Multilayer interconnection shutter lifting device

A technology of lifting equipment and rolling shutters, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of inability to realize cargo transportation and transfer, single transportation path, simple function, etc., and achieve high degree of automation and flexible transportation , The effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

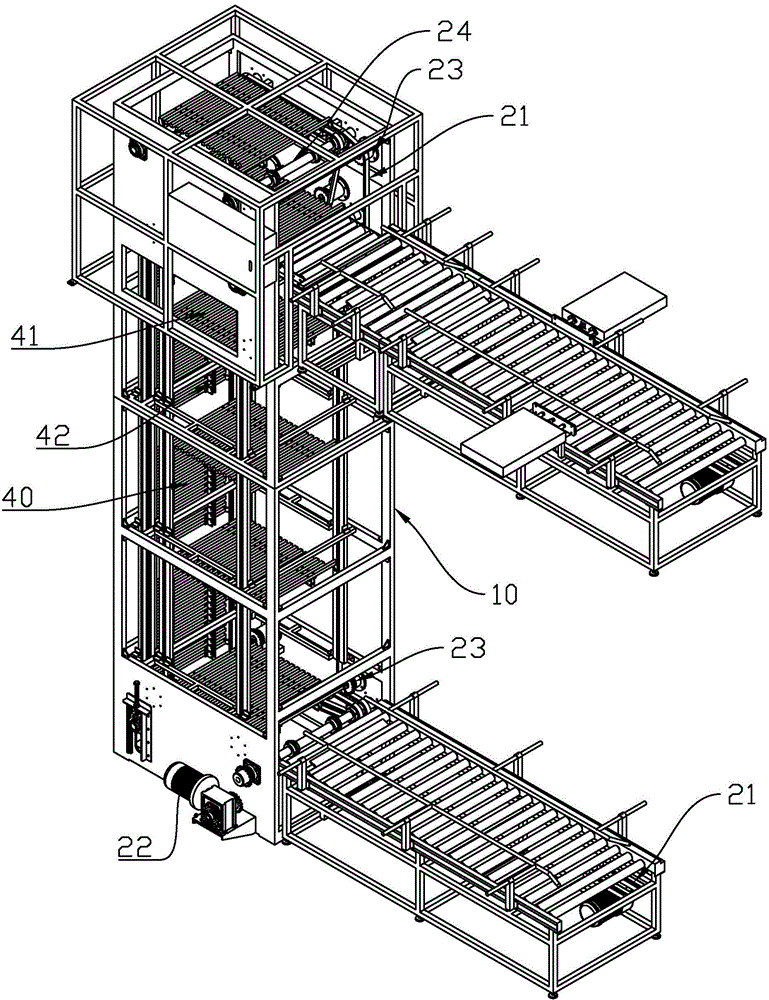

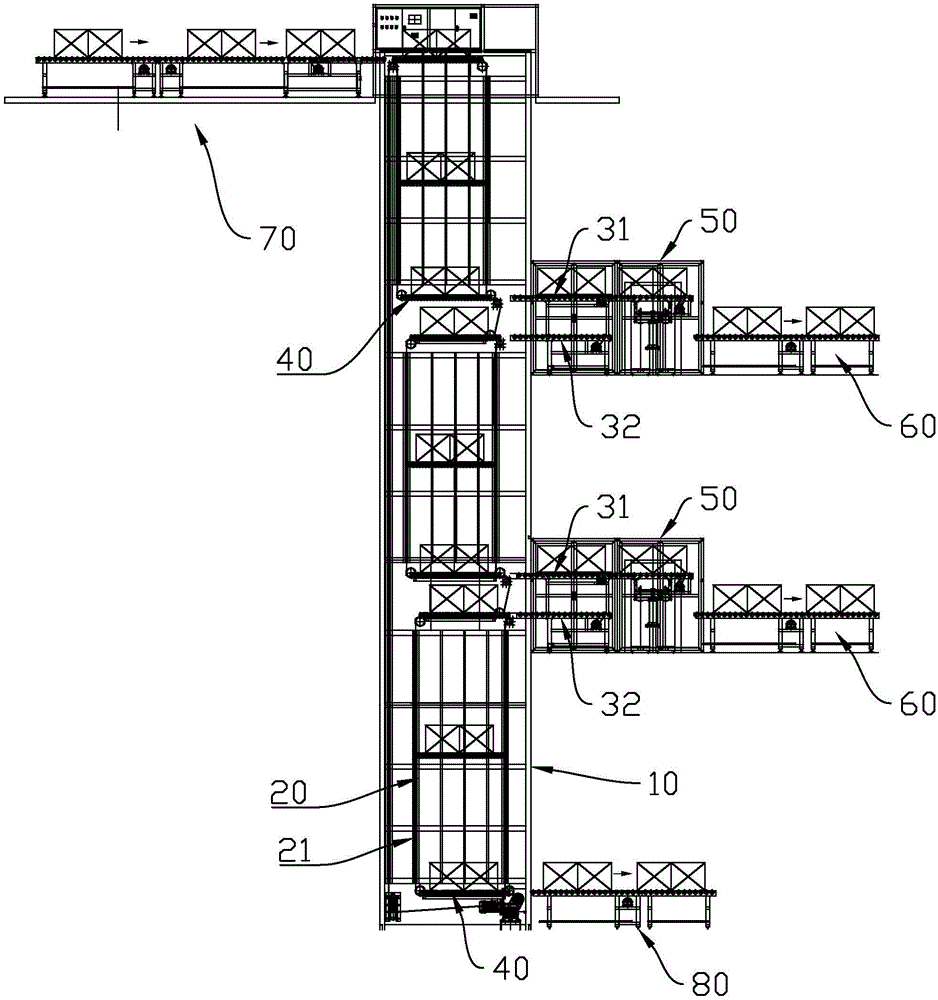

[0022] Such as Figure 1 to Figure 6 As shown, the multi-layer intercommunicating rolling shutter lifting equipment of the present invention can realize multi-layer intercommunication transportation of articles, and it can transport articles to any layer, thereby facilitating the transportation of articles or the logistics transportation of goods. The multi-layer intercommunicating rolling shutter lifting device of the present invention can be used in the fields of assembly line production operations in factories, logistics transportation in automatic warehouses, etc. In this embodiment, it is used in vertical logistics transportation of articles.

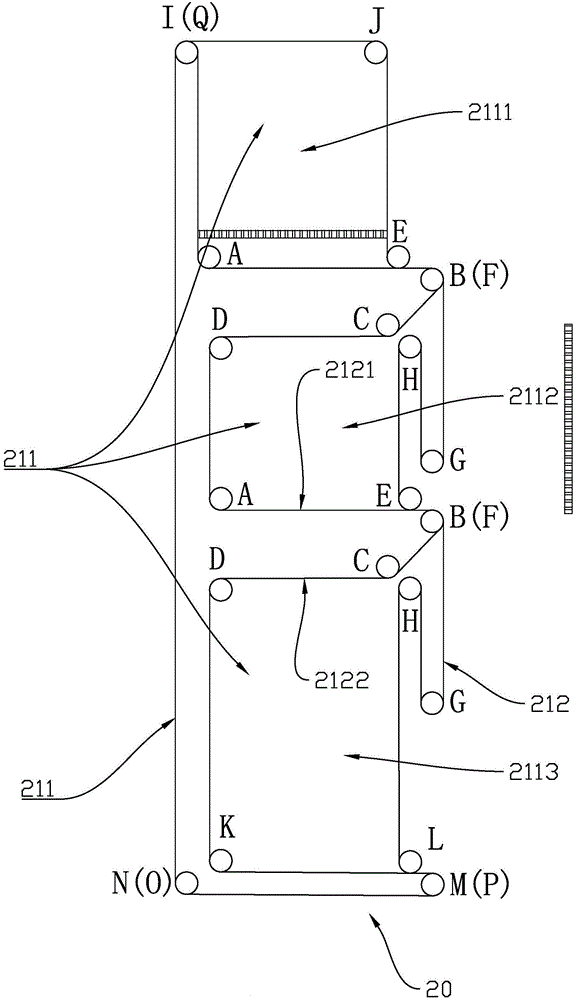

[0023] Such as figure 1 , figure 2 As shown, the multi-layer intercommunicating roller blind lifting equipment of the present invention includes a frame 10, a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com