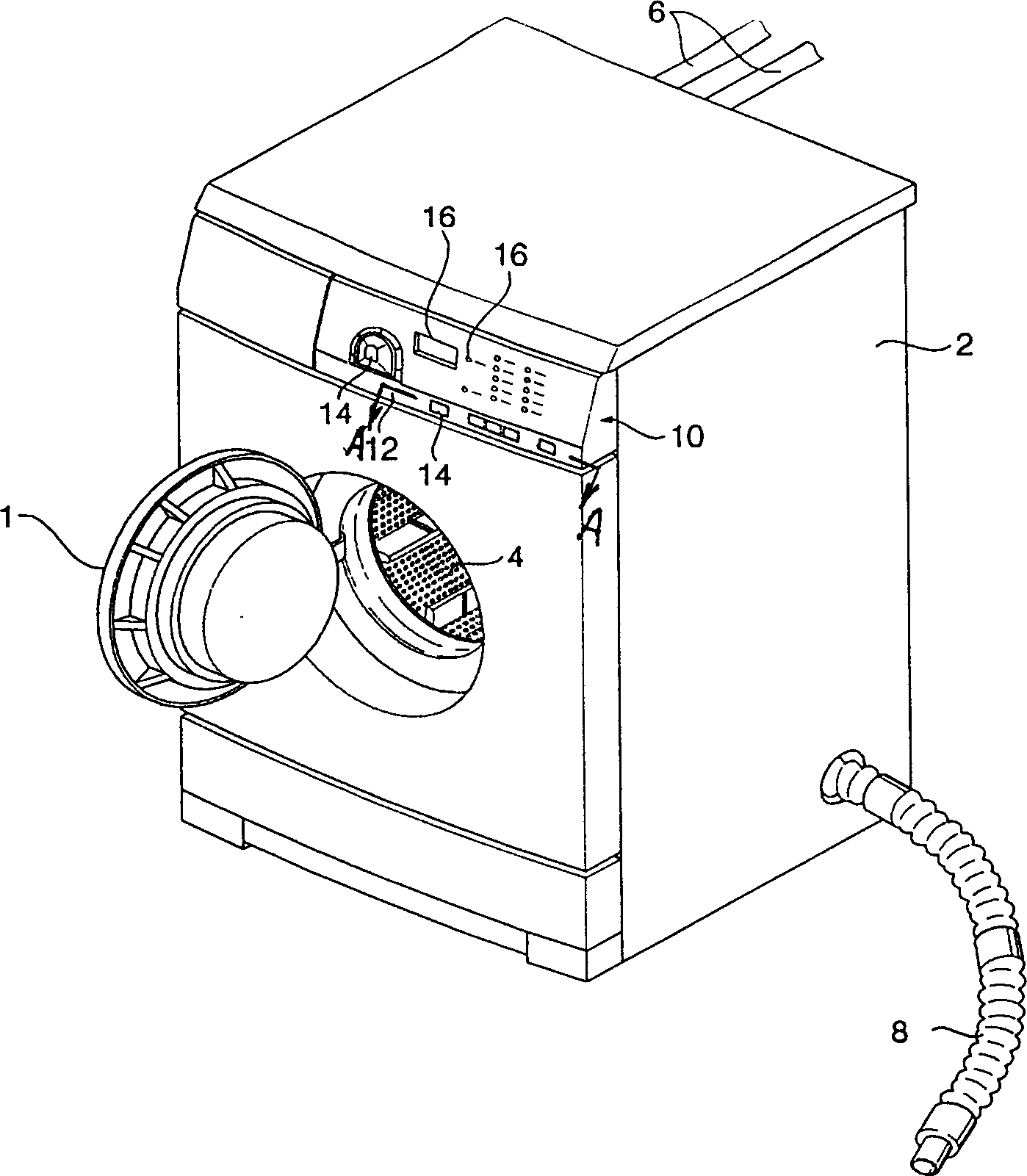

Button assembling structure of washer

An assembly structure and washing machine technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of button 14 assembly position replacement, etc., and achieve the effect of improving appearance quality and preventing mutual replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

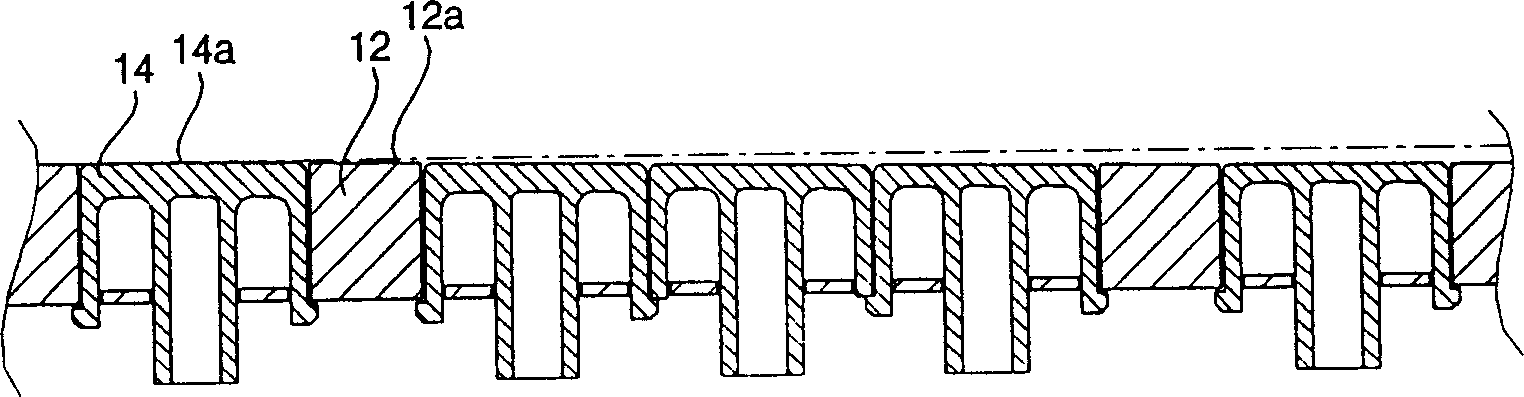

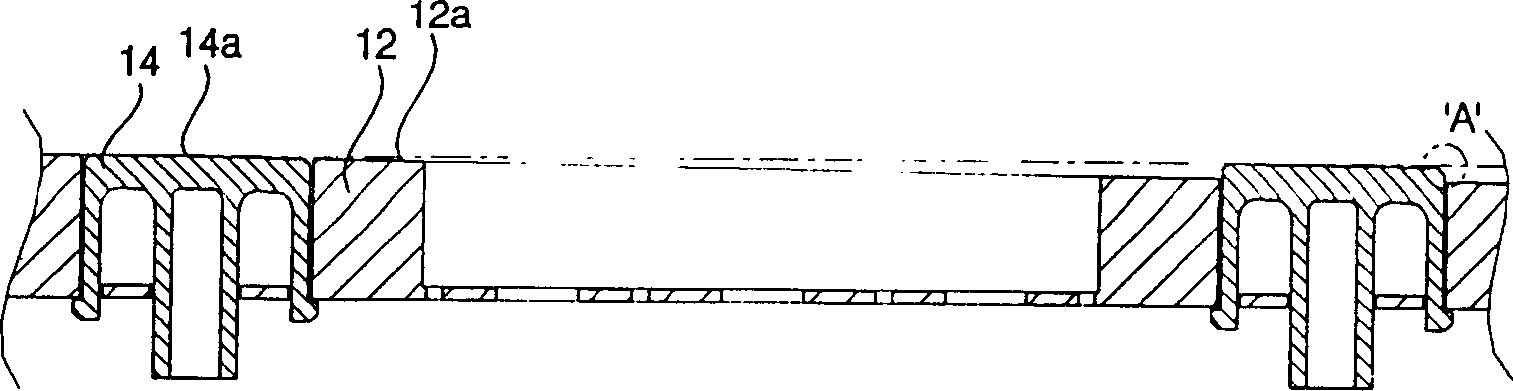

[0022] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. like Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the button assembly structure of the washing machine of the present invention includes: a control panel 50, whose surface 50a forms a slow left and right curved surface, and a plurality of square holes 51 for installing buttons are formed side by side at the bottom; The holes 51 are assembled in one-to-one correspondence, and the buttons can be operated at the same time; the button position determination device 60 determines the assembly position of each button 52, so that each button 52 is assembled in the correct position in the plurality of square holes 51.

[0023] The button 52 includes the following structure: the button panel 52a has the same shape as the button 52 and the square hole 51, so that the button 52 is fully clamped in the square hole 51, and when the surface of the button 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com