Control rod rod position measuring system based on electric vortex sensor

An eddy current sensor and measurement system technology, applied in the field of reactor measurement and control, can solve the problems of low measurement accuracy, slow response speed, difficult maintenance, etc., and achieve the effects of meeting interchangeability requirements, fast response speed, and avoiding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

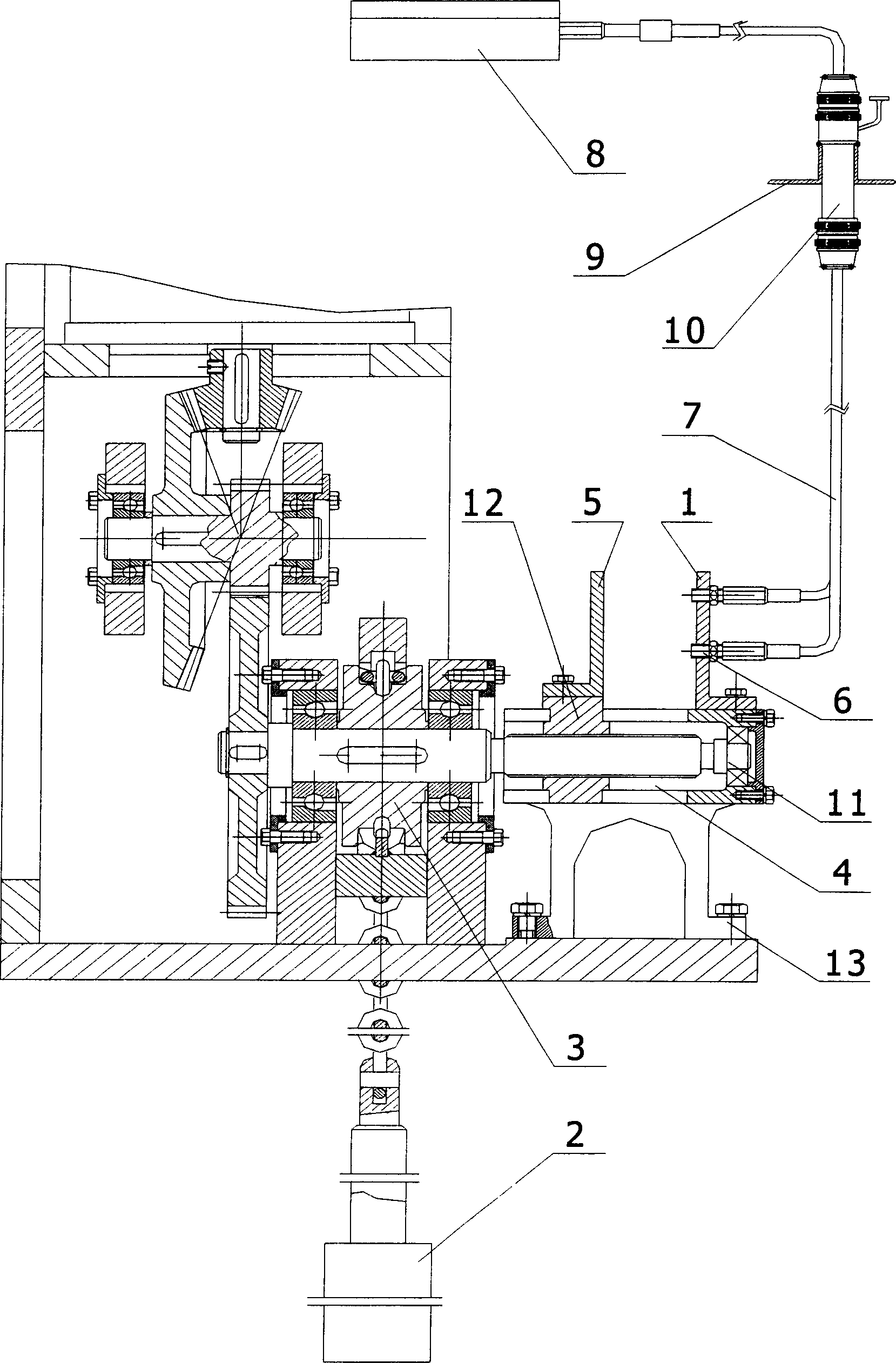

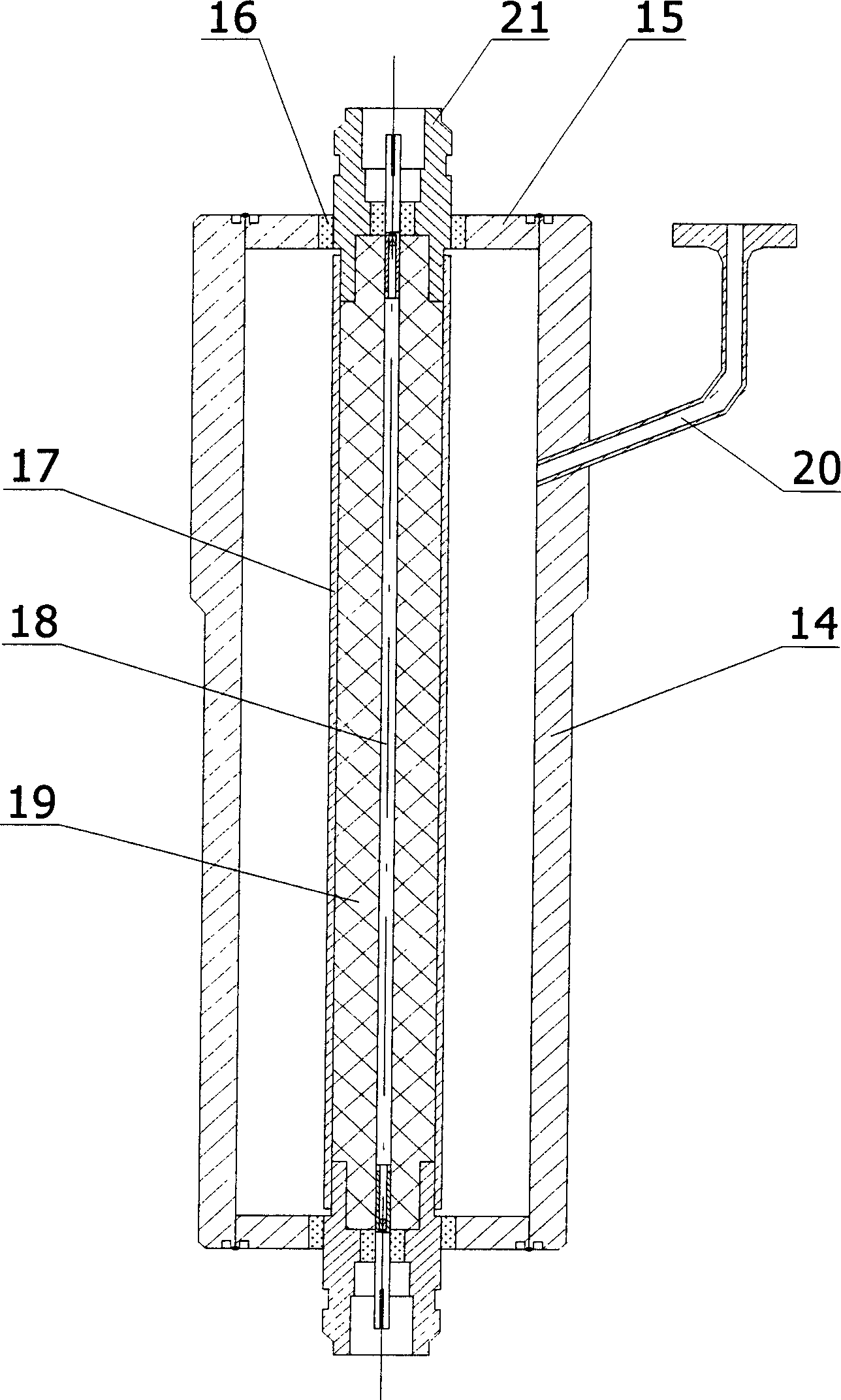

[0013] The control rod position measurement system based on the eddy current sensor provided by the present invention is composed of an eddy current sensor 1, a control rod assembly 2, a sprocket-chain device 3, a precision screw-nut assembly 4, and a measured body 5. The sensor 1 includes a sensor probe 6 , a signal transmission cable 7 with an electrical penetration 10 and a preamplifier 8 , and the precision screw-nut assembly 4 includes a precision screw 11 , a nut 12 and its bracket 13 . The eddy current sensor 1 is a non-contact displacement and vibration sensor based on the high-frequency eddy current effect, which can perform precise non-contact measurement of the motion parameters of metal objects entering its measurement range. In order to adapt to the helium environment of high temperature, high pressure and radioactivity in the reactor, the probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com