Down-hole sliding-sleeve-type blowout-preventing switching valve

A switch valve and sliding sleeve type technology, which is applied in the direction of wellbore/well valve devices, wellbore/well components, earthwork drilling and production, etc., to solve the problem of lax setting and injury accidents, reduce the risk of well control, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

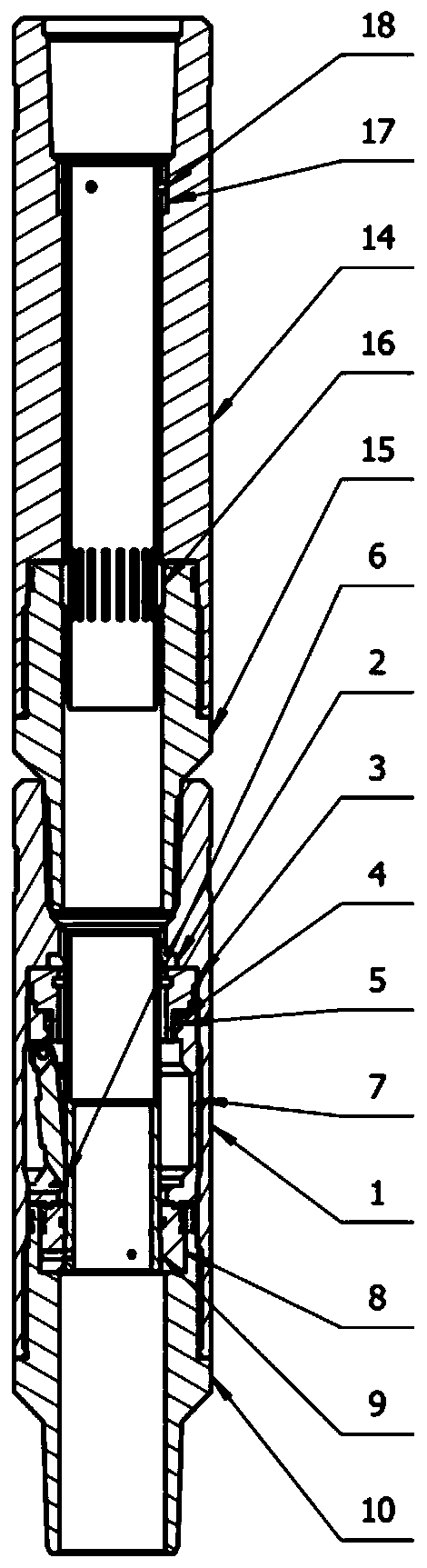

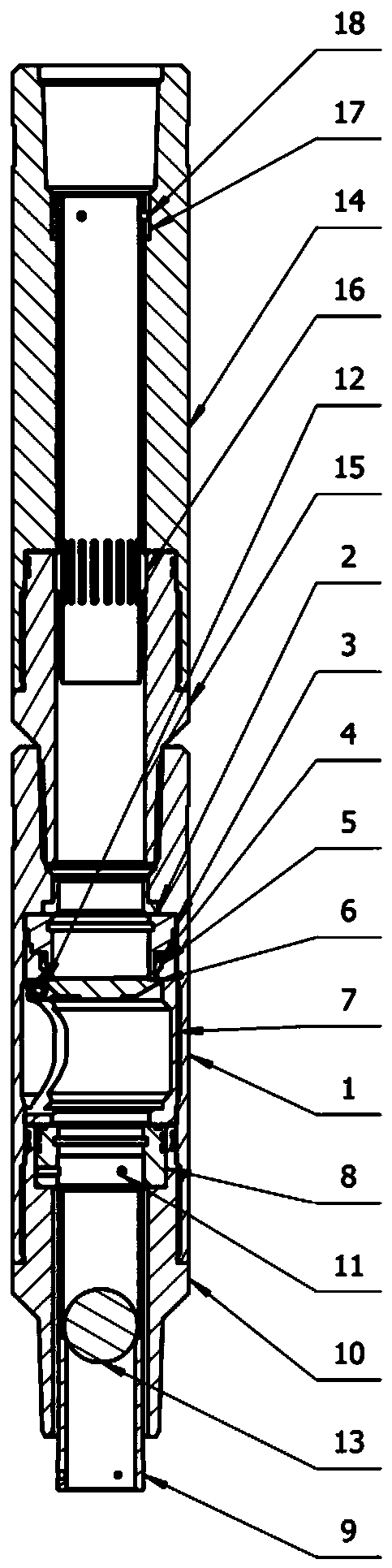

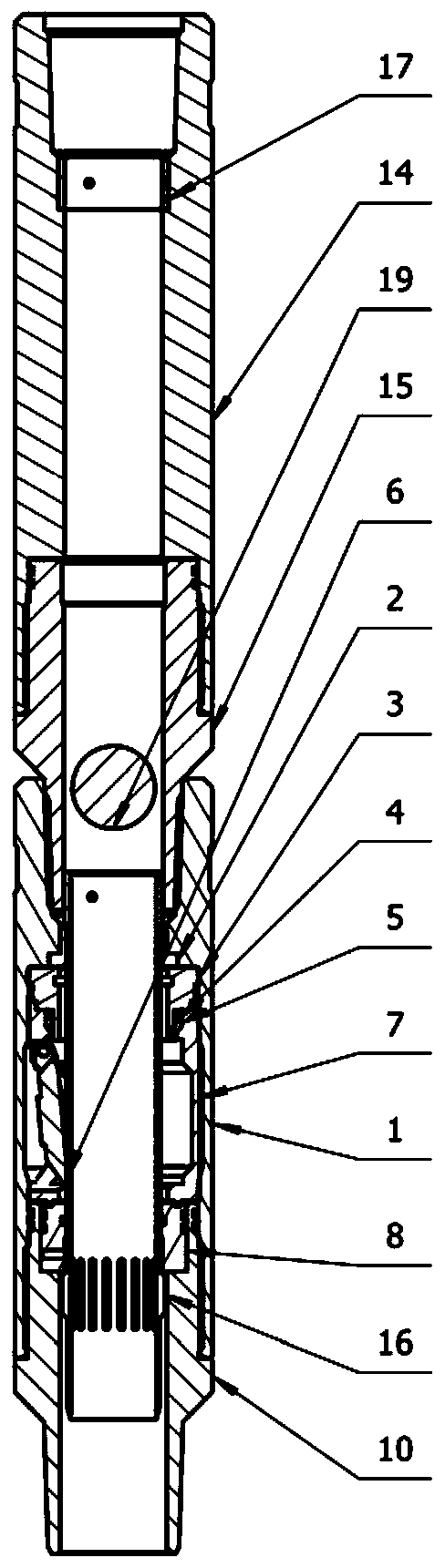

[0024] Embodiment one, such as figure 1 , 2 As shown, a downhole sliding sleeve type blowout prevention switch valve includes a blowout prevention switch valve main body (housing) and a blowout prevention sliding sleeve main body; the blowout prevention sliding sleeve main body is fixed above the blowout prevention switching valve main body, and the blowout prevention switch The main body of the valve is equipped with an anti-wear alloy sleeve, a blowout-proof switch valve seat, an elastic seal, a hard seal, a blowout-proof switch tongue, a support frame for the tongue plate, a fixed ring for a blowout-proof switch valve sliding sleeve, a blowout-proof switch valve sliding sleeve, Bottom joint of BOP switch valve, pin, torsion spring; under the wear-resistant alloy sleeve is sleeve-shaped BOP switch valve seat; ring-shaped elastic seal is used to seal and install the BOP switch valve seat on the main body of BOP switch valve , the valve seat of the BOP switch valve is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com