Intelligent well cementation slide sleeve separate-layer fracturing transformation process pipe column without stage limitation

A process string and intelligent cementing technology, which is applied to wellbore/well components, wellbore/well valve devices, production fluids, etc. Issues such as controlled mining and selective mining in the later stage, leakage at pipeline connections, etc., can reduce the risk of manual operation, reduce the risk of well control, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

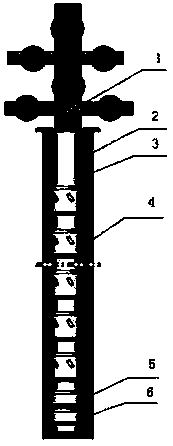

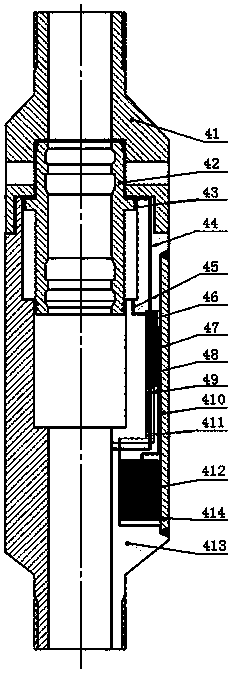

[0013] The process pipe string of the present invention is set in the cement sheath 2, the upper end is connected to the wellhead 1, and is composed of a multi-stage intelligent cementing sliding sleeve 4 connected through the casing 3, and a floating hoop 5 and a floating shoe 6 connected to the tail end of the pipe string. The upper cylinder 41 of the intelligent cementing sliding sleeve 4 is threadedly connected to the lower cylinder 413 , and a piston 42 sealed by a sealing ring 43 is arranged in the chamber connected between the upper and lower cylinders. The wall of the upper cylinder 41 is provided with a radial fracturing port, and the wall of the lower cylinder 413 is provided with grooves, and the grooves are buried with hydraulic pipelines A44, hydraulic pipelines B45, and two-position four-way electromagnetic valves connecting the hydraulic pipelines. Valve 46, battery 47, wireless induction receiving device 48, hydraulic pipeline C49, hydraulic pipeline D410, anten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com