Jet pump and oil test technologies based on same

A technology of jet pumps and processes, applied in jet pumps, pumps, non-volume pumps, etc., can solve problems such as inability to pressurize through the annular space, and achieve improved effects and data collection quality, strong adaptability, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

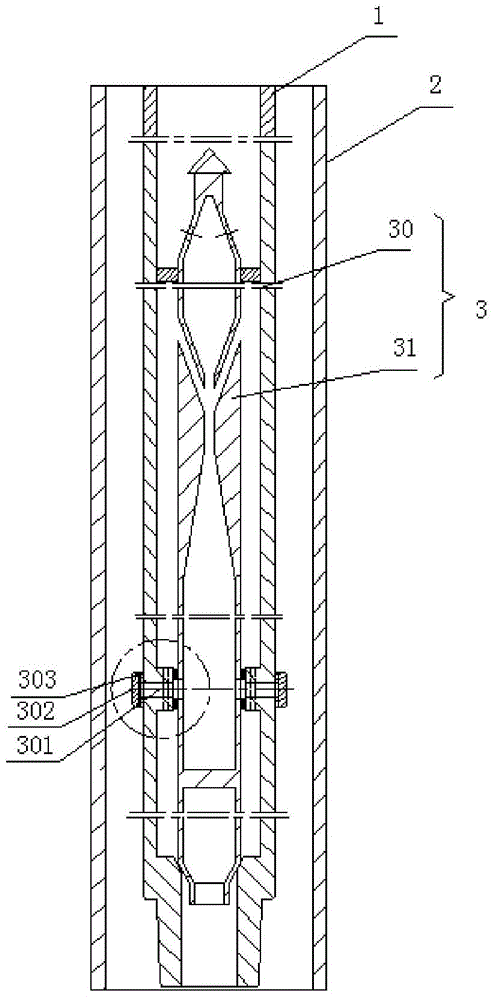

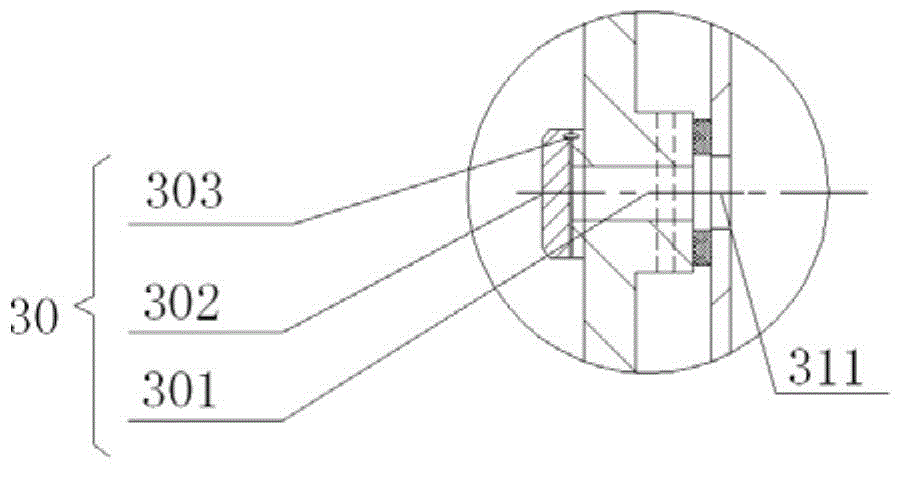

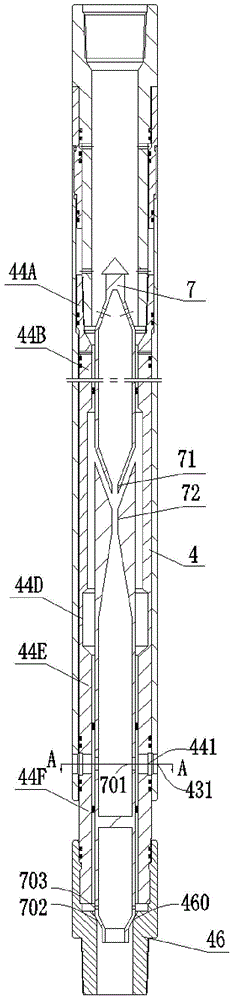

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art Modifications to various equivalent forms of the present invention fall within the scope defined by the appended claims of the present application.

[0041] The invention provides a jet pump, which can reliably control the opening or closing of the jet pump when the pressure-bearing capacity of the casing is low, so that the reservoir can be realized by running a set of well-testing process strings matched with it. Accurate fluidity of the pump discharge before transformation, medium and high pressure pump injection after transformation, and pump discharge after transformation.

[0042] The up or d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com