Water injection well layered electric testing method employing metallic sheath detective cable

A metal sheath, detection cable technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problem of wasting manpower and material resources, and achieve the effect of reliable work and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

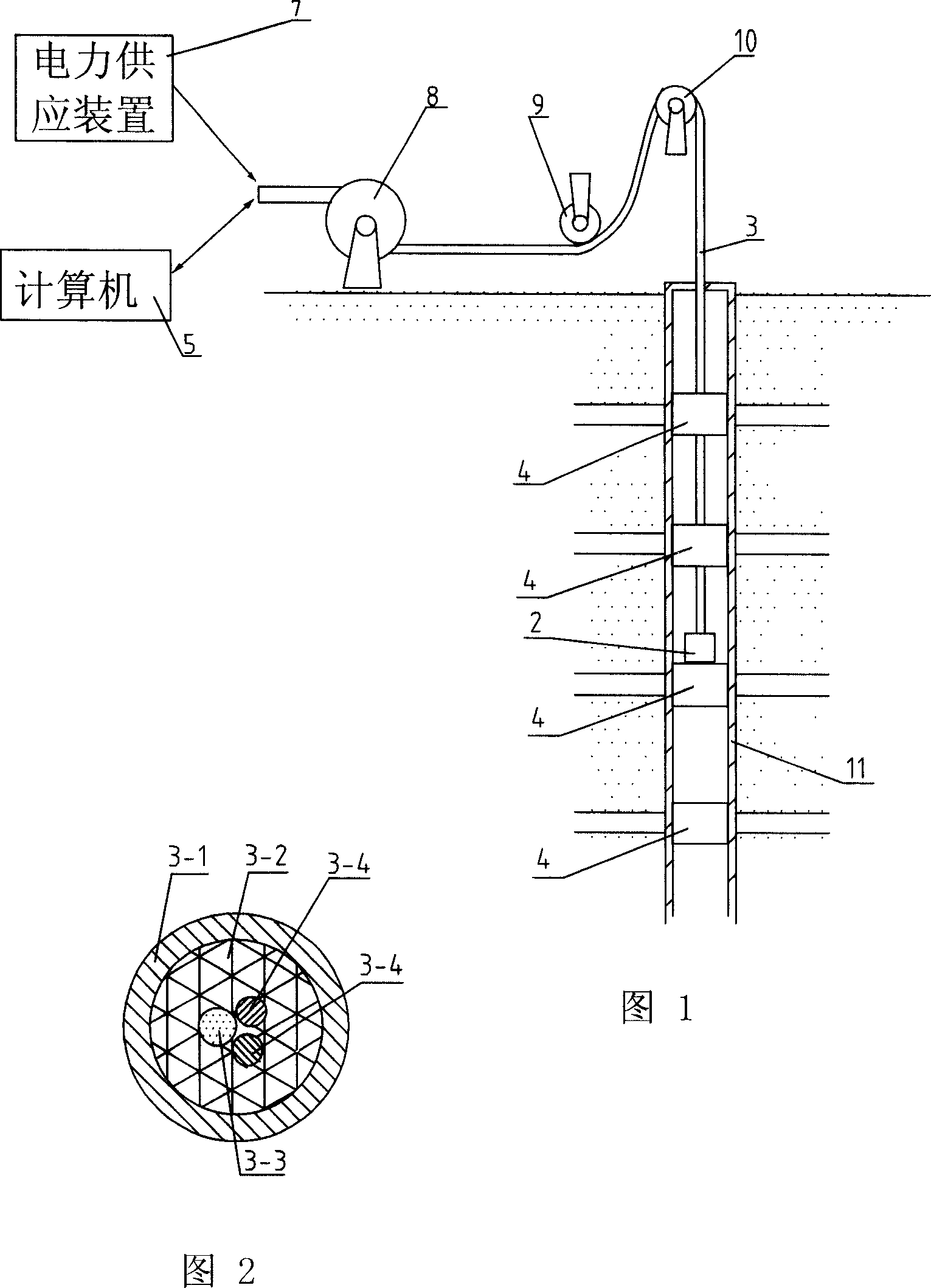

[0007] Specific implementation manner 1: The following specifically describes this implementation manner in conjunction with FIG. 1 and FIG. 2. It consists of the following steps: 1. The downhole measuring and adjusting instrument 2 is suspended by the test cable 3 to the interval to be deployed in the oil well 11 and is set under the command of the computer 5. The test cable 3 is made of a metal sheath located on the outer layer. 3-1. The insulating layer 3-2 at the middle layer, the communication line 3-3 at the core, and the power transmission line 3-4 are composed. The computer 5 set on the ground is connected to the communication line 3-3 of the test cable 3 Upper end; 2. The adjusting arm of the downhole measuring and adjusting instrument 2 is docked with the adjustable eccentric water injection plug 4 preset in the oil well 11, and water is injected into the interval that needs to be deployed in the oil well 11 and the water flow is tested, and the water in the adjusted int...

specific Embodiment approach 2

[0009] Specific implementation manner 2: The following specifically describes this implementation manner with reference to FIG. 1. The difference between this embodiment and the first embodiment is: the test cable 3 is wound on the cable winch 8. The cable winch 8 installed in the well raises or lowers the downhole tester 2 in the oil well, and the test cable 3 is wound in turn. The ground pulley 9 and the sky pulley 10 extend into the oil well 11. When the downhole tester 2 installed at the lower end of the test cable 3 is dropped into the well through the cable winch 8, the computer can collect the depth value of the test cable 3 into the oil well 11 to realize the accurate positioning of the downhole tester 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com