Guide rail type intelligent sliding sleeve sieve tube tool

An intelligent sliding sleeve, guide rail technology, applied in the production fluid, wellbore/well components, earthwork drilling and other directions, can solve the problem that the screen can not be guaranteed to be independent and fully opened, the pressure is not easy to control, and the acid fracturing effect is not ideal. and other problems, to achieve the effect of reducing well control risk and operation cost, simple structure and improving open rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

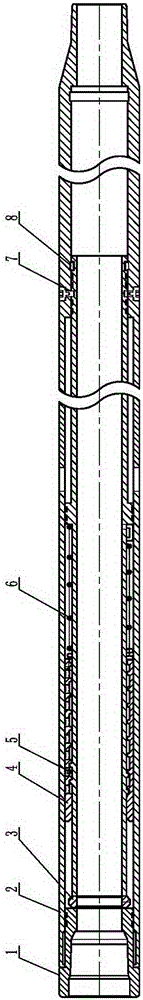

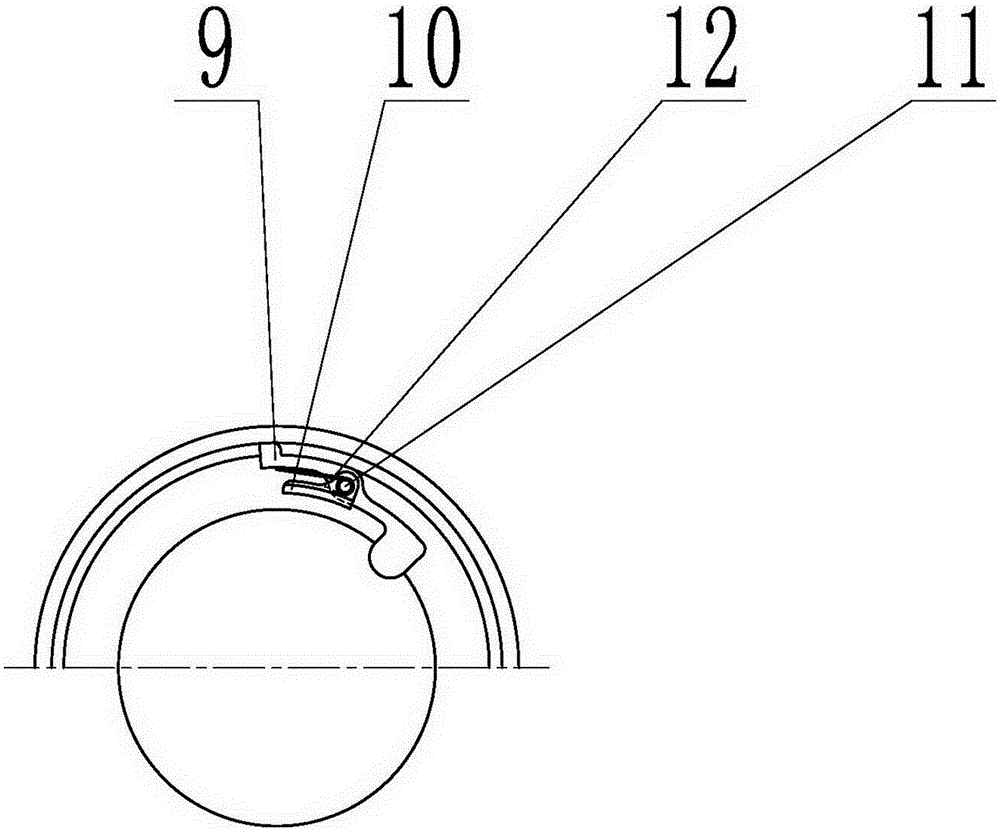

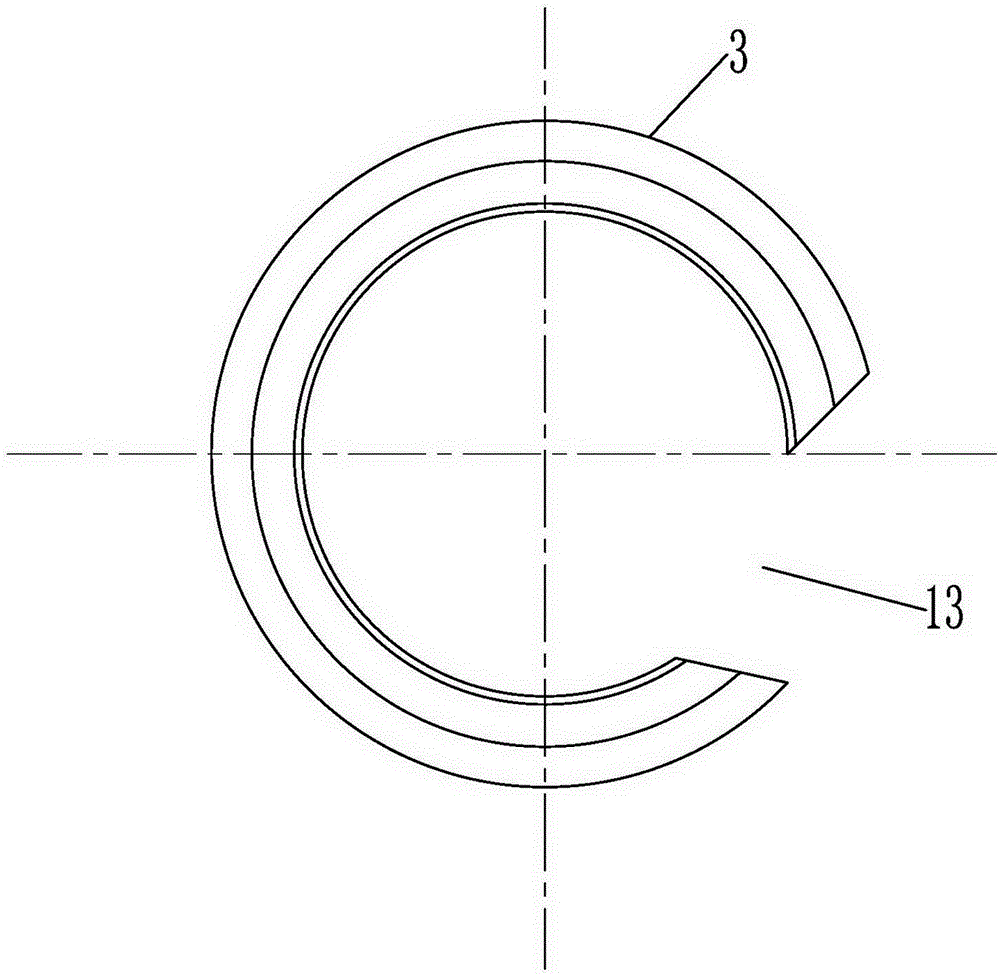

[0011] Embodiment 1, guide rail type intelligent sliding sleeve screen pipe tool, such as Figure 1-6 As shown, it includes a lifting joint 1 and a housing 2. The lifting joint 1 is a male and female joint. The external thread of the lifting joint 1 is matched with the female thread of the housing 2, so that the sliding sleeve screen tool A closed working chamber is formed inside, and a retractable C ball seat 3, a counting sleeve 4, a positioning sleeve 5, a spring 6, a shear pin 7 and a limit ring 8 are arranged on the housing 2; The end face fit between the ball seat 3 and the lifting joint 1 and the positioning sleeve 5; a housing limit groove is provided in the lower end tube of the housing 2, and the C ball seat 3 and the positioning sleeve 5 can slide in the housing 2 , in the middle section of the housing 2, a number of sieve holes are evenly distributed, and the rear end is provided with a pin hole, and a shear pin 7 is installed in the pin hole; the middle section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com