-tested function points is considered in the test process, the obtained to-be-tested function points are automatically tested, and thecommon data dependence problem of automatic test is solved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

Two-layer delamination perforation-delamination test combined pipe string in one trip and its operation method

ActiveCN106150445BImprove admission qualityIncrease the proportion of stratified oil testingFluid removalWell/borehole valve arrangementsInternal pressureHierarchical test

The invention relates to a one-trip string two-layer layering perforation-layering testing combining tubular column and an operation method. The tubular column comprises a first oil tube, a depth correction short joint, a second oil tube, a circulating valve, a third oil tube, a testing valve assembly, a second pressure gauge supporting cylinder, a second pressure transfer joint, a straddle packer, a second sieve tube, a spacer tube, a pressure guiding joint, a second ignition head, a second perforating gun, a pressure release device, sealing layer well shut-in sampling valve, a damping pressure gauge supporting cylinder, a first pressure transfer joint, an anchor packer, a first sieve tube, a shock absorber, a fourth oil tube, a first ignition head, a first perforating gun, a pressure relieving device, a second inner pressure transfer tube, a first pressure transfer tube and a first outer pressure transfer tube. The sealing layer well shut-in sampling valve is located between the second perforating gun and the anchor packer. The damping pressure gauge supporting cylinder is located below the sealing layer well shut-in sampling valve. by adopting the tubular column, two-layer layering perforation and layering testing combination can be completed, final well shut-in of the first layer does not need to occupy the operation machine time independently, down-hole sampling is convenient, and the tubular column has the advantages of being short in period, low in cost and the like.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

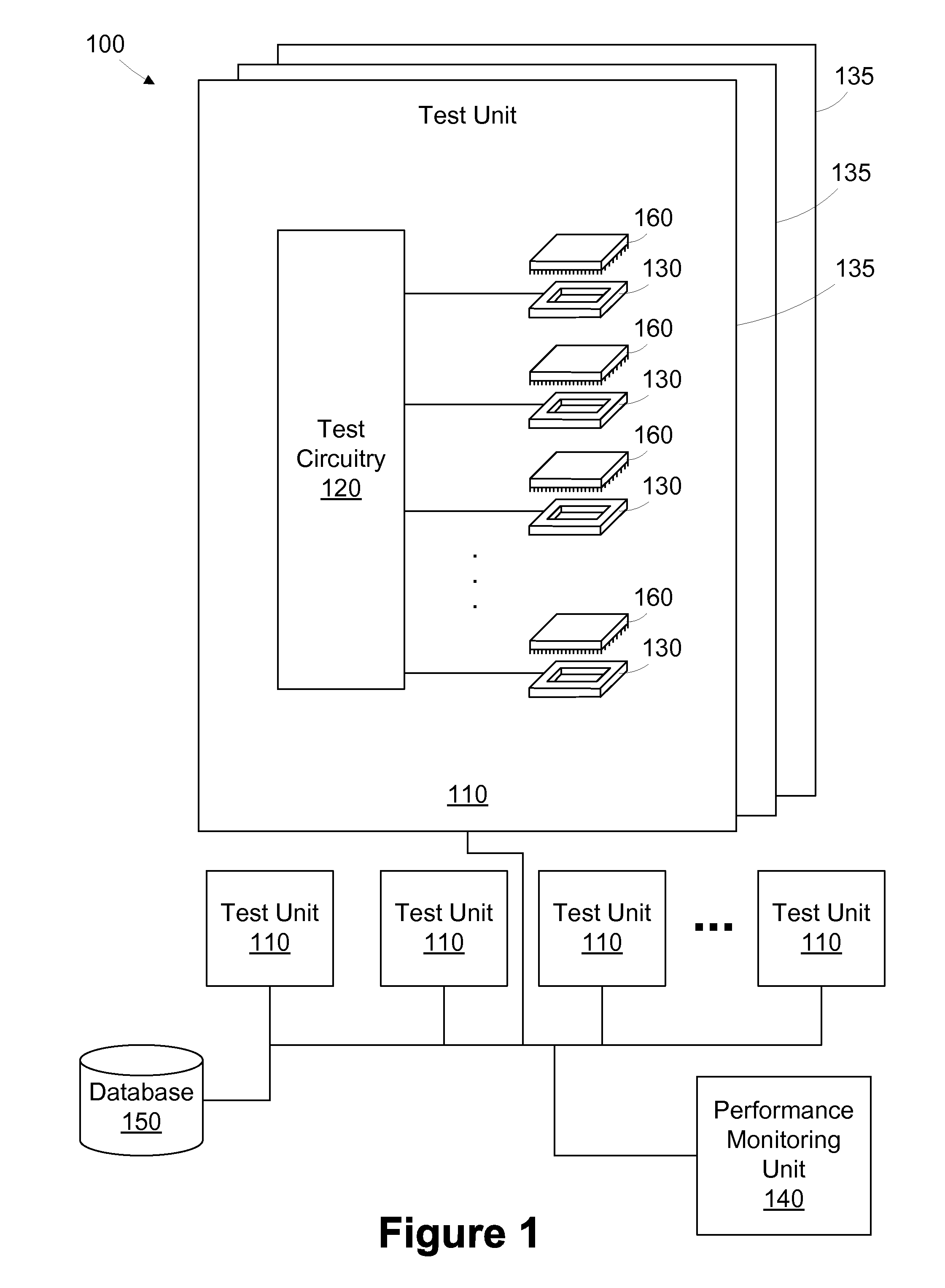

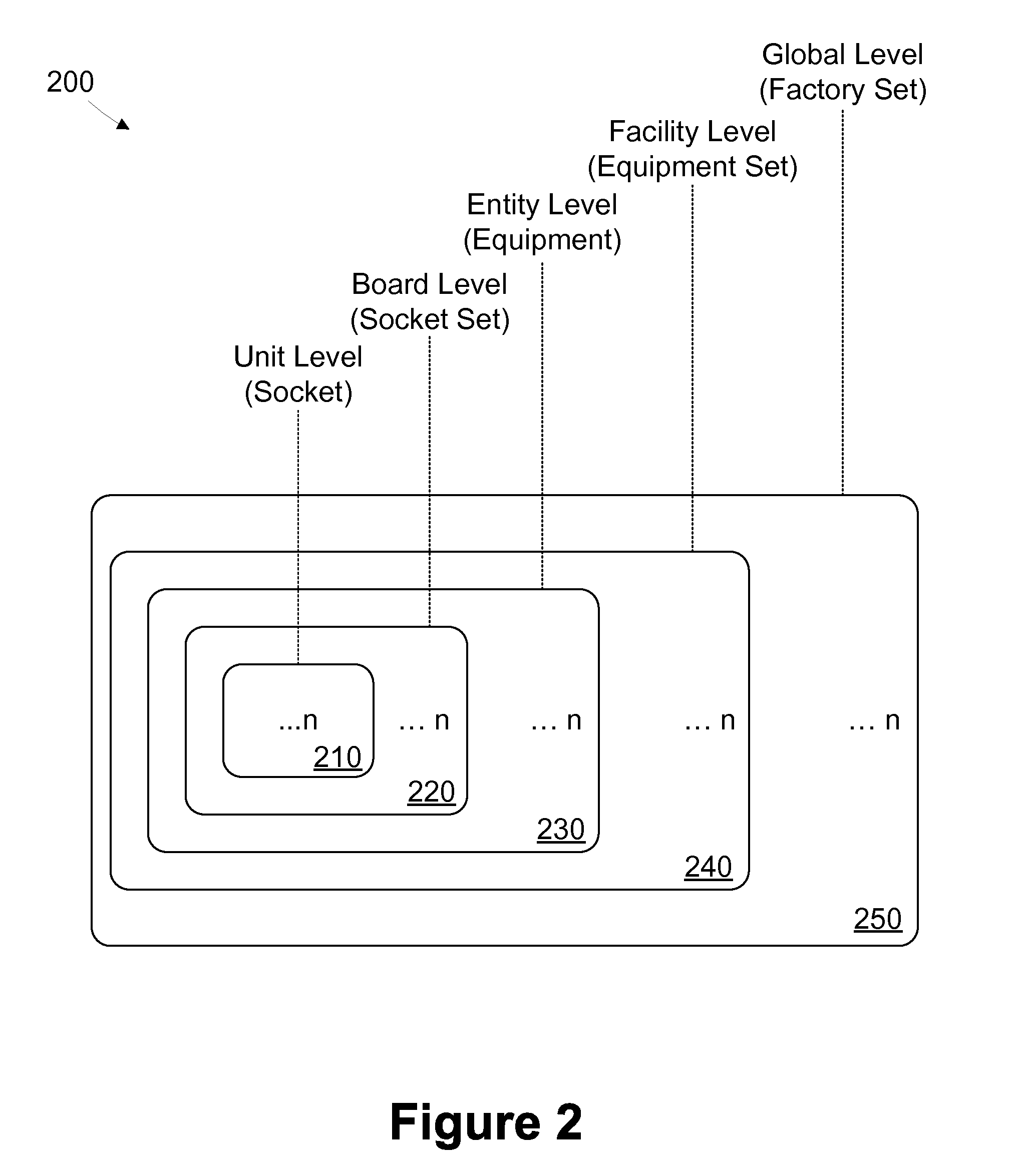

Method and apparatus for measuring performance of hierarchical test equipment

A method includes defining a hierarchy associated with a test system including a plurality of test units for testing integrated circuit devices. At least some of the test units have a plurality of sockets. The hierarchy includes a first level including a first plurality of entities each associated with one of the sockets and at least a second level including a second plurality of entities each associated with a grouping of the sockets. State data associated with operational states of the sockets is received. A set of state metrics is generated for each entity at each level of the hierarchy based on the state data. Each set of state metrics identifies time spent in the operational states.

Owner:GLOBALFOUNDRIES INC

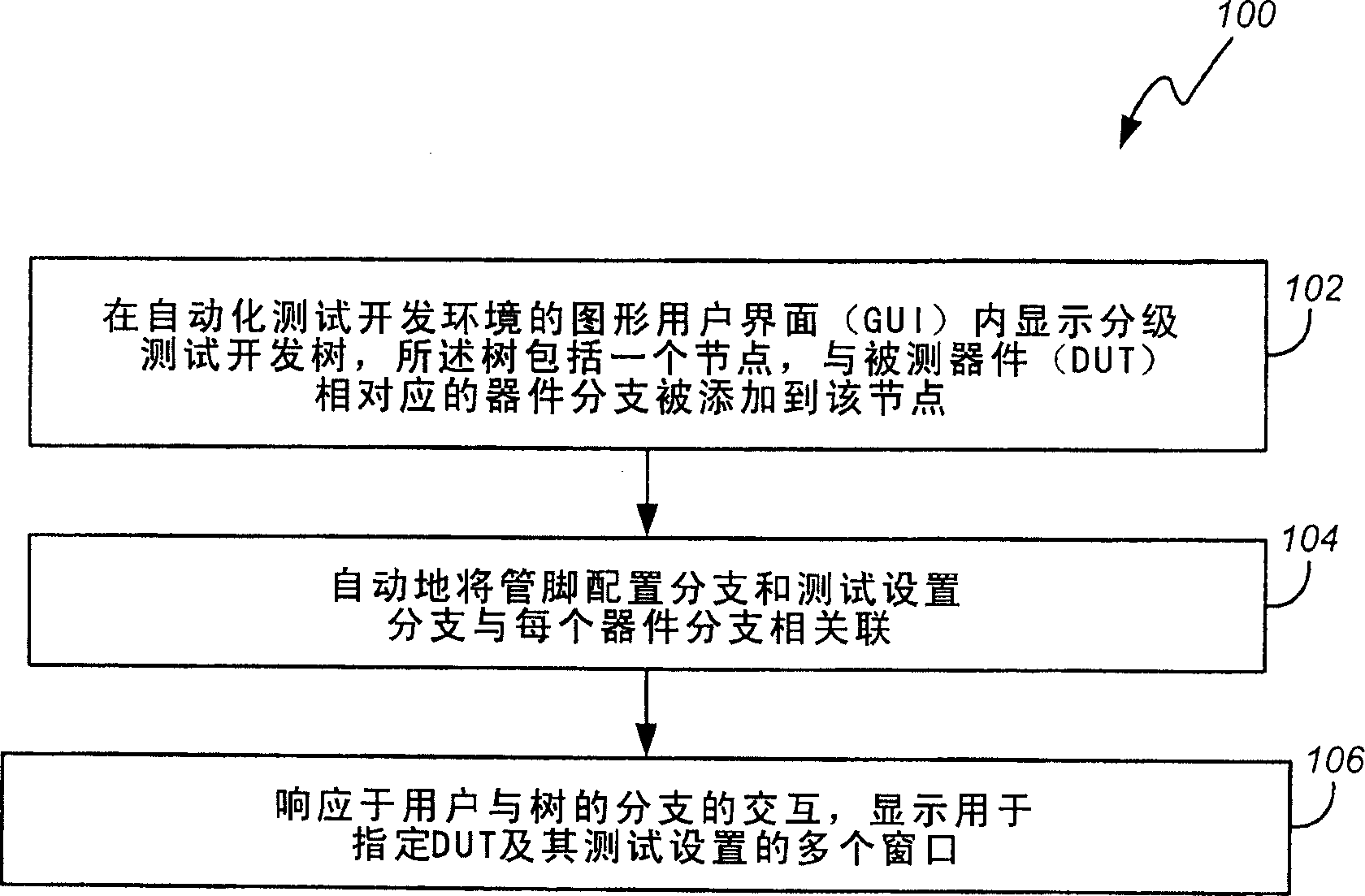

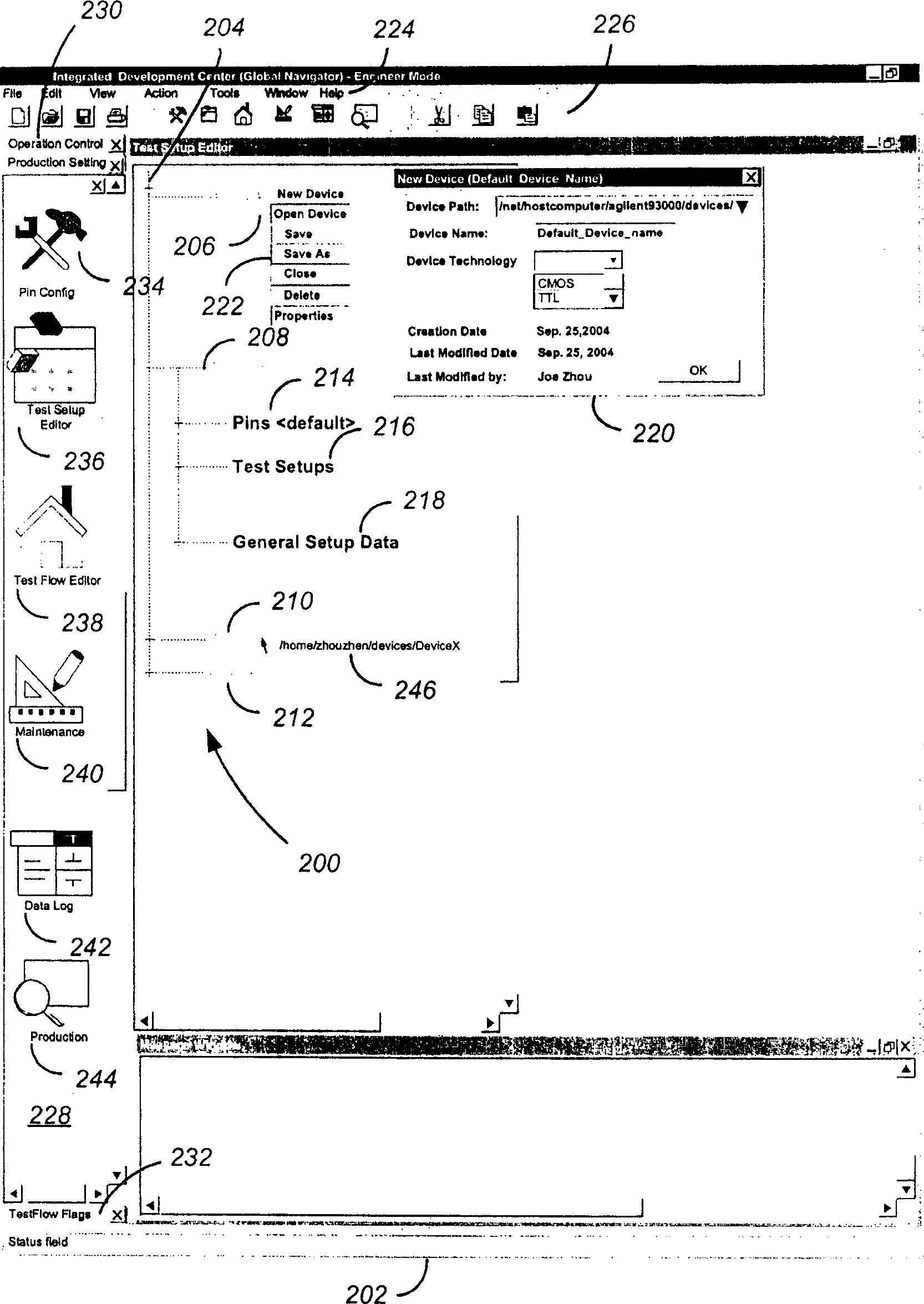

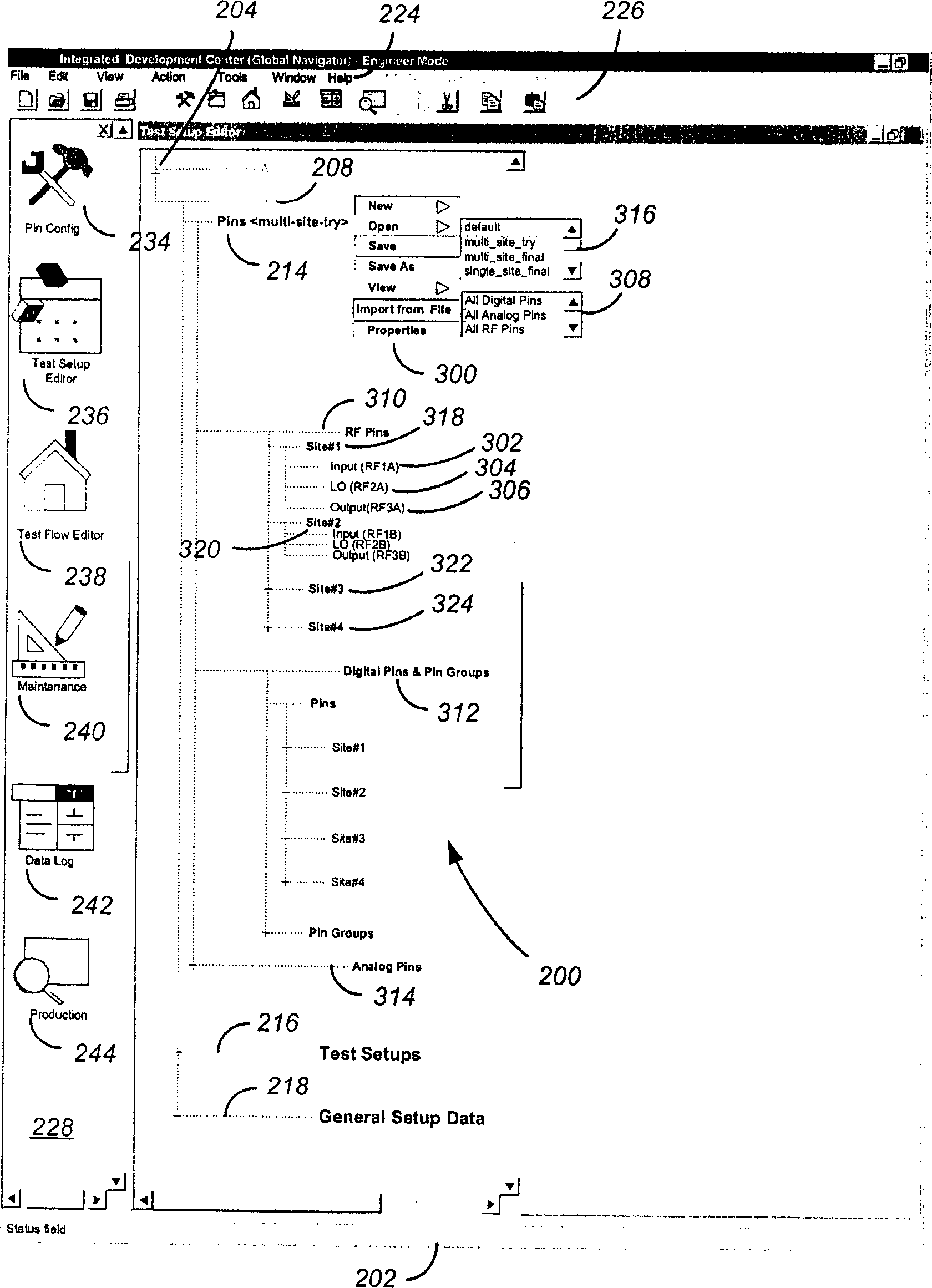

Methods and apparatus using a hierarchical test development tree to specify devices and their test setups

Owner:VERIGY PTE

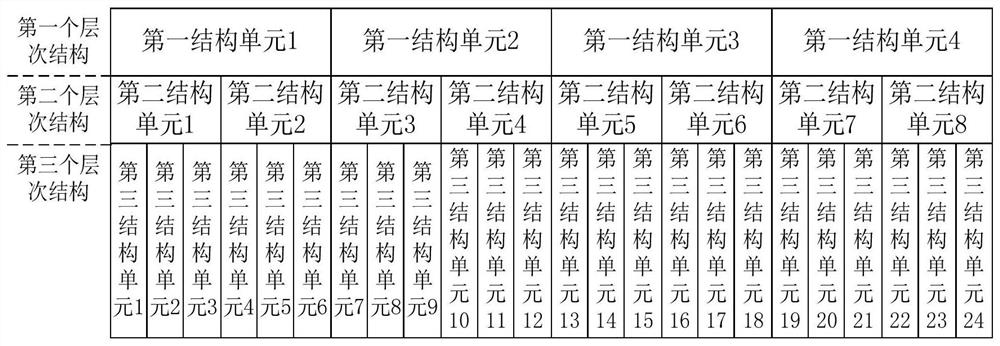

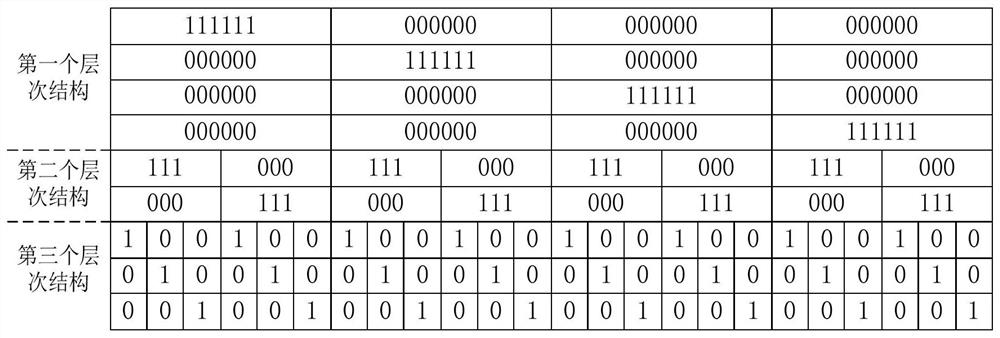

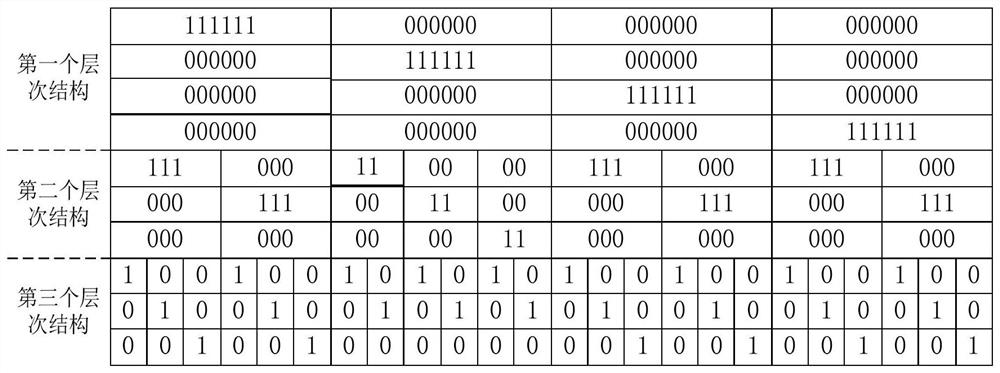

Efficient test method based on hierarchical test vectors

ActiveCN111722089AReduce in quantityFast testElectronic circuit testingHierarchical testTest efficiency

The invention discloses an efficient test method based on hierarchical test vectors, relating to the technical field of chip testing. According to the method, a to-be-tested interconnection path is divided into a plurality of hierarchical structures; a test sequence is generated for each hierarchical structure; each test vector, corresponding to the same structural unit in the previous hierarchical structure, in each hierarchical structure is used as a test group to perform serial shift in sequence; the hierarchical test sequences are correspondingly generated according to the hierarchies of the interconnection paths, the number of the test sequences can be greatly reduced on the basis of ensuring full-coverage test, so that the test speed is increased, the test efficiency is improved, andthe method is particularly suitable for a structure containing a large number of interconnection paths, such as a multi-bare-chip FPGA.

Owner:WUXI ESIONTECH CO LTD

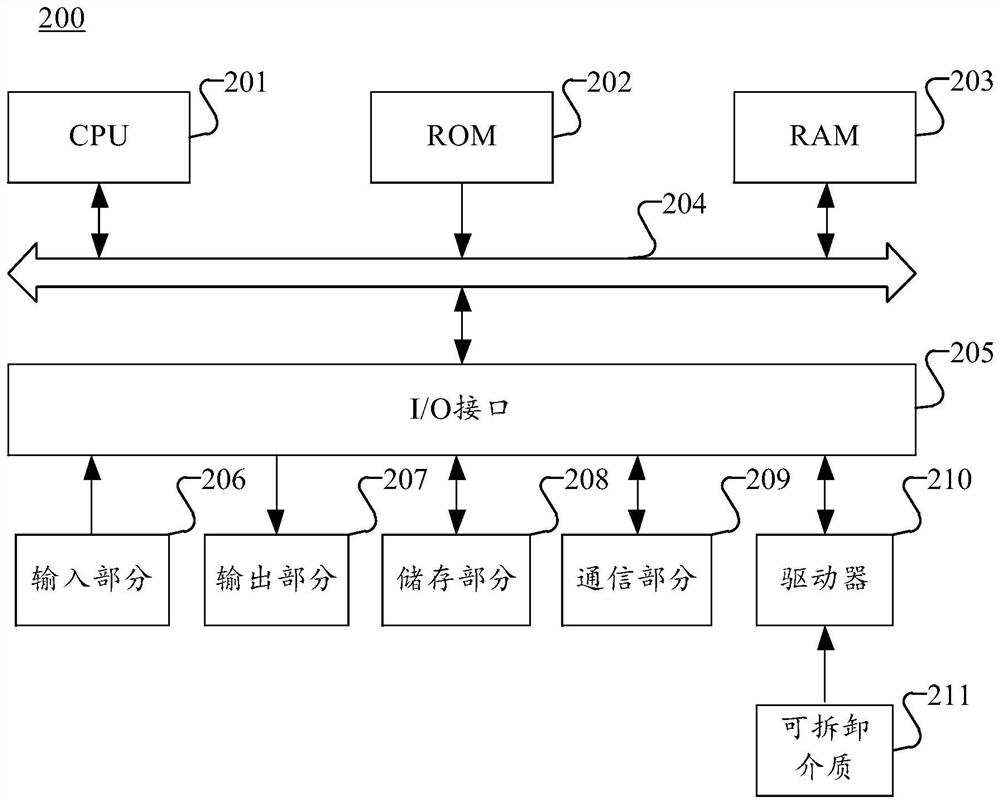

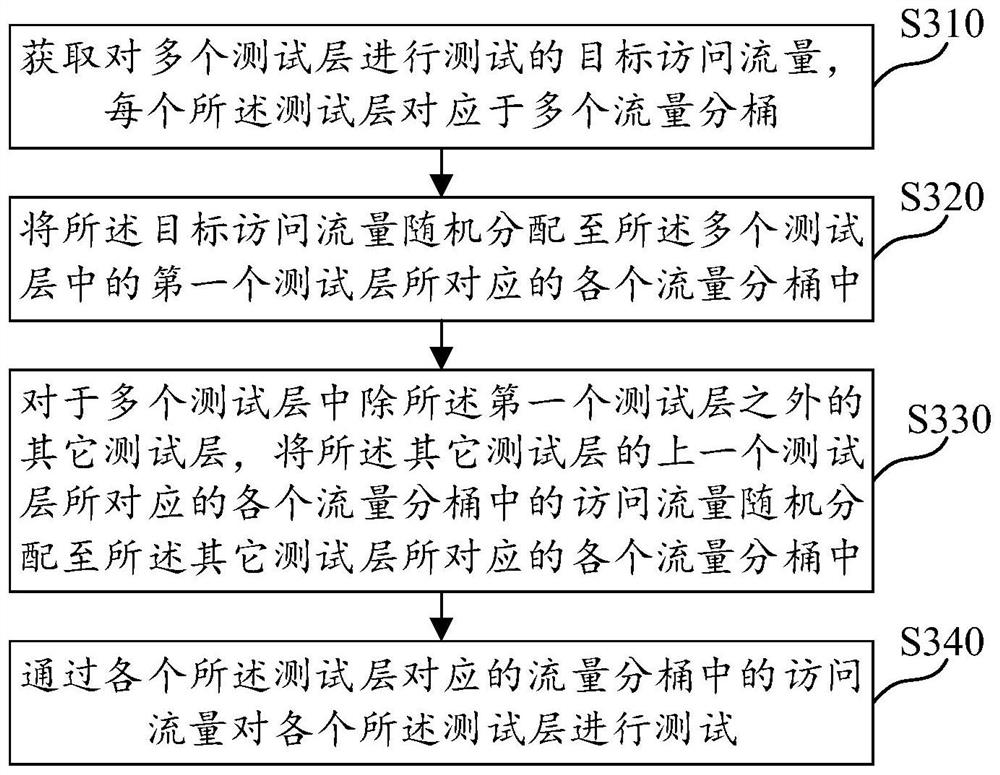

Hierarchical testing method, apparatus, computer readable medium and electronic device

ActiveCN110750436BIncrease randomnessImprove objectivitySoftware testing/debuggingHierarchical testComputer network

Owner:TENCENT TECH (SHENZHEN) CO LTD

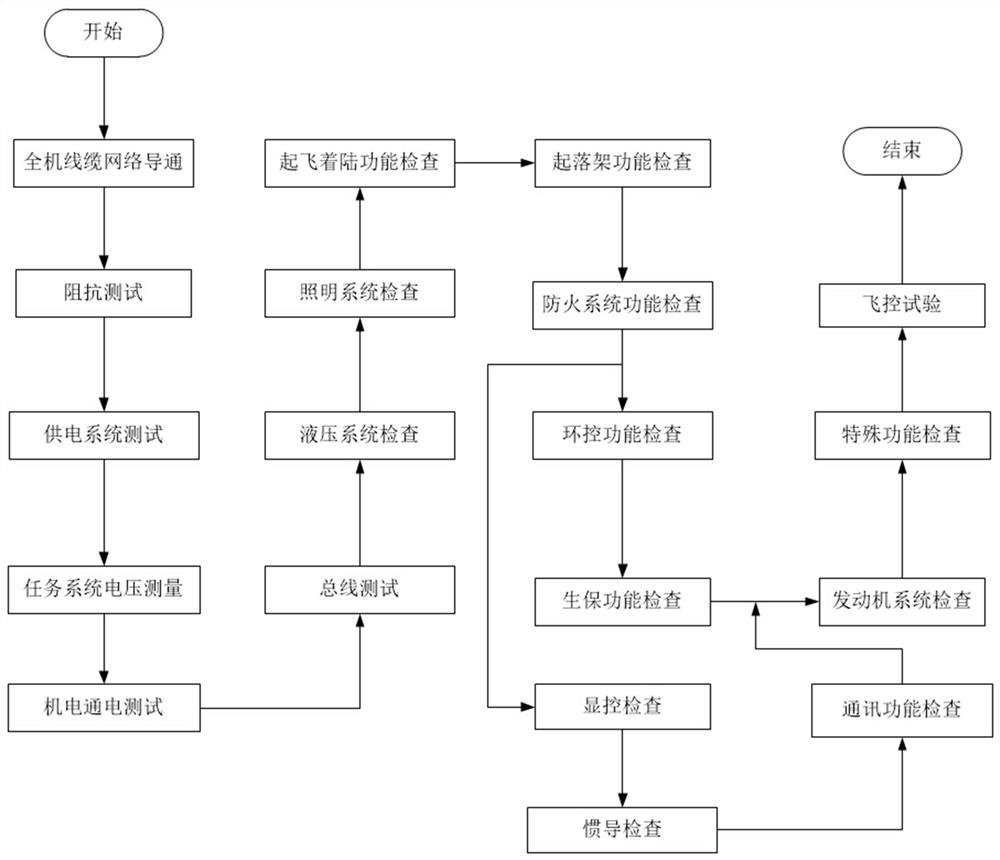

A kind of general assembly test method of aircraft system

ActiveCN110304268BReduce repeated executionImprove safety and reliability performanceAircraft components testingFly controlFire prevention

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

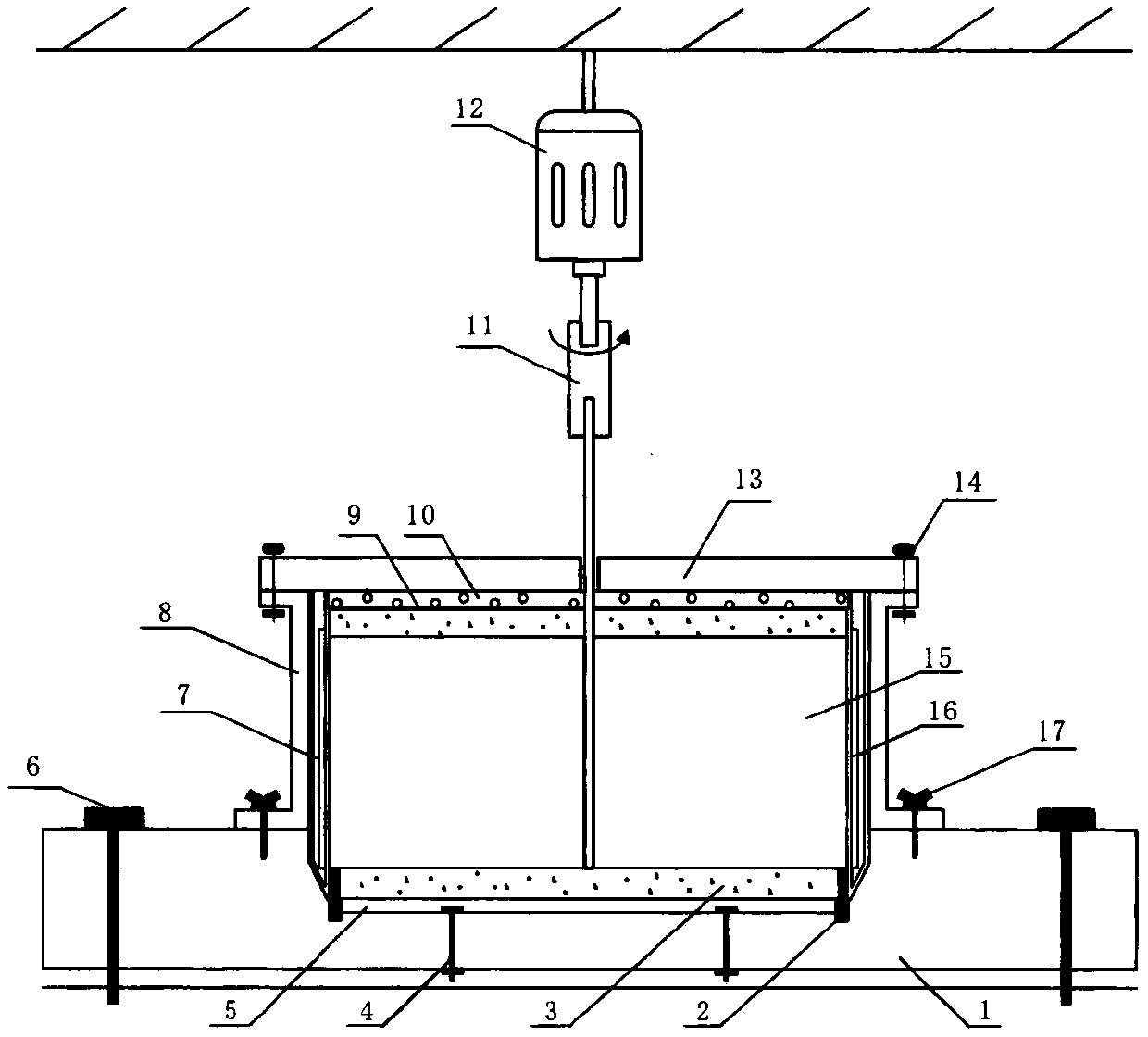

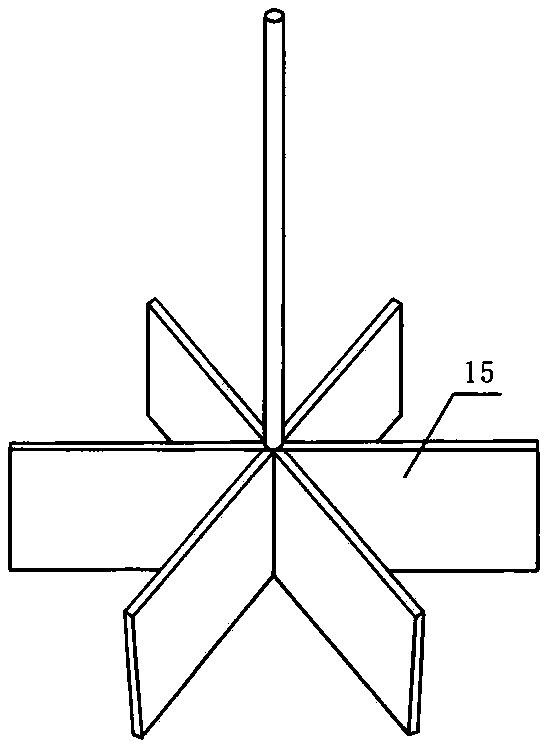

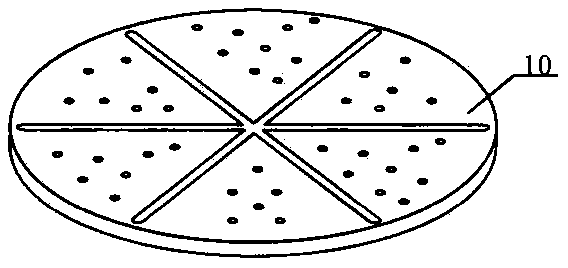

Layered rotary cutting test device and test method for adhesion near interface with volume change being restrained

PendingCN110487717AImplement small changesConstant distanceMaterial strength using steady torsional forcesUsing mechanical meansHierarchical testEngineering

The invention provides a layered rotary cutting test device and test method for adhesion near an interface with volume change being restrained. The device is formed by a base with a groove, a metal washer, a soil sample, bolt pins I-III, a metal bottom plate, bolts, a ring cutter, a wall protection cylinder, filter paper, a water permeable plate, a torque meter, a driving power supply, a pressurization cover plate, a rotary cutting plate and a sliding ring. The distance between the rotary cutting plate and the metal bottom plate is changed through the metal washer, the driving power supply drives the rotary cutting plate at different constant speeds, and shear load is recorded by the torsion meter, thereby realizing a function of testing the shear load of the soil sample sheared at different speeds under different rotary cutting distances; the setting of the metal washer effectively solves the problem of changing the micro rotary cutting spacing between the rotary cutting plate and themetal bottom plate; and the setting of the wall protection cylinder effectively solves the problem of observing the soil sample shear damage characteristics on the metal bottom plate after test. Thelayered rotary cutting test method for adhesion near the interface with the volume change being restrained is an effective method for studying rotary cutting adhesion near the interface and adhesion difference characteristics.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com