Initiative reciprocating type zero-tillage anti-blocking unit body

A reciprocating, unitary technology, applied in the field of agricultural machinery, can solve the problems of high vibration and noise of the machine, poor safety performance, poor anti-blocking ability, etc., and achieve the effect of clearing accumulation blockage, easy disassembly and assembly, and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The concrete structure of the embodiment of the present invention and working process are described below in conjunction with accompanying drawing:

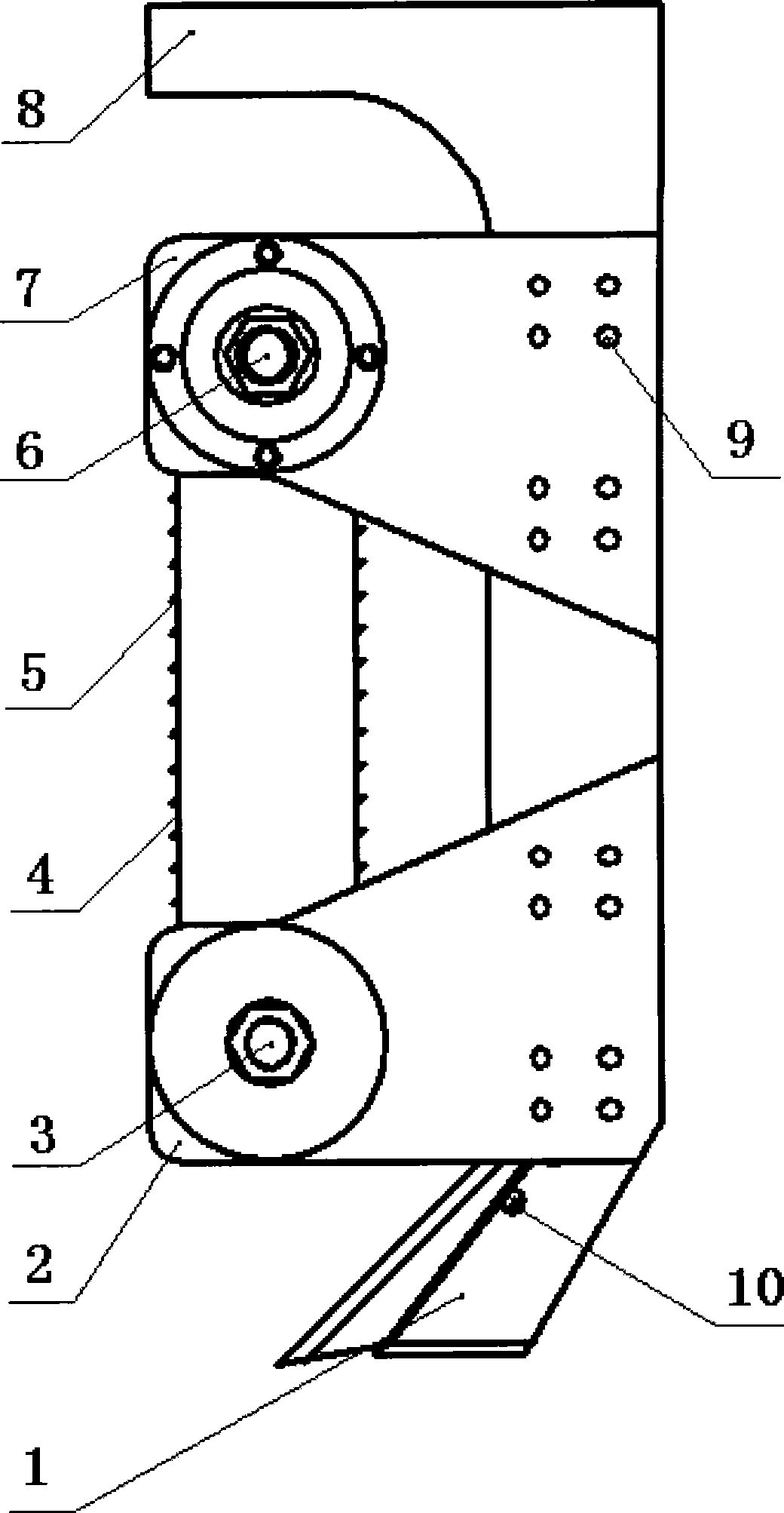

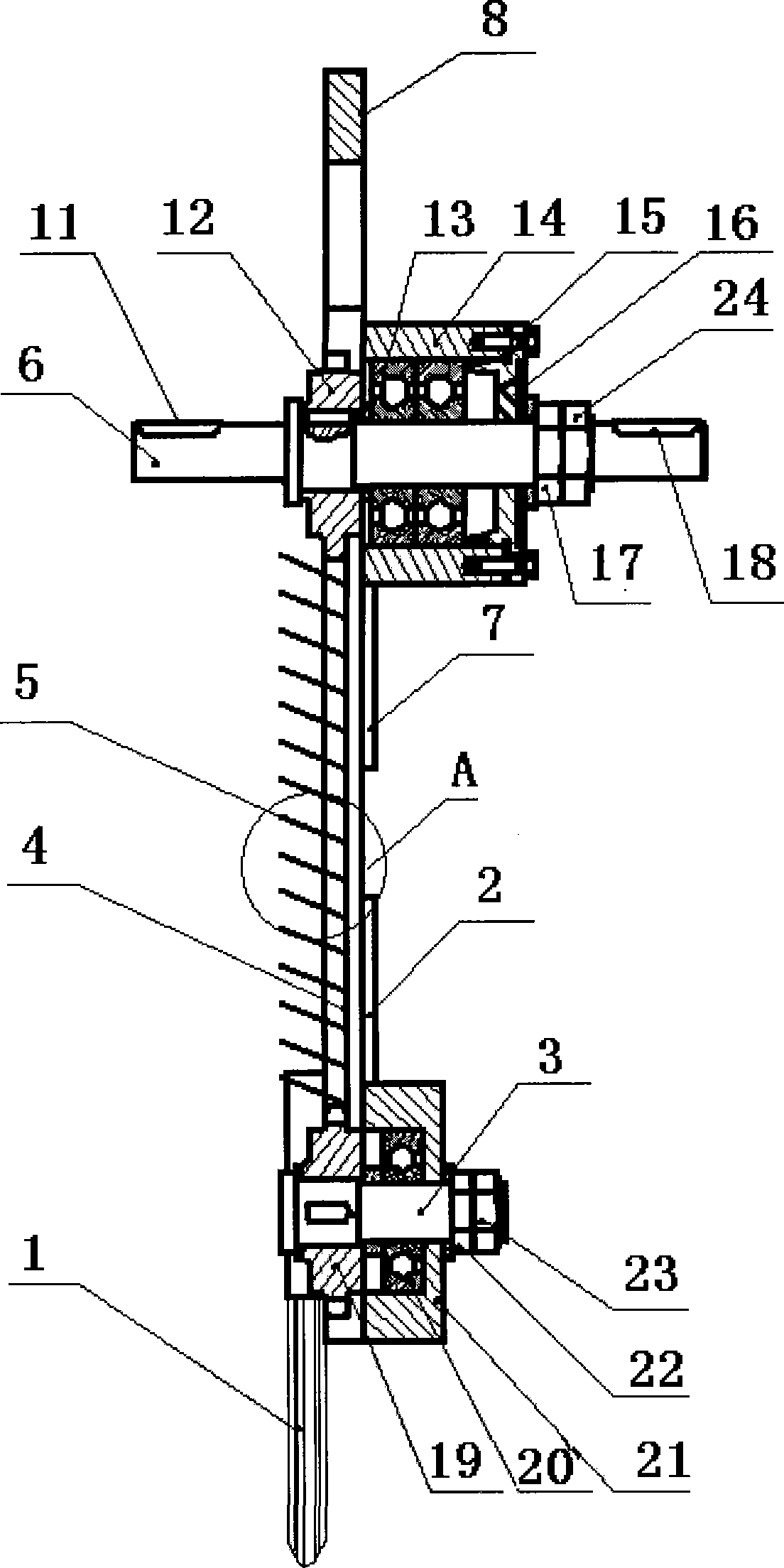

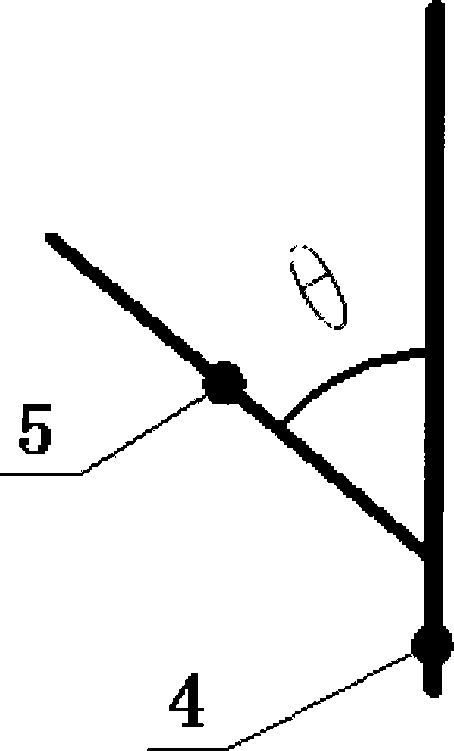

[0015] Such as figure 1 , figure 2 The shown active reciprocating no-tillage anti-blocking unit body is mainly composed of ditch opener 1, ditch opener shovel handle 8, upper fixing plate 7, lower fixing plate 2, short axis 3, long axis 6, chain 4, finger 5, Upper sprocket 12, lower sprocket 19 etc. constitute. Wherein the ditcher 1 and the ditch opener shovel handle 8 are connected together by the hexagon socket head bolt 10, and the left half of the whole structure leaves 2 / 3 gaps to form a concave structure. The upper fixed plate 7 and the lower fixed plate 2 are respectively positioned through the positioning hole 9 and fixed on the upper and lower parts of the right side of the opener shovel handle 8 with bolts up and down. The long axis 6 passes through the upper bearing 13, the upper bearing sleeve 14, The faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com