Gapping machine with positioning devices

A positioning device and technology for dimensioning, applied in the direction of sliding fastener components, applications, fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

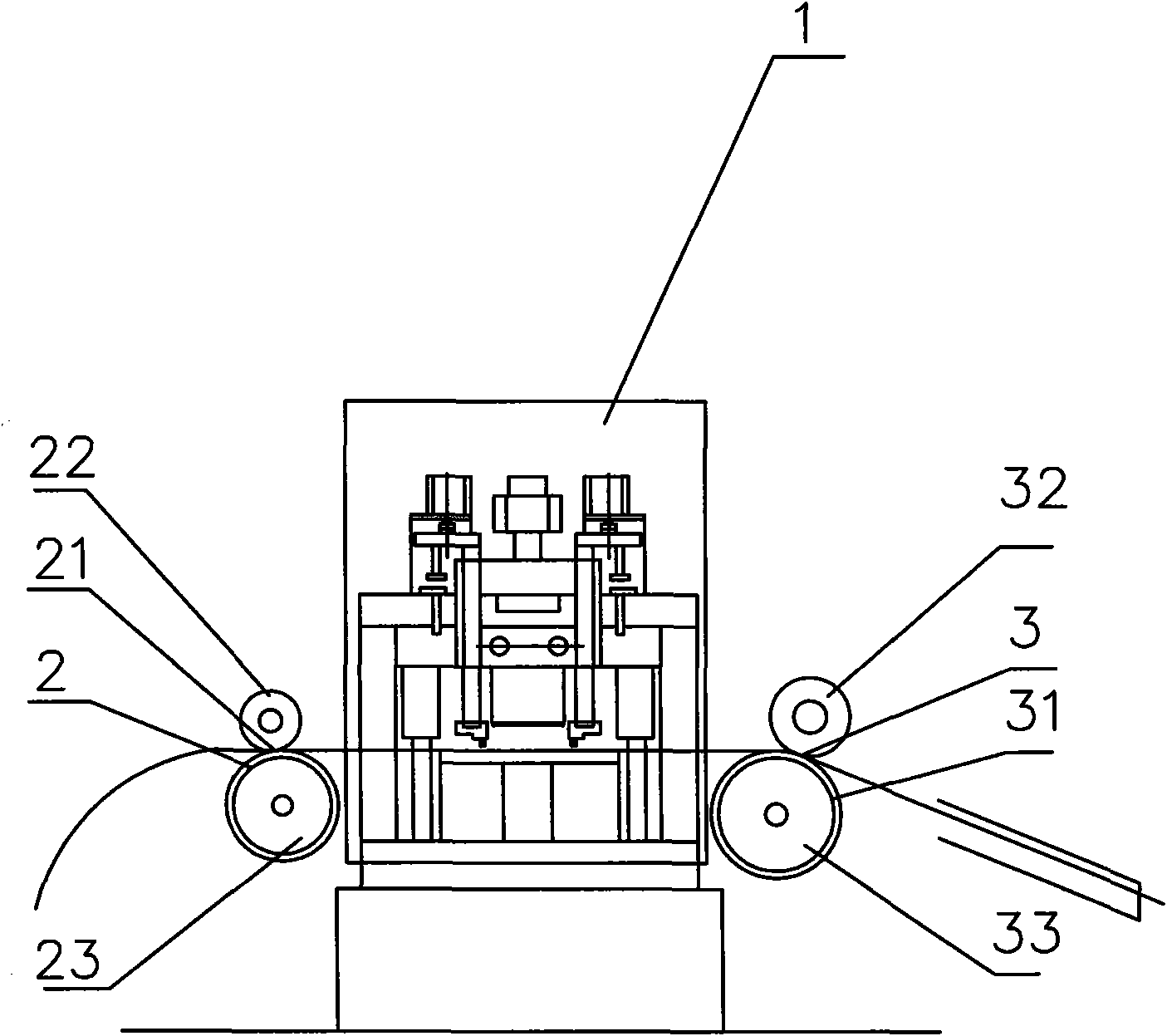

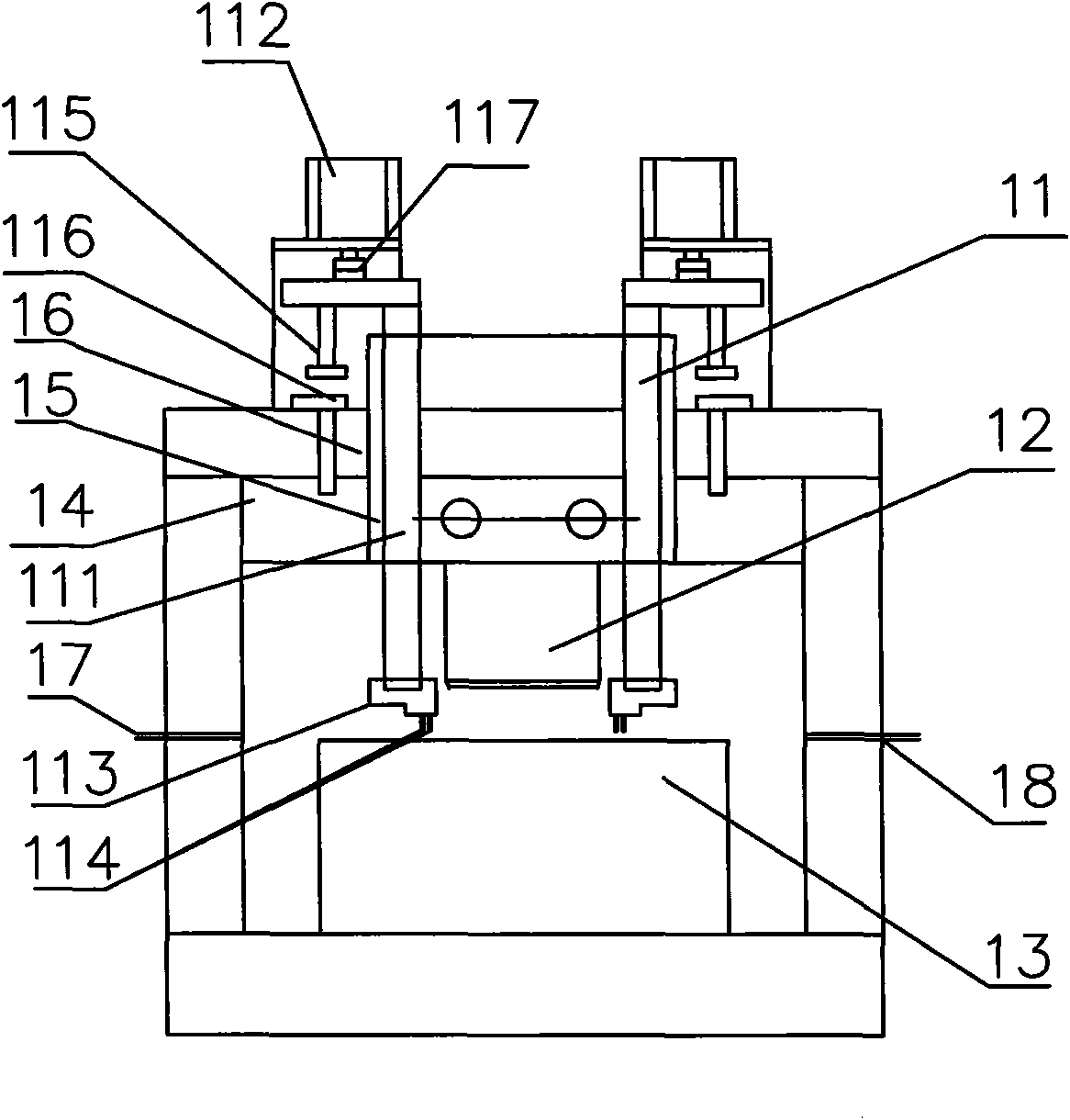

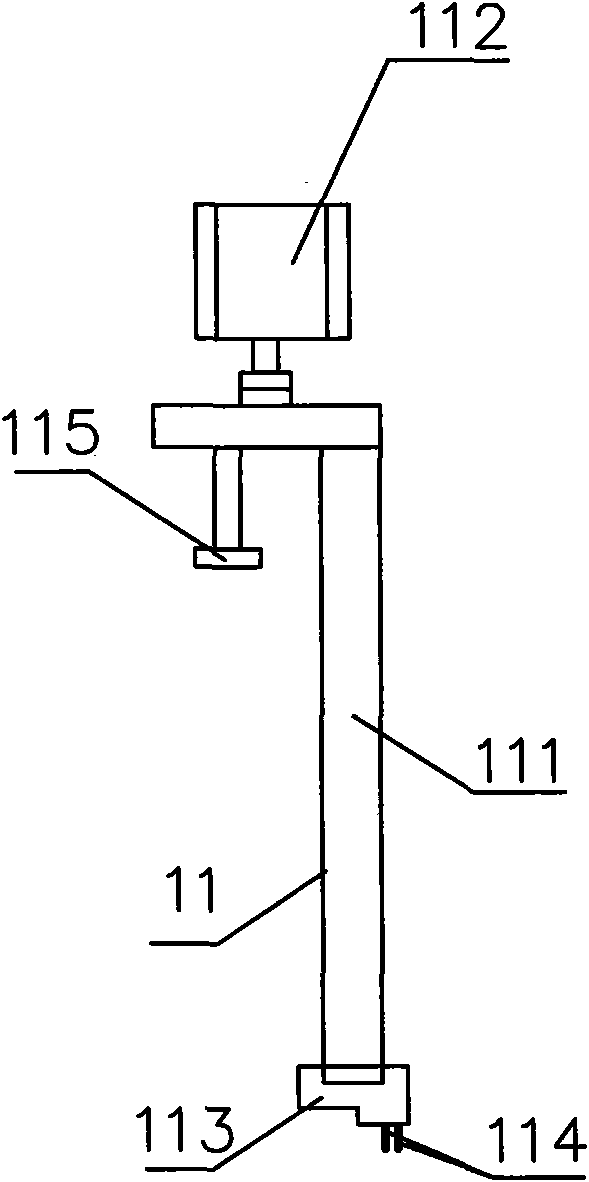

[0019] A sizing machine with a positioning device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a fixed-size mold 1, an input chain guide device 2 that delivers the zipper chain to the fixed-size mold 1, and an output chain guide device 3 that outputs the zipper chain from the fixed-size mold 1. The fixed-size mold 1 includes a fixed-size upper knife Device 12, fixed-size cutting device 13, fixed seat 14, fixed-size mold frame 15, guide groove 16, two left and right symmetrical positioning devices 11, and described fixed-size mold 1 also includes zipper chain lead-in end 17 and zipper chain export end 18, the positioning device 11 is a cylinder double-needle positioning device, and the cylinder double-needle positioning device is equipped with a moving rod 111 that can move through the guide groove 16, a cylinder 112 that is fixedly connected to the moving rod 111, and the moving rod 111. The connected needle mold 113 and the two positioning p...

Embodiment 2

[0021] A sizing machine with a positioning device, such as Figure 5 As shown, the chain belt enters the sizing machine through the chain belt conveying device 4, first passes through the feed wheel 21 and the pressing wheel 22, then enters the sizing die 1, and then discharges from the right side of the sizing die 1 end out, pass between the discharge wheel 31 and the pressure wheel 32, and then walk out of the sizing machine; the conveying of the chain belt is mainly completed by the rotation of the pulling motor 33 connected to the discharge wheel 31, and the feed wheel 21 is connected The chain belt length counter 23 calculates the length that the chain belt has walked through; after the chain belt walked through the set length, the material pulling motor 33 stopped rotating, the chain belt stopped moving, and waited still. At this time, the left cylinder double needle positioning device 11 action, The left movable needle mold 113 moves downward, and the positioning double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com