Precisively butting apparatus for photoelectric device package

A technology for optoelectronic devices and docking devices, which can be used in piezoelectric/electrostrictive/magnetostrictive devices, electrical components, microstructure devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

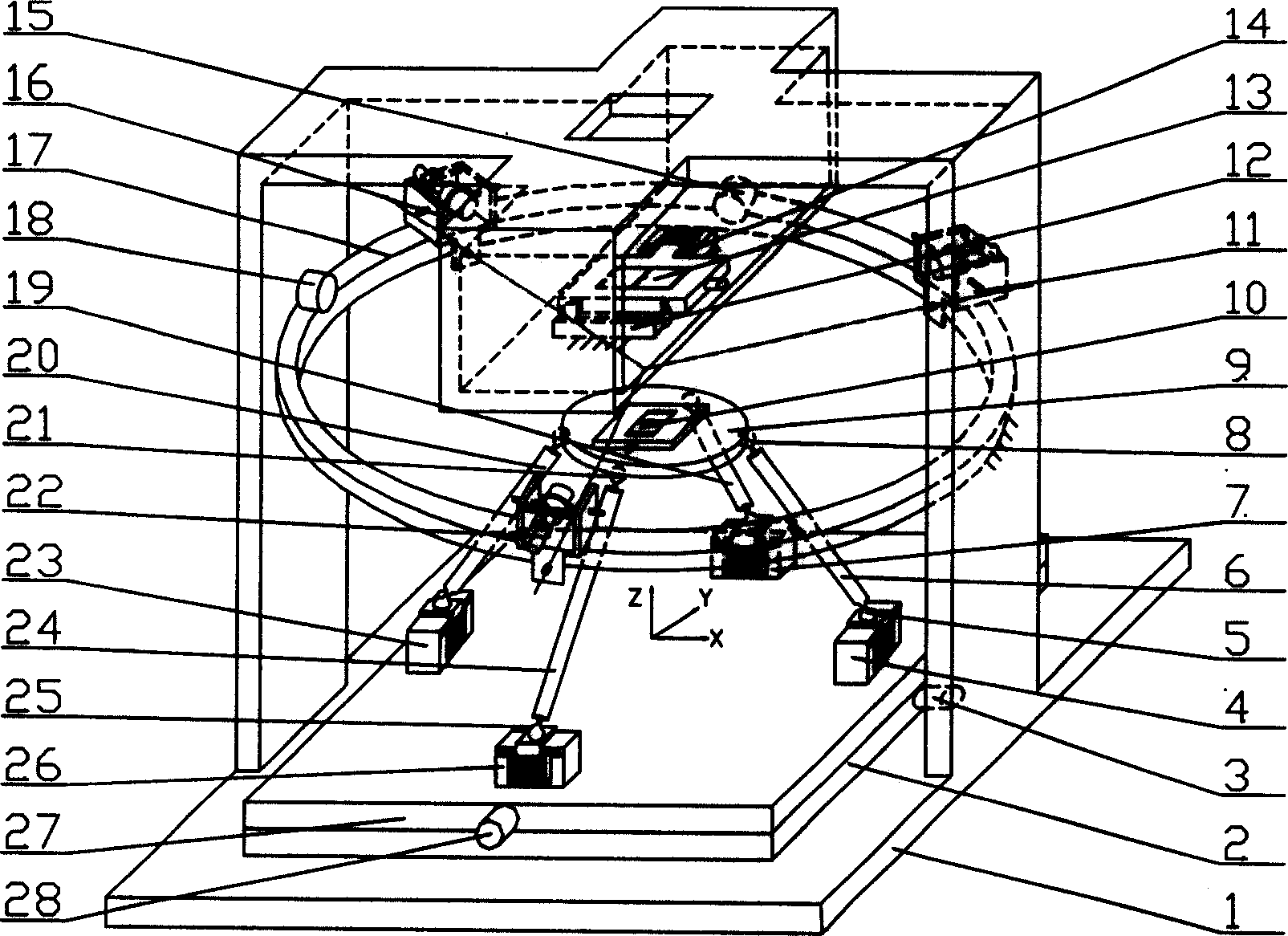

[0028] attached figure 1 is an embodiment of the present invention. This precision docking device for optoelectronic device packaging consists of a base (1), a moving platform (9), fixed length rods (6, 19, 20, 24), positioning seats (4, 7, 23, 26), micro It is composed of a displacement driver, a two-way translation platform (2, 27), an optical fiber clamp (10, 13) and the like. The base 1 and the moving platform 9 are connected by 4 fixed-length rods, one end of the two fixed-length rods (6, 20) is connected with the parallel plate moving pair on the positioning seat (4, 23) through the rotating pair, The other end is connected with the moving platform (9) through a ball joint, and one end of the other two fixed-length rods (19, 24) is connected with the parallel plate moving pair on the positioning seat (7, 26) through a Hooke joint or a ball joint. The other end is connected with the moving platform (9) through a ball joint, thereby forming a spatial parallel mechanism. ...

Embodiment 2

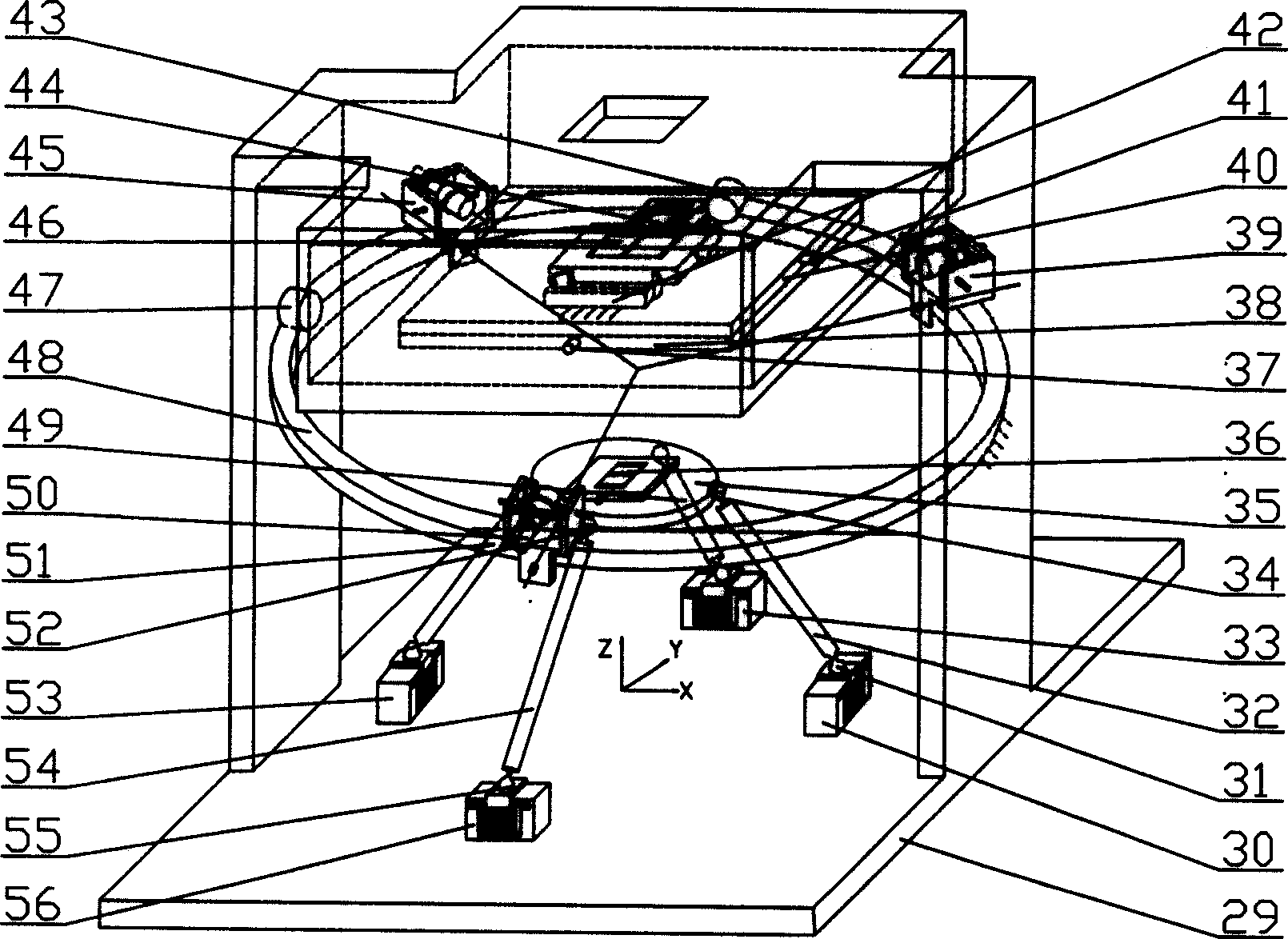

[0030] attached figure 2is another embodiment of the present invention. It consists of a base (29), a moving platform (35), a fixed length rod (32, 49, 51, 54), a positioning seat (30, 33, 53, 56), a micro-displacement driver, and a two-way translation platform (38, 40 ) and optical fiber clamps (36, 46) and other components. The base 29 and the moving platform 35 are connected by four fixed-length rods, one end of the two fixed-length rods (32, 51) is connected with the parallel plate moving pair on the positioning seat through a rotating pair, and the other end is connected through a ball joint. Linked with the moving platform (35), one end of the other two fixed length rods (49, 54) is connected with the parallel plate moving pair on the positioning seat through a Hooke hinge or a spherical hinge, and the other end is connected with the moving platform (35) through a spherical hinge. ) to form a spatial parallel mechanism. The positioning seat is provided with a micro-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com