Device and method for automatically assembling bullet chain

A technology of automatic assembly and bullets, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems that affect the quality of sorting work, time-consuming and labor-intensive, and low work efficiency, so as to achieve simple and effective sorting, ensure the quality of sorting, and overcome time-consuming and labor-intensive problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

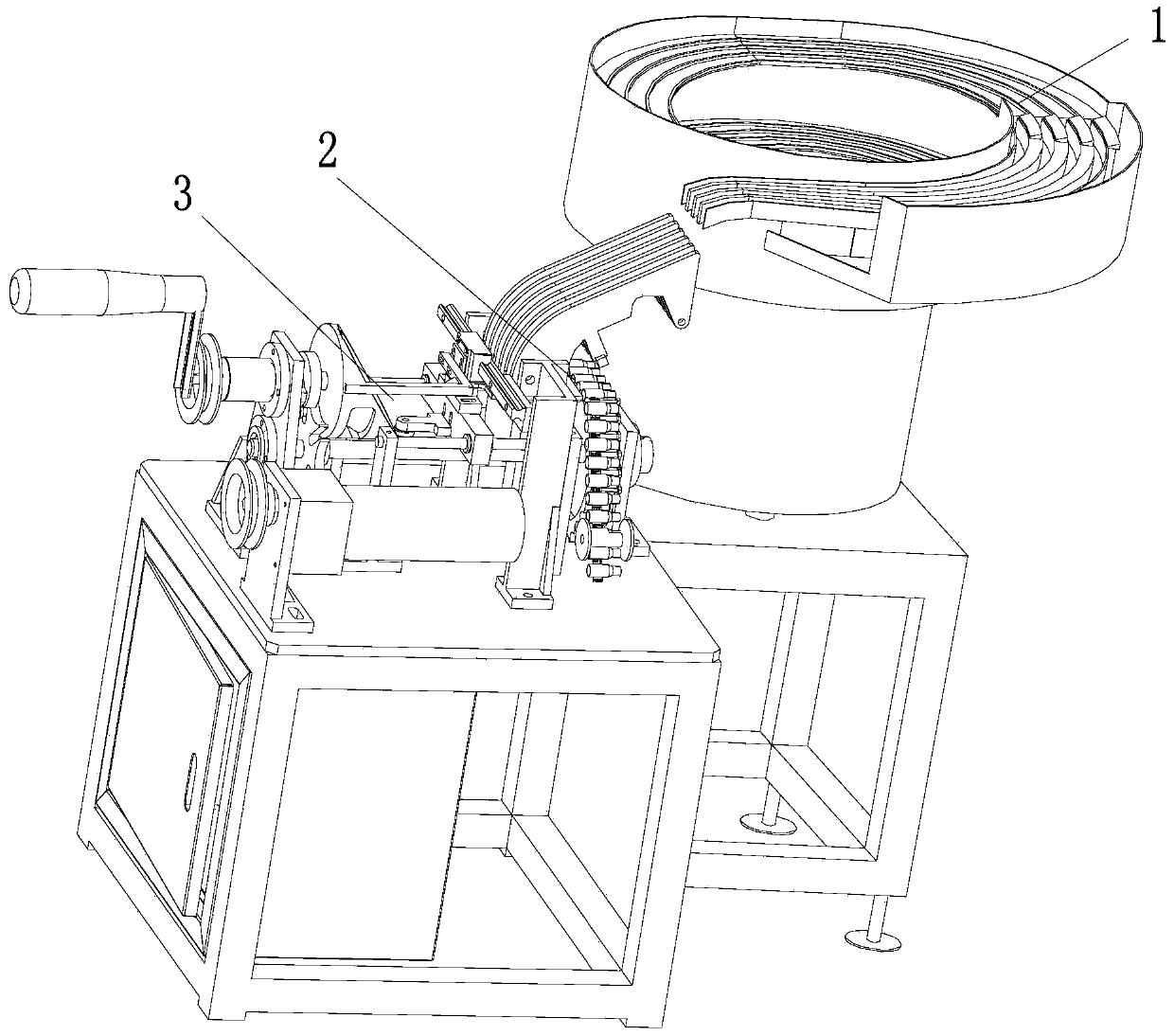

[0031] see Figure 1~5 , the embodiment of the present invention is provided with a bullet sorting device 1, a feeding device 2 of a bullet chain assembly mechanism and a bullet automatic winding device 3;

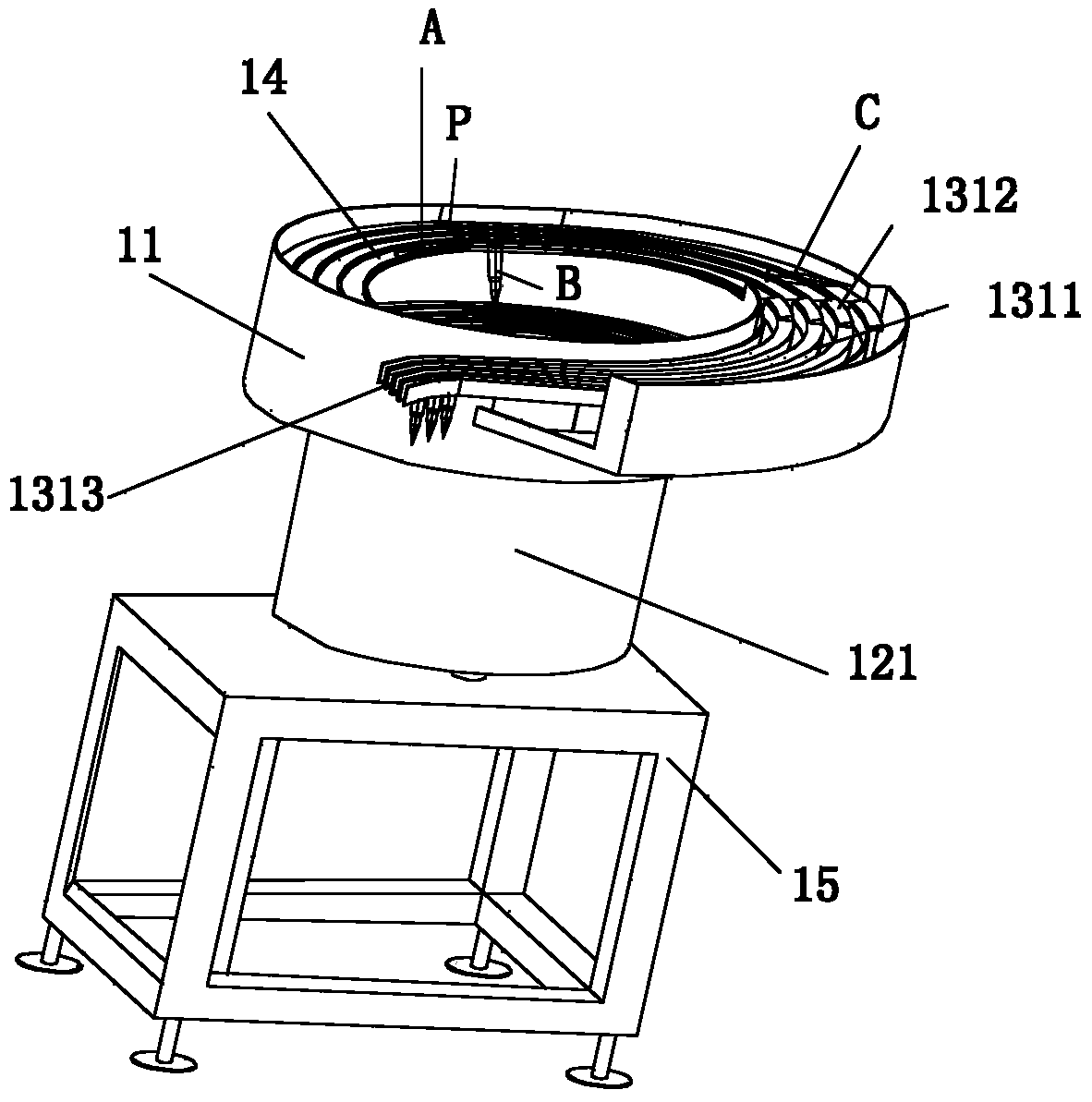

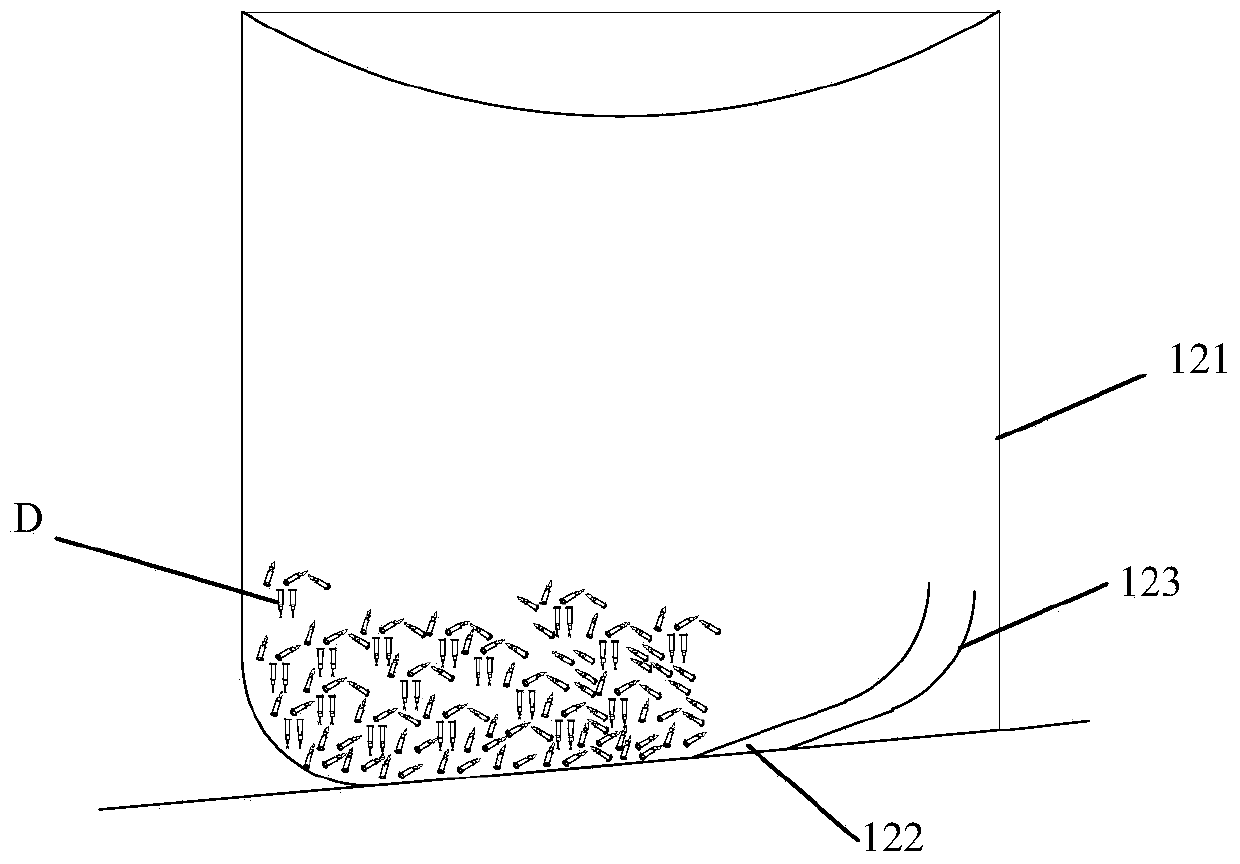

[0032]The bullet sorting device 1 is provided with a stainless steel bucket 11, a shot container, at least 2 bullet slides, a bullet slide 14, and a frame 15; the bullet slides are made up of stainless steel sheets 1311, and stainless steel stoppers are arranged between the bullet slides. Sheet 1312, a supporting plate is provided below the bullet chute; the opening bottom of the stainless steel barrel 11 is connected to the top of the shotgun container, the shotgun container is arranged on the frame 15, and the bullet-feeding end of the bullet chute 14 is arranged on the stainless steel barrel The bottom of 11, the ejection end of bullet chute 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com