Sponge cutting machine that can be rotated and sliced and can be divided and delivered

A technology of flat cutting machine and rotating mechanism, which is applied in metal processing and other directions to meet market demand, improve production and processing efficiency, and be convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

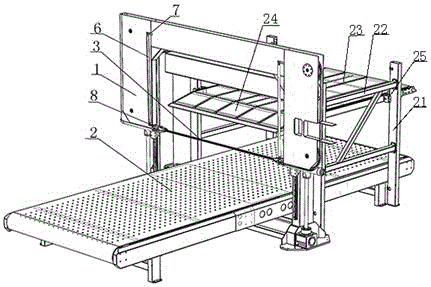

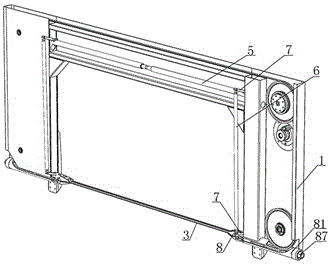

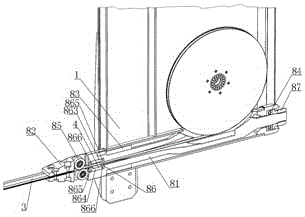

[0018] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0019] Referring to the accompanying drawings, the sponge flat cutting machine that can be rotated and sliced and can be divided and discharged includes a frame 1, a workbench 2, a knife box 3, a blade 4, a drive shaft 5, a pull rod 6, a rotating arm 7, and a rotating mechanism 8. The frame 1 is installed on both sides of the workbench 2, the knife box 3 is installed at the lower end of the frame 1, the blade is installed in the knife box 3, and the two ends of the knife box 3 are fixed on the lower end of the frame 1 through the rotating mechanism 8, and the rotating mechanism 8 upper end is connected with rotating arm 7, and driving shaft 5 is installed on the frame 1 upper end, and one side of driving shaft 5 is connected with driving motor, and rotating arm 7 is installed on driving shaft 5 upper end, and the rotating arm 7 at the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com