Anti-sticking temperature-controllable material mixing machine

A material mixer and anti-sticking technology, applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of material loss, troublesome cleaning, poor mixing effect of materials, etc., and achieve precise control of mixing ratio , Guaranteed mixing effect, convenient cleaning effect in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The anti-adhesion and temperature-controllable material mixer of the present invention will be further described in detail through specific examples below.

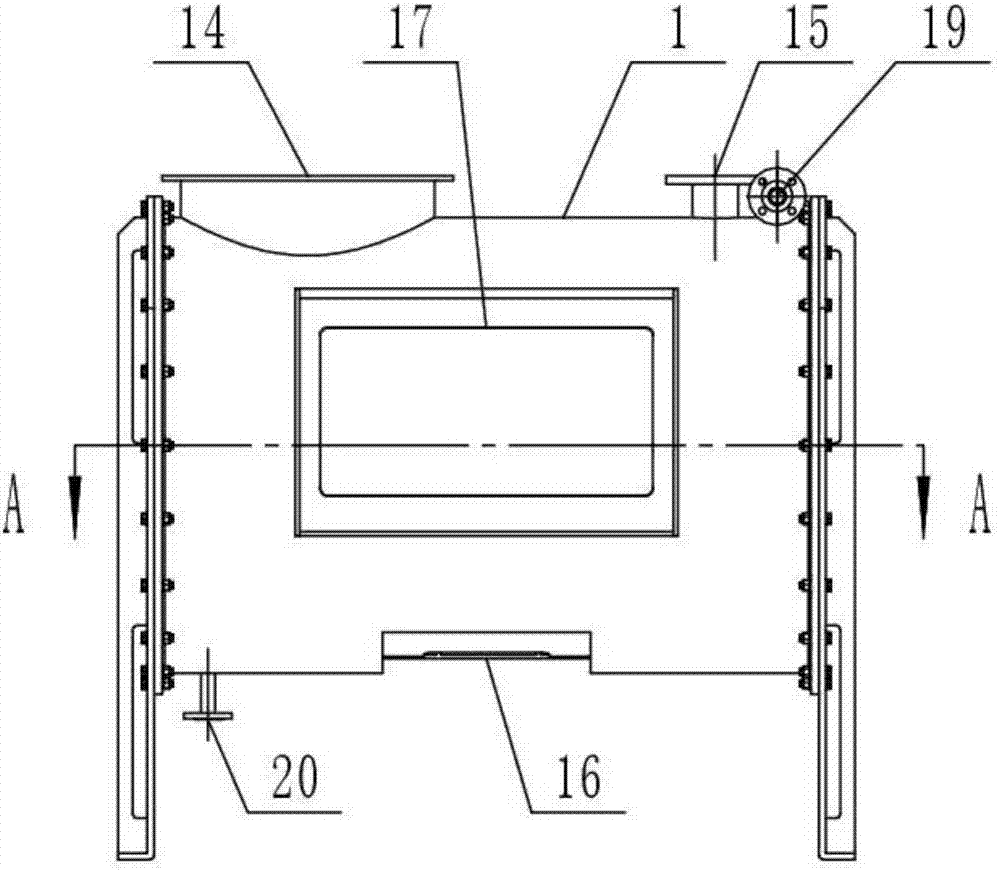

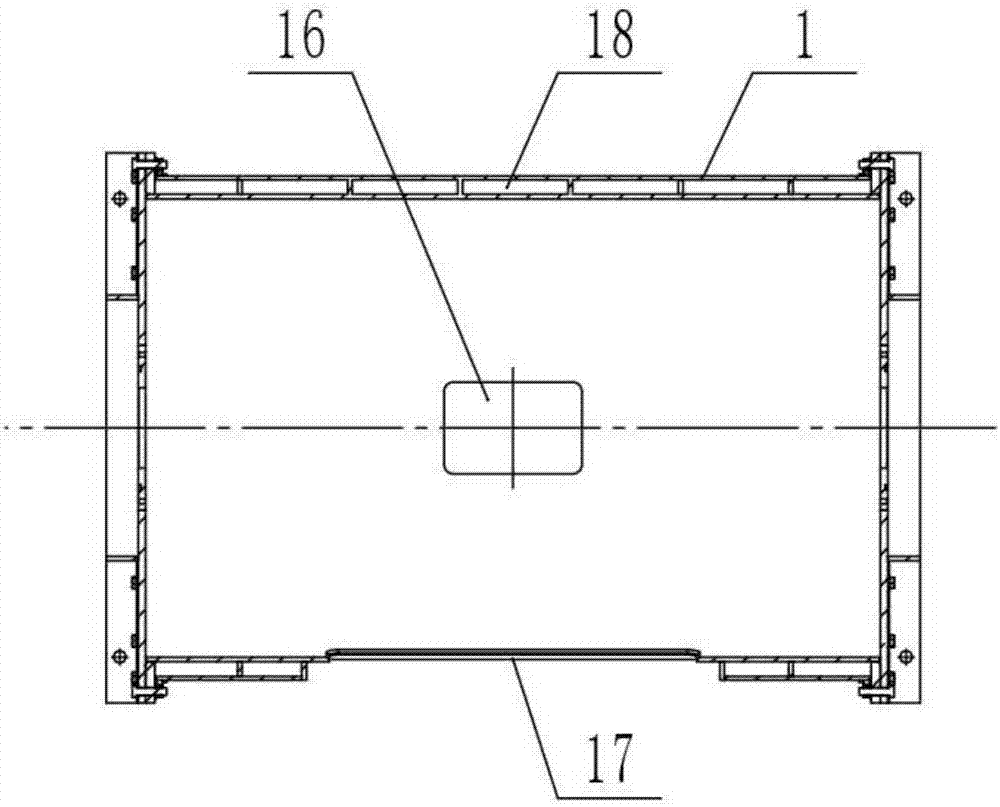

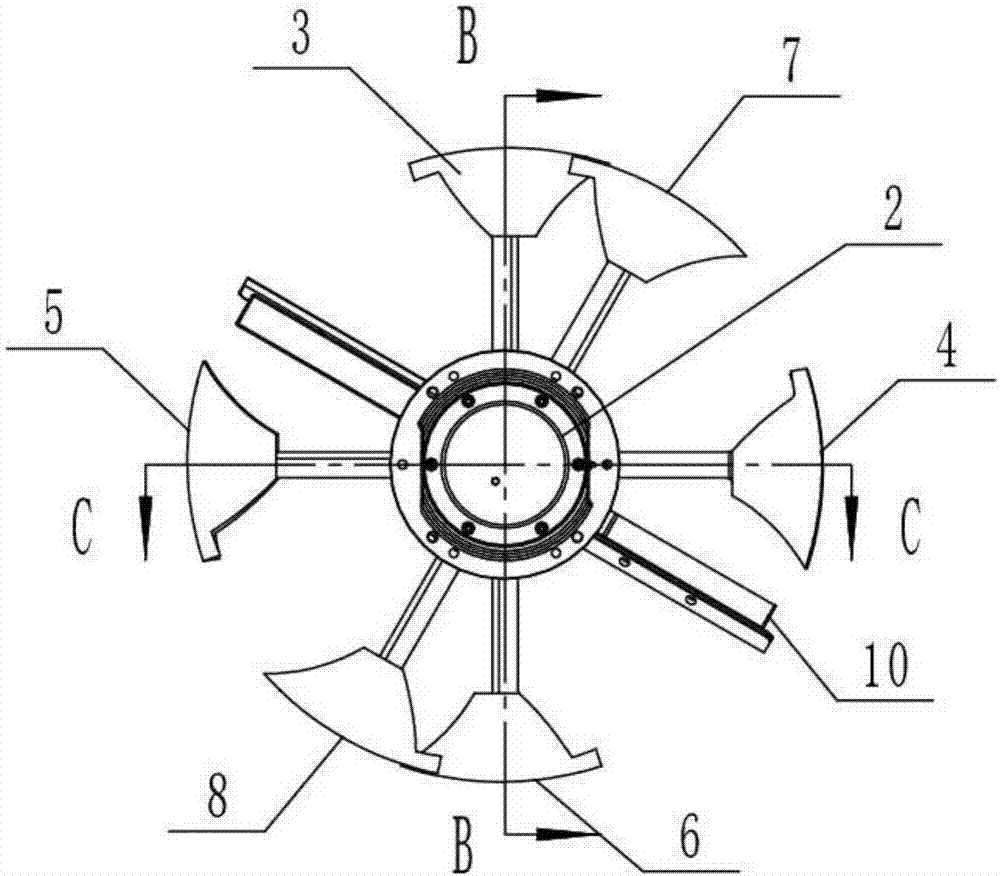

[0024] Such as Figure 1 to Figure 5 As shown, an anti-bonding, temperature-controllable material mixer includes a barrel body 1 and a main shaft 2 arranged in the barrel body 1, the two ends of the main shaft 2 are connected with the barrel body 1, and one end of the main shaft 2 extends The outside of the bucket body 1 is connected to the driving device, and the main shaft 2 is provided with six coulters, two half coulters 9 and two scrapers 10, wherein one half coulter 9 and one scraper 10 are located near the barrel body 1 One end, another half coulter 9 and another scraper 10 are located at the other end close to the barrel body 1, and six coulters are arranged at intervals on the main shaft 2, and adjacent coulters are interlaced; the barrel body 1 The parts in contact with the material inside are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com