Blowout prevention valve

A blowout preventer and floating core technology, which is applied in wellbore/well valve devices, wellbore/well components, and earth-moving drilling and production, etc., can solve the problems of insufficient oil pipe blockage, difficult operation, and difficulty in blocking the liner. , to achieve the effect of accurate delivery, convenient operation and reliable blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

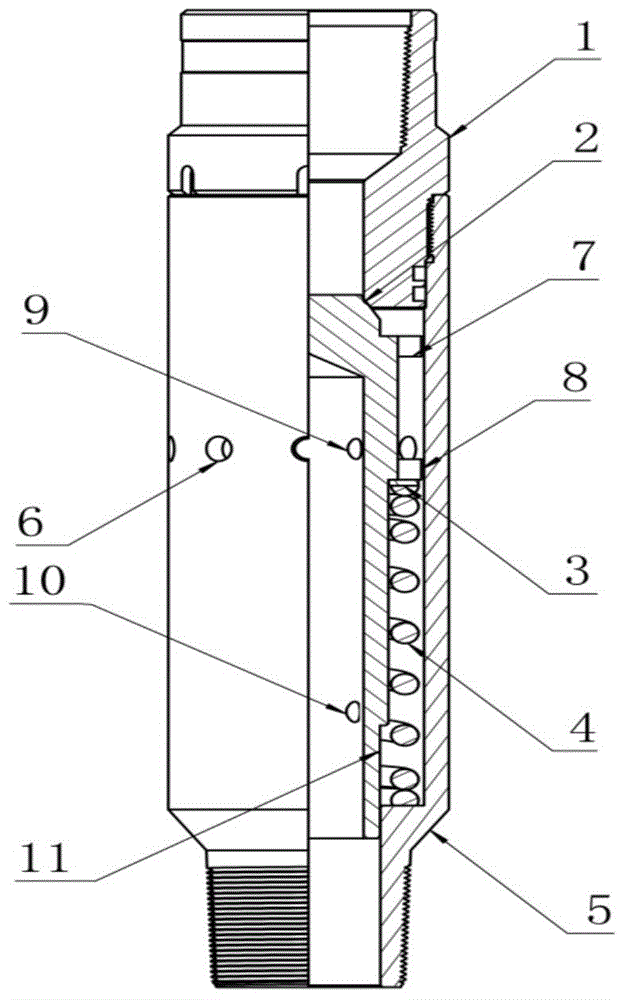

[0030] Such as figure 1 As shown: the blowout preventer of the present invention prevents blowout when lifting and lowering the pipe string and prevents blowout during re-operation. During the process of lifting and lowering the pipe string, the floating mandrel 2 moves upward due to the high-pressure flow at the bottom of the well. The fluid medium enters the blowout preventer valve from the lower end of the main body joint 5 or several outer wall guide holes 6 on the outer wall, but the floating mandrel 2 seals the step hole of the upper joint 1 of the blowout preventer valve to form a seal, which plays a role Anti-blowout effect.

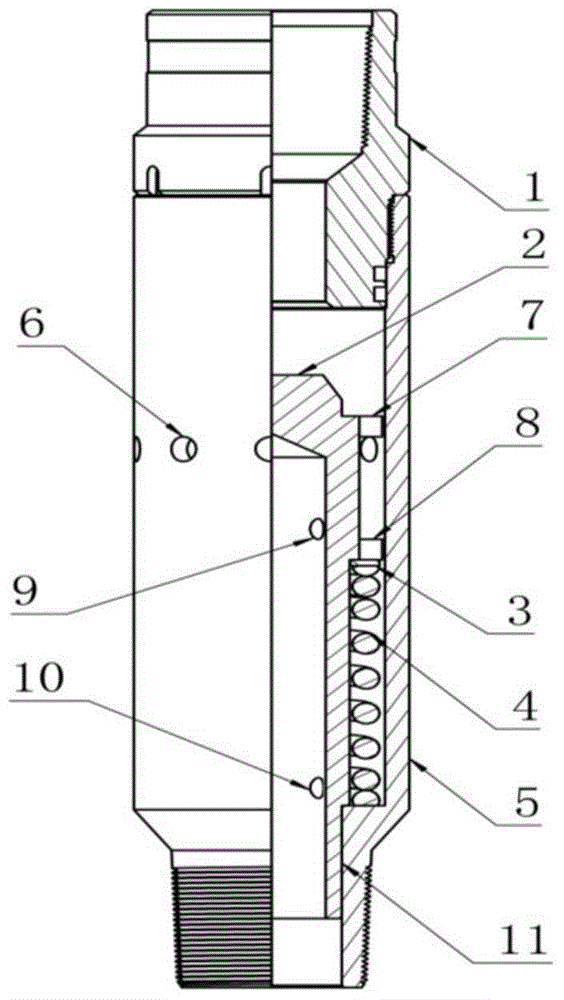

[0031] Such as figure 2 As shown: when the internal blowout preventer valve of the present invention is being injected or used, the pipe string is lowered to reach the predetermined position, and the oil pipe is being pressed until the floating mandrel 2 moves down, and the supporting and righting upper body 7, the supporting and righting lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com