Holder

A clamper and slip seat technology, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of large clamping force, loss of clamping force, small size, etc. Large force, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

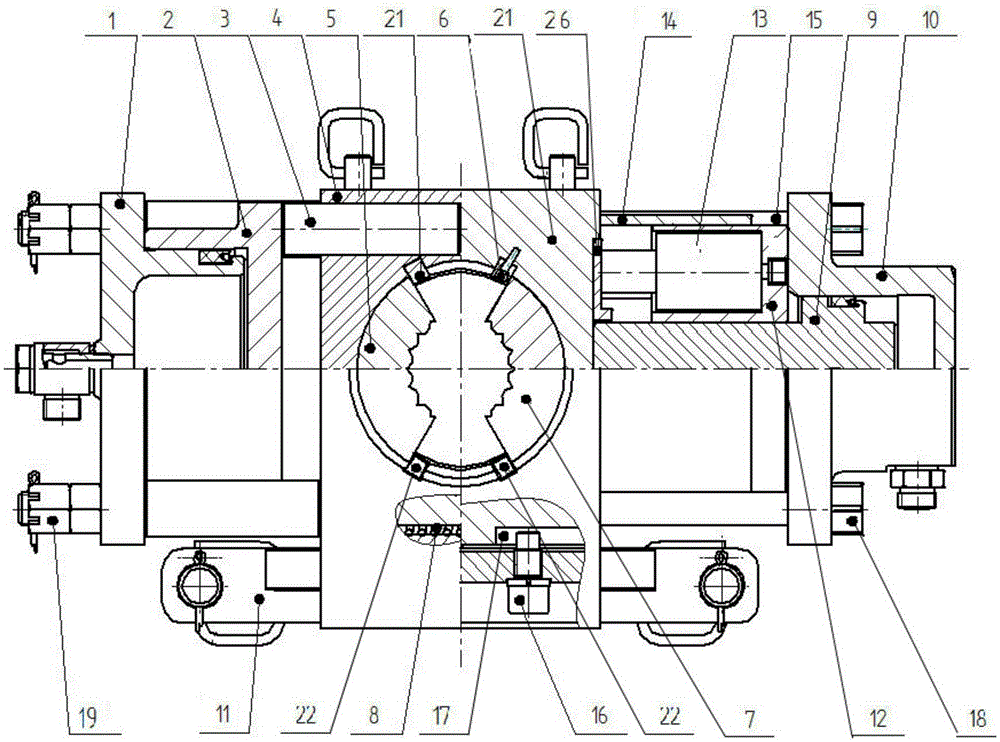

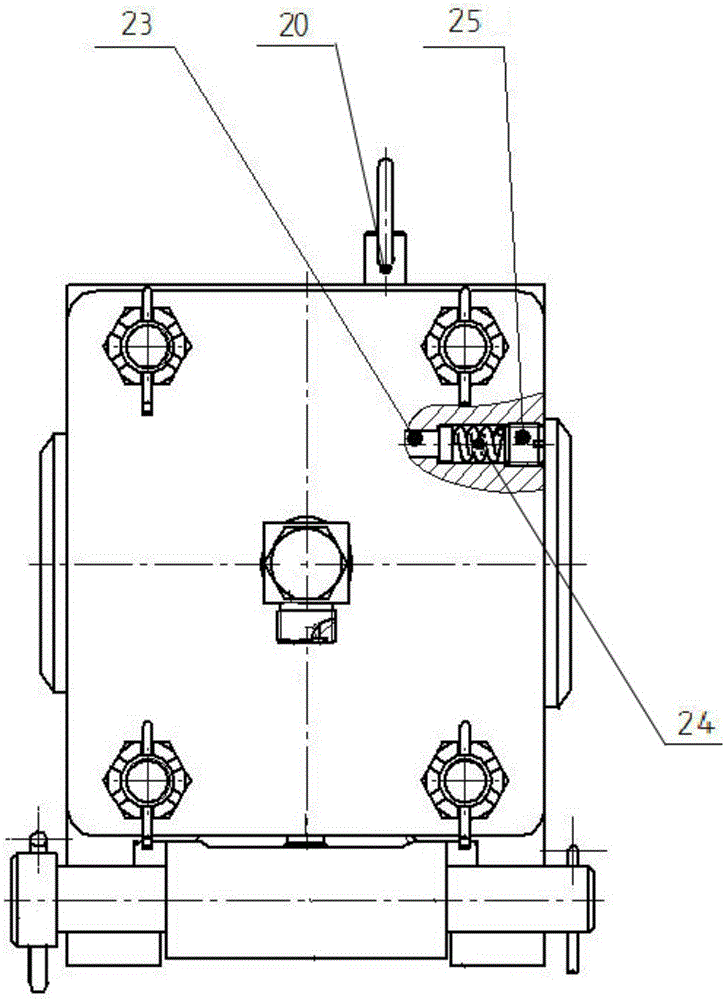

[0038] figure 1 Schematic diagram of the structure of the clamper provided by the embodiment of the present invention, figure 2 for figure 1 left view of . Such as figure 1 and figure 2As shown, the present invention provides a clamper, which includes a left cylinder piston 1, a left cylinder body 2, a top column 3, a left slip seat 4, a left slip seat 5, a right slip seat 6, and a right slip seat 7 , slip seat spring 8, right cylinder piston 9, right cylinder body 10, guide rail 11, nitrogen gas spring seat 12 and nitrogen gas spring 13; left cylinder piston 1 is inserted in left cylinder body 2, and the inner wall of left cylinder piston 1 is connected to the left The inner wall of the oil cylinder body 2 forms a left oil chamber for injecting hydraulic oil, and the ejection end of the left oil cylinder body 2 abuts against one end of the top column 3, and the top column 3 penetrates in the left slip seat 4, and the top column 3 The other end is in contact with the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com