A kind of general assembly test method of aircraft system

A test method and aircraft system technology, applied in the direction of aircraft component testing, etc., can solve the problems of lack of specific specifications for the test process, repetitive labor of operators, affecting test efficiency, etc., so as to facilitate and quickly locate faults and improve safety and reliability. , the effect of clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

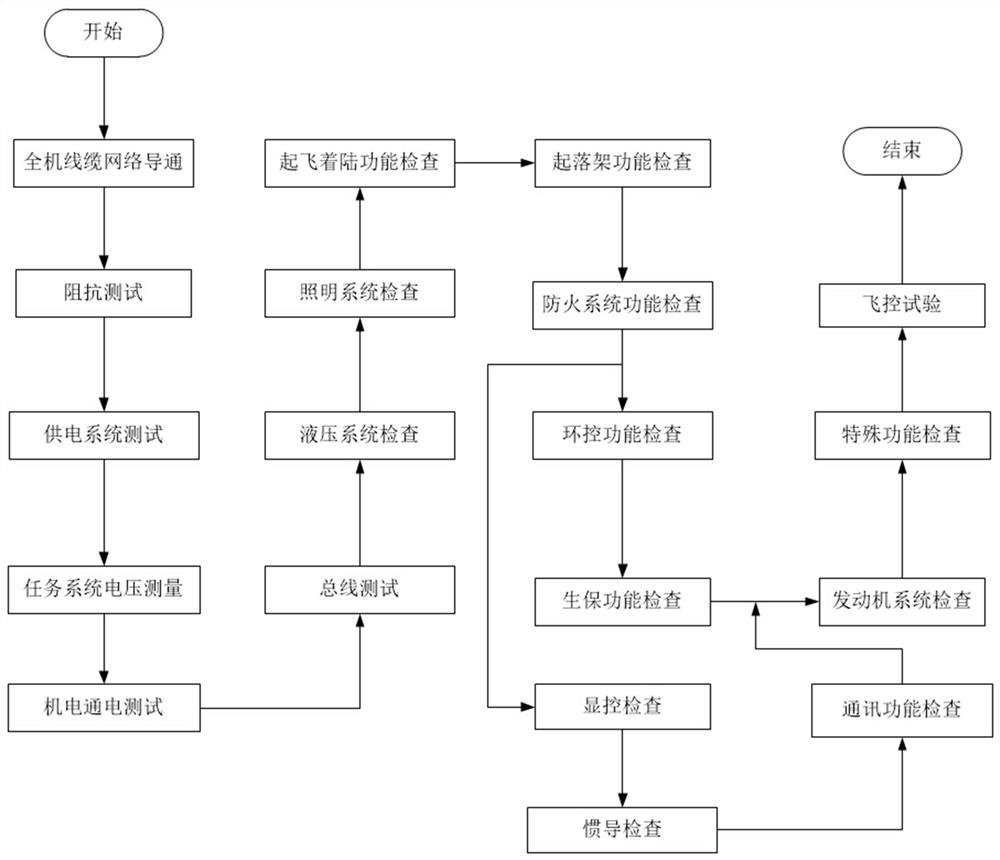

[0041] This embodiment provides a method for general assembly testing of an aircraft system. The first step is to perform a conduction and impedance test without power-on, and perform a safe measurement to eliminate some faults to prevent damage to the finished product due to faults; the second step is Ensure the power supply voltage; the third step: conduct system function test and hydraulic inspection; the fourth step is to conduct system function inspection that requires hydraulic pressure; the fifth step is to do flight control and large synthesis. The system can effectively reduce test risk and facilitate and quickly locate faults. Gradually convert from signal-level testing to functional and performance testing.

[0042] The flow of the method, such as figure 1 As shown, it specifically includes the following steps:

[0043] Step 1: The cable network of the whole machine is connected, the connection relationship of the transfer plug is removed, and the connection relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com