Optical glass small strip material molding device

A technology of optical glass and forming device, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve problems such as inability to draw strips, reduce glass cutting processes, avoid adhesion, and uniform glass cold lines small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Various exemplary embodiments, features, and aspects of the invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

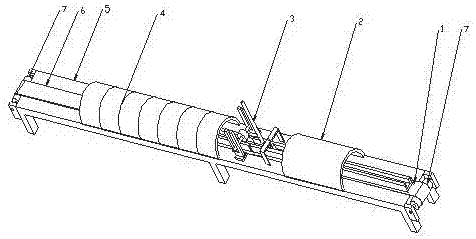

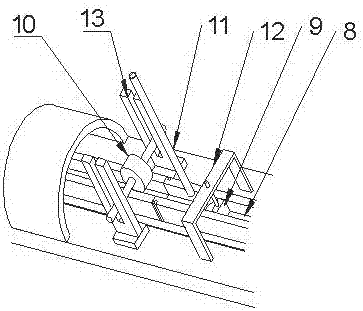

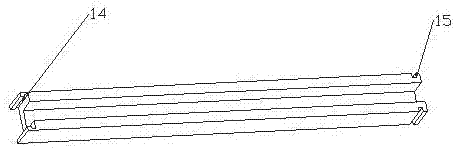

[0021] Examples such as figure 1 As shown, the present invention provides an optical glass strip forming device, which includes a transmission mechanism 1 , a preheating part 2 , a forming part 3 and an annealing part 4 . The preheating section 2 , forming section 3 and annealing section 4 are respectively located at the head end, middle end and end of the transmission mechanism 1 . The transmission mechanism 1 is composed of a frame body 5, a roller 7, a conveyor belt 6 and a power device. There is a roller 7 at each end of the frame body 5, and the conveyor belt 6 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com