Hierarchical prediction method for composite material multi-direction lamination board by considering fiber bridge connection influence based on improved B-K criterion

A composite material and criterion technology, applied in special data processing applications, instruments, design optimization/simulation, etc., can solve the problem of inability to accurately simulate the layered expansion behavior of multi-directional laminates, and achieve shortened test workload, high precision, good consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention is described in further detail:

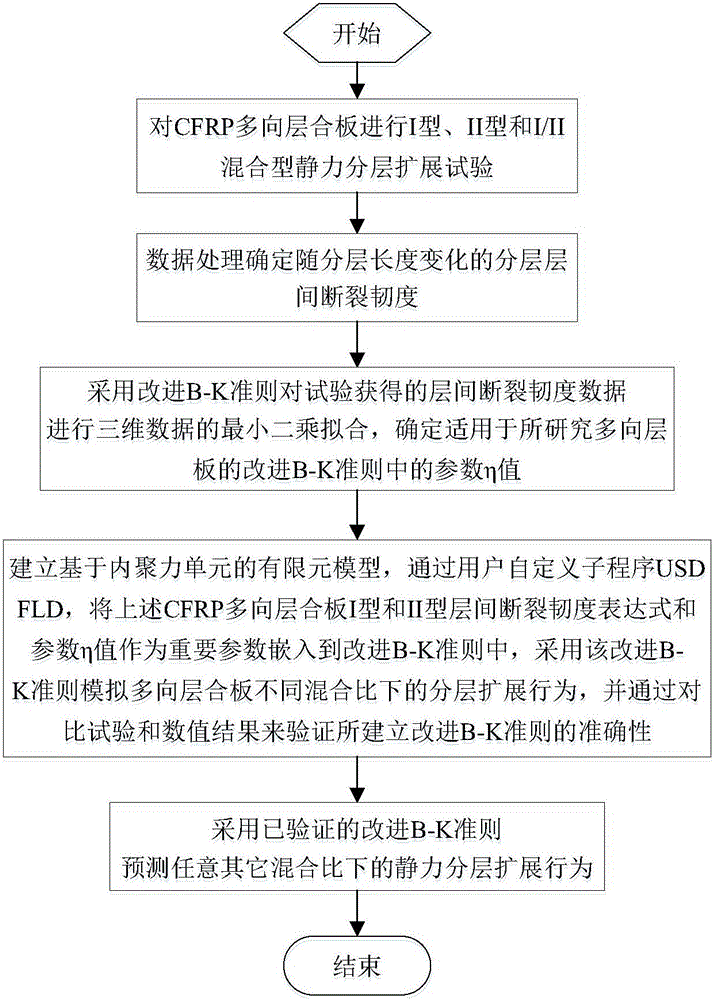

[0040] An improved B-K criterion of the present invention is used to predict the delamination of composite multi-directional laminates affected by fiber bridges. The specific implementation steps are as follows:

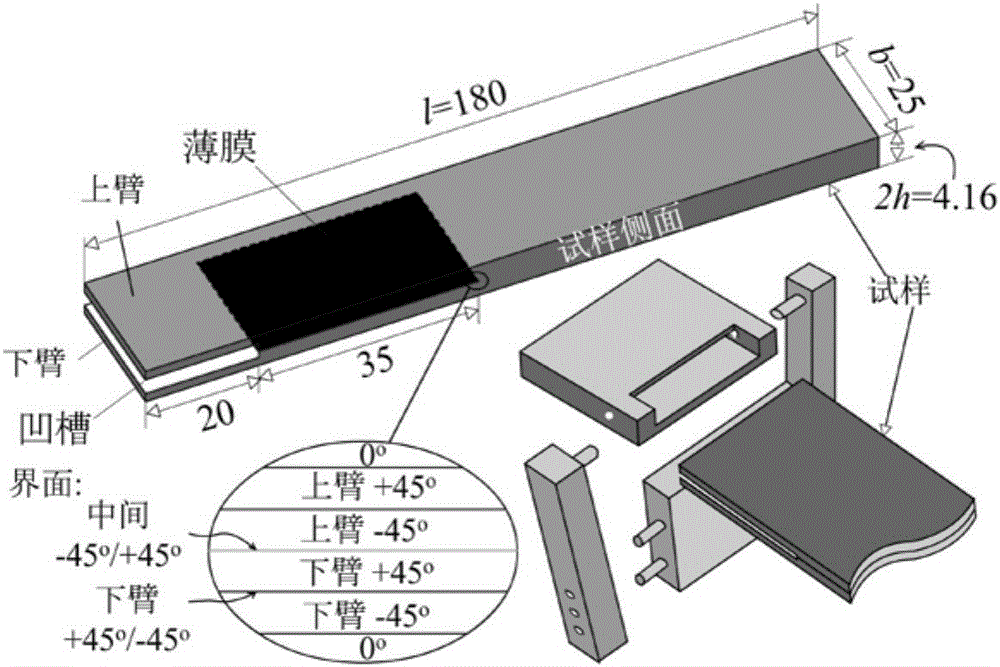

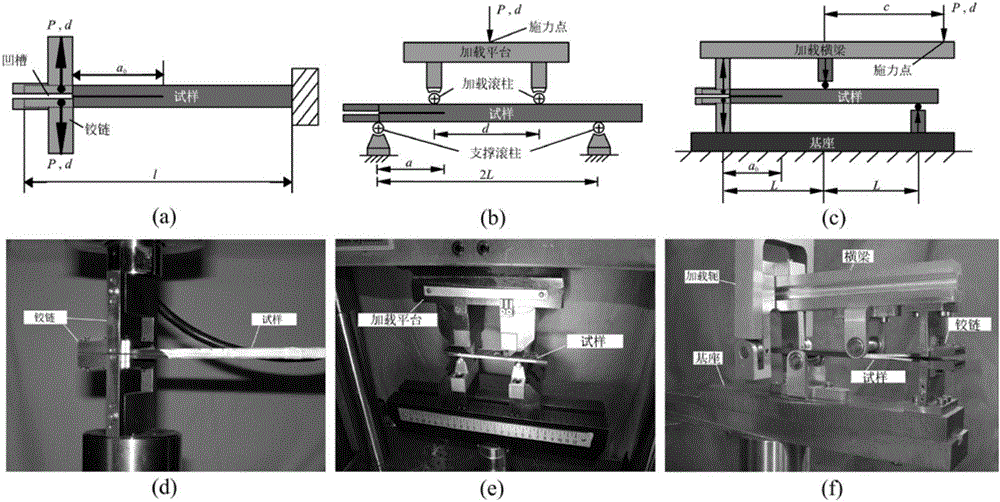

[0041] Step 1: The test specimen is made of unidirectional prepreg of T700 / 9511 carbon fiber / bismaleimide resin system, and the layup sequence is (+45 / -45 / 06) S / / (-45 / +45 / 06) S CFRP multi-directional laminates, in order to ensure that the displacement load is effectively applied to the mid-plane of the cantilever beam, a quick-mounted hinge was used in the DCB and MMB tests, as figure 2 Shown; According to ASTM standard D5528-01, conduct type I delamination expansion test (DCB) on CFRP multidirectional laminates, and use 4ENF test device to conduct type II delamination expansion test on CFRP multidirectional laminates, according to ASTM standard D6671M-06 Mixing ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com