Zonation testing method used for downhole intelligent well shutdown

A layered testing and intelligent technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve problems such as slow recovery of formation pressure, long test period, and inability to select templates, etc., to achieve true formation pressure recovery data, The effect of saving test cost and shortening test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings:

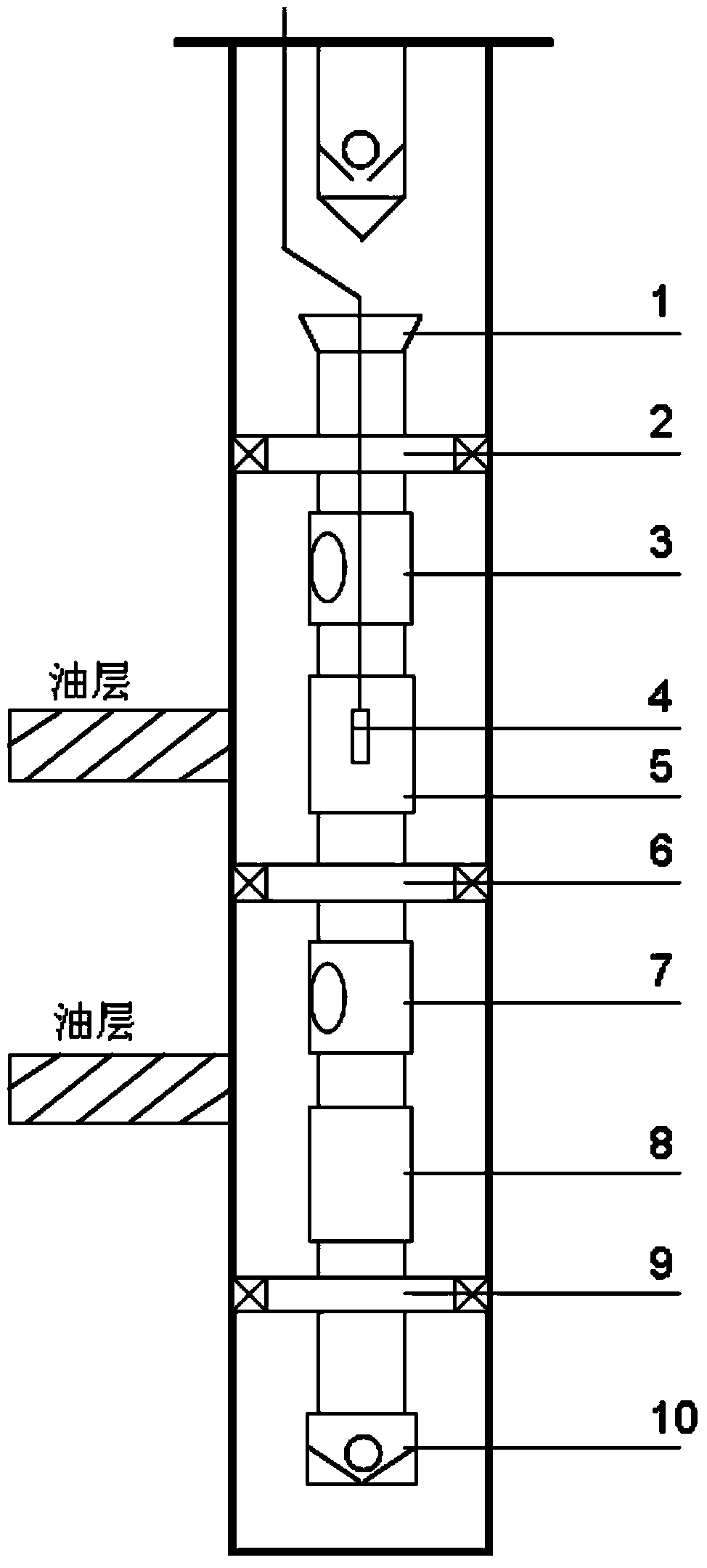

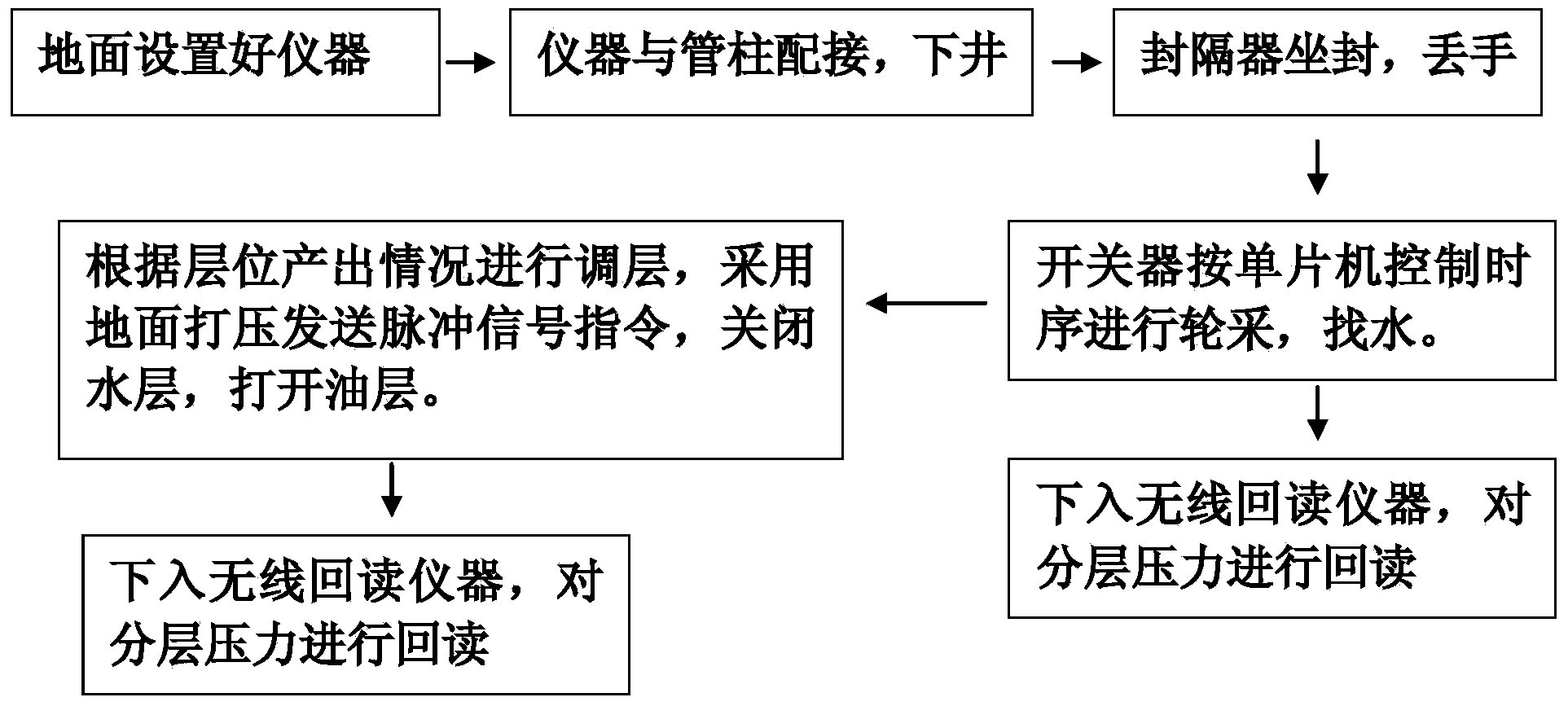

[0033] The device used in the layered test method for intelligent downhole shut-in of the present invention includes, from top to bottom, such as figure 1 As shown in the components, 1 is a drop-off connector, which realizes the positioning of the pipe string when it is dropped and removed, 2 is a drop-off packer, used to seal the layer, and 3 is a switch, used for automatic or manual intervention Turn on or off the horizon. 4 is a wireless readback instrument, which can be used to read the data in the pressure measurement nipple at any time during the test or production process. 5 is the pressure measurement nipple to measure the horizon pressure and temperature. And other parameters are stored, 6 is a packer, used to seal the horizon, 7 is a switch, used to automatically or manually intervene to open or close the horizon, 8 is a pressure measurement sub-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com