Patents

Literature

45results about How to "Improve molding processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

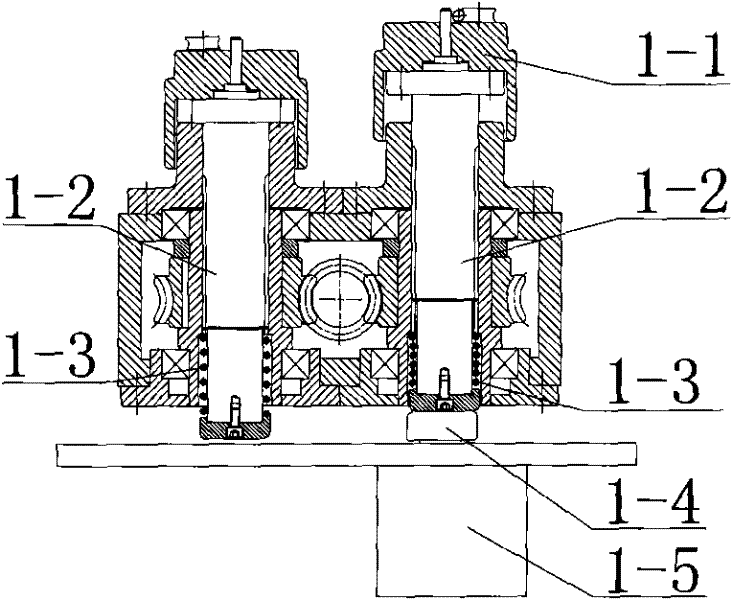

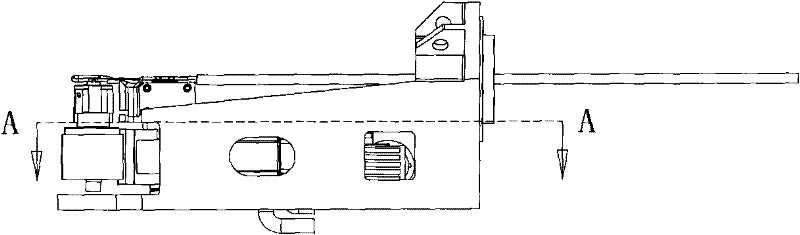

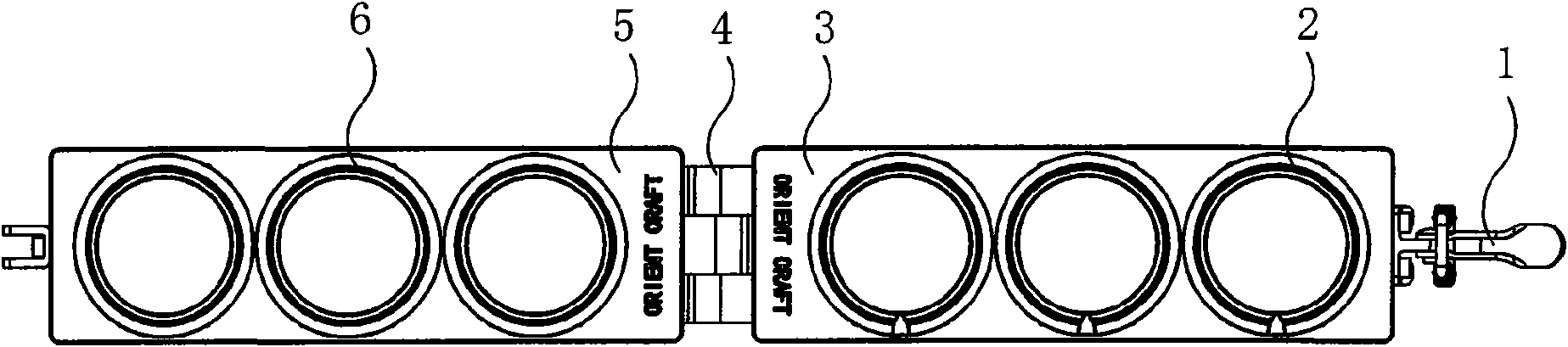

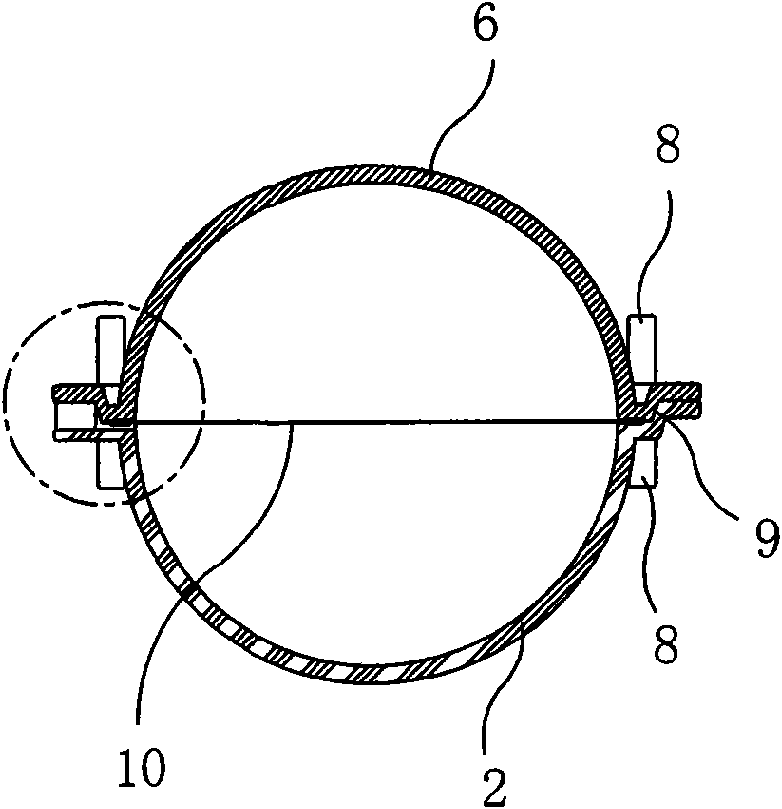

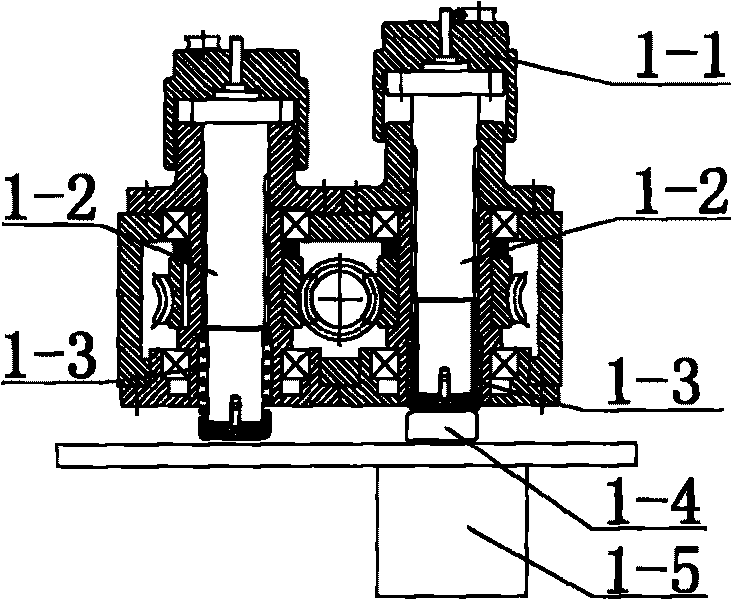

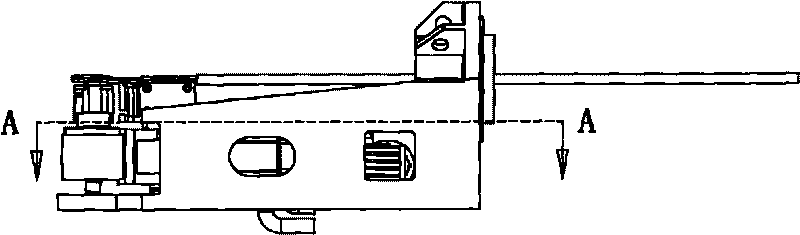

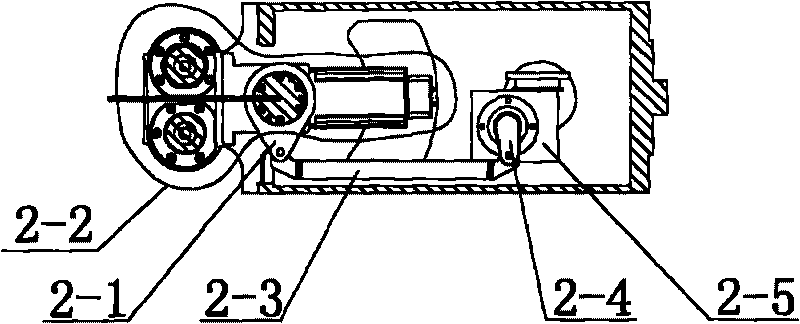

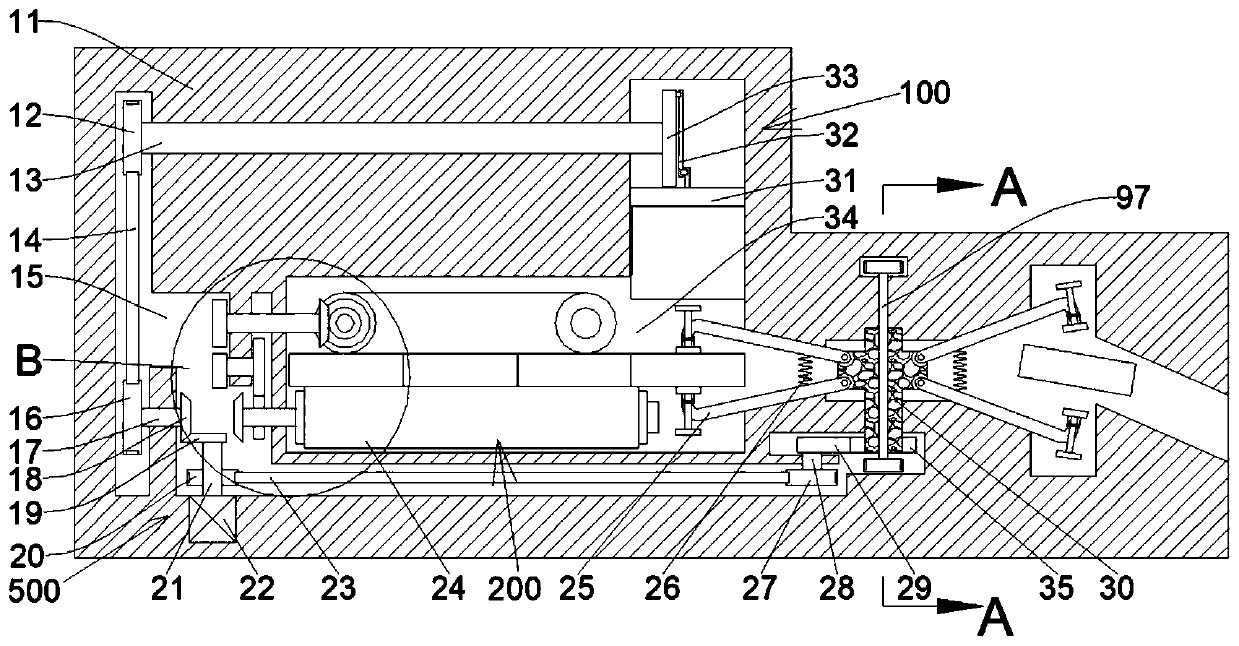

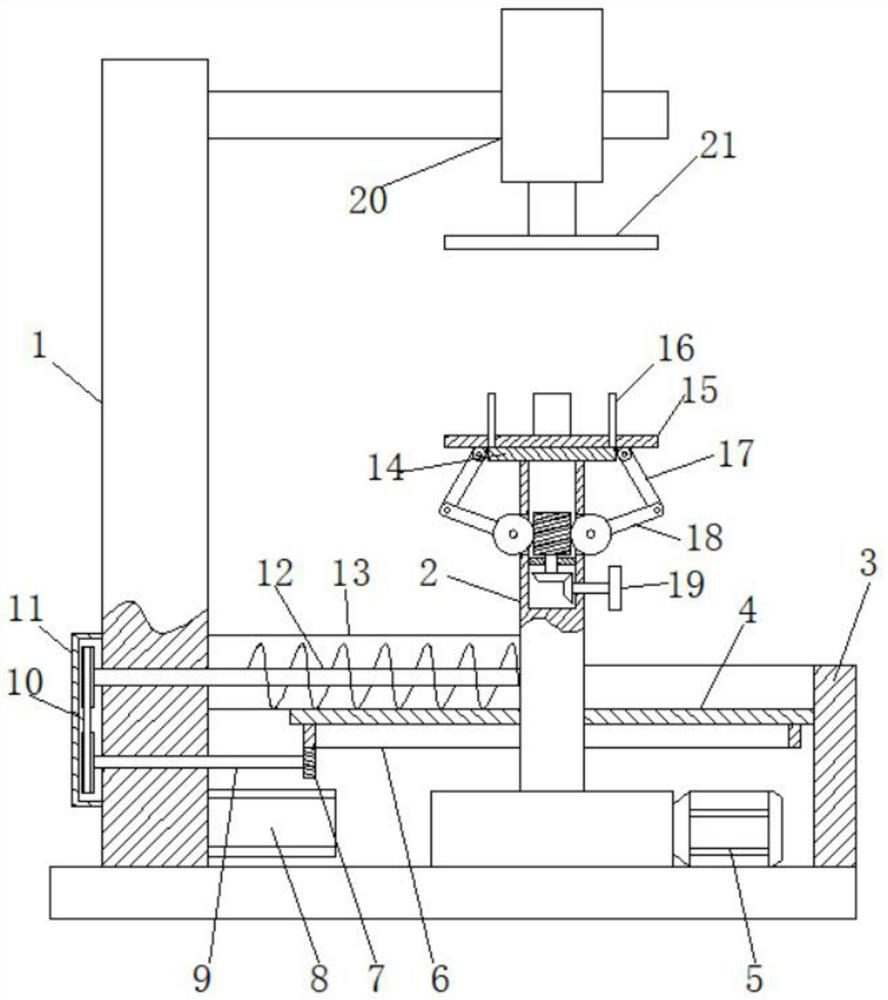

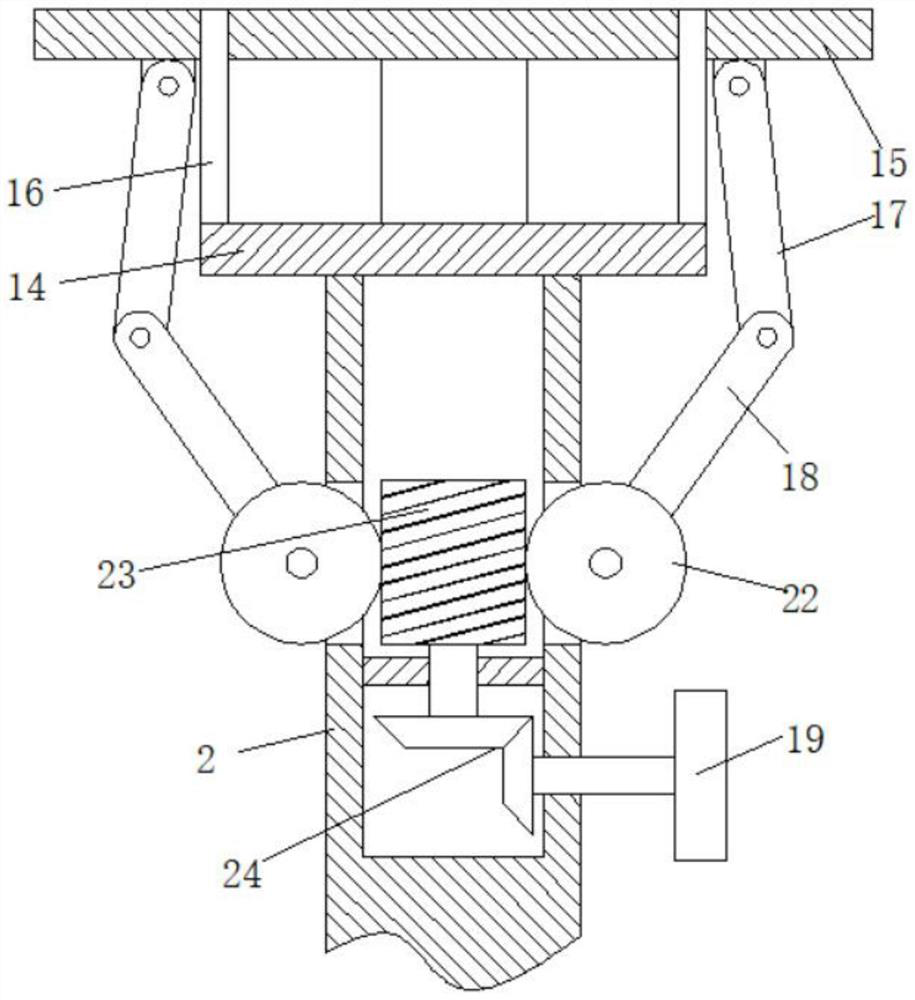

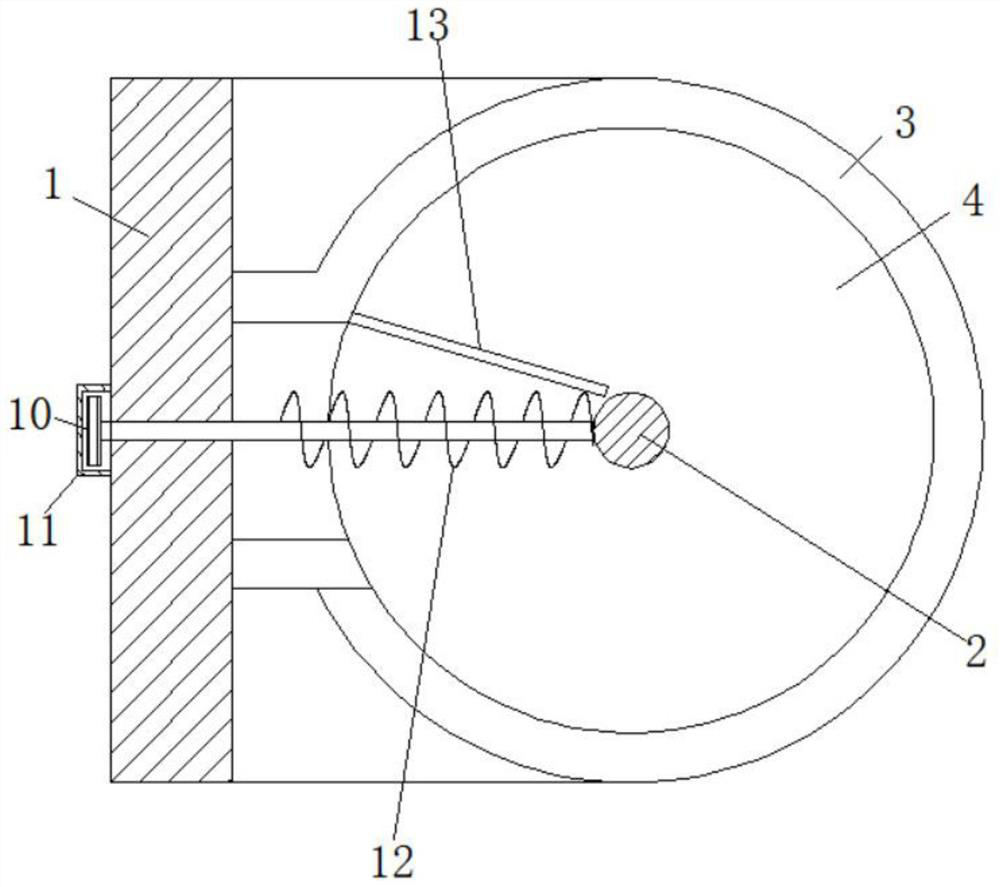

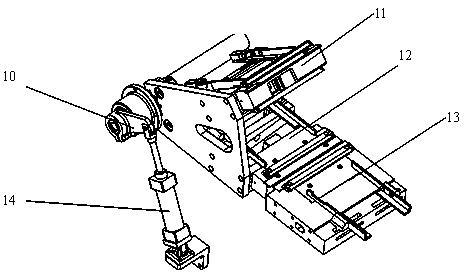

Working handpiece of numerical control wire bending machine

InactiveCN101733344BImprove molding efficiencyImprove molding processing efficiencyAxial displacementNumerical control

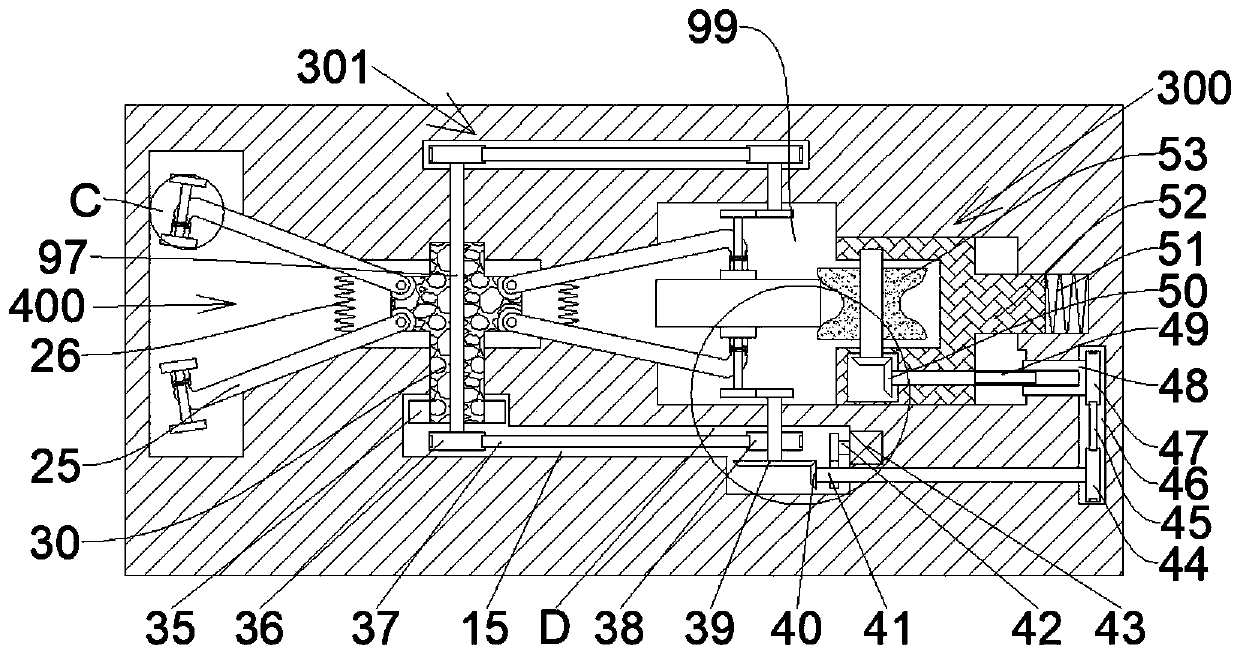

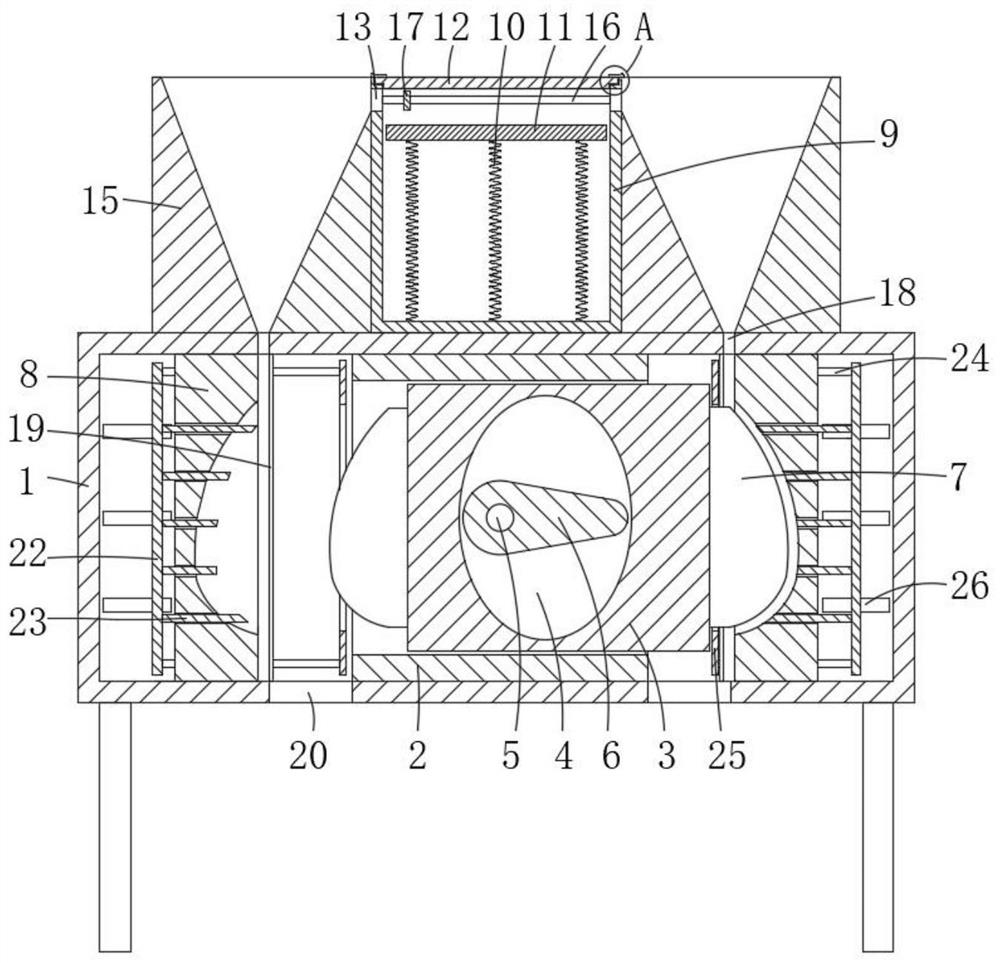

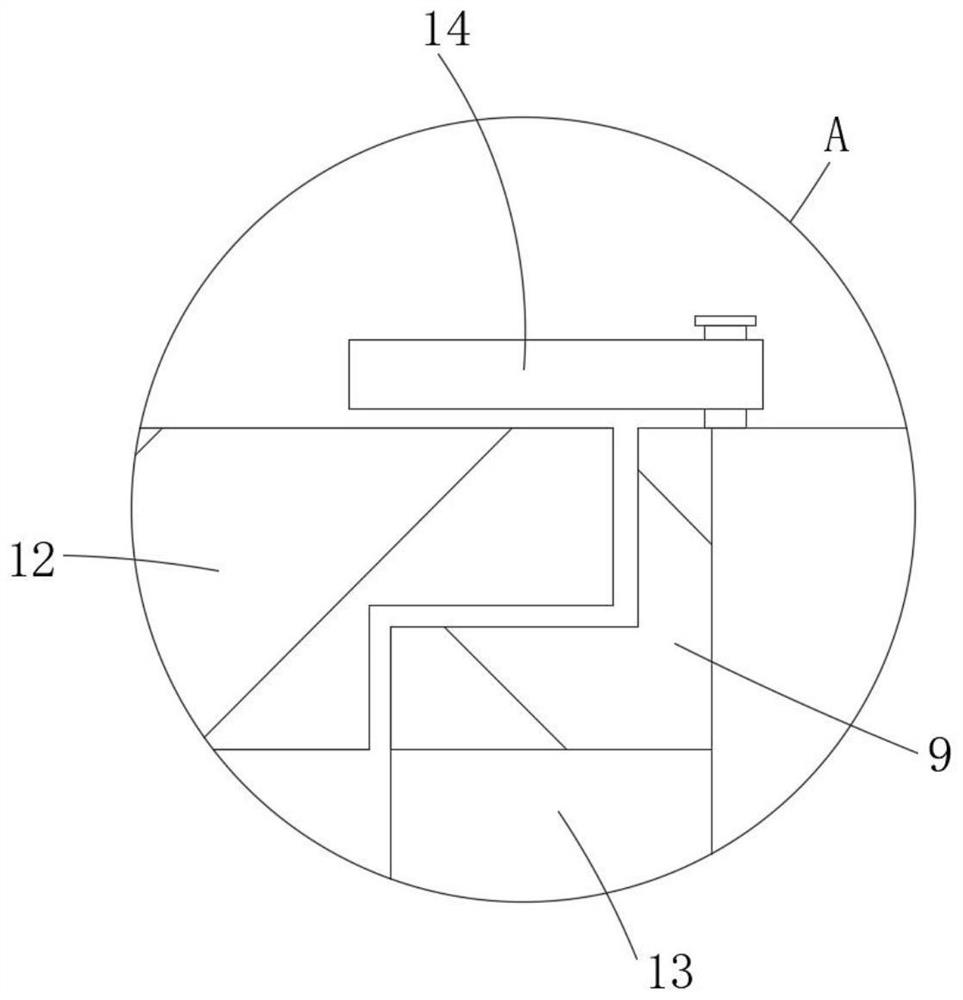

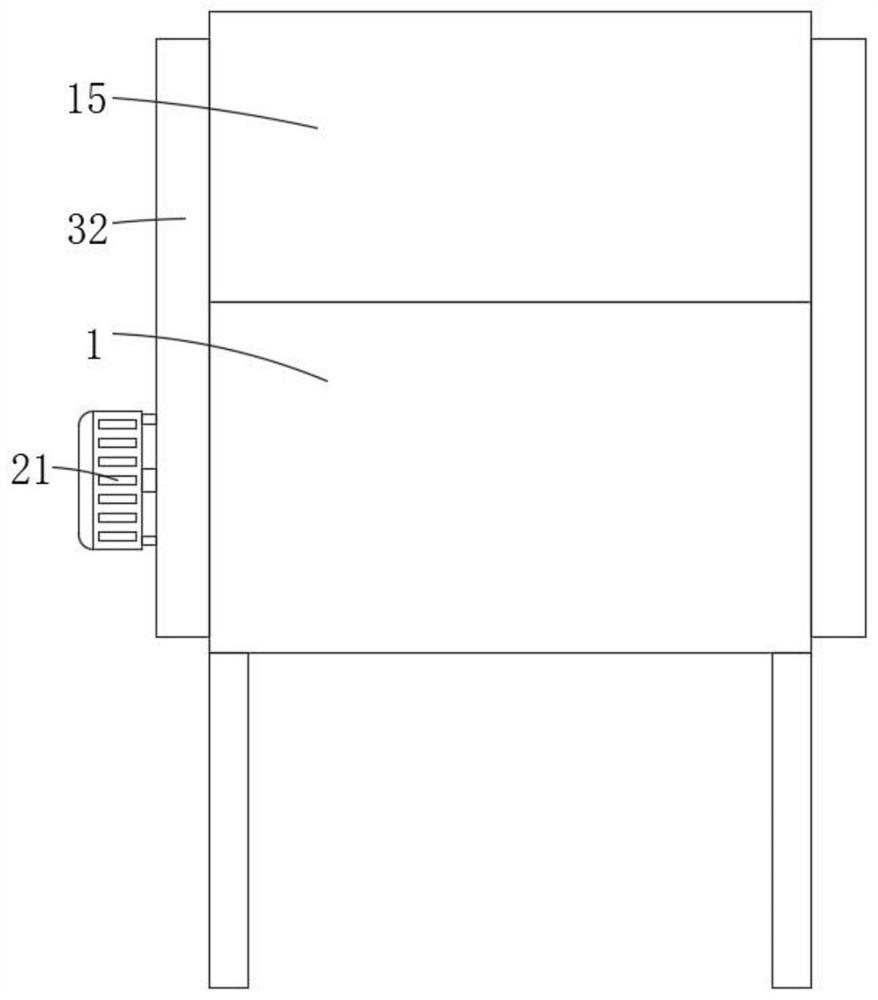

The invention relates to a working handpiece of a numerical control wire bending machine, which comprises the working handpiece of the numerical control wire bending machine. Two die heads in the die-changing and die head steering lifting position-hiding mechanism in the numerical control wire bending machine are connected with two spline shafts without relative displacement; the bottom parts of the spline shafts are contacted with the lower end of a pressure spring; the upper end of the pressure spring is contacted with the inner step of a main shaft and drives the spline shafts to move downwards; a swing arm of the position changing and swinging mechanism of the bending die head in the numerical control wire bending machine is connected with a wire bending power driving device without relative displacement; one end of a connecting rod is moveably connected with the swing arm, while the other end is moveably connected with the swing arm; the swing arm is connected with a rotating shaft of a numerical angle graduator without relative displacement; a driving device takes a worm-gear case as a main body; a worm is supported by a bearing without axial displacement, and at the same time drives two worm gears which are connected with the main shaft without relative displacement; splines are arranged in the main shaft; the spline shafts are connected with the splines in the main shaft; the main shaft and the worm-gear case are supported by the bearing without axial displacement; and two bending die heads are connected with the two spline shafts respectively without relative displacement.

Owner:浙江博雷重型机床制造有限公司

Polyurethane foam forming mould and manufacturing method of mould cavities

The invention discloses a polyurethane foam forming mould and a manufacturing method of mould cavities. The mould comprises a mould frame, mould cavities, filling layers between the mould frame and the mould cavities, a locking device and a mould opening and closing device; the mould cavities are made of crystalline resin materials; an exhaust hole is arranged on the lower mould cavity; spew grooves are respectively arranged on the upper mould cavity and the lower mould cavity; and a blade parting surface and an upper and lower mould cavity positioning surface are respectively arranged on the upper mould cavity and the lower mould cavity. The mould cavities are made of the crystalline resin materials, and the manufacturing method of the mould cavities comprises the following steps: firstly designing the mould cavities by using a computer three-dimensional design software and then manufacturing the mould cavities by adopting the CNC numerical control processing, the injection-moulding processing, the rapid forming processing and the vacuum moulding processing methods. The invention solves the technical problems that a mould cavity parting line between an aluminum alloy casting mould and an epoxy resin mould has worse matching, the mould cavities are required to be coated with mould release agents, and formed products are easy to generate flash edges, so that the forming processing efficiency of similar products is improved, thereby reducing the production cost and improving the availability of resources.

Owner:黄吉力

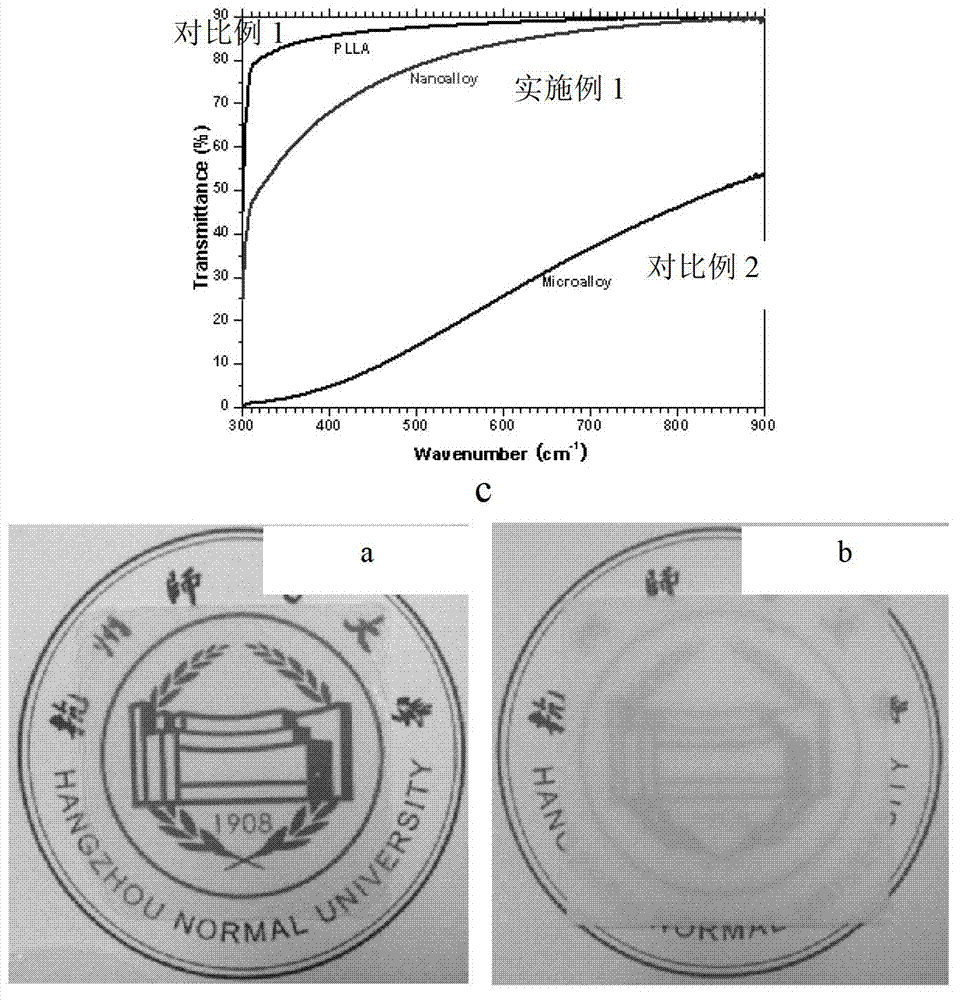

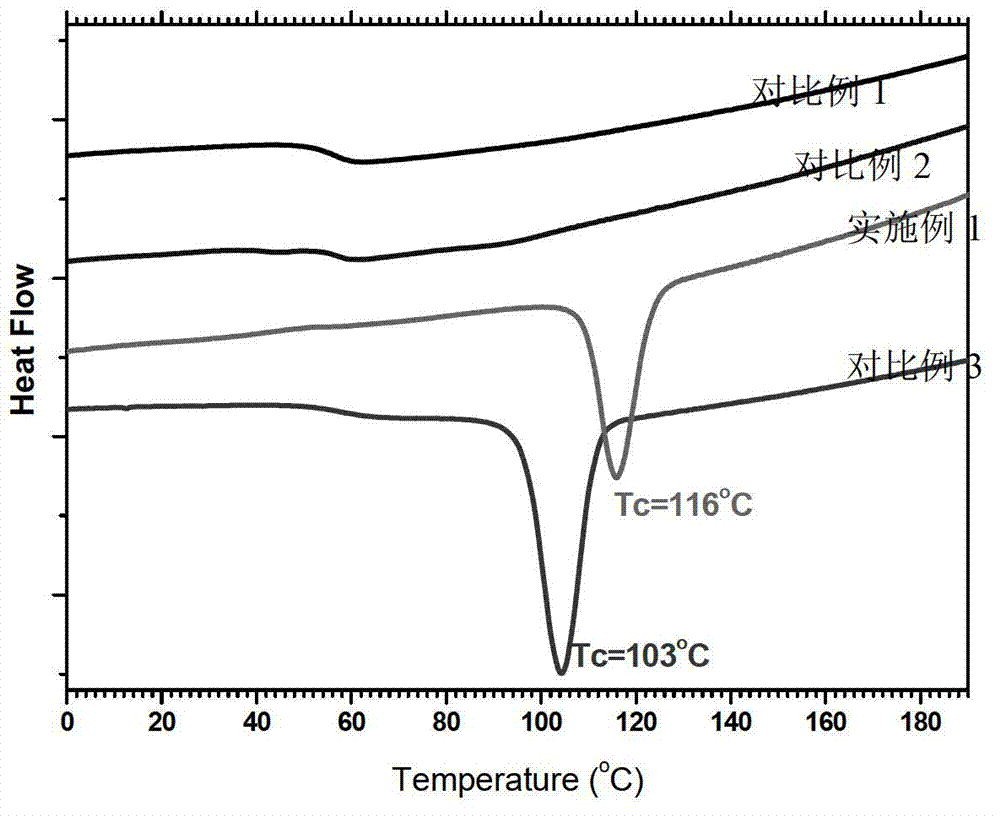

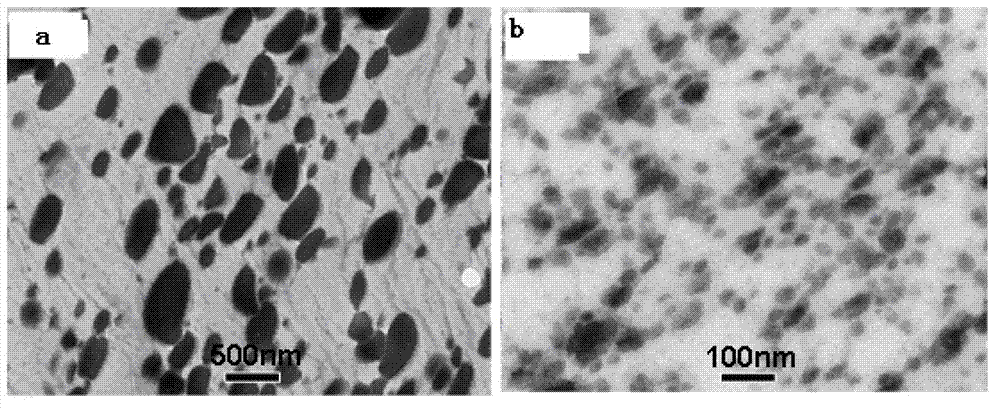

Transparent polylactic acid alloy material

The invention discloses a transparent polylactic acid alloy material, which is prepared by polylactic acid and an elastomer by a melt mixing device through melt blending, based on the polylactic acid and the elastomer, the mass fraction of the polylactic acid accounts for 75-98% and the mass fraction of the elastomer accounts for 2-25%, and the elastomer is the elastomer containing maleic anhydride or an epoxy group. According to the invention, a certain amount of elastomer capable of being reacted with polylactic acid is added in the polylactic acid, the melt blending condition of the material is adjusted in a reasonable mode, all elastomer micro-areas are uniformly dispersed in the polylactic acid, and the disperse size is less than 100nm, thereby the transparent polylactic acid alloy material with substantially enhanced material shock resistance and fast crystallization speed of matrix polylactic acid can be obtained. A purpose that primary modification overcomes a plurality of polylactic acid application barriers can be realized. The transparent polylactic acid alloy material can be used in the industries of package, electron, building material, automobile and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

Working handpiece of numerical control wire bending machine

InactiveCN101733344AImprove molding efficiencyImprove molding processing efficiencyAxial displacementNumerical control

The invention relates to a working handpiece of a numerical control wire bending machine, which comprises the working handpiece of the numerical control wire bending machine. Two die heads in the die-changing and die head steering lifting position-hiding mechanism in the numerical control wire bending machine are connected with two spline shafts without relative displacement; the bottom parts of the spline shafts are contacted with the lower end of a pressure spring; the upper end of the pressure spring is contacted with the inner step of a main shaft and drives the spline shafts to move downwards; a swing arm of the position changing and swinging mechanism of the bending die head in the numerical control wire bending machine is connected with a wire bending power driving device without relative displacement; one end of a connecting rod is moveably connected with the swing arm, while the other end is moveably connected with the swing arm; the swing arm is connected with a rotating shaft of a numerical angle graduator without relative displacement; a driving device takes a worm-gear case as a main body; a worm is supported by a bearing without axial displacement, and at the same time drives two worm gears which are connected with the main shaft without relative displacement; splines are arranged in the main shaft; the spline shafts are connected with the splines in the main shaft; the main shaft and the worm-gear case are supported by the bearing without axial displacement; and two bending die heads are connected with the two spline shafts respectively without relative displacement.

Owner:浙江博雷重型机床制造有限公司

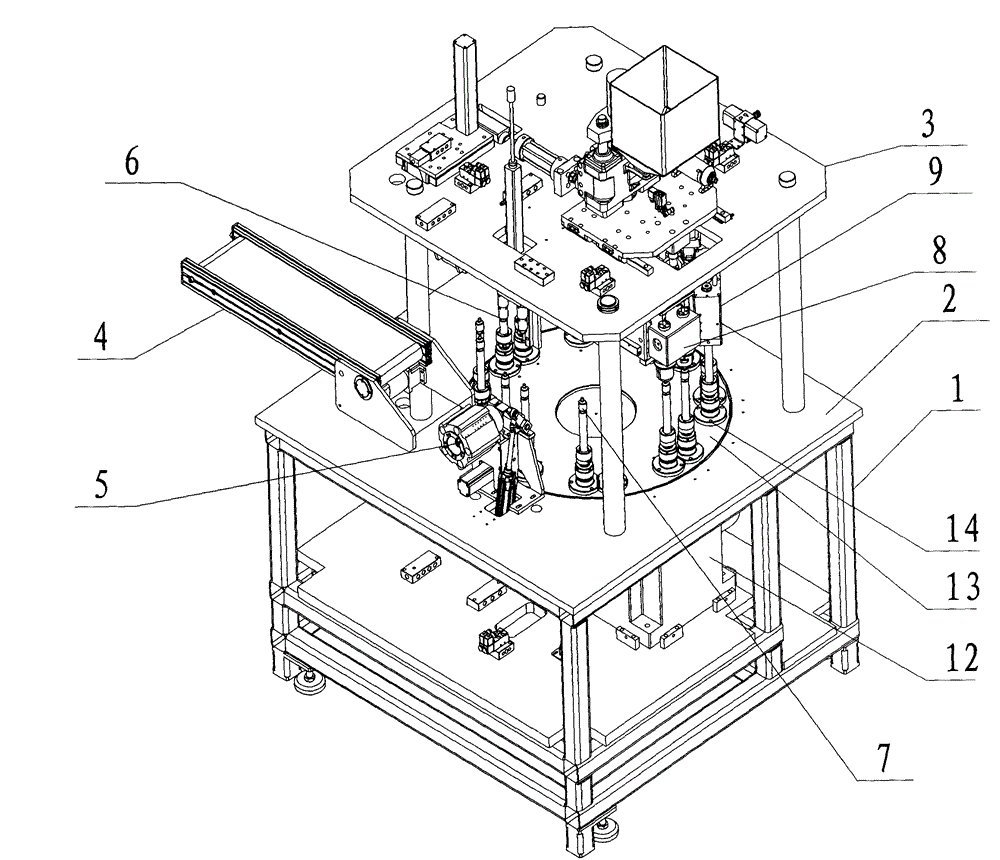

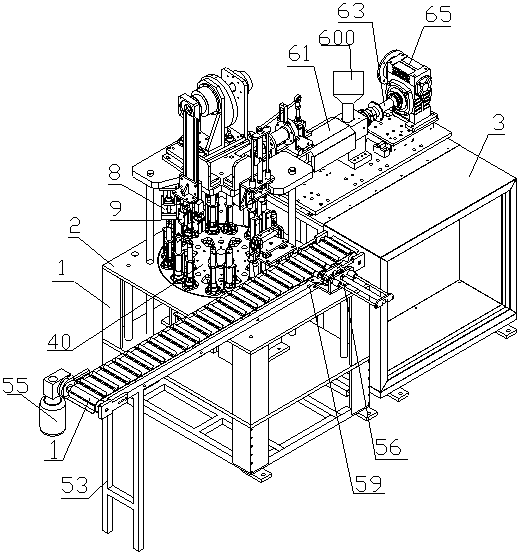

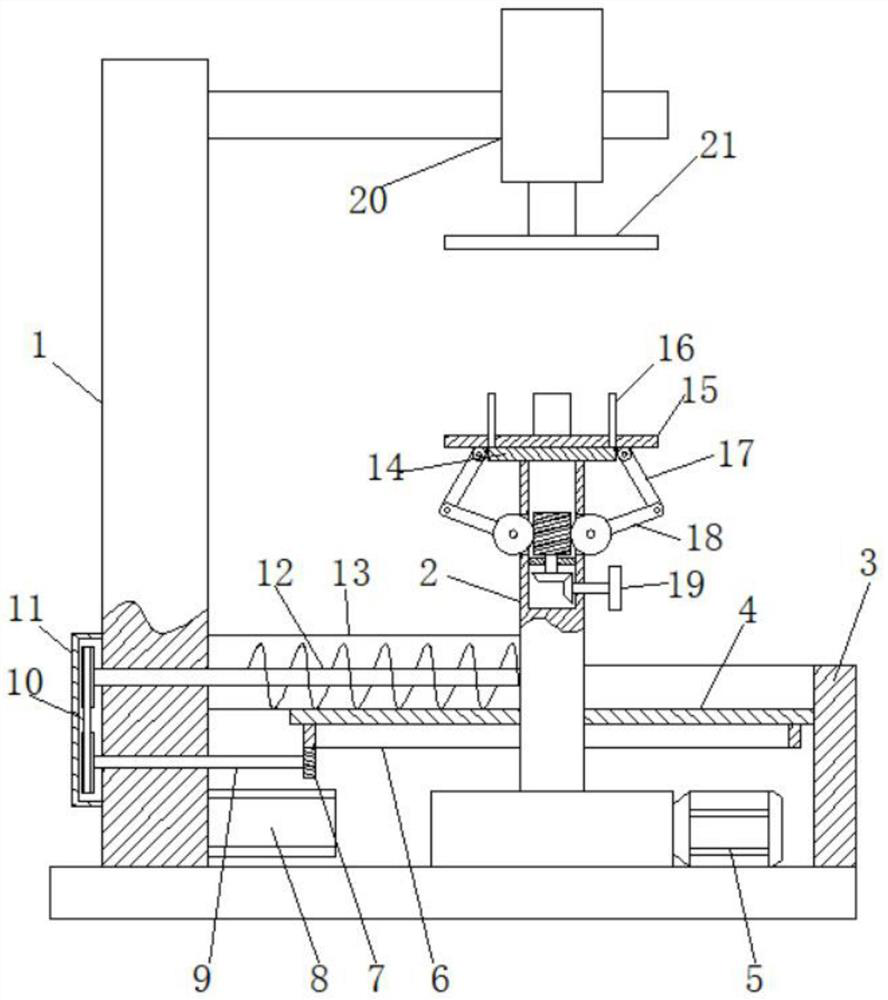

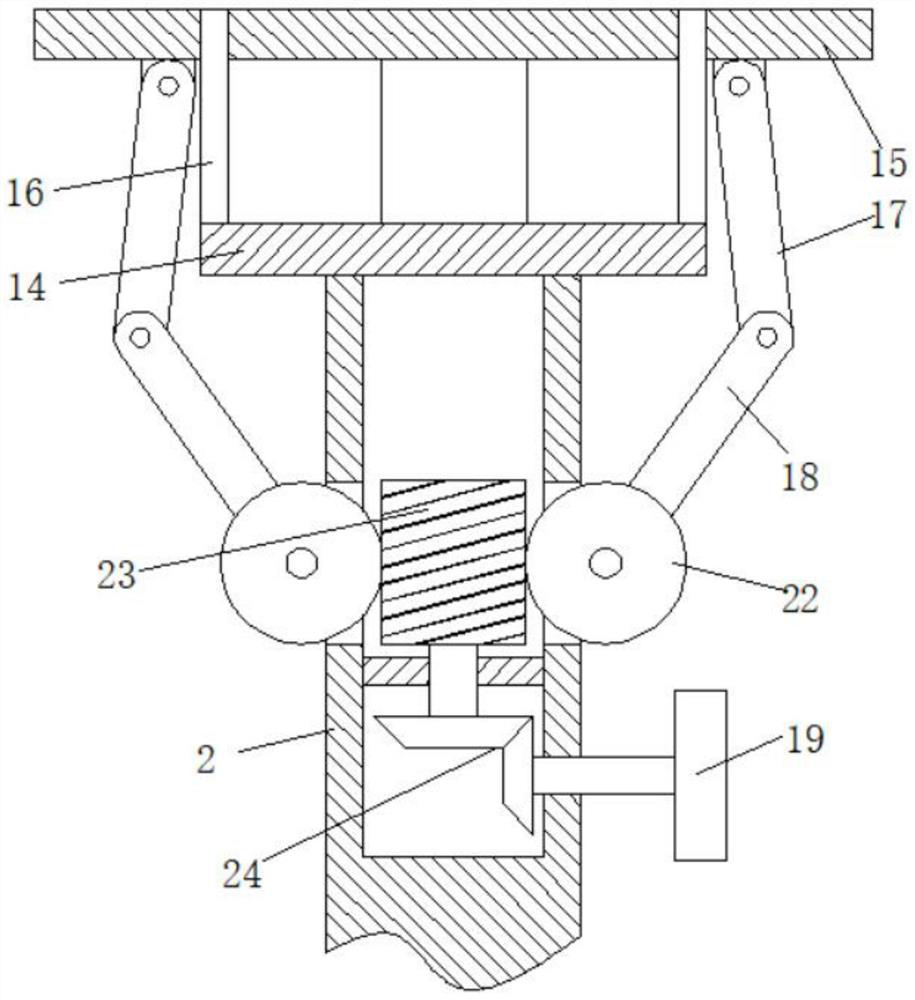

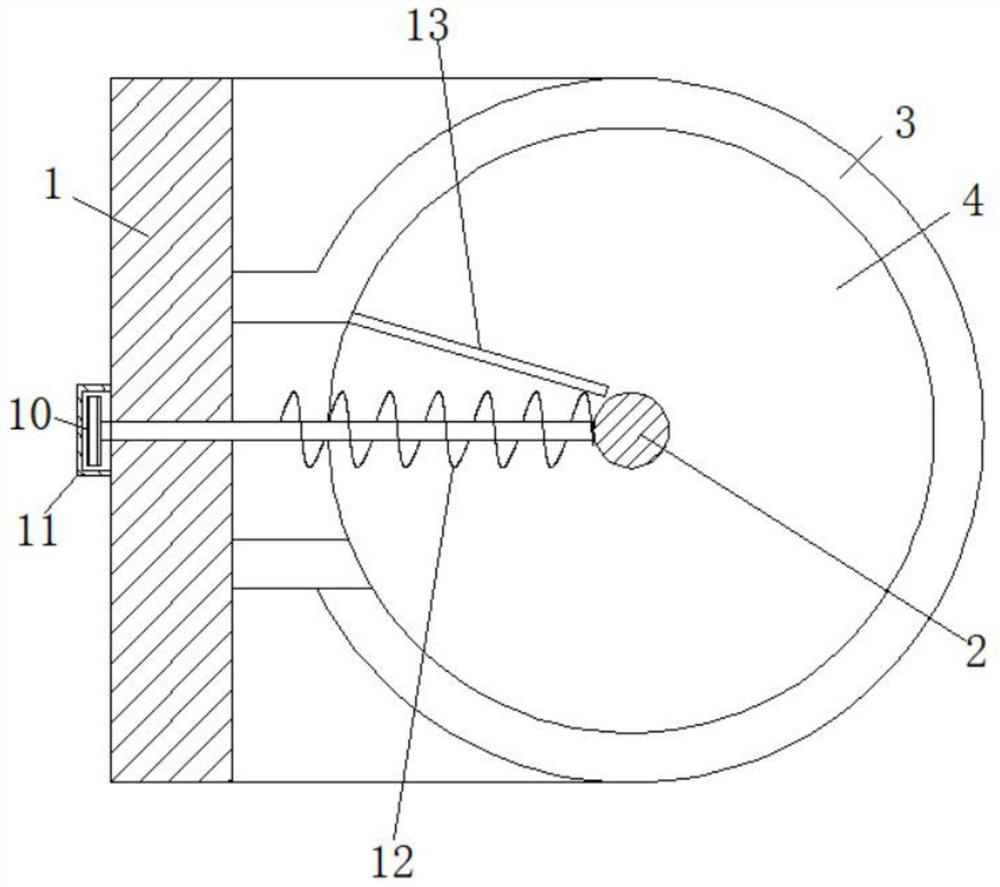

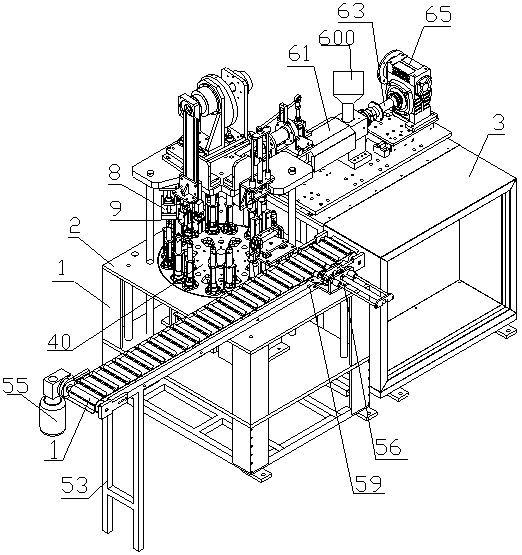

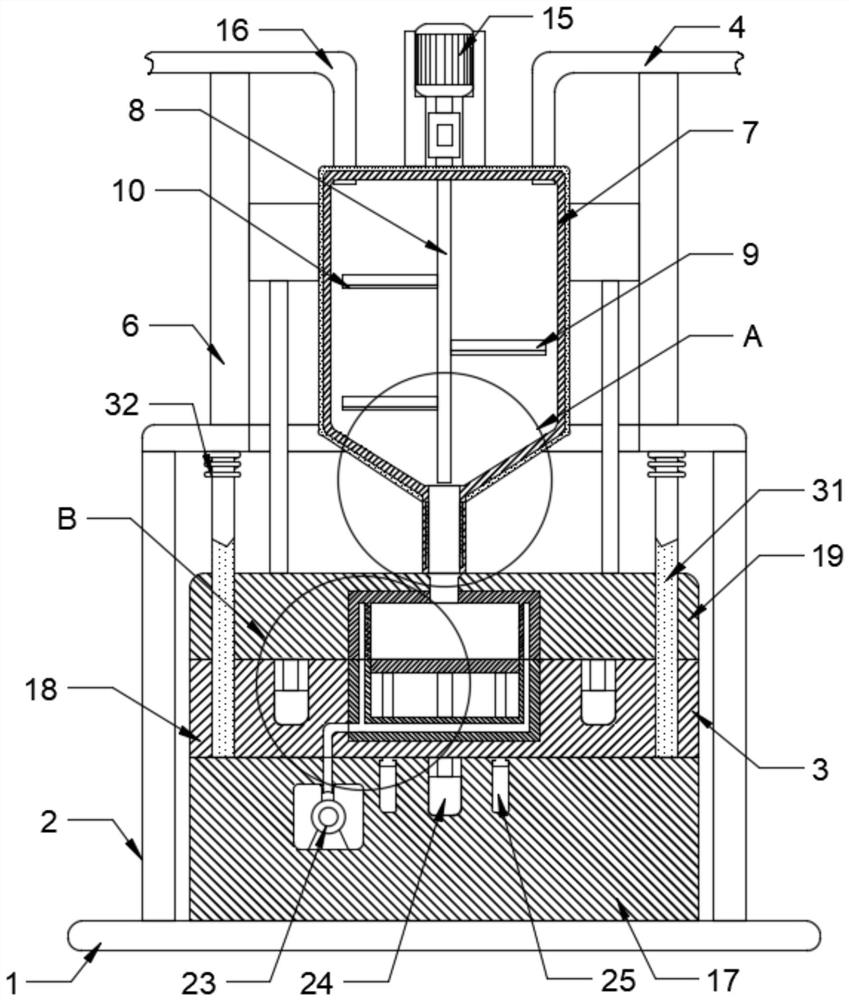

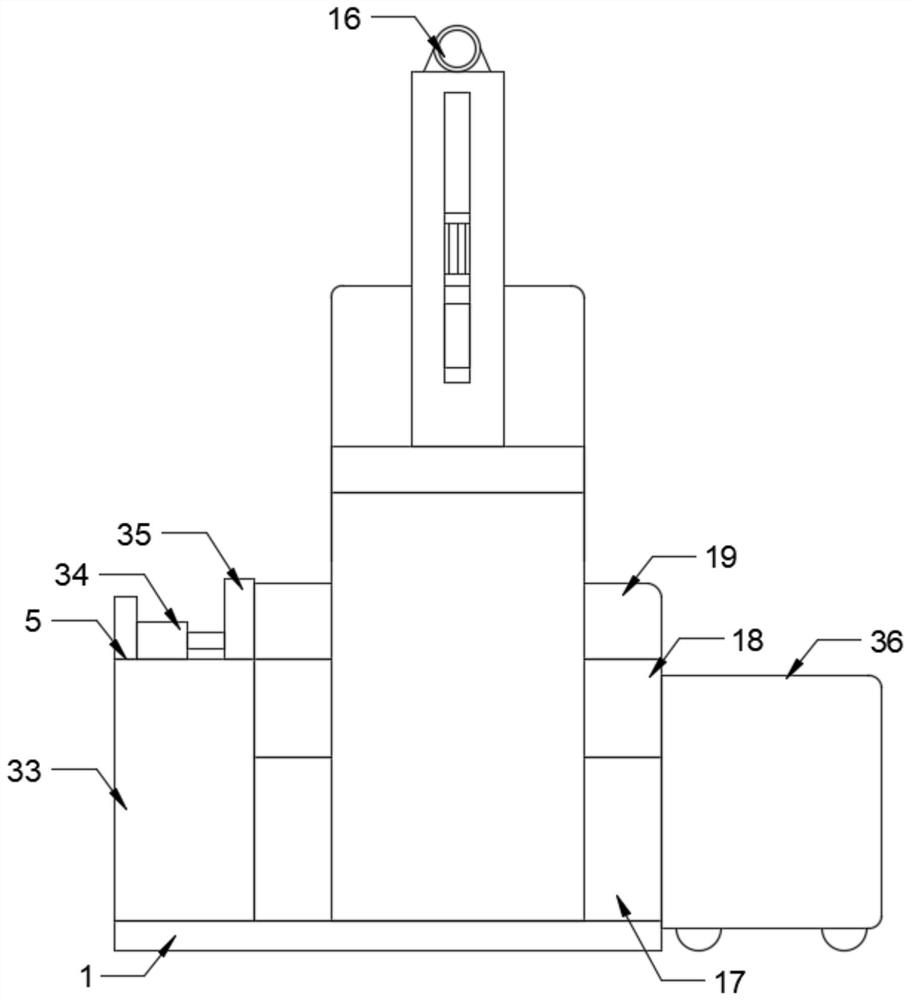

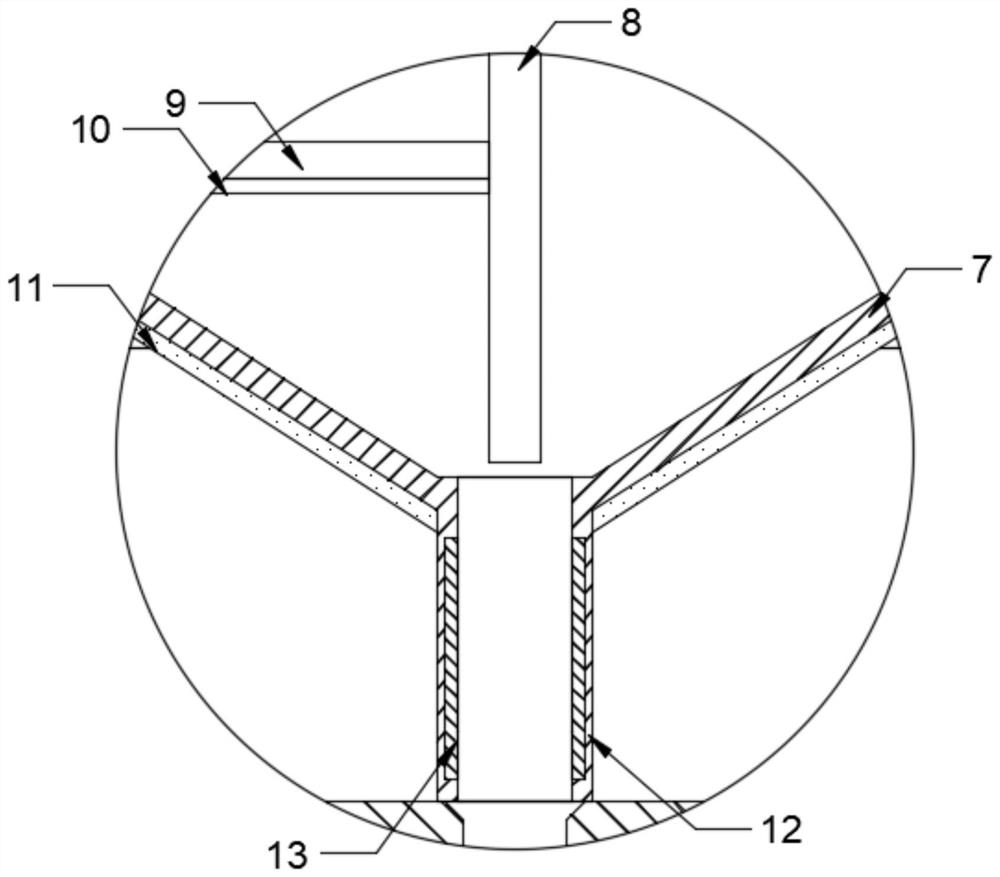

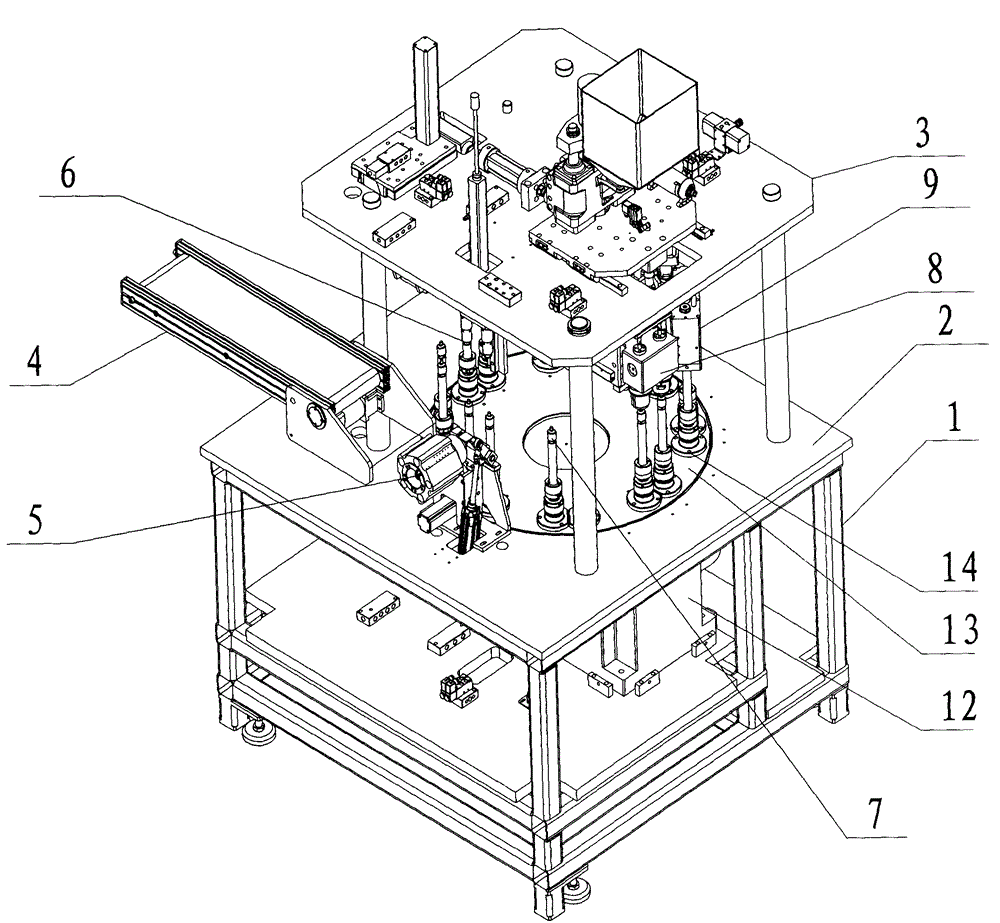

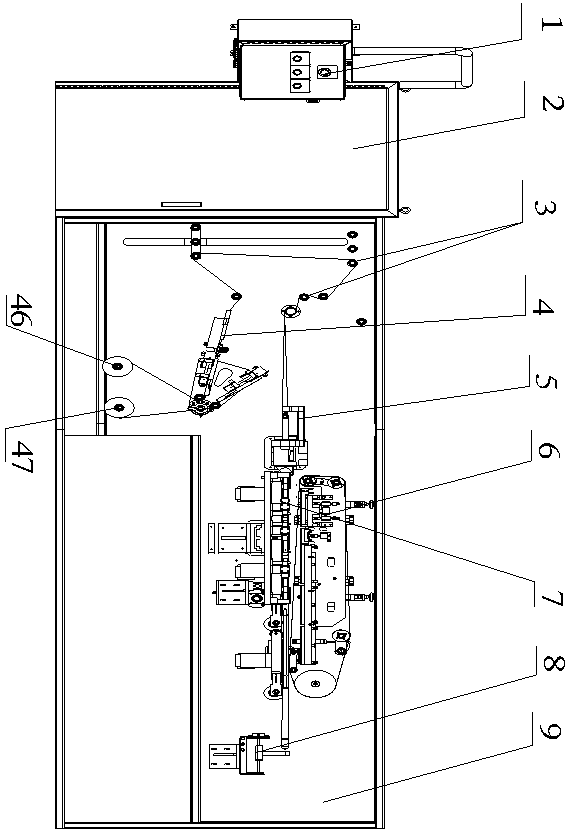

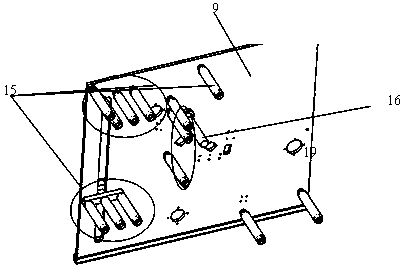

Automatic high speed flexible pipe shoulder forming machine

ActiveCN102744831AImprove molding processing efficiencyReduce labor intensityTubular articlesControl systemForm processing

The invention discloses an automatic high speed flexible pipe shoulder forming machine which comprises a frame and a working platform arranged on the frame, wherein a circular turntable mechanism driven by a main driving motor is mounted on the working platform. The forming machine is characterized in that the circular turntable mechanism is provided with a plurality of pairs of material cups, an automatic pipe feeding device, a detection device, an automatic plastic spitting device, an automatic forming device, a cooling device and an automatic pipe discharging device are correspondingly arranged around each pair of the material cups in order, and all the devices are controlled by PLC. According to the invention, the automation degree of the forming machine provided in the invention is high; an industrial PLC control system is used for automatic pipe feeding, automatic plastic spitting and automatic pipe discharging, and therefore, automatic forming processing operation of flexible pipes is realized, forming processing efficiency of the flexible pipes is improved, labor intensity is mitigated, and precise positioning and smooth and steady motion in processing of the flexible pipes are guaranteed; through utilization of the automatic pipe feeding device and simultaneous running of double pipes, high speed running is realized and production efficiency is enhanced.

Owner:NANTONG BAOTIAN PACKING MACHINERY

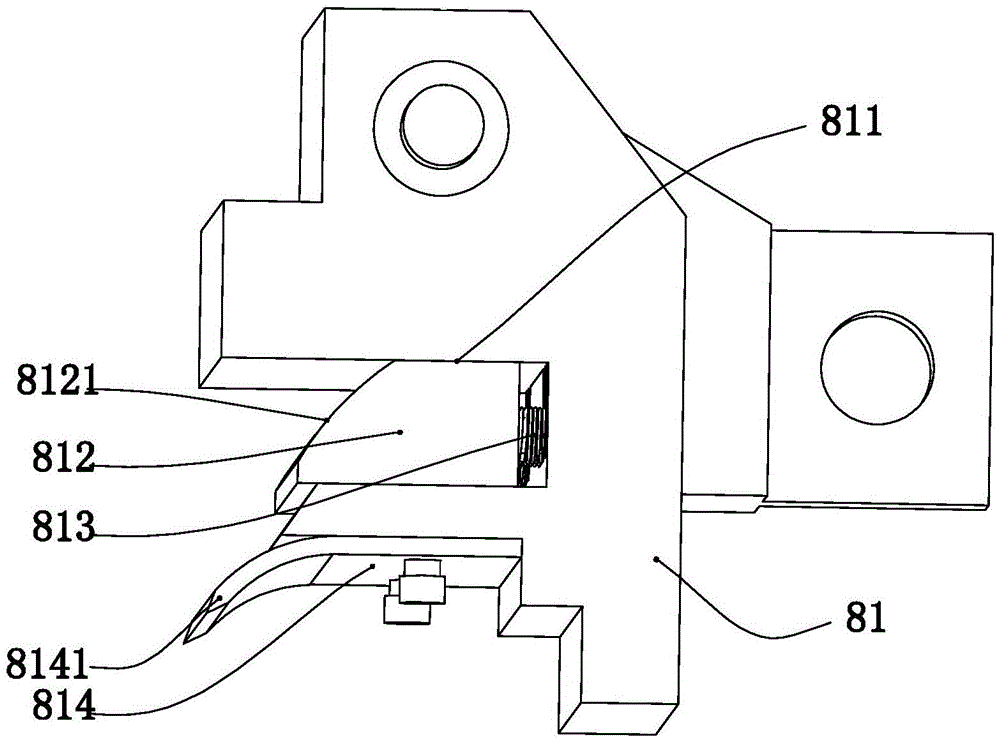

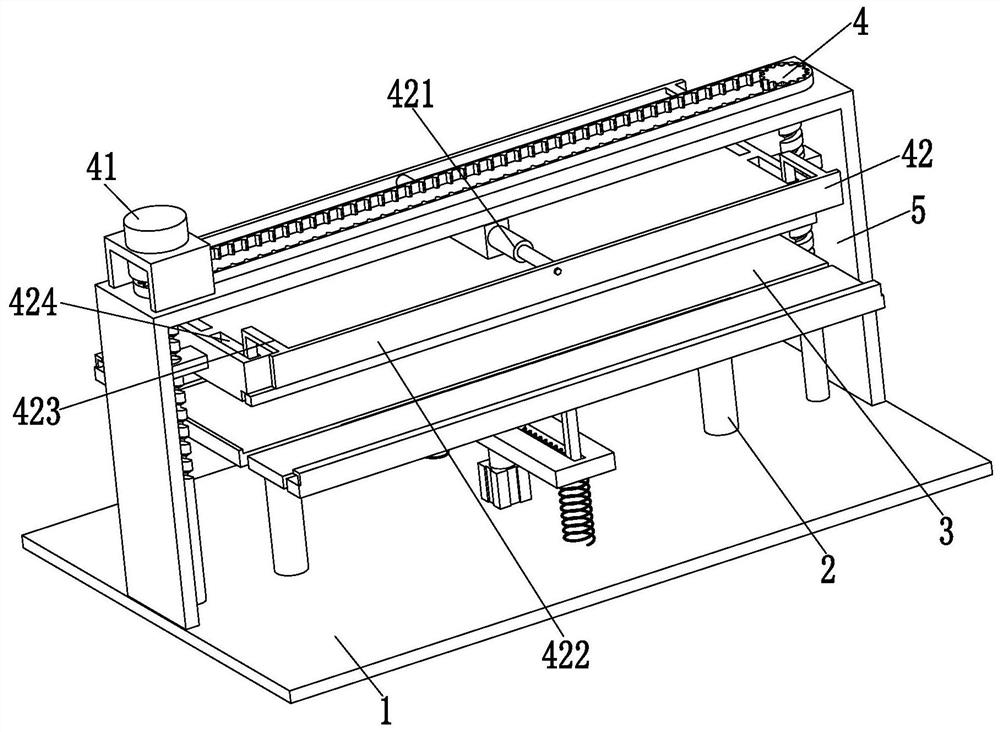

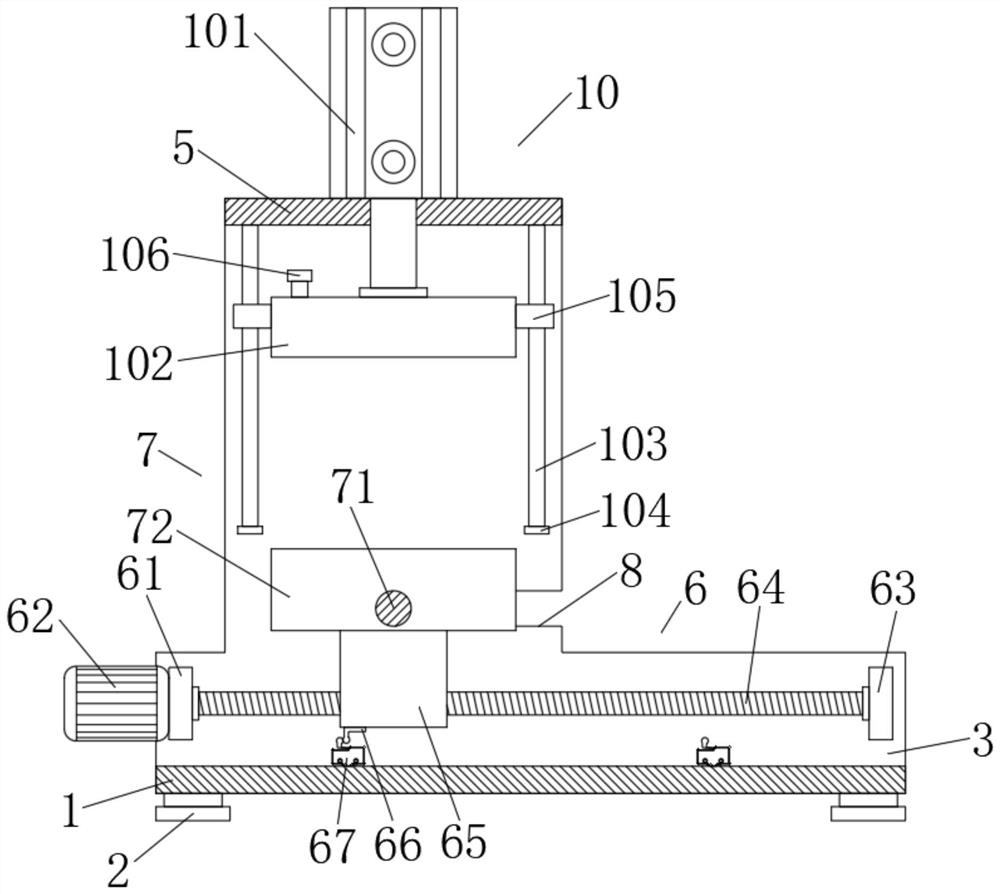

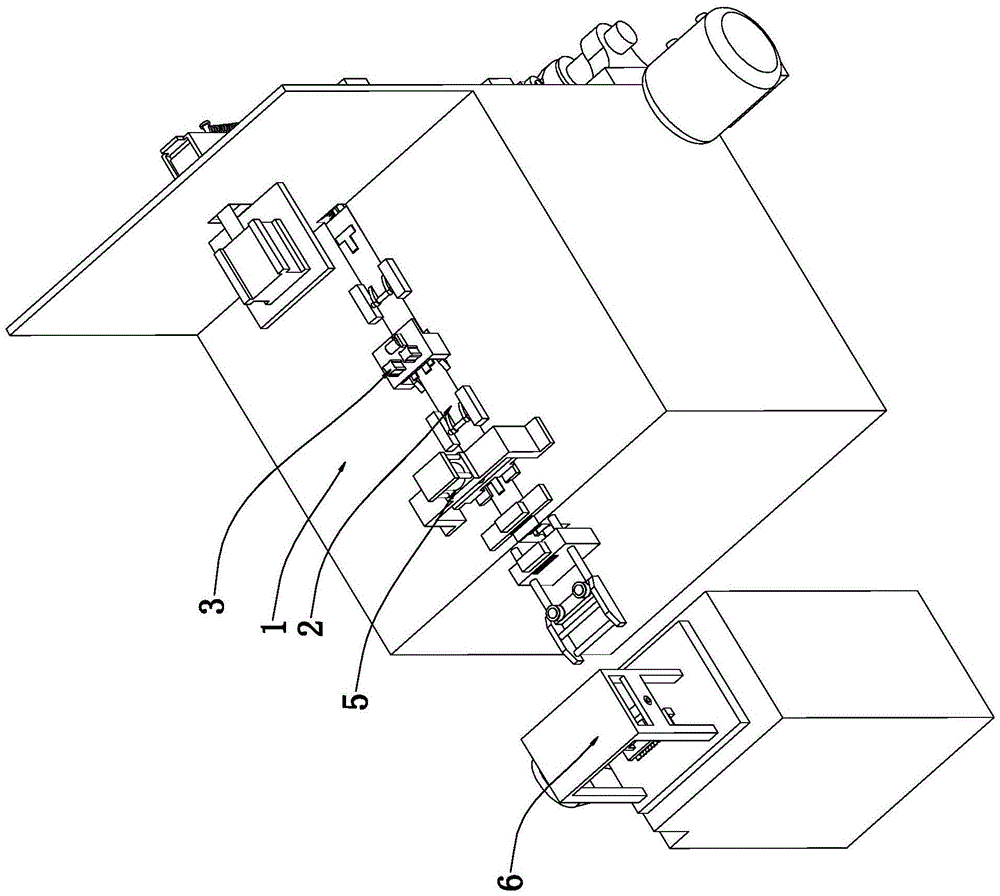

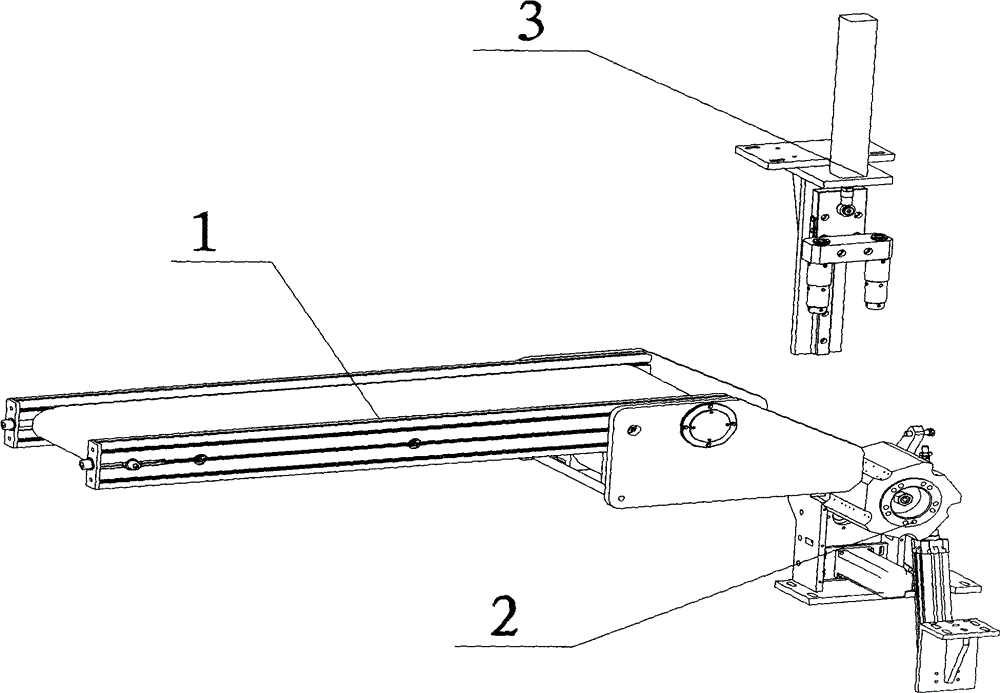

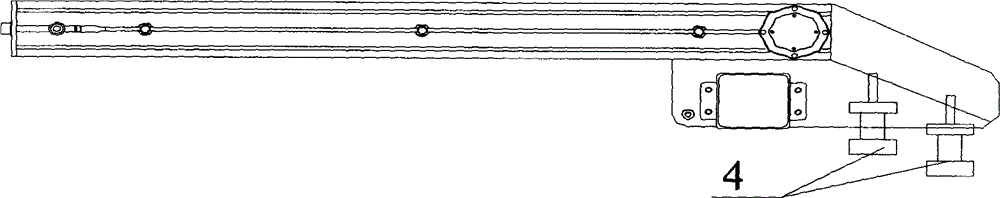

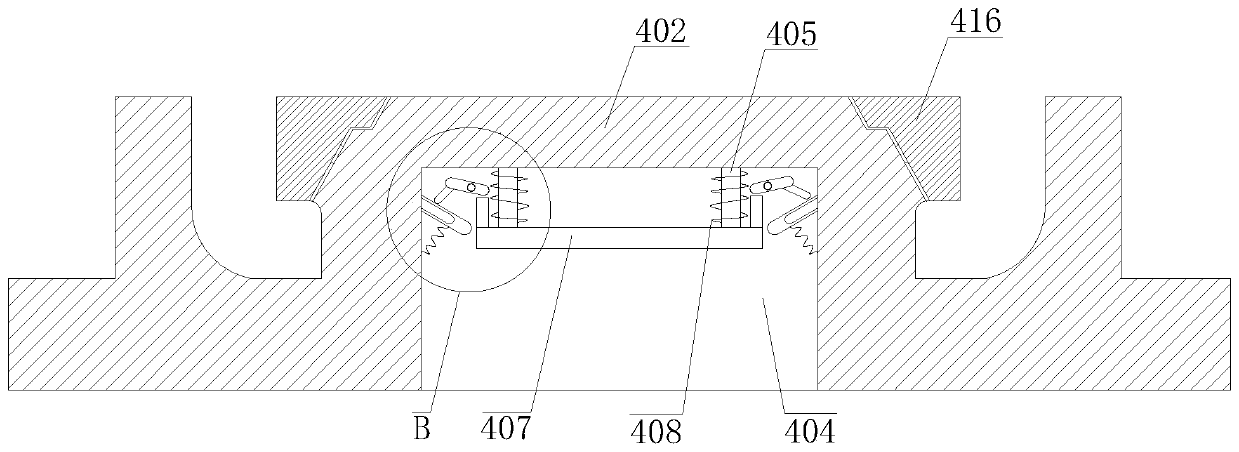

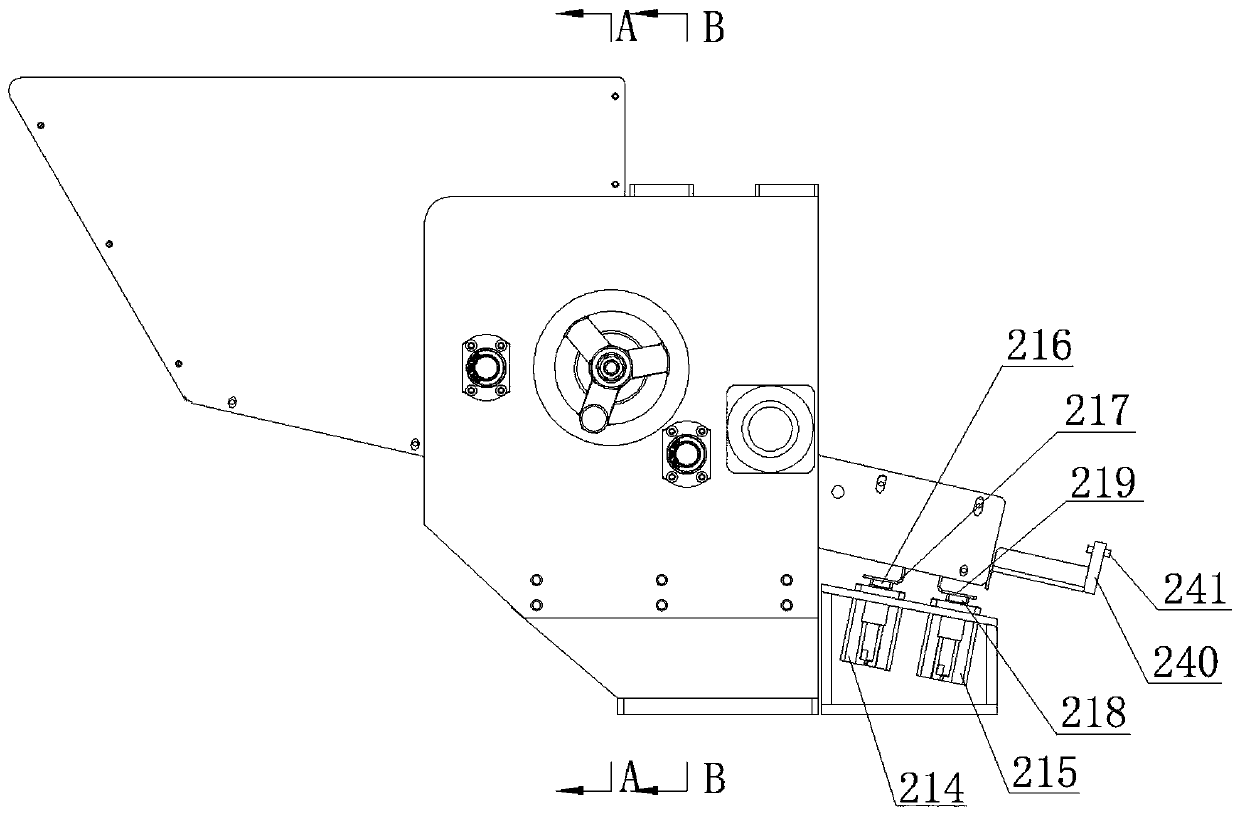

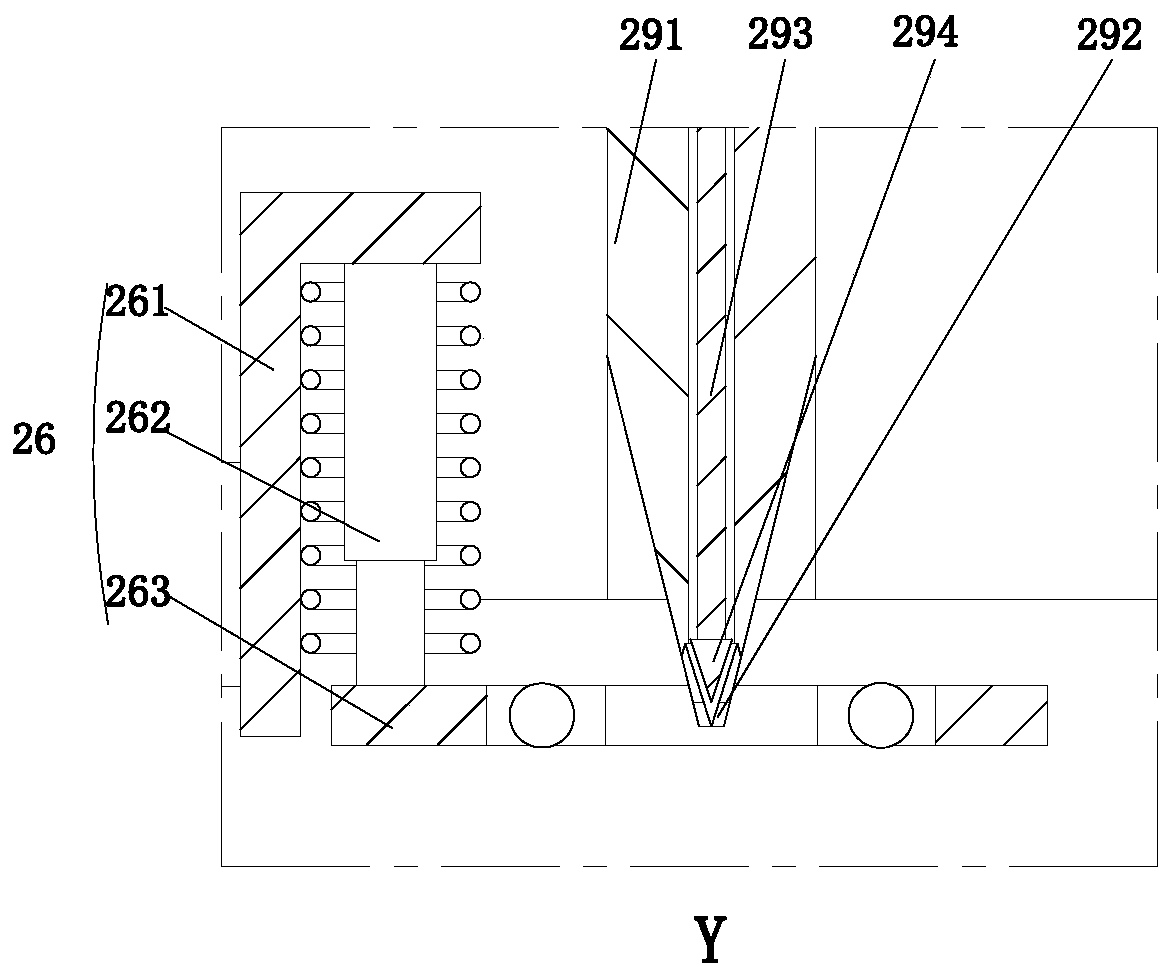

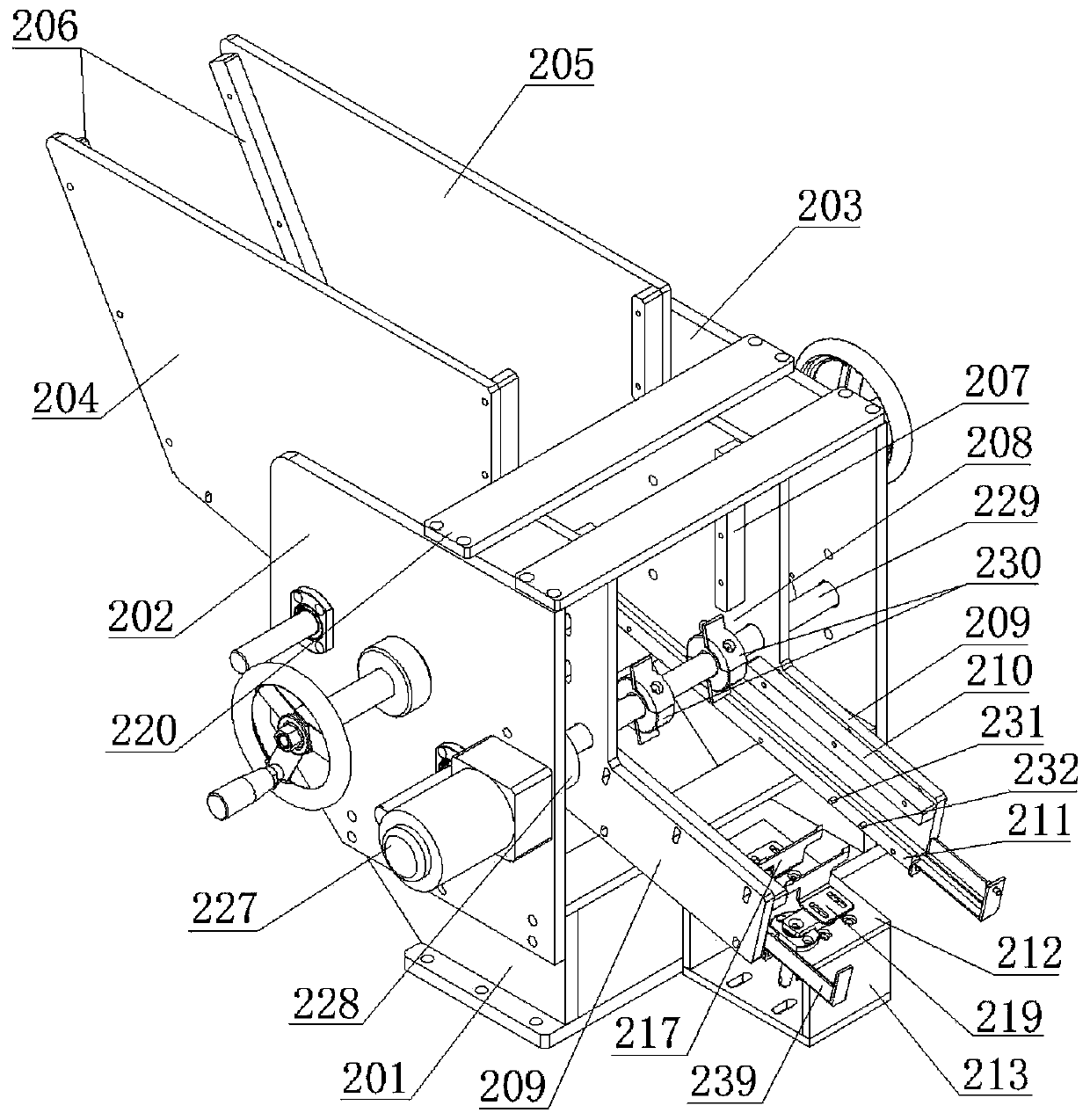

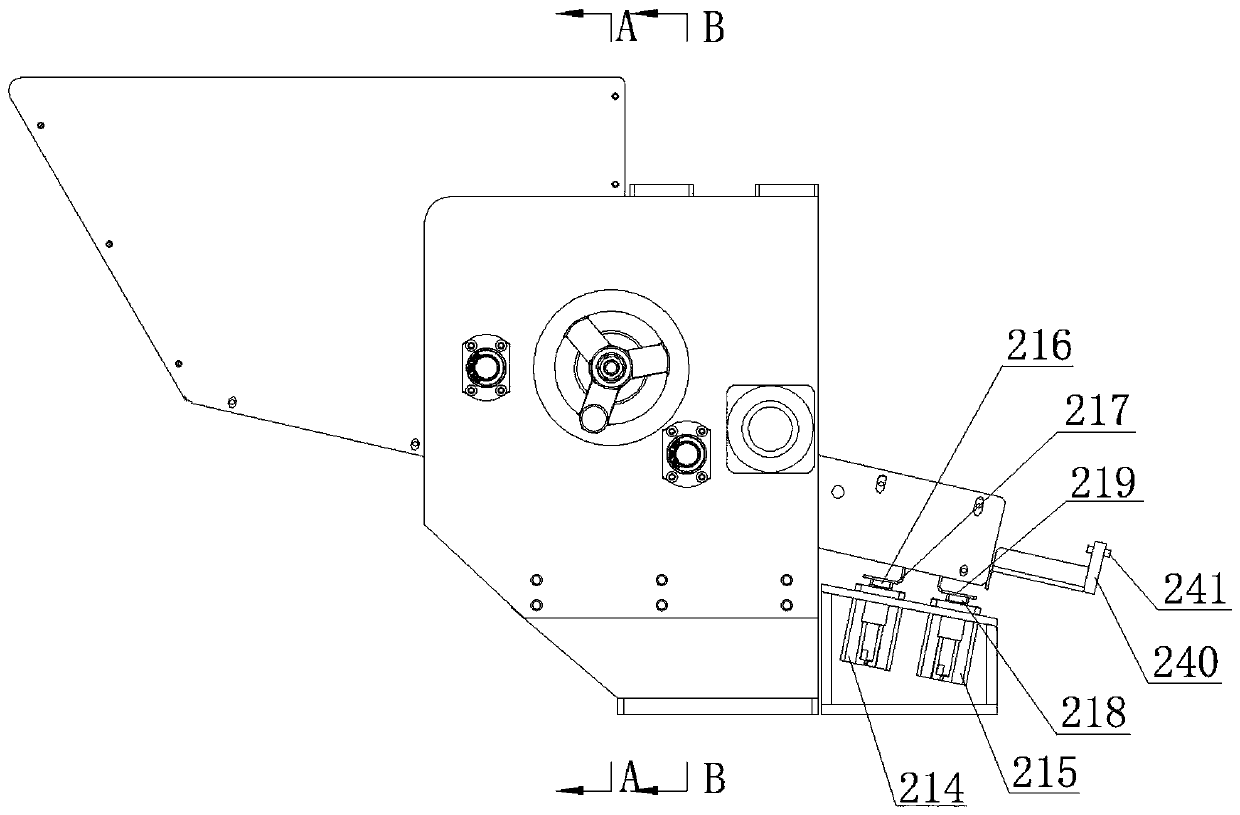

Edge folding, embracing and edge clamping device of filter center pipe forming machine

ActiveCN105598242AImprove molding processing efficiencyGood molding consistencyMetal-working feeding devicesPositioning devicesForm processingForms processing

The invention discloses an edge folding, embracing and edge clamping device of a filter center pipe forming machine. The device comprises an edge folding mechanism and an embracing-edge clamping mechanism connected to the discharge end of the edge folding mechanism, wherein the edge folding mechanism comprises a sheet transporting rail, and a left edge folding assembly and a right edge folding assembly arranged on left and right sides of the sheet transporting rail; the embracing-edge clamping mechanism comprises a support plate, an embracing mandrel, an embracing positioning pressing plate, an edge clamping top block and two embracing force application assemblies arranged on left and right sides of an embracing die, and the support plate is provided with a feed inlet. The edge folding, embracing and edge clamping device has the advantages of high forming processing efficiency and good product forming consistency.

Owner:温州市法法服饰有限公司

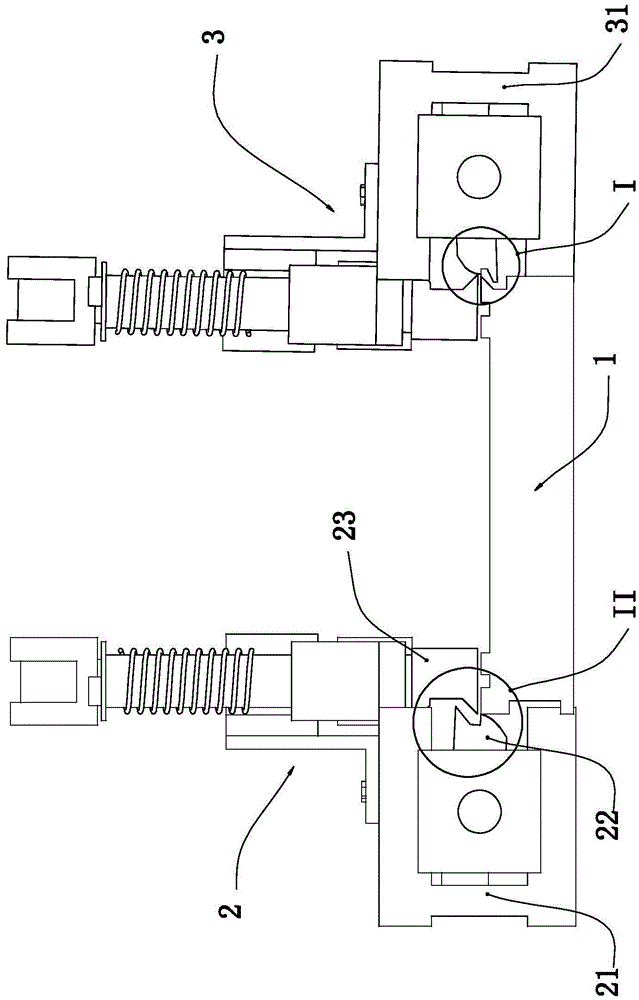

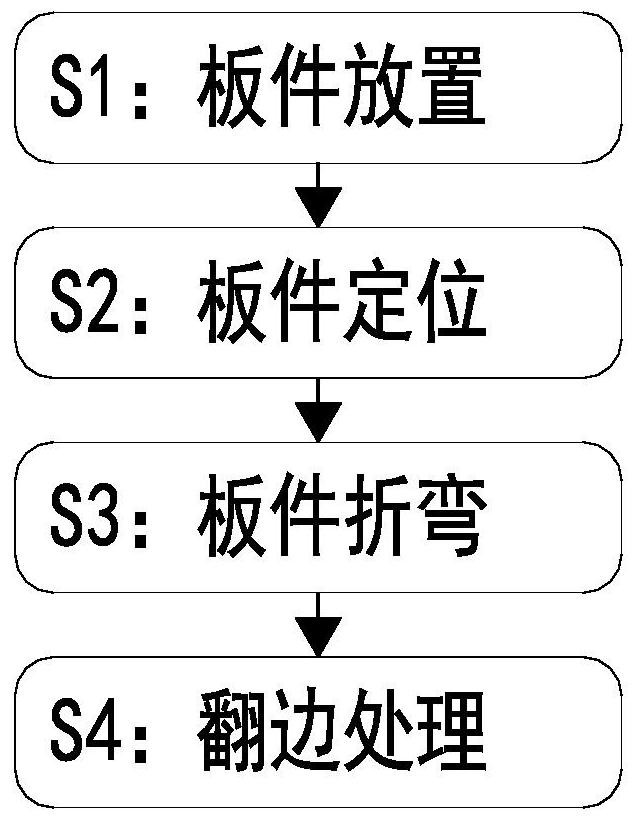

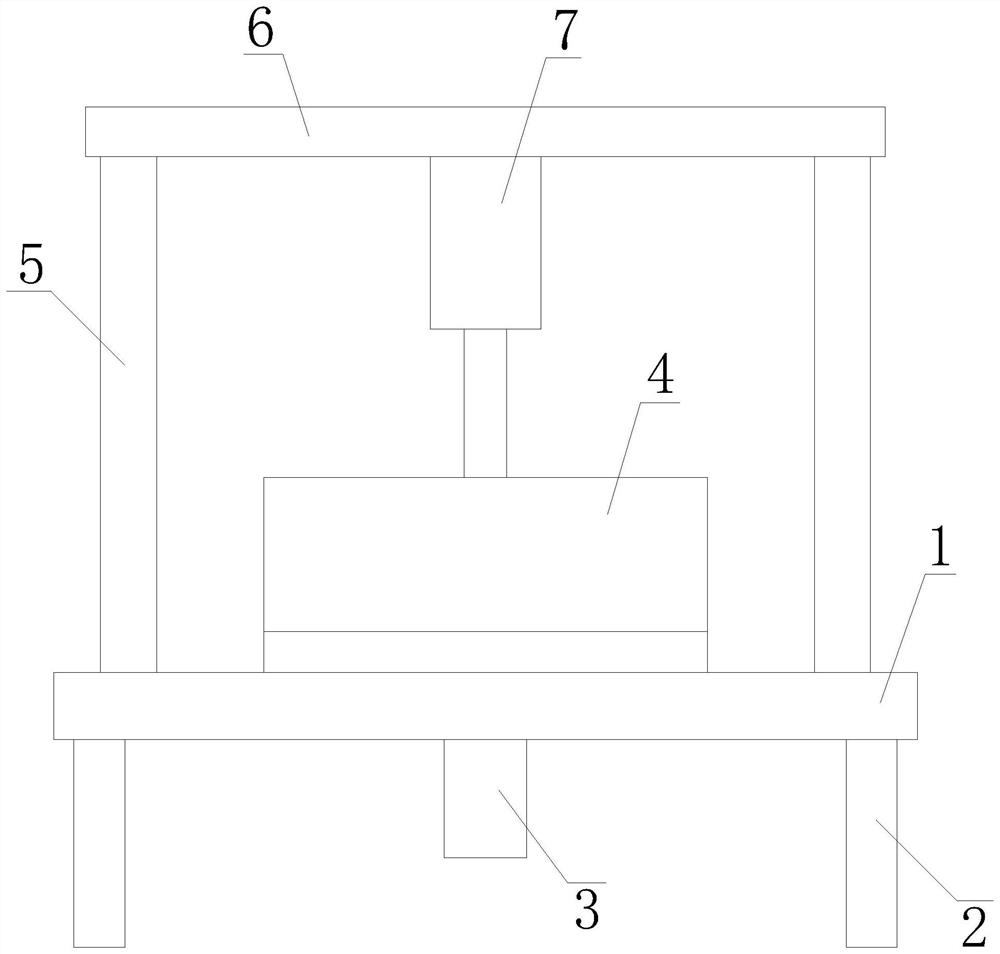

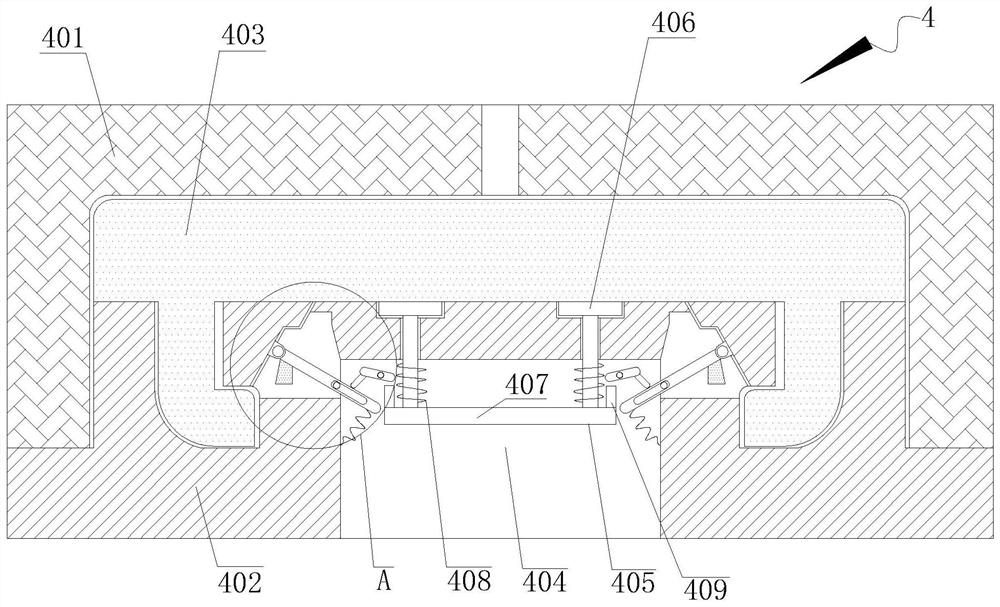

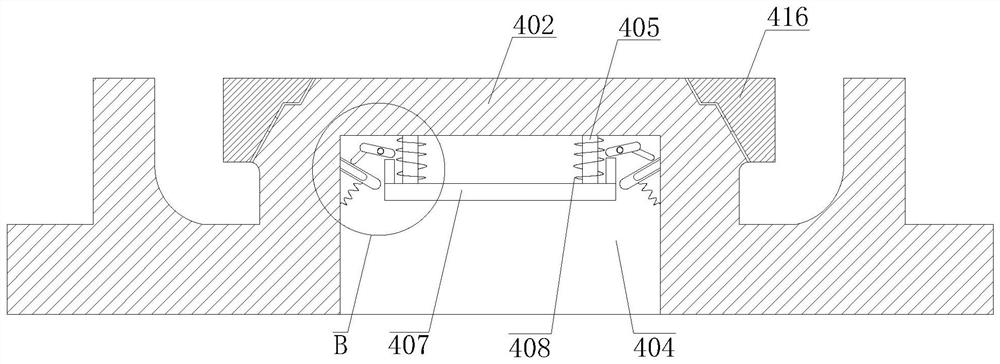

Alloy plastic-spraying wire and cable bridge manufacturing and forming machining method

ActiveCN113102586AImprove molding processing efficiencyQuality assuranceMetal-working feeding devicesPositioning devicesStructural engineeringAlloy

The invention relates to an alloy plastic-spraying wire and cable bridge manufacturing and forming machining method. An alloy plastic-spraying wire and cable bridge manufacturing and forming machining machine is used and comprises a base, installation columns, a containing base, a downward-pressing flanging device and a fixed frame. The installation columns are symmetrically installed on the left side and the right side of the upper end face of the base. The upper ends of the installation columns are connected with the containing base, the downward-pressing flanging device is arranged above the containing base, the downward-pressing flanging device is installed on the fixed frame, and the fixed frame is fixed to the middle of the upper end face of the base. The problems that according to a traditional alloy plastic-spraying wire and cable bridge manufacturing and machining method, fixing, bending and flanging often need to be conducted on different mechanical devices, the machining efficiency is low, stations need to be moved, time and labor are wasted, and after bending is conducted, it is difficult to ensure the bending effect, lateral sides can be bent back, and consequently the aesthetic degree of electric wire and cable bridges is lowered and the use of the electric wire and cable bridges is influenced can be solved.

Owner:深圳深华新电缆实业有限公司

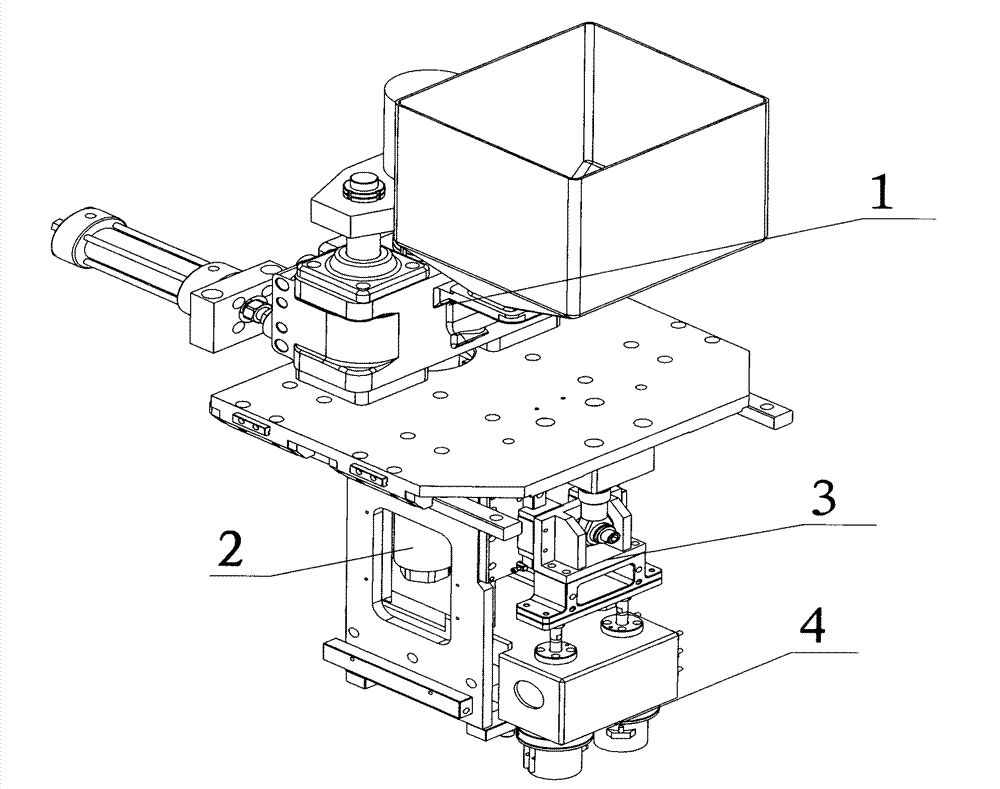

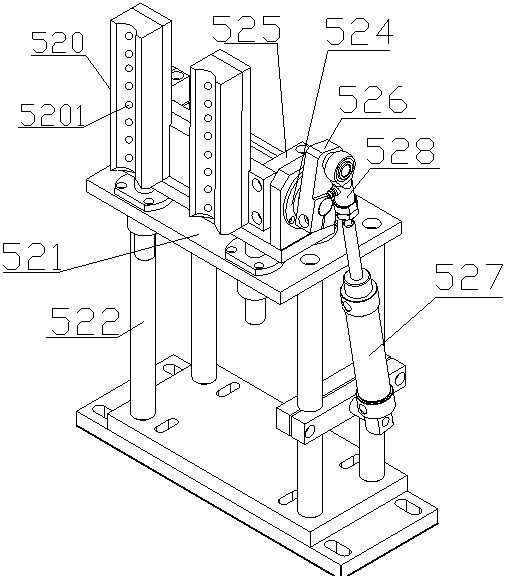

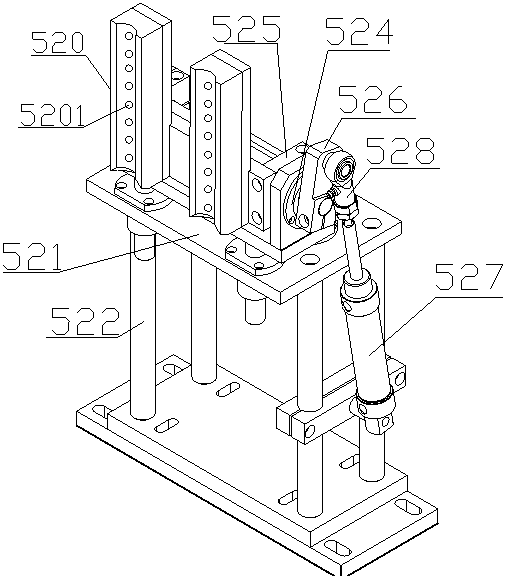

Automatic plastic-spraying device used for high-speed hose shoulder-molding machine

InactiveCN102729420AImprove molding processing efficiencyReduce labor intensityControl systemMolding machine

The invention discloses an automatic plastic-spraying device used for a high-speed hose shoulder-molding machine. The automatic plastic-spraying device comprising a rack and a roof plate mounted on the rack, is characterized in that: the device comprises a material-storing mechanism, a heating barrel, a material-cutting mechanism and a material-discharging mechanism; the material-storing mechanism is disposed on the roof plate; the heating barrel, material-cutting mechanism and the material-discharging mechanism are all disposed under the roof plate; an upper end opening of the heating barrel is connected to an outlet of the material-storing mechanism; a lower end opening of the heating barrel is connected to the material-discharging mechanism; the material-cutting mechanism is disposed on the material-discharging mechanism; and the device is controlled by a PLC. The device provided in the invention, adopting the industrial PLC control system to perform automatic plastic spraying, can assist in realizing an operation of automatic molding processing of a hose, improving molding processing efficiency of the hose, reducing labor intensity and guaranteeing precise positioning and stable movement in the processing process.

Owner:NANTONG BAOTIAN PACKING MACHINERY

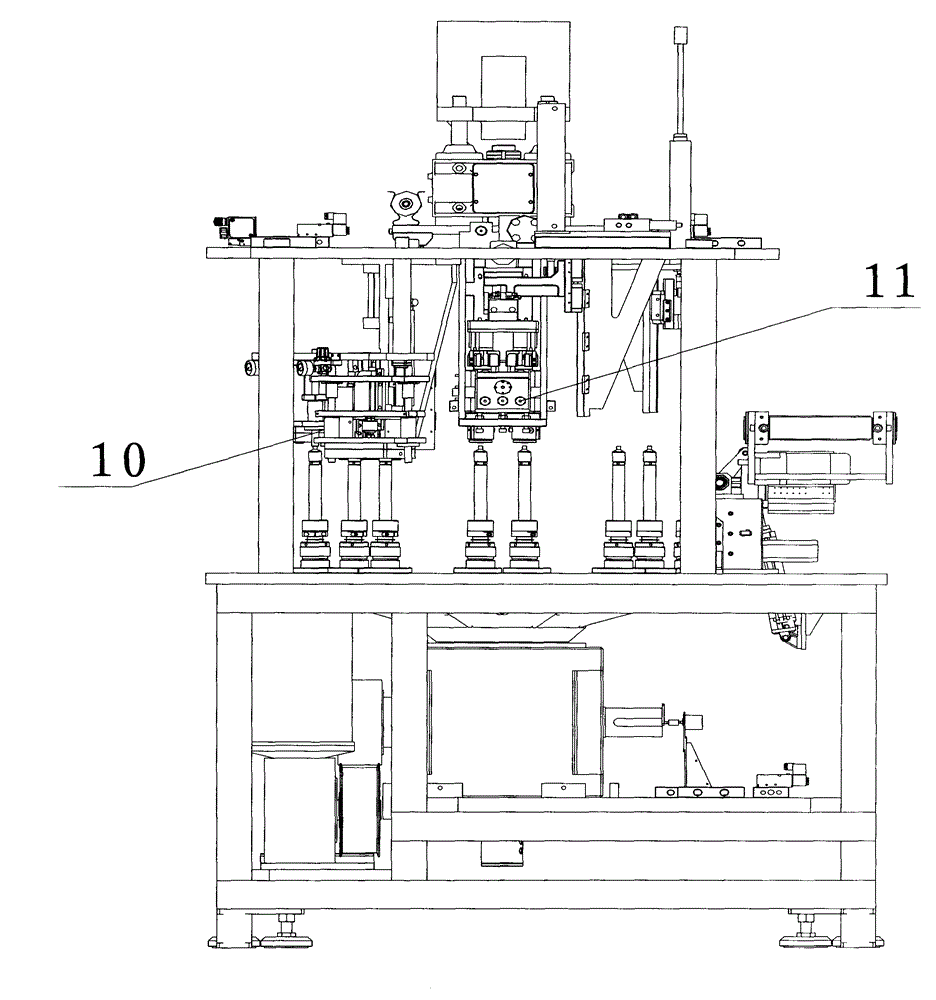

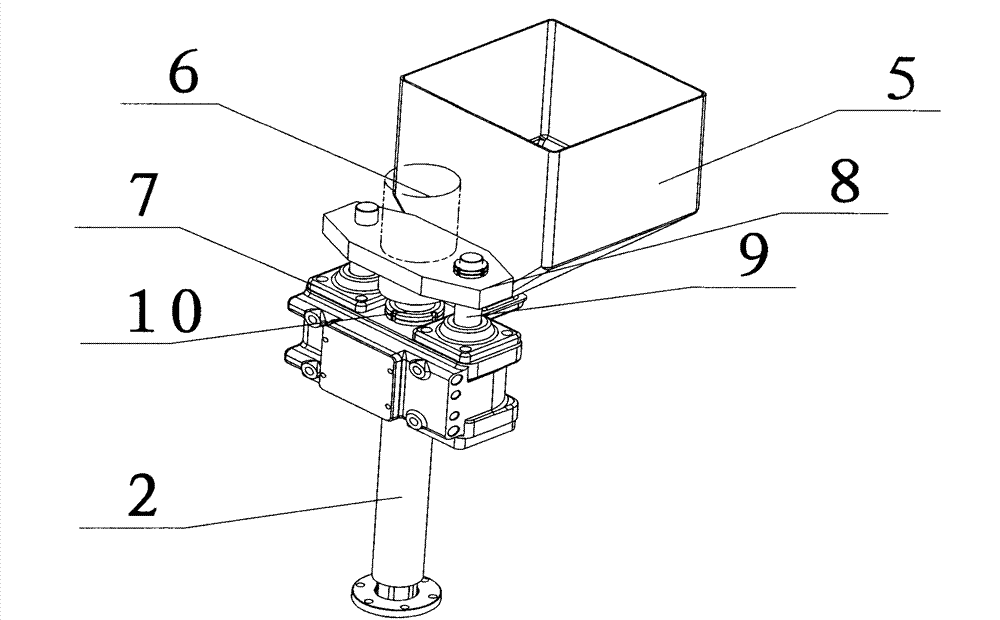

Full-automatic double-head shoulder injection molding machine

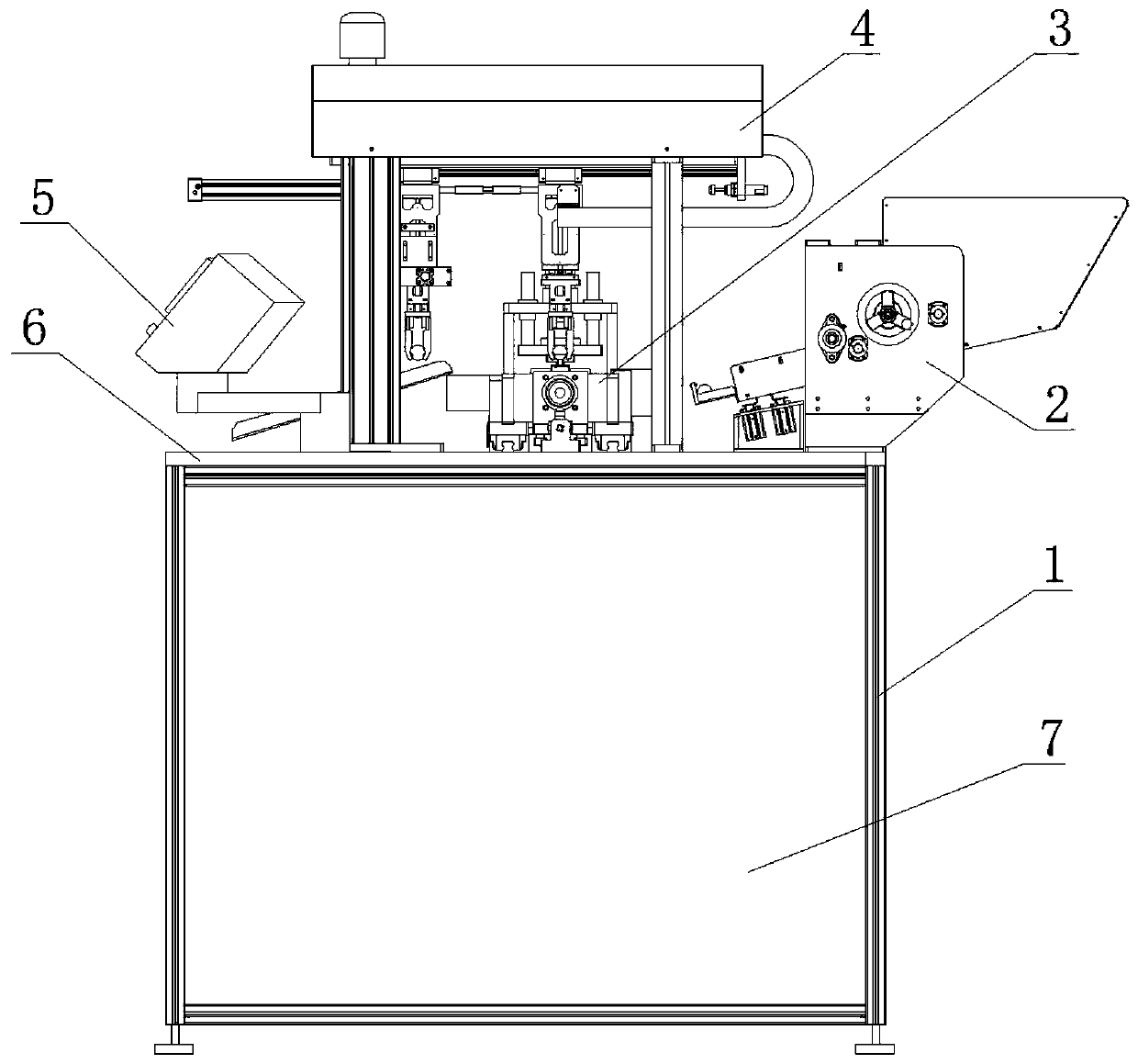

ActiveCN107856332AImprove molding processing efficiencyReduce labor intensityTubular articlesElectric machineryEngineering

The invention discloses a full-automatic double-head shoulder injection molding machine which comprises a rack, and a working platform I and a working platform II which are mounted on the rack, wherein a motor I and a circular turntable mechanism driven by the motor I are mounted on the working platform I; the full-automatic double-head shoulder injection molding machine is characterized in that aplurality of mandrel holders are arranged on the circular turntable mechanism; mandrels are arranged on the mandrel holders; a plurality of air blowing openings are formed in the mandrels; and an automatic pipe feeding device, an automatic injection molding device, an automatic forming device, a cooling device and an automatic pipe discharging device are arranged on the circular turntable mechanism in sequence. Compared with the prior art, the full-automatic double-head shoulder injection molding machine disclosed by the invention has the advantages that by full-automatic forming machining operation of a hose, the hose forming machining efficiency is improved, and the labor intensity is reduced; and by the adoption of the full-automatic pipe feeding device, two pipes are fed simultaneously, so that high-speed operation can be realized, the production efficiency is improved, the number of the used mandrels is reduced, the efficiency is improved, and the cost is reduced.

Owner:NANTONG BAOTIAN PACKING MACHINERY

Device for forming plastic shell of LED lamp and application method of device

The invention discloses a device for forming a plastic shell of an LED lamp and an application method of the device. The device comprises a bottom plate; the four corners of the bottom of the bottom plate are each fixedly connected with a supporting leg; one end of the top of the bottom plate is fixedly connected with a first fixing plate; the end, far away from the first fixing plate, of the topof the bottom plate is fixedly connected with a second fixing plate; and a fixing frame which is of a U-shaped structure is fixedly connected between the first fixing plate and the second fixing plate. The device disclosed by the invention is compact in structure, easy and convenient to operate and high in practicability; a moving mechanism is arranged to cooperate with a turnover mechanism, so that a lower mold can be driven to move and be turned over simultaneously; in this way, a formed LED plastic shell in the lower mold can be quickly discharged; meanwhile, a cooling mechanism is arrangedat the bottom of the lower mold to cool the lower mold; and thus the machining efficiency for formation of equipment is greatly improved, and actual use is facilitated.

Owner:惠州大亚湾鸿通工业有限公司

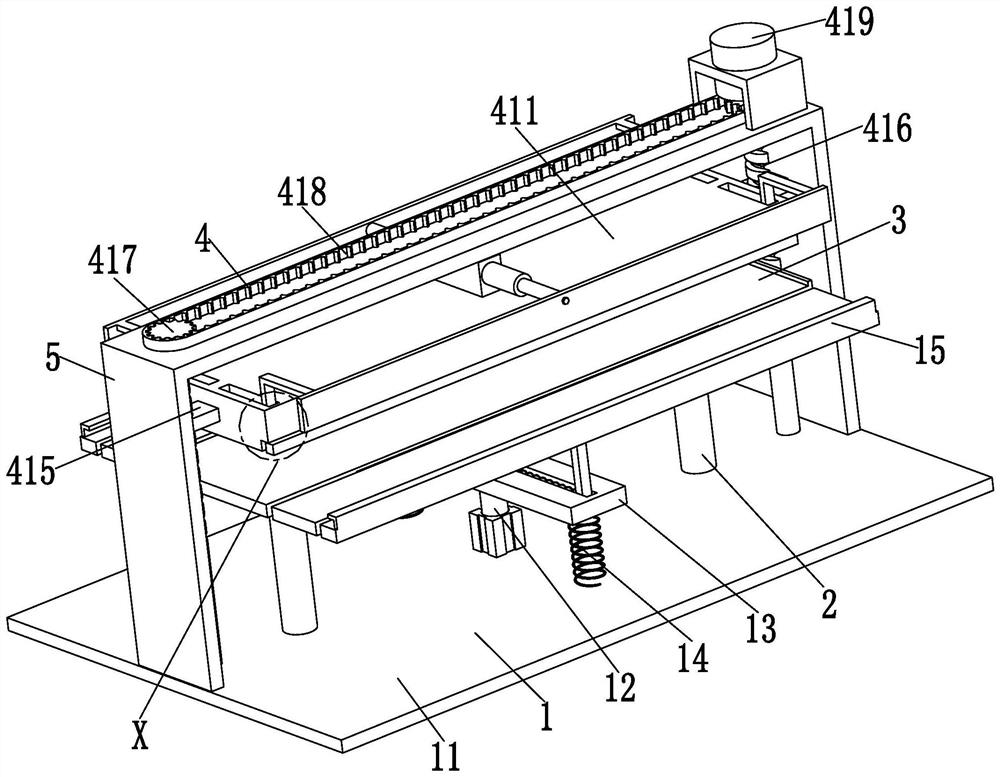

Tubular corrugated paper sleeve forming machine with tapping mechanism and material cutting mechanism

ActiveCN105479820AImprove molding processing efficiencyProduct molding consistency is goodPaper/cardboard articlesForming forceEngineering

The invention discloses a tubular corrugated paper sleeve forming machine with a tapping mechanism and a material cutting mechanism. The tubular corrugated paper sleeve forming machine comprises a machine frame, a feeding mechanism, an edge gluing mechanism and a circle forming edge baking mechanism, wherein the feeding mechanism comprises a feeding rail plate and a feeding rail plate gliding driving cylinder; the edge gluing mechanism is arranged on a gluing baseplate above the feeding rail plate; the circle forming edge baking mechanism comprises a supporting plate, a circle forming mandrel, a circle forming positioning pressing plate, an edge clamping top plate and two circle forming force application assemblies arranged on the left side and the right side of a circle forming mold, wherein a feeding hole is formed in the supporting plate and is connected to a discharging end of the feeding mechanism; a hot air cavity is formed in the edge clamping top plate; a plurality of hot air holes which communicate with the hot air cavity are formed in a top plate of the edge clamping top plate; a calorifier which is connected with a hot air cavity pipe is also arranged on the supporting plate. The tubular corrugated paper sleeve forming machine disclosed by the invention has the advantages of being reasonable in structure design, high in processing efficiency, and good in forming consistency of products.

Owner:重庆独角兽知识产权管理咨询有限公司

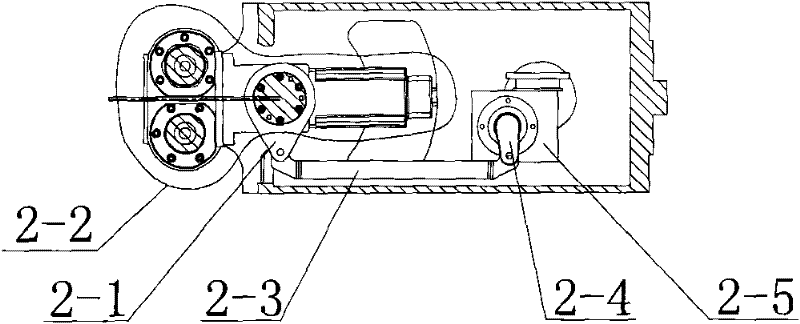

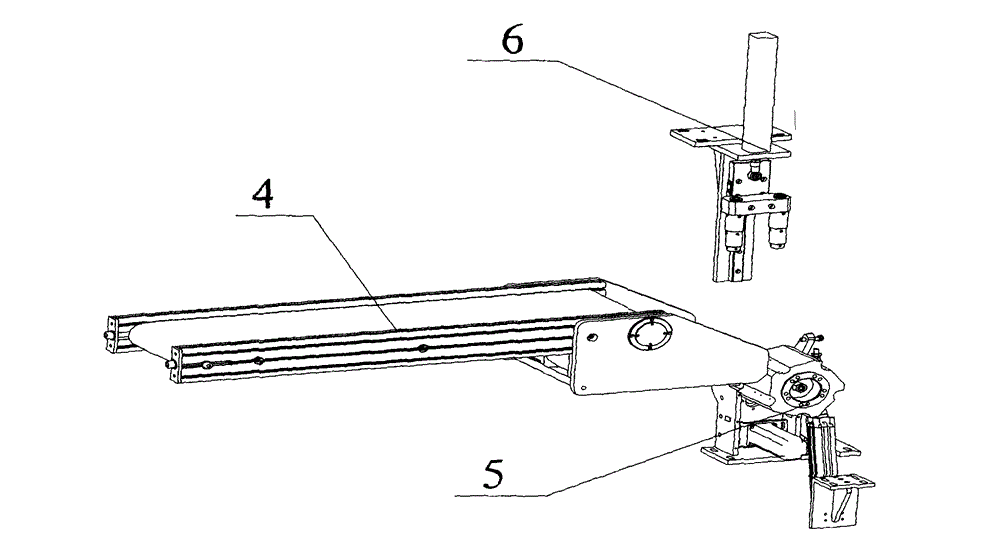

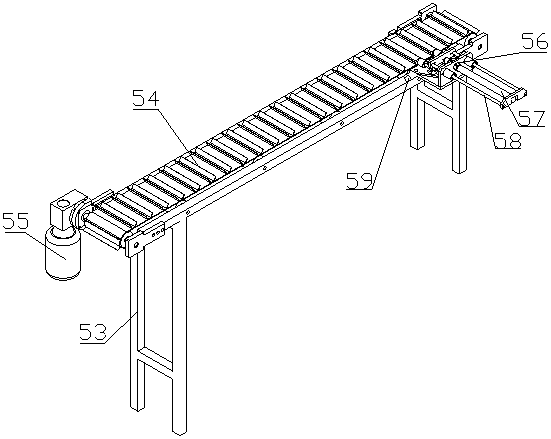

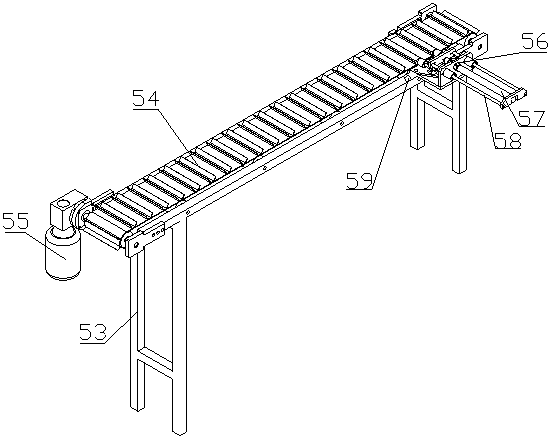

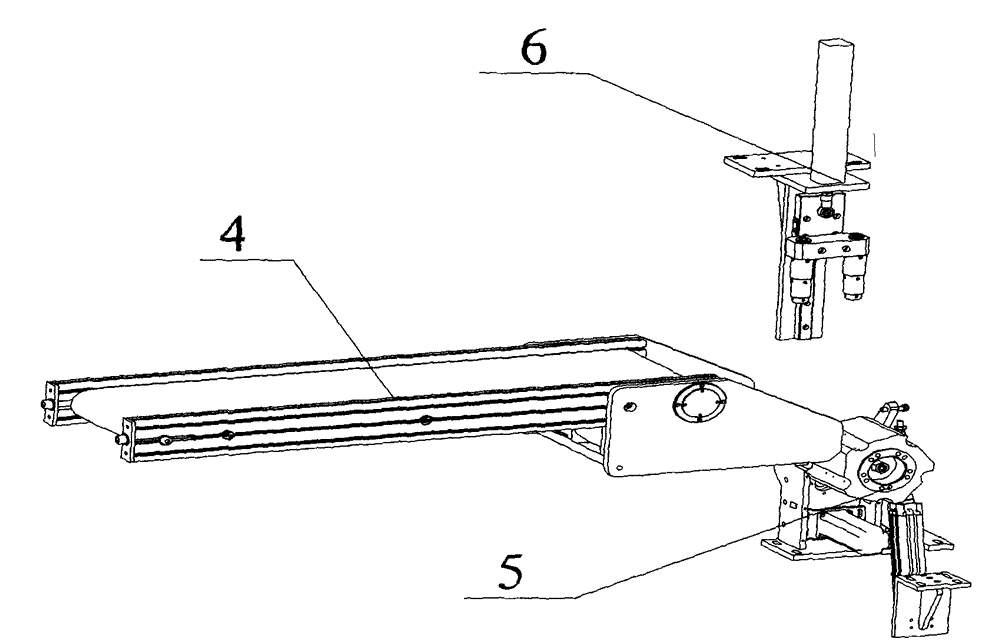

Automatic pipe feeding device for high speed flexible pipe shoulder forming machine

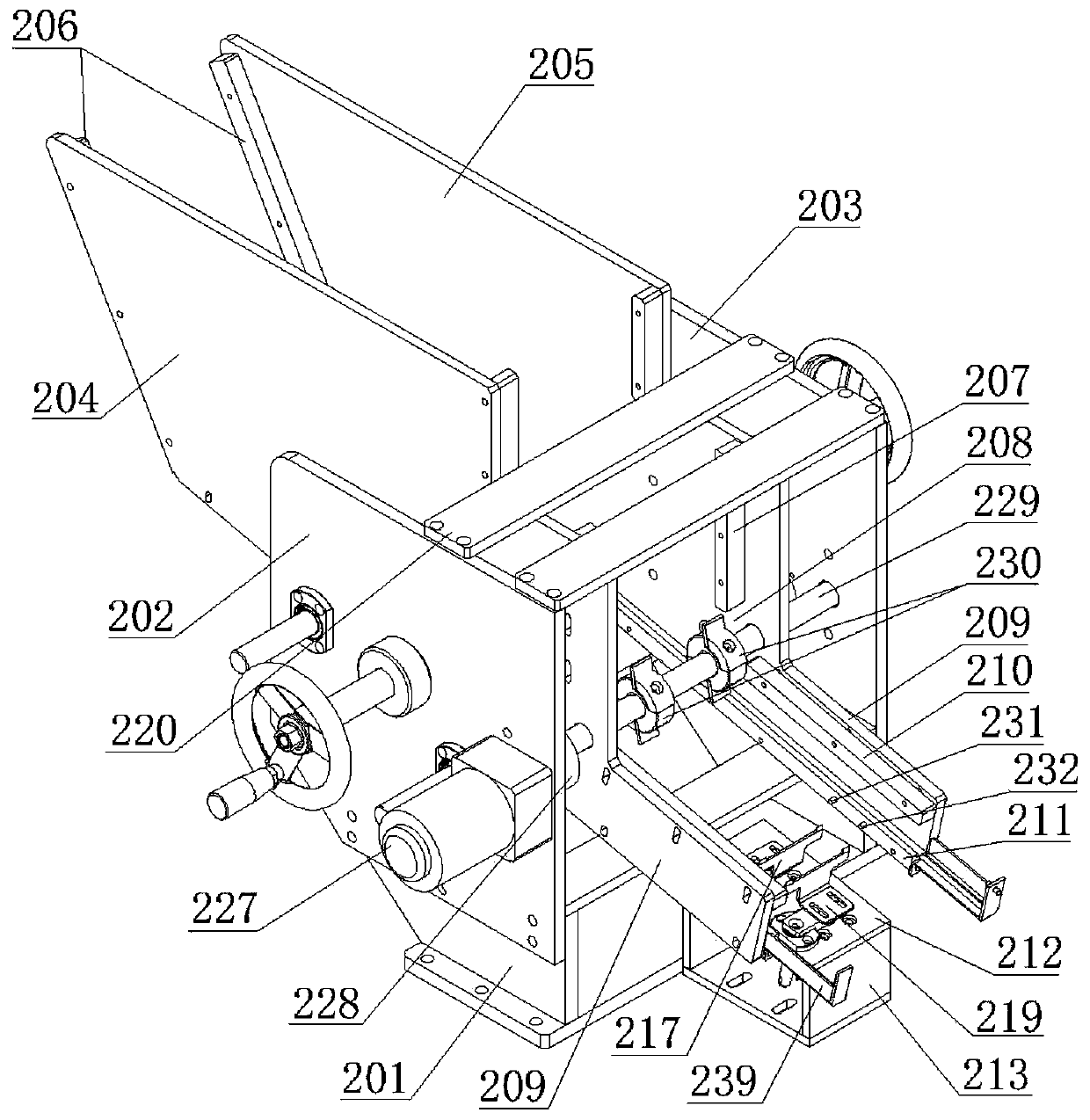

ActiveCN102744809AImprove molding processing efficiencyReduce labor intensityForm processingForms processing

The invention discloses an automatic pipe feeding device for a high speed flexible pipe shoulder forming machine. The pipe feeding device comprises a frame and a working platform and a top plate arranged on the frame, and is characterized in that the device comprises a pipe feeding tray, a pipe feeding mechanism and a pipe pressing mechanism, wherein the pipe feeding tray and the pipe feeding mechanism are both fixed on the working platform, the pipe pressing mechanism is fixed on the top plate and the device is controlled by PLC. According to the invention, the automation degree of the forming machine provided in the invention is high; an industrial PLC control system is used for automatic pipe feeding, and therefore, automatic forming processing operation of flexible pipes is realized, forming processing efficiency of the flexible pipes is improved, labor intensity is mitigated, and precise positioning and smooth and steady motion in processing of the flexible pipes are guaranteed; through utilization of the automatic pipe feeding device and simultaneous running of double pipes, high speed running is realized and production efficiency is enhanced.

Owner:NANTONG BAOTIAN PACKING MACHINERY

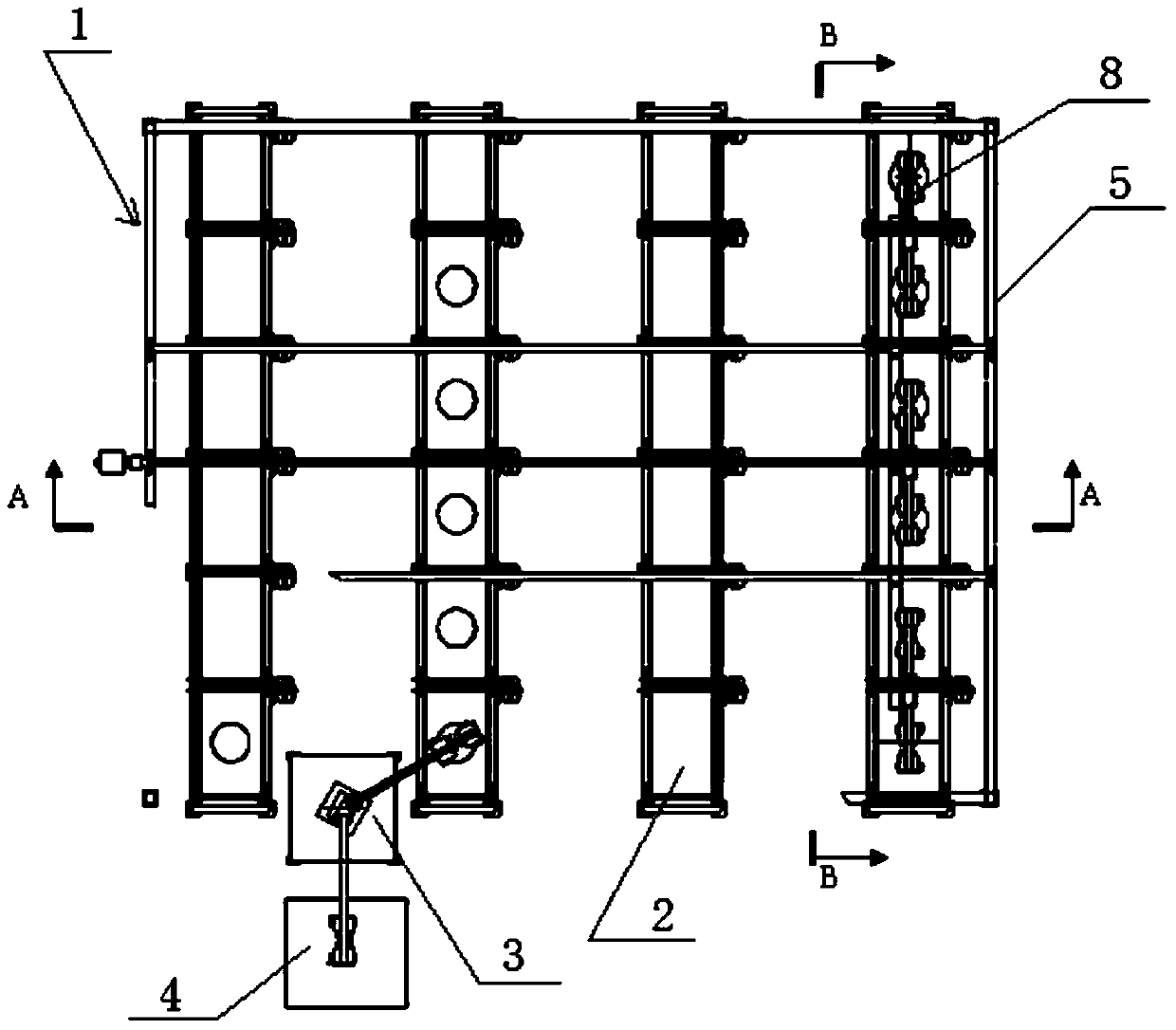

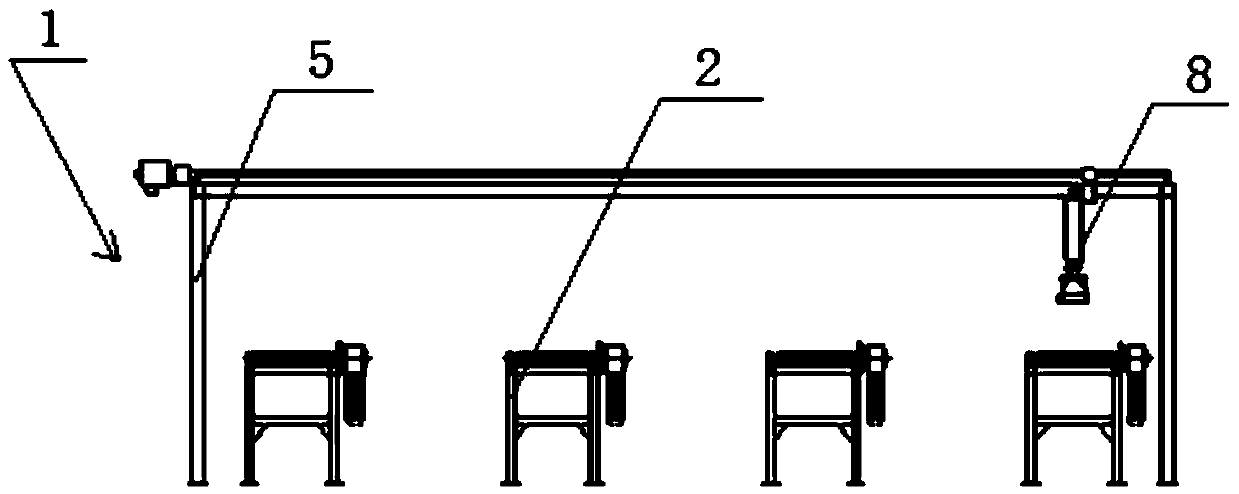

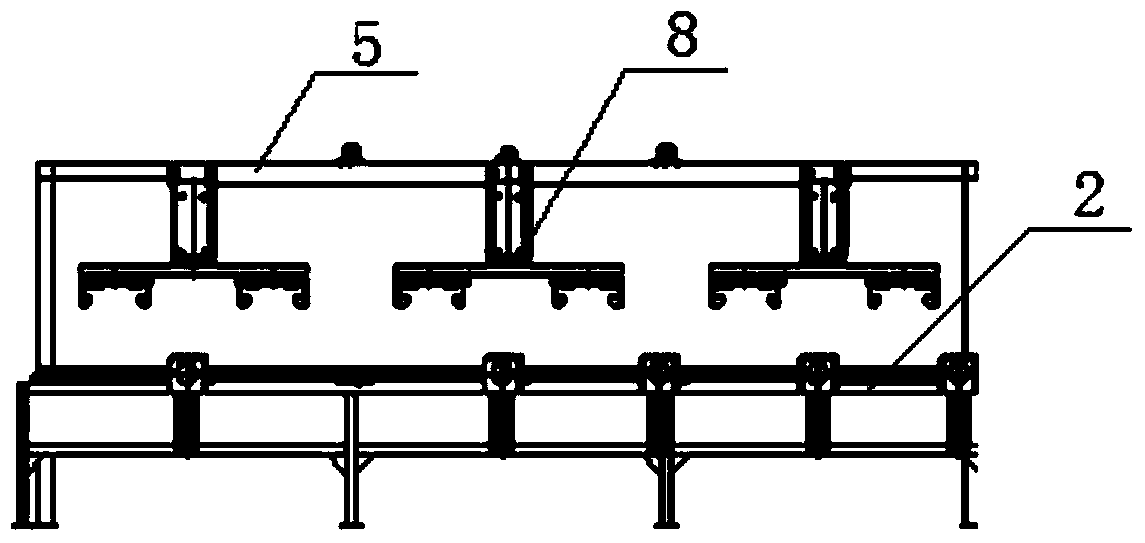

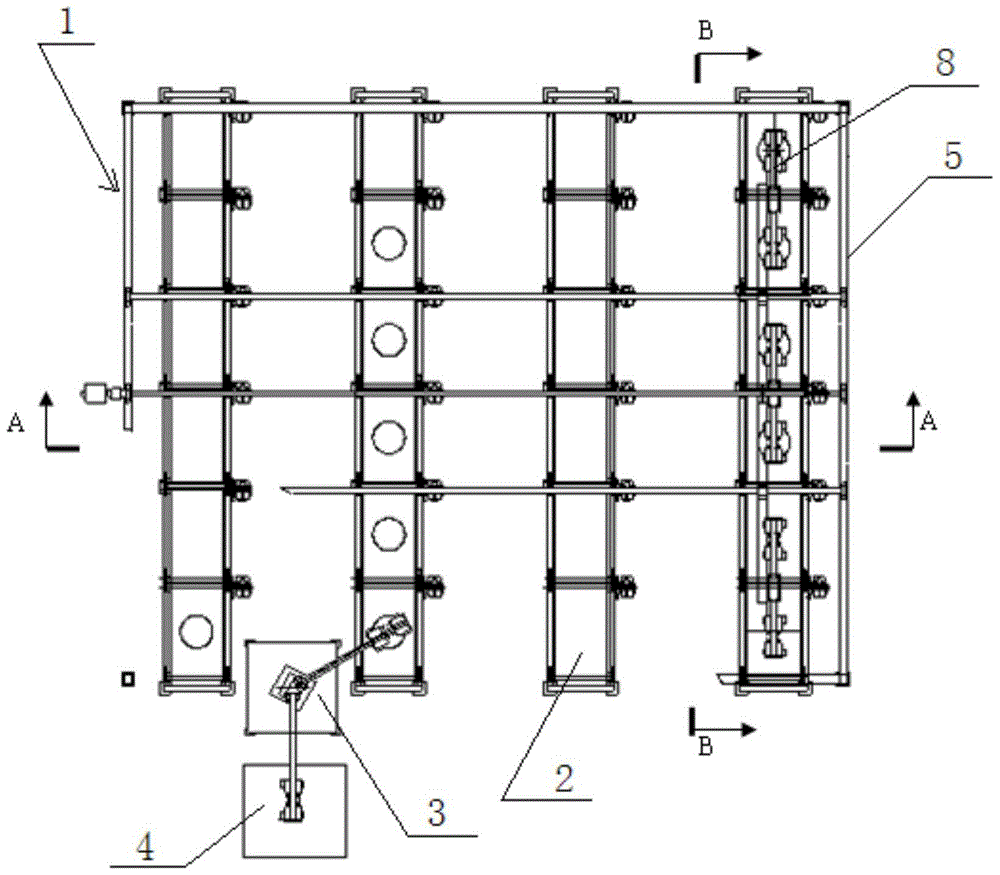

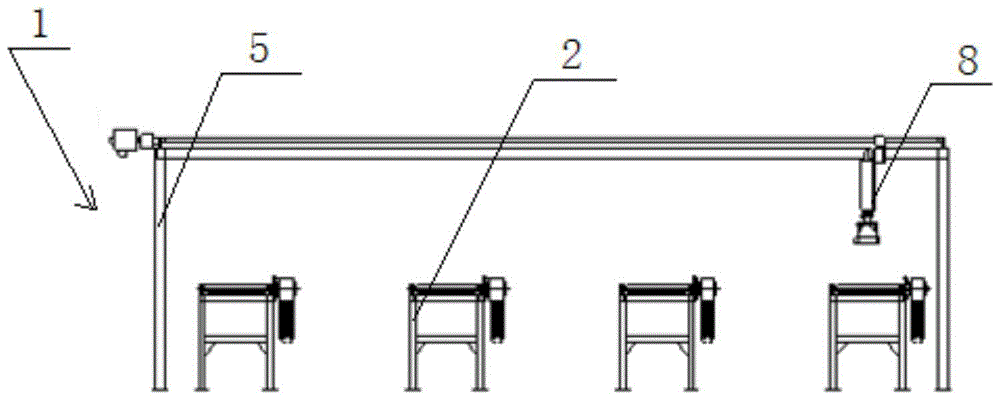

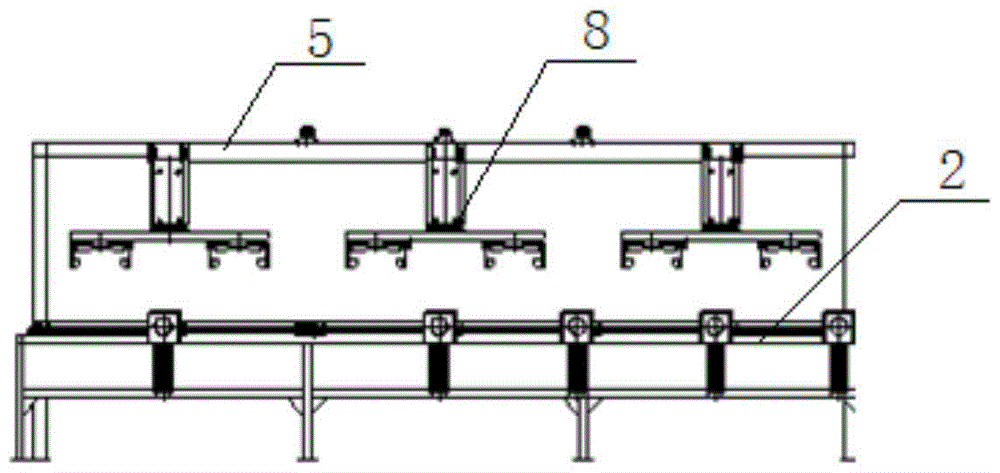

Group porcelain automatic blank feeding device

InactiveCN103434843AReduce laborImprove working environmentDischarging arrangementConveyor partsMolding machineWorking environment

A group porcelain automatic blank feeding device comprises a synchronization carrying mechanical hand, more than two sectional conveyor belts and a two-connection rotating mechanical hand, wherein the synchronization carrying mechanical hand is composed of a rack assembly and a synchronization gripping device, and the synchronization gripping device is movably arranged on the rack assembly and used for gripping and moving unprocessed clay bodies or processed porcelain blanks located at the lower position; the sectional conveyor belts are arranged below the synchronization carrying mechanical hand and used for placing the unprocessed clay bodies and the processed porcelain blanks respectively; the two-connection rotating mechanical hand is used for moving the clay bodies on the sectional conveyor belts to a forming machine and moving the processed porcelain blanks on the forming machine to the sectional conveyor belts. By the adoption of the group porcelain automatic blank feeding device, formed green bodies can be automatically placed on a drying machine by the group mechanical hands, so that blank feeding and end product fetching can be automatically achieved, manual operation of operators is replaced, labor capacity of workers is reduced, one operator can simultaneously be in charge of a plurality of forming machines, labor is saved, the working environment of the workers is improved, and production efficiency is greatly improved.

Owner:TANGSHAN COLLEGE

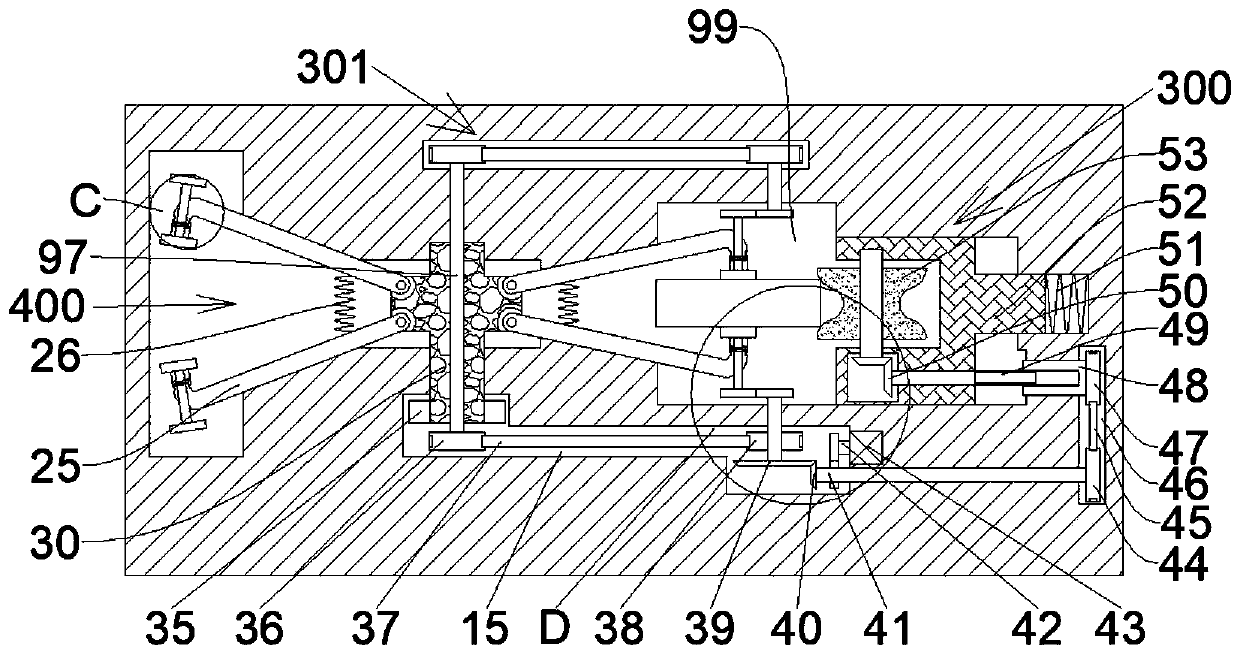

Molding processing technology of circuit board

ActiveCN110213894ASimple structureEasy to operateInsulating layers/substrates workingEquipment useOperation time

The invention discloses a molding processing technology of a circuit board. Equipment used in the technology comprises a main body, a cutting cavity is formed in the interior of the main body, the cutting cavity is internally provided with a cutting device, a main cavity is formed in the interior of the left wall of the cutting cavity, the cutting cavity is internally provided with a conveying device, a polishing cavity communicated with the cutting cavity is formed in the interior of the right wall of the cutting cavity, the polishing cavity is internally provided with a polishing device, thepolishing cavity is internally provided with a clamping device, and the main cavity is internally provided with a power device. The equipment is simple in structure, convenient in operation and convenient in maintenance, and the equipment can operate uninterruptedly for cutting operation and polishing operation, the operation time of the circuit board is reduced, the molding processing efficiencyof the circuit board is improved, and the production cost of the circuit board is reduced, so that the equipment has preferable application and popularization values.

Owner:LONGNAN JUNYA ELECTRONICS TECH CO LTD

Refrigerator door liner injection molding machining device capable of safely and quickly demolding

The invention relates to the technical field of injection molding of refrigerator door liners, and discloses a refrigerator door liner injection molding machining device capable of safely and quicklydemolding. The refrigerator door liner injection molding machining device capable of safely and quickly demolding comprises a workbench, four supporting bases are fixedly connected to four corners ofthe bottom of the workbench, a first hydraulic cylinder fixedly is sleeved with the bottom of the workbench, an injection mold is fixedly arranged at the top of the workbench, two sets of supporting rods are symmetrically and fixedly connected to the top of the workbench, the number of each set of supporting rods is two, a top plate is fixedly connected between the top ends of the two sets of supporting rods, a second hydraulic cylinder is fixedly connected to the bottom of the top plate, and the injection mold comprises a top mold, a bottom mold and a refrigerator door liner. According to therefrigerator door liner injection molding machining device capable of safely and quickly demolding, the problems that hanging walls are arranged on refrigerator door liners of existing refrigerators,so that the contact area between the refrigerator door liners and a mold cavity is increased, and the demolding difficulty of the refrigerator door liners is increased are solved.

Owner:安徽锴模装备模具股份有限公司

Cross arm insulator forming machine

ActiveCN112621982AImprove molding processing efficiencyForming operations do not affectAuxillary shaping apparatusCleaning using toolsMain bearingStructural engineering

The invention relates to the field of insulator production equipment, in particular to a cross arm insulator forming machine which comprises a forming machine rack, a bearing table used for supporting a mud blank and driving the mud blank to rotate is arranged at the bottom of the forming machine rack, and a main shaft is perpendicularly and fixedly connected to the bottom face of the bearing table. A plurality of inserting teeth used for inserting and fixing the mud blank are fixed to the upper surface of the bearing table, a lifting plate used for cleaning the mud blank is arranged on the upper side of the bearing table, the inserting teeth penetrate through the lifting plate, the lifting plate can slide on the inserting teeth, and the lifting plate is in transmission connection with a lifting mechanism arranged on the main shaft. The main shaft is provided with a cleaning mechanism used for cleaning waste generated by mud blank forming, and the cleaning mechanism is in transmission connection with the main shaft. According to the cross arm insulator forming machine, mud blanks can be cleaned conveniently, time and labor are saved, the forming machining efficiency of the mud blanks can be improved, generated waste materials are cleaned away in time and discharged, manual waste material cleaning is not needed, time and labor are saved, and the forming machining operation of the mud blanks is not affected.

Owner:HUNAN LILING XIANGRUI POWER ELECTRIC

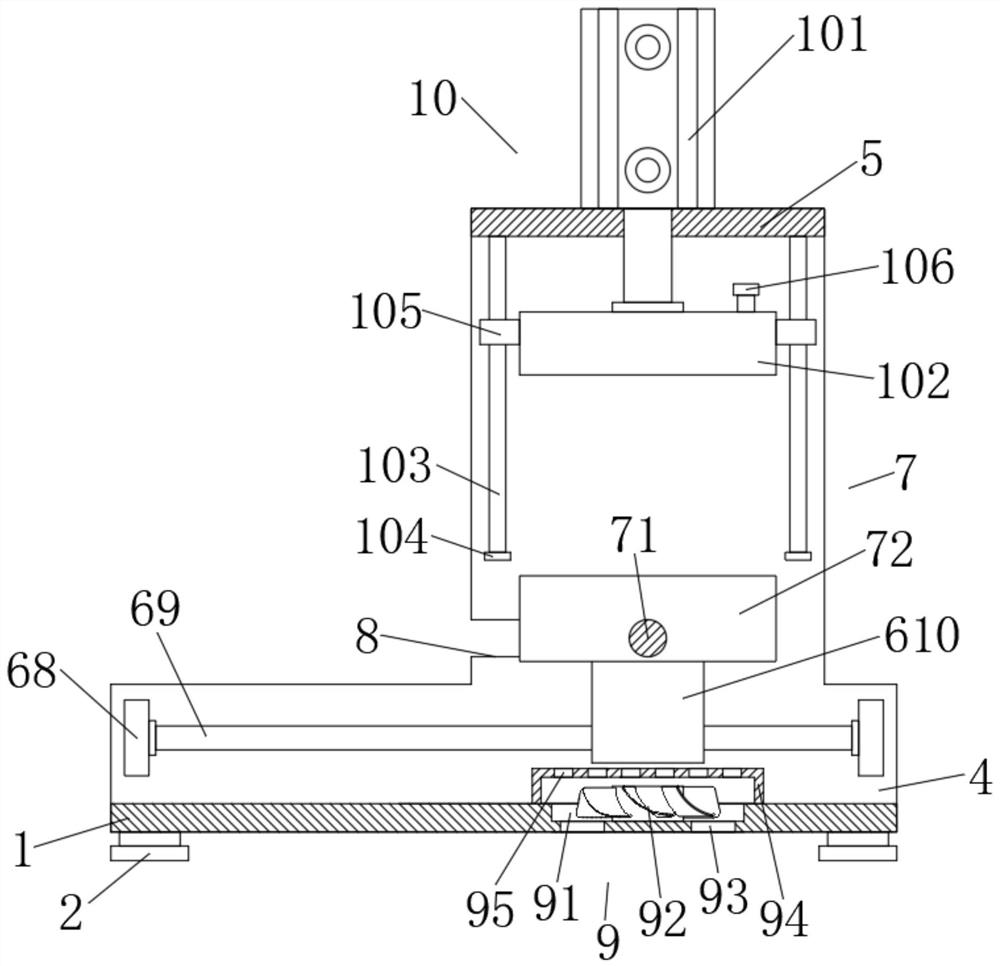

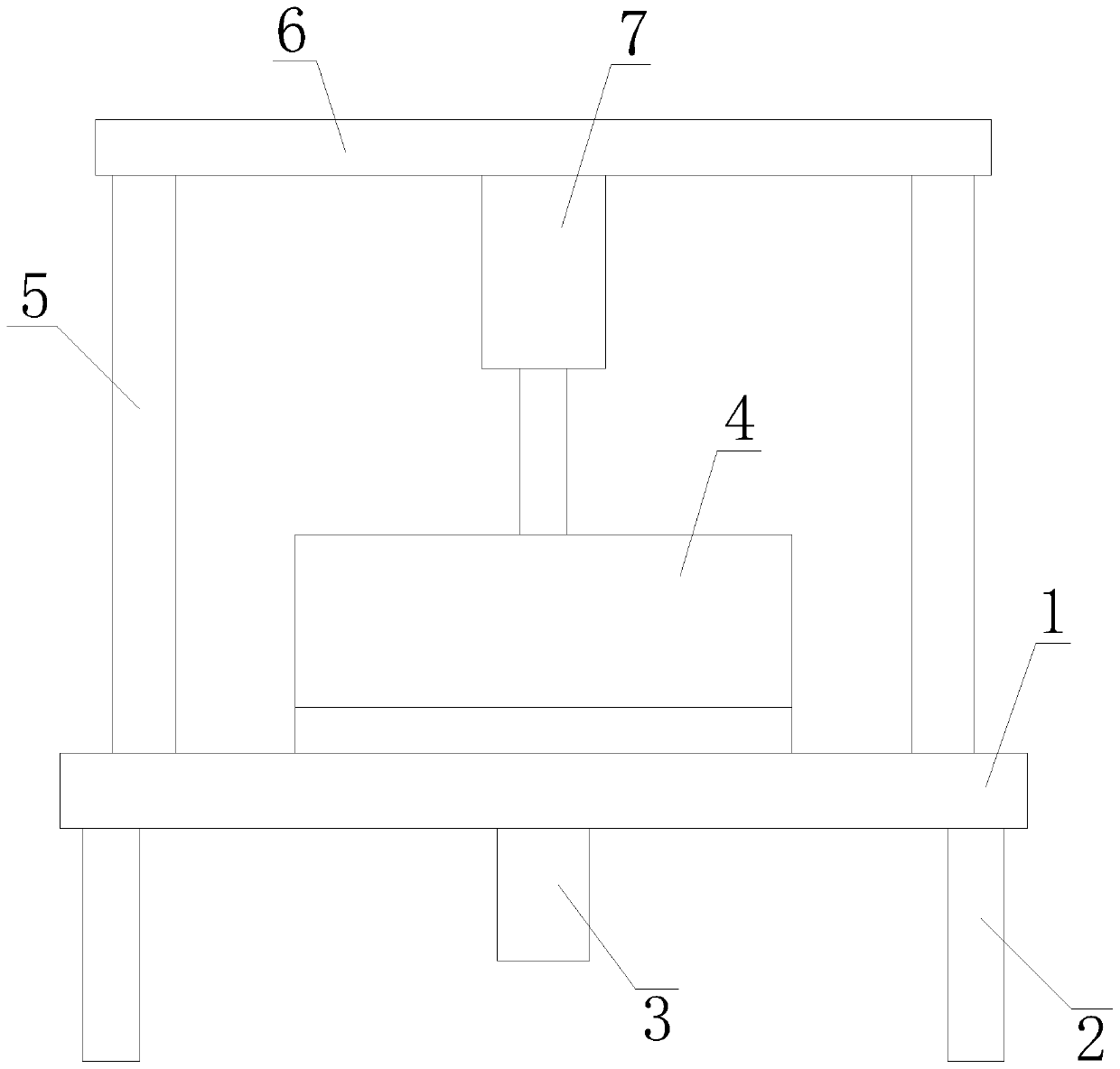

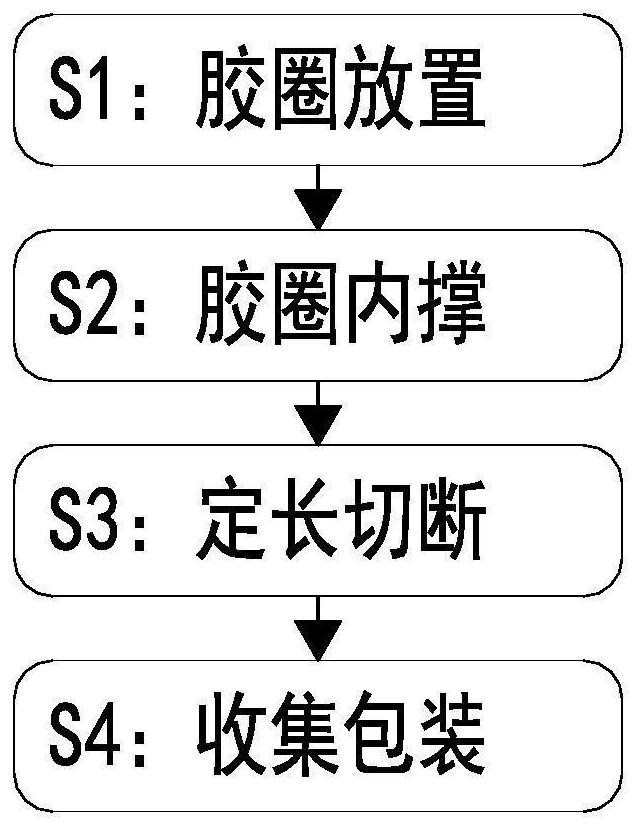

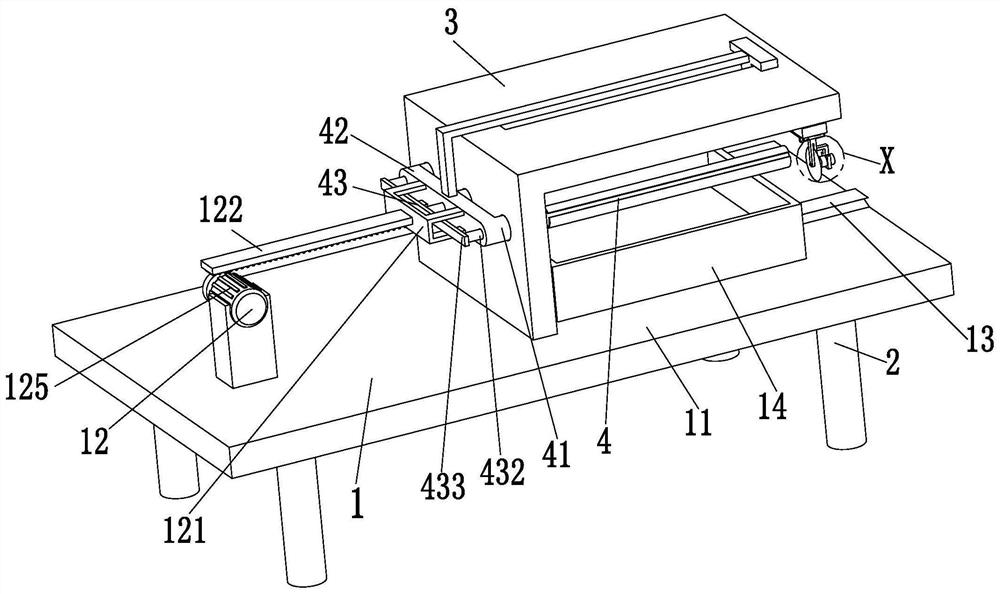

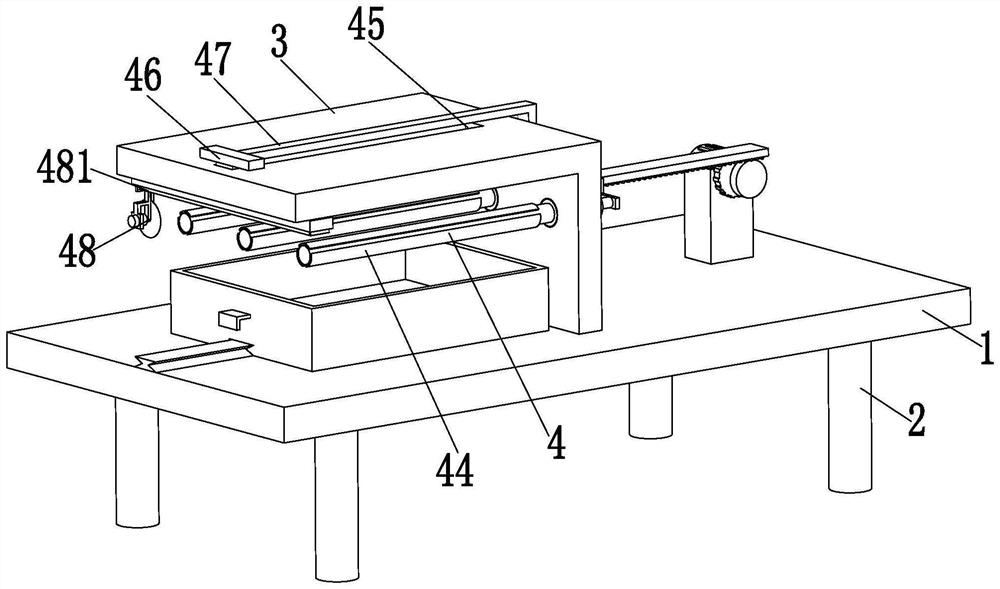

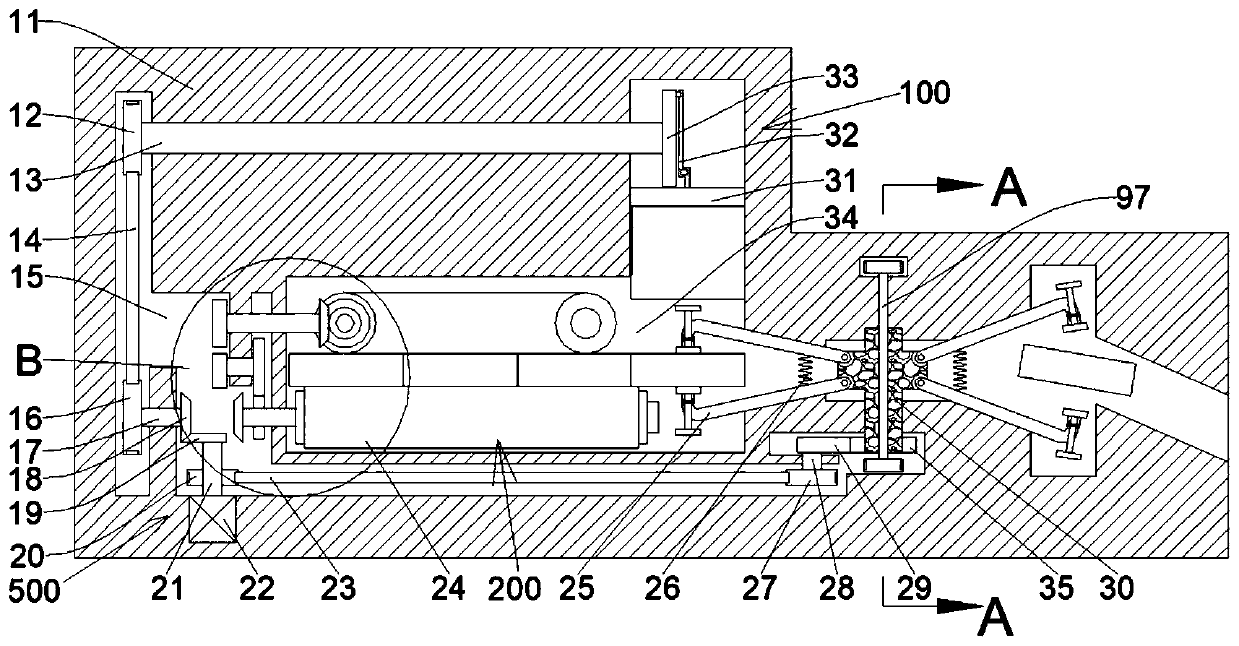

Nitrile rubber sealing ring forming processing method

ActiveCN112894928AImprove molding processing efficiencyImprove seal qualityMetal working apparatusRubber ringNitrile rubber

The invention relates to a nitrile rubber sealing ring forming processing method. A nitrile rubber sealing ring forming processing machine is used in the method. The machine comprises a working bottom plate, mounting columns, an L-shaped plate and a forming device, wherein the mounting columns are evenly fixed to the positions, close to the four corners, of the lower end of the working bottom plate; the L-shaped plate is mounted on the right side of the upper end face of the working bottom plate; and the forming device is arranged on the L-shaped plate. The problems that during existing nitrile rubber sealing ring forming processing, due to the fact that a nitrile rubber ring is soft, a notch of the nitrile rubber ring is prone to deformation during cutting, the smoothness of the notch is low, and the sealing quality of the notch is affected can be solved; and the problems that in an existing nitrile rubber sealing ring forming processing method, nitrile rubber sealing rings are usually cut out from the whole section of nitrile rubber ring manually, the working efficiency is low, multiple nitrile rubber rings cannot be cut off at the same time, the cut nitrile rubber rings need to be divided in a fixed-length mode, and manpower and material resources are wasted are solved.

Owner:温州瓯宏密封件有限公司

A circuit board forming and processing equipment

ActiveCN110213894BSave time in transitImprove molding processing efficiencyInsulating layers/substrates workingEngineeringPower apparatus

The invention discloses a molding processing technology of a circuit board. Equipment used in the technology comprises a main body, a cutting cavity is formed in the interior of the main body, the cutting cavity is internally provided with a cutting device, a main cavity is formed in the interior of the left wall of the cutting cavity, the cutting cavity is internally provided with a conveying device, a polishing cavity communicated with the cutting cavity is formed in the interior of the right wall of the cutting cavity, the polishing cavity is internally provided with a polishing device, thepolishing cavity is internally provided with a clamping device, and the main cavity is internally provided with a power device. The equipment is simple in structure, convenient in operation and convenient in maintenance, and the equipment can operate uninterruptedly for cutting operation and polishing operation, the operation time of the circuit board is reduced, the molding processing efficiencyof the circuit board is improved, and the production cost of the circuit board is reduced, so that the equipment has preferable application and popularization values.

Owner:LONGNAN JUNYA ELECTRONICS TECH CO LTD

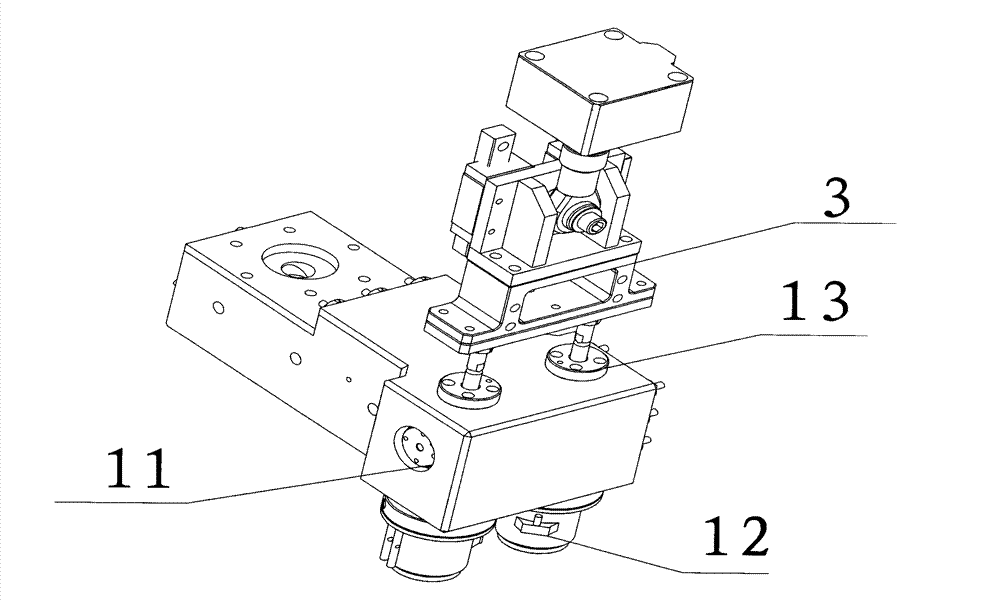

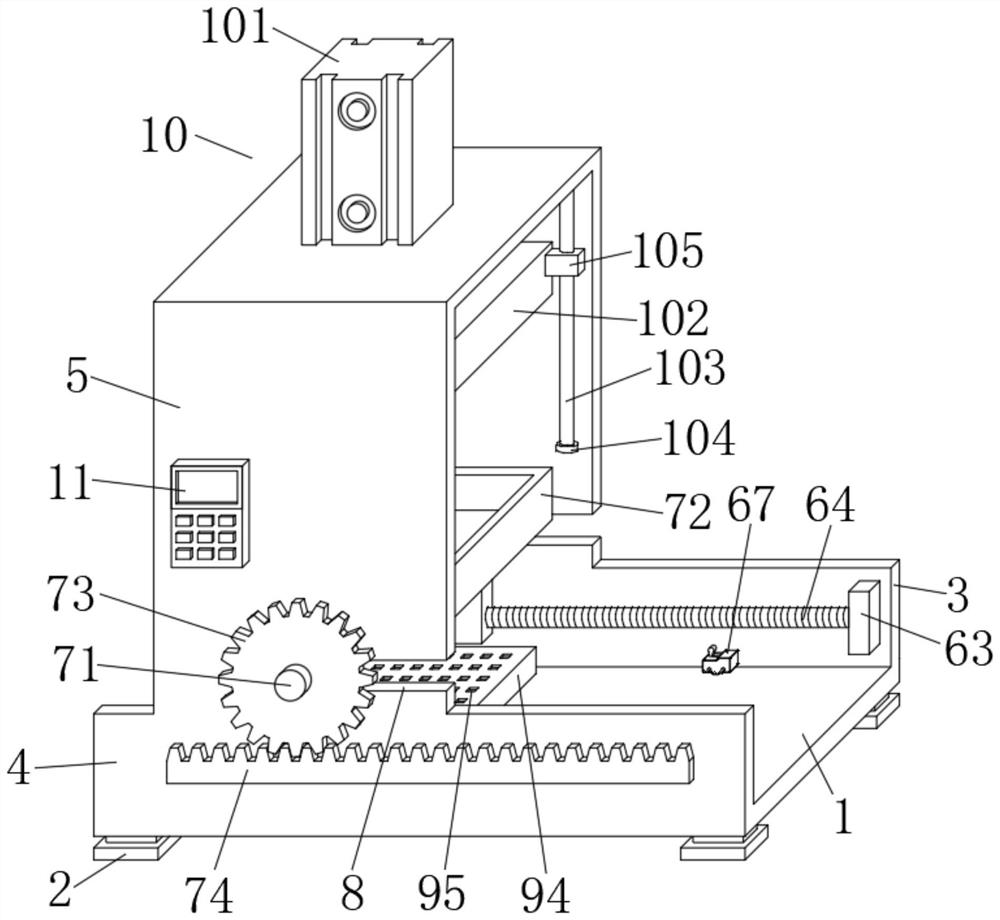

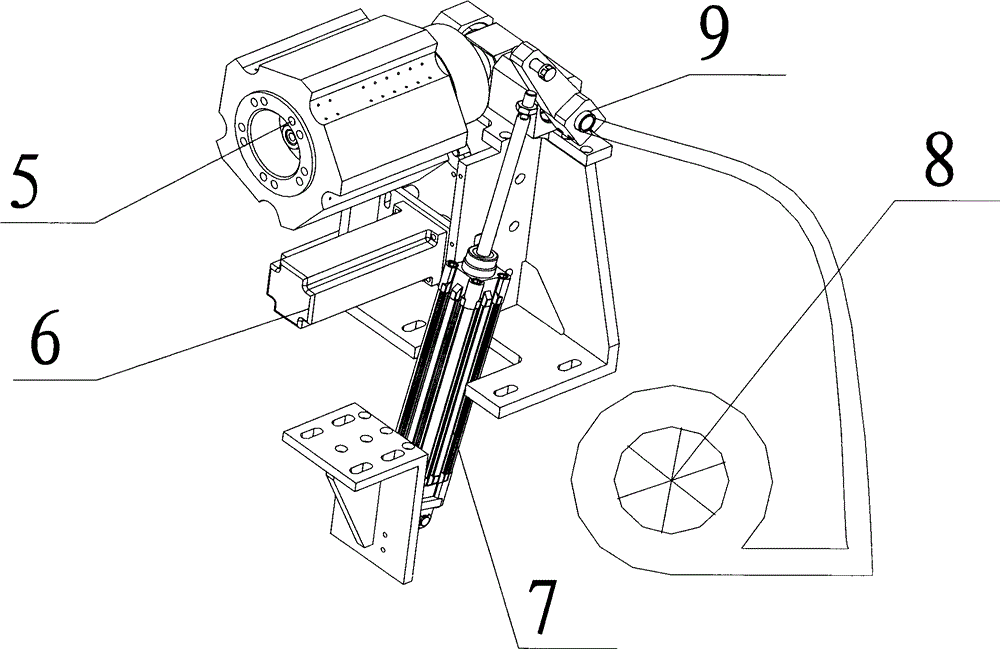

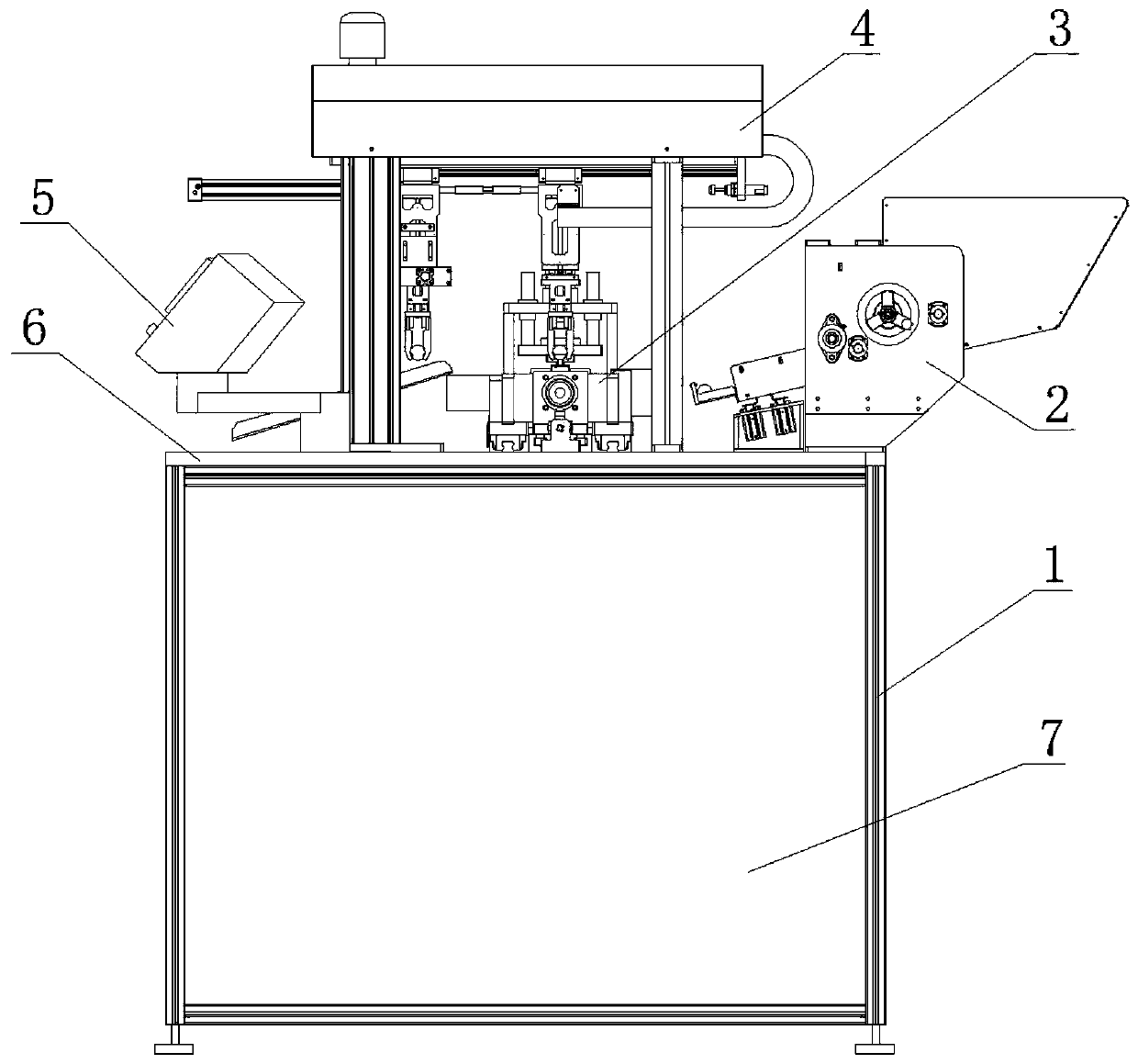

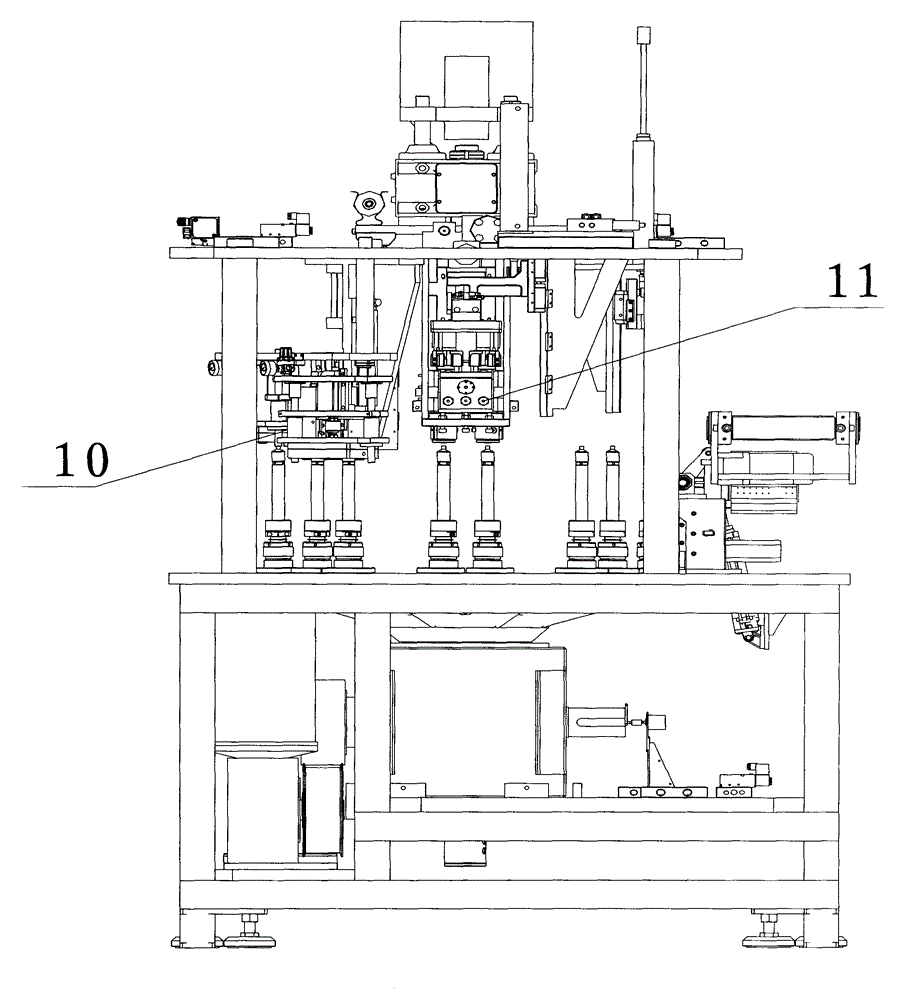

Pipe forming method based on pipe port forming device

InactiveCN110640000AReduce labor intensityImprove practicalityMetal-working feeding devicesPositioning devicesMechanical componentsEngineering

The invention relates to a pipe forming method based on a pipe port forming device. The pipe forming method mainly solves the problems of high labor intensity and low machining efficiency in existingmanual forming. The pipe port forming device comprises a rack, a feeding mechanism, a stamping mechanism, a transfer mechanism, an operation panel, a workbench and an electrical cabinet, wherein the electrical cabinet is mounted on the rack, the workbench is arranged at the top of the electrical cabinet, the feeding mechanism, the stamping mechanism and the transfer mechanism are mounted on the workbench, the transfer mechanism is arranged on one side of the feeding mechanism, and the stamping mechanism is arranged below the transfer mechanism. The operation panel is further installed on the workbench, the operation panel is connected with the input end of a PLC, the output end of the PLC is connected with each mechanical component of the device, and the PLC receives a control instructionof the operation panel and controls the action of each mechanical component of the device. By means of the technical scheme, the problem is well solved, and the device can be used for forming pipe ports.

Owner:苏州维创度信息科技有限公司

A cross-arm insulator forming machine

ActiveCN112621982BImprove molding processing efficiencyForming operations do not affectAuxillary shaping apparatusCleaning using toolsMolding machineEngineering

The invention relates to the field of insulator production equipment, in particular to a cross-arm insulator forming machine, comprising a forming machine frame, the bottom of the forming machine frame is provided with a supporting platform for supporting the mud blank and driving the mud blank to rotate, the supporting platform The bottom surface of the platform is vertical and fixedly connected with the main shaft. The upper surface of the supporting platform is fixed with a plurality of pinches for inserting and fixing the mud. The upper side of the supporting platform is provided with a lifting plate for cleaning the mud. The pins go through the lifting plate, and the lifting plate can slide on the gear, the lifting plate is connected with the lifting mechanism arranged on the main shaft, and the main shaft is provided with a cleaning mechanism for cleaning the waste generated by mud forming, and the cleaning mechanism is connected with the main shaft. This kind of cross-arm insulator forming machine is convenient for cleaning the mud, saves time and effort, helps to improve the efficiency of molding and processing the mud, cleans up and discharges the generated waste in time, and does not need manpower to clean the waste, saving time and effort. It does not affect the molding and processing of the mud.

Owner:HUNAN LILING XIANGRUI POWER ELECTRIC

Forming device facilitating machining of special-shaped curved surface of automobile fairing

InactiveCN113828675AImprove molding processing efficiencyAvoid stickingShaping toolsMetal-working feeding devicesElectric machineryEngineering

The invention relates to the technical field of automobile accessory machining, in particular to a forming device facilitating machining of a special-shaped curved surface of an automobile fairing. By aiming at the problems of high labor intensity and low machining efficiency in the prior art, the following scheme is provided, wherein the forming device comprises a shell, a sliding sleeve is fixedly connected to the inner side of the shell, a mounting block is slidably connected to the inner side of the sliding sleeve, male dies are fixedly connected to the outer walls of the two sides of the mounting block, female dies cooperating with the male dies are fixedly connected to the inner walls of the two ends of the shell, a driving motor is mounted on one side of the outer portion of the shell, a rotating shaft is mounted at the output end of the driving motor, the other end of the rotating shaft is in transmission connection with the mounting block so as to drive the mounting block to move in the length direction of the shell, and the two ends, on the outer portion of the shell, of the rotating shaft are connected with transmission plates in a sleeved manner. The forming device is reasonable and stable in structure and easy to operate, the labor intensity of operators is effectively reduced, the working efficiency of guide plate forming machining is improved, and the forming device is easy to use and popularize.

Owner:安徽国泰智能科技有限公司

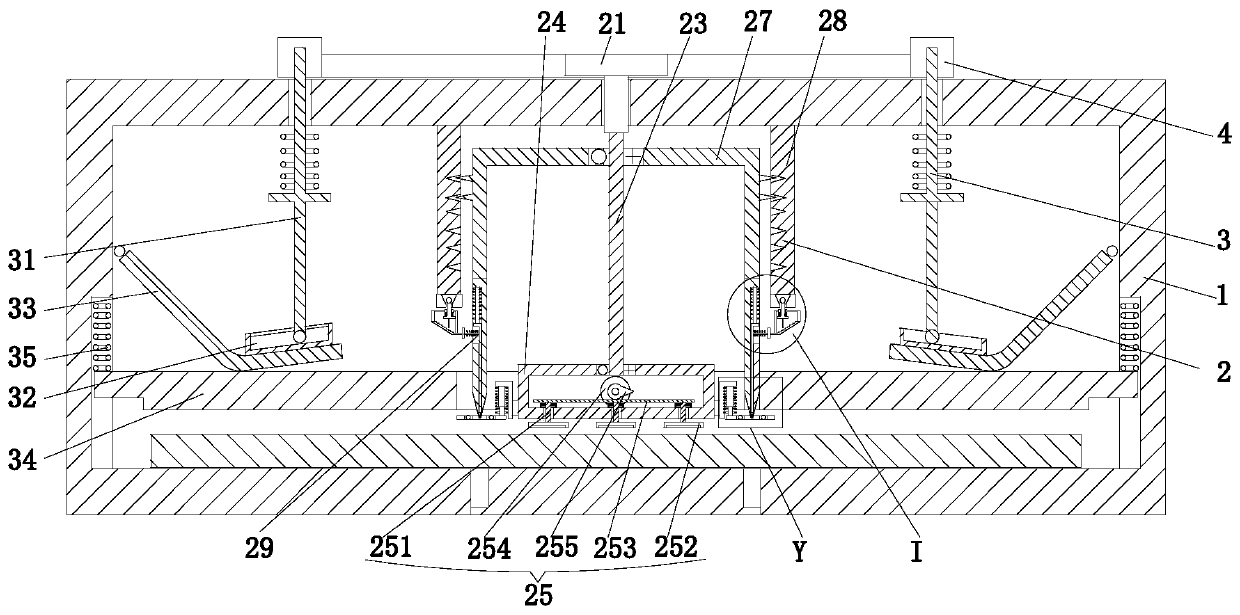

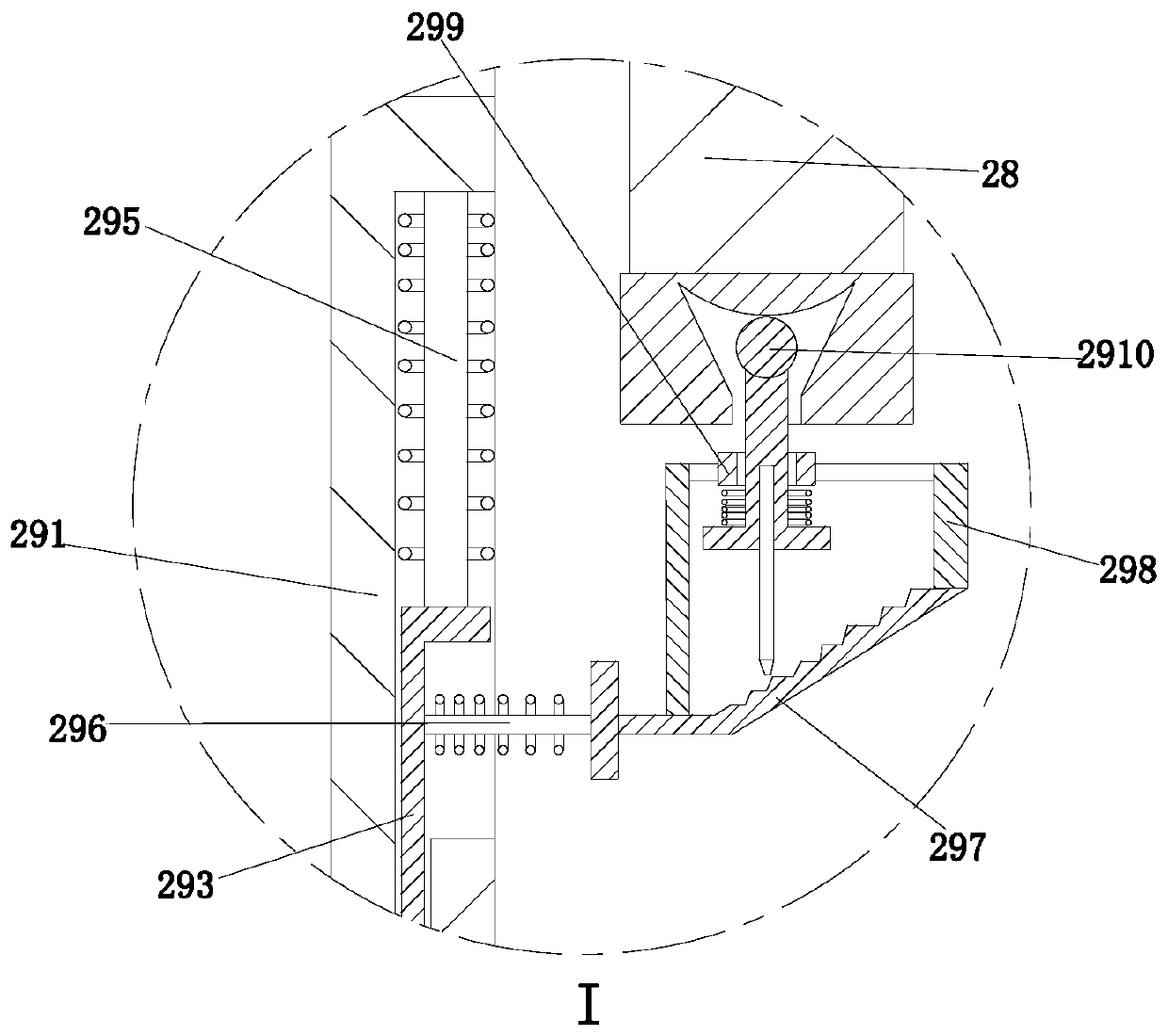

A fully automatic double-head shoulder injection machine

ActiveCN107856332BImprove molding processing efficiencyReduce labor intensityTubular articlesDouble tubeEngineering

Provided is a fully automatic double head shoulder-injection machine, comprising a frame (1) and a working platform A (2) and a working platform B (3) which are mounted on the frame (1), wherein the working platform A (1) is installed with a motor A (4) and a circular turntable mechanism (40) driven by the motor A (4), wherein the circular turntable mechanism (40) is provided with a plurality of core rod holders (41), which are provided with core rods (42), and the core rod (42) is provided with a plurality of air-blowing ports (43), and the circular turntable mechanism (40) is provided with an automatic tube loading device (5), an automatic plastic spitting device (6), an automatic molding device (7), a cooling device (8) and an automatic tube unloading device (9). The fully automatic double head shoulder-injection machine can achieve a fully automatic molding operation, which improves the molding processing efficiency and reduces the labor intensity. It uses the automatic tube loading device so that the double tube is operated at the same time, realizing a high-speed operation, improved production efficiency, reduced core rods, improved efficiency and reduced cost.

Owner:NANTONG BAOTIAN PACKING MACHINERY

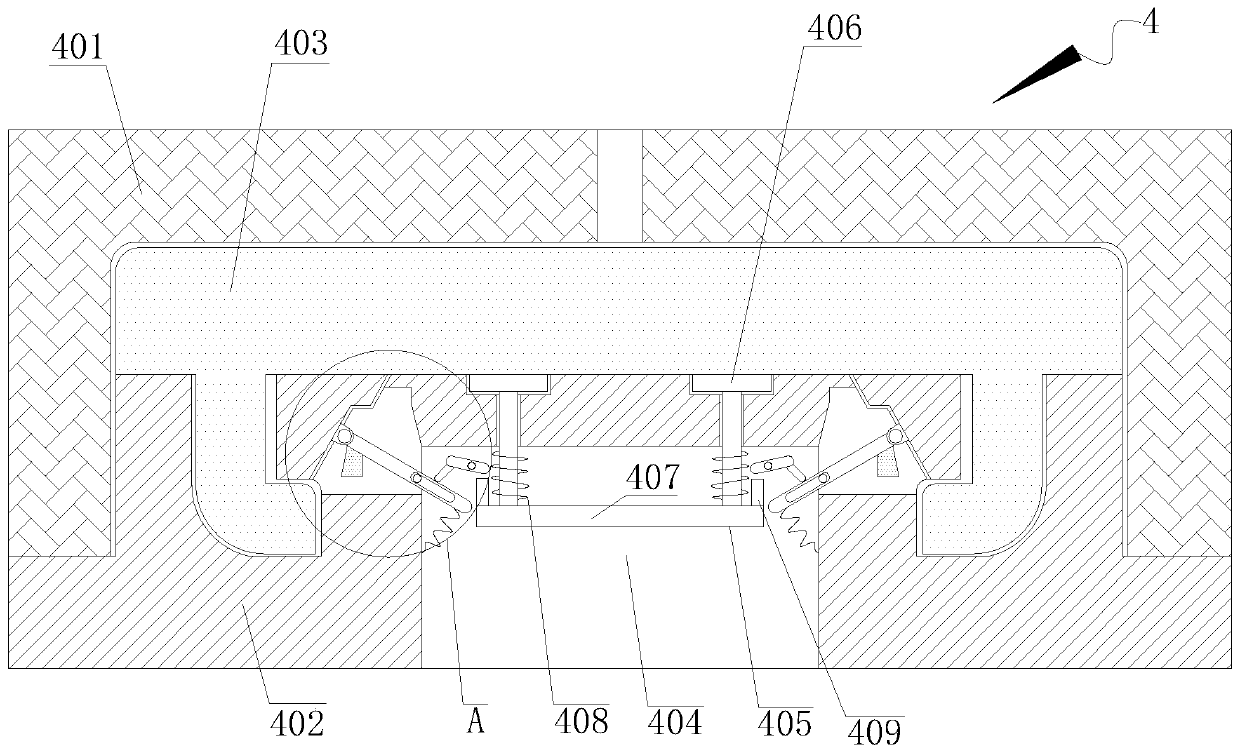

A forming device for a lithium-ion power battery cover plate and a processing method thereof

ActiveCN110369758BEasy and efficient processingGuaranteed stabilityCell lids/coversMetal working apparatusPower batteryStructural engineering

The invention relates to a forming device for a lithium ion power battery cover plate and a machining method of the forming device. The forming device comprises a forming frame, an executing mechanismis arranged in the middle of the upper end of the forming frame, locking mechanisms are symmetrically arranged at the left end and the right end of the forming frame, the upper ends of the locking mechanisms abut against the locking blocks, the locking blocks are arranged on locking air cylinders correspondingly, and the locking air cylinders are fixed on the forming frame. The forming device andthe machining method can solve the following problems, existing in forming machining process of an existing lithium ion battery cover plate, that a, existing hole opening operation of the battery cover plate cannot accurately control the strength of cutting machining, and damage and deformation of a base material can be easily caused during operation, so that the base material needs to be subjected to secondary machining and repairing; and b, a special clamp is adopted to fix the base material in a traditional forming drilling operation, the operation is complex, base material taking and placing is troublesome, the consumed time is long, the base material is not fixed through simple placement, potential safety hazards exist, and the stability of the machining operation is poor.

Owner:深圳昆宇电源科技有限公司

Mold injection molding equipment for producing illuminating apparatus

InactiveCN111890627AEasy for automatic loadingStir wellDomestic articlesEngineeringInjection moulding

The invention discloses mold injection molding equipment for producing an illuminating apparatus. The equipment comprises a base, a supporting frame and an injection molding mechanism, wherein the supporting frame is installed at the top of the base, the injection molding mechanism is arranged at the portion, located in the supporting frame, of the top of the base, a feeding mechanism is arrangedat the top of the supporting frame, a pushing mechanism and a collecting trolley are arranged at the portion, located at the two sides of the injection molding mechanism, of the top of the base respectively, the injection molding mechanism comprises a base, a fixed plate and a top plate, the base is installed at the top of the base, the fixed plate is installed at the top of the base, the top plate is connected to the top of the fixed plate, a feeding port is formed in the top of the top plate, an upper template is embedded in the bottom of the top plate, a lower template is embedded in the top of the fixed plate, and a mold cavity is formed between the lower template and the upper template and communicates with the feeding port. The mold injection molding equipment for producing the illuminating apparatus is simple in overall structure, capable of saving time and labor and high in degree of automation, and the efficiency of molding parts of the illuminating apparatus is greatly improved.

Owner:嘉兴市光炬五金科技有限公司

An injection molding device for refrigerator door sleeve capable of safe and rapid demoulding

The invention relates to the technical field of refrigerator door injection molding, and discloses a refrigerator door injection molding processing device that can be safely and quickly demolded. The bottom of the worktable is fixedly sleeved with a first hydraulic cylinder, the top of the worktable is fixedly provided with an injection mold, and the top of the worktable is symmetrically and fixedly connected with two groups of support rods, and the number of each group of the support rods is two. A top plate is fixedly connected between the top ends of the two groups of the support rods, a second hydraulic cylinder is fixedly connected to the bottom of the top plate, and the injection mold includes a top mold, a bottom mold and a refrigerator door. The invention solves the problem that the refrigerator door of the existing refrigerator is designed with a hanging wall, thereby increasing the contact area between the refrigerator door and the mold cavity, and further increasing the demoulding difficulty of the refrigerator door.

Owner:安徽锴模装备模具股份有限公司

Toughness modified bottle cap

InactiveCN104371177AIncrease the rate of crystallizationShorten molding cycleAntimony trioxideBottle cap

The invention provides a toughness modified bottle cap. The bottle cap comprises the following raw materials in parts by weight: 60-80 parts of polyethylene particles, 0.2-0.4 part of styrene block copolymer, 0.5-0.8 part of antimonous oxide and 0.3-0.5 part of saponified EVA (ethylene-vinyl acetate copolymer) or comprises the following raw materials in parts by weight: 60-70 parts of polyethylene particles, 0.2-0.3 part of styrene block copolymer, 0.5-0.6 part of antimonous oxide and 0.3-0.4 part of saponified EVA (ethylene-vinyl acetate copolymer) or comprises the following raw materials in parts by weight: 70-80 parts of polyethylene particles, 0.3-0.4 part of styrene block copolymer, 0.6-0.8 part of antimonous oxide and 0.4-0.5 part of saponified EVA (ethylene-vinyl acetate copolymer). The bottle cap is simple in proportioning and has high production efficiency and excellent quality.

Owner:青岛浩恩医药耗材有限公司

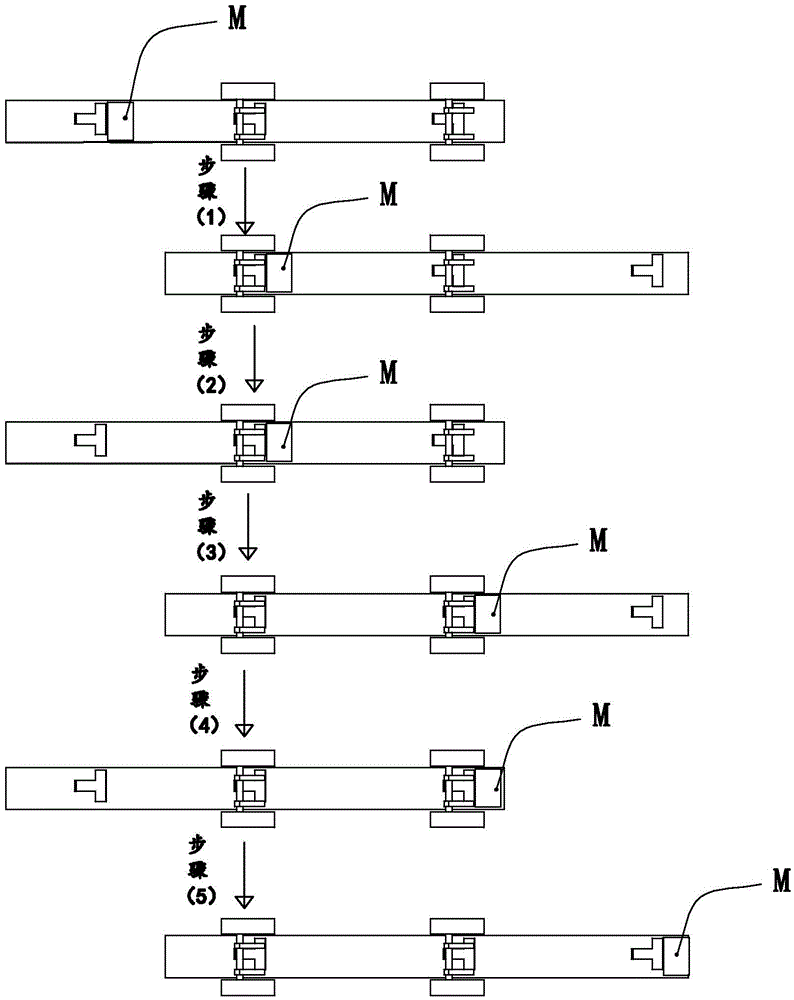

Pipe port forming device

InactiveCN111250579AReduce labor intensityImprove practicalityMetal-working feeding devicesPositioning devicesMechanical componentsControl engineering

The invention relates to a pipe port forming device, and mainly solves the problems that existing manual forming is large in labor intensity and low in machining efficiency. The pipe port forming device comprises a rack, a feeding mechanism, a stamping mechanism, a transferring mechanism, an operation panel, a workbench and an electrical cabinet, wherein the electrical cabinet is installed on therack, the workbench is arranged at the top of the electrical cabinet, the feeding mechanism, the stamping mechanism and the transferring mechanism are installed on the workbench, the transferring mechanism is arranged on one side of the feeding mechanism, and the stamping mechanism is arranged below the transferring mechanism; and the operation panel is further installed on the workbench, the operation panel is connected with the input end of a PLC controller, the output end of the PLC controller is connected with all mechanical components of the device, and the PLC controller receives a control instruction of the operation panel and controls the actions of the mechanical components of the device. By the adoption of the technical scheme, the problems are well solved, and the device can beused for forming the pipe ports.

Owner:苏州维创度信息科技有限公司

A group of porcelain automatic charging device

InactiveCN103434843BReduce laborImprove working environmentDischarging arrangementConveyor partsWorking environmentEngineering

Owner:TANGSHAN COLLEGE

Automatic high speed flexible pipe shoulder forming machine

ActiveCN102744831BImprove molding processing efficiencyReduce labor intensityTubular articlesControl systemMolding machine

The invention discloses an automatic high speed flexible pipe shoulder forming machine which comprises a frame and a working platform arranged on the frame, wherein a circular turntable mechanism driven by a main driving motor is mounted on the working platform. The forming machine is characterized in that the circular turntable mechanism is provided with a plurality of pairs of material cups, an automatic pipe feeding device, a detection device, an automatic plastic spitting device, an automatic forming device, a cooling device and an automatic pipe discharging device are correspondingly arranged around each pair of the material cups in order, and all the devices are controlled by PLC. According to the invention, the automation degree of the forming machine provided in the invention is high; an industrial PLC control system is used for automatic pipe feeding, automatic plastic spitting and automatic pipe discharging, and therefore, automatic forming processing operation of flexible pipes is realized, forming processing efficiency of the flexible pipes is improved, labor intensity is mitigated, and precise positioning and smooth and steady motion in processing of the flexible pipes are guaranteed; through utilization of the automatic pipe feeding device and simultaneous running of double pipes, high speed running is realized and production efficiency is enhanced.

Owner:NANTONG BAOTIAN PACKING MACHINERY

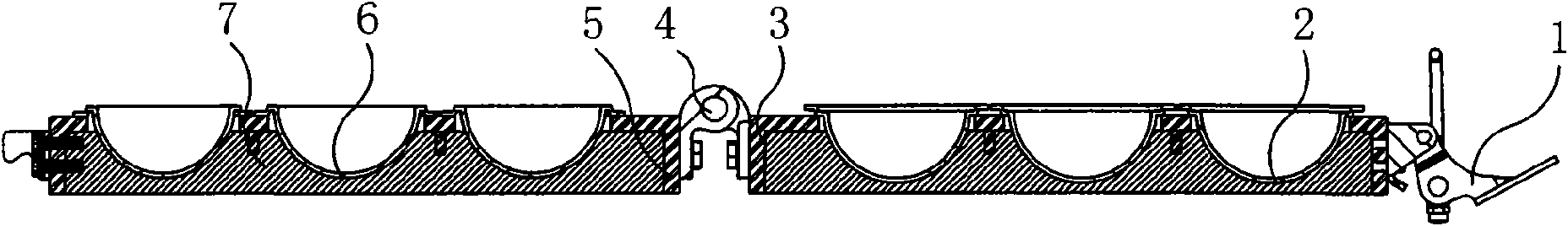

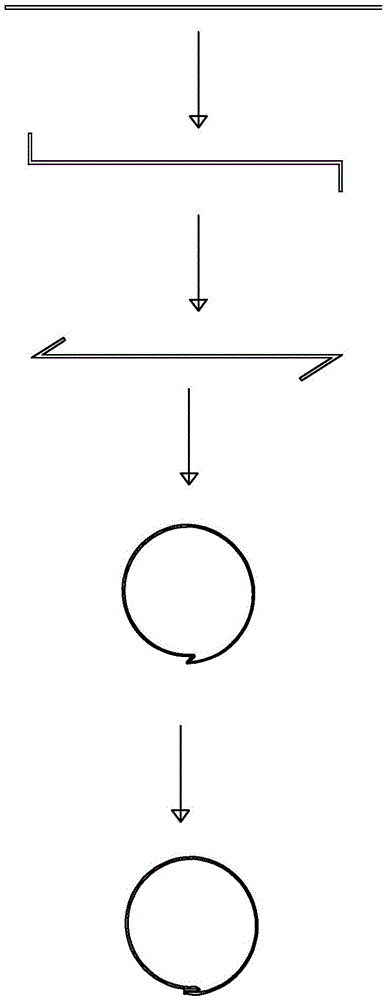

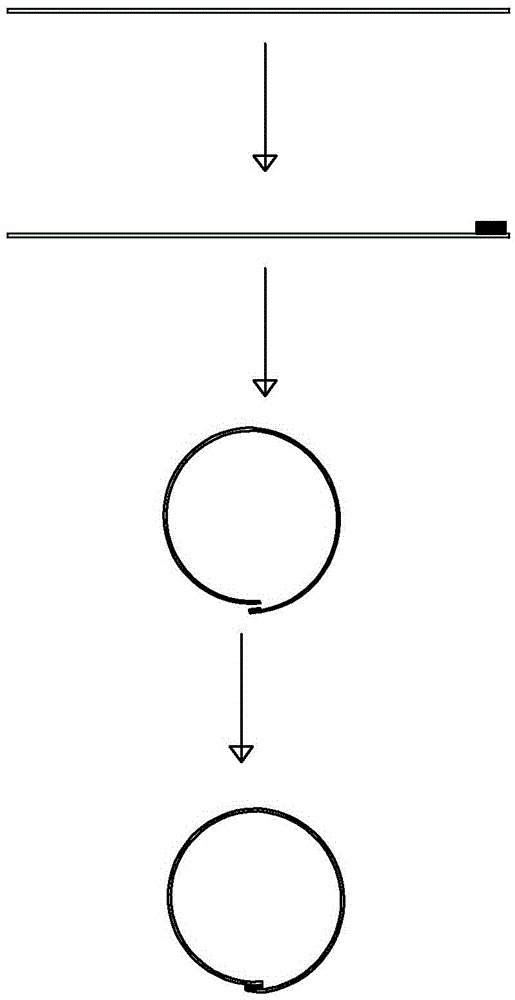

Pipe maker for all-plastic hose forming

ActiveCN102358052BImprove molding processing efficiencyReduce labor intensityTubular articlesHuman–machine interfaceMan machine

The present invention discloses a pipe maker for all-plastic hose forming. The pipe maker comprises a frame. The pipe maker is characterized in that: the pipe maker further comprises a sheet material conveying apparatus forming a fixed connection on the frame, a sheet material overlapping apparatus, a hose forming apparatus, an interface welding apparatus, a hose conveying apparatus and a hose cutting apparatus. The sheet material overlapping apparatus is arranged below the sheet material conveying apparatus. The sheet material conveying apparatus is arranged in front of the hose forming apparatus. The hose forming apparatus is arranged in front of the interface welding apparatus and the hose conveying apparatus. The hose interface welding apparatus is arranged above the hose conveying apparatus. The hose cutting apparatus is arranged on the rear of the hose conveying apparatus. According to the present invention, the pipe maker for the all-plastic hose forming has high automaticity; an aerodynamic and servo system is adopted; the actions are precise and smooth; the operation adopts a man-machine interface; the parameter setting can be completed on the interface; the pipe maker has functions of cumulative shift production, fault displaying, work state displaying, automatic and manual switching and flexible operation.

Owner:NANTONG BAOTIAN PACKING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com