Gel solid slug segmented trip method

A kind of tripping and gel technology, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc. The effect of reducing well control risks and protecting reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

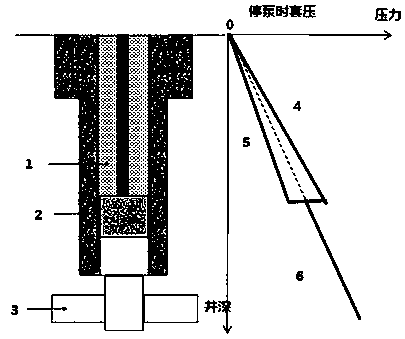

[0021] As a preferred embodiment of the present invention, it discloses a method for tripping out of a gel solid slug compartment, the steps of which are as follows:

[0022] Step 1: Pull out under pressure to the designed well depth, pump in the designed amount of gel, and pull out to the upper part of the gel slug;

[0023] The second step: cycle for n hours, and trigger the gel solidification by the formation temperature;

[0024] Step 3: After the gel is solidified, verify whether the downhole pressure is completely cut off. If it is completely cut off, the open well is tripped in the conventional way;

[0025] Step 4: When tripping in, go down the open well to the top of the gel solid slug, drill out the gel solid slug, then add pressure and go down to the bottom of the well with pressure to resume drilling.

Embodiment 2

[0027] As the best implementation mode of the present invention, concrete work process of the present invention:

[0028] Step 1: Pull out under pressure to the designed well depth, pump in the designed amount of gel, and pull out to the upper part of the gel slug 0.1-100m;

[0029] The second step: cycle for n hours (n=0.1-999), trigger gel solidification by formation temperature;

[0030] Step 3: After the gel is solidified, verify whether the downhole pressure is completely cut off. If it is completely cut off, the open well is tripped in the conventional way;

[0031] Step 4: When tripping in, go down the open well to the top of the gel solid slug, drill out the gel solid slug, then add pressure and go down to the bottom of the well with pressure to resume drilling.

[0032] Before the open well is pulled out, the gel is injected into the design position of the well, and then the temperature control triggers the solidification to form a slug, which cuts off the downhole p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com