Mining plate-belt feeder

A feeder, plate and belt technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of limited use occasions, high noise, high power loss, etc., to reduce power loss, reduce operating noise, Low rolling friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

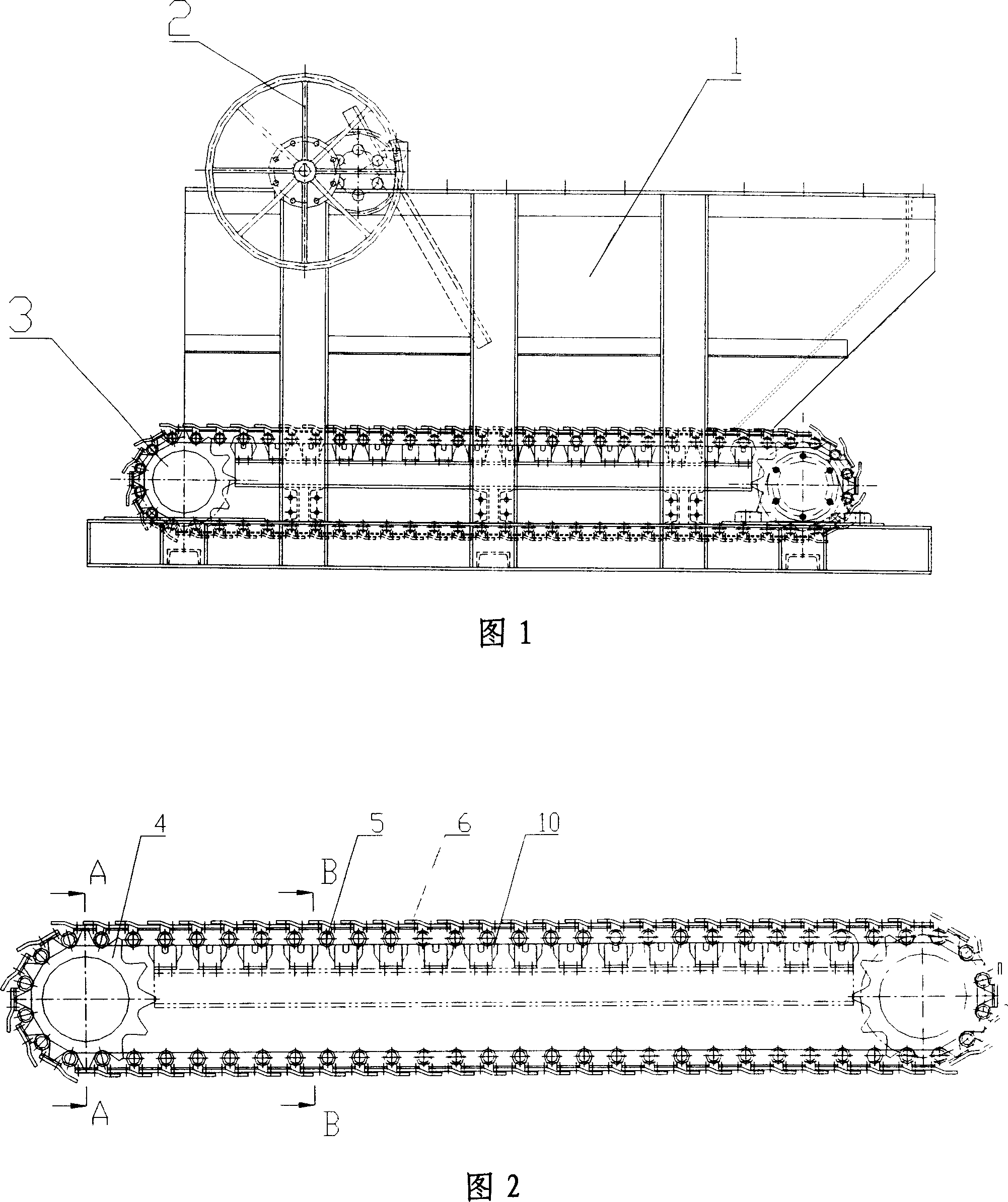

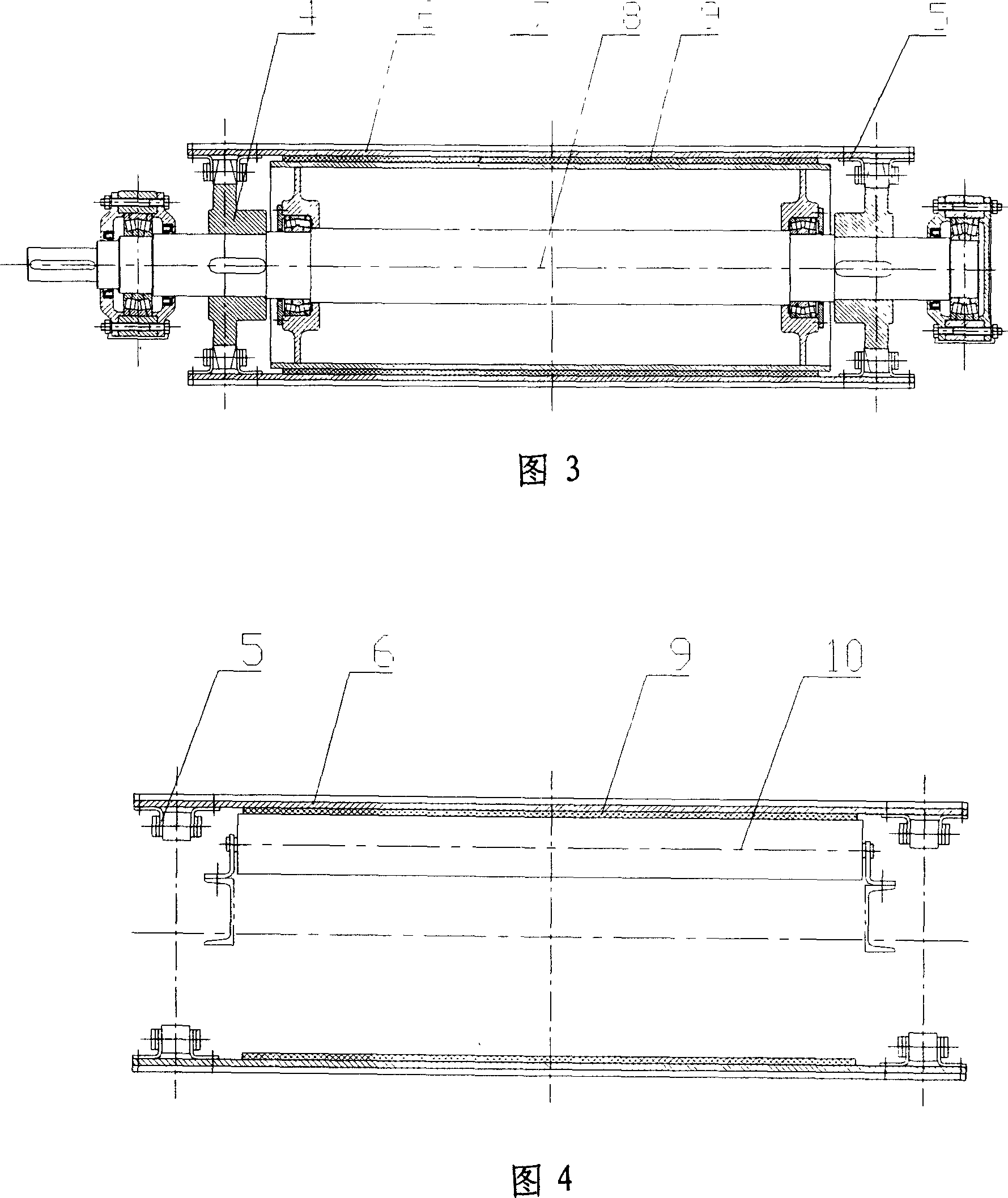

[0012] With reference to Fig. 1, 2, 3, 4, the plate-belt type feeder for mining of the present invention, it is to be provided with adjusting gate 2 and transmission mechanism 3 and drive shaft 8 to form on support frame 1, drive sprocket wheel is set on drive shaft 8 4 and tape head roller 7, the chain plate 6 is fixed on the chain 5 by bolts, the tape 9 is arranged on the inner side of the chain plate 6, the chain 6 is installed on both sides of the tape 9, and a plurality of idlers 10 are set under the tape 9 Rolling bearings are arranged on both sides of the idler roller 10. The idler roller 10 finally supports the chain plate 6 through the tape 9. The transmission mechanism 3 is composed of the drive sprocket 4, the chain 5 and the chain plate 6. The driving device rotates through the drive sprocket 4 to drive The chain 5 and the chain plate 6 run continuously to realize the purpose of feeding. The head roller 7 of the tape 9 is installed on the same drive shaft 8 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com