Group porcelain automatic blank feeding device

A kind of porcelain and automatic technology, applied in unloading device, ceramic molding machine, transportation and packaging, etc., can solve the problems of difficult production efficiency, low work efficiency and short processing time, so as to save manpower, improve efficiency and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

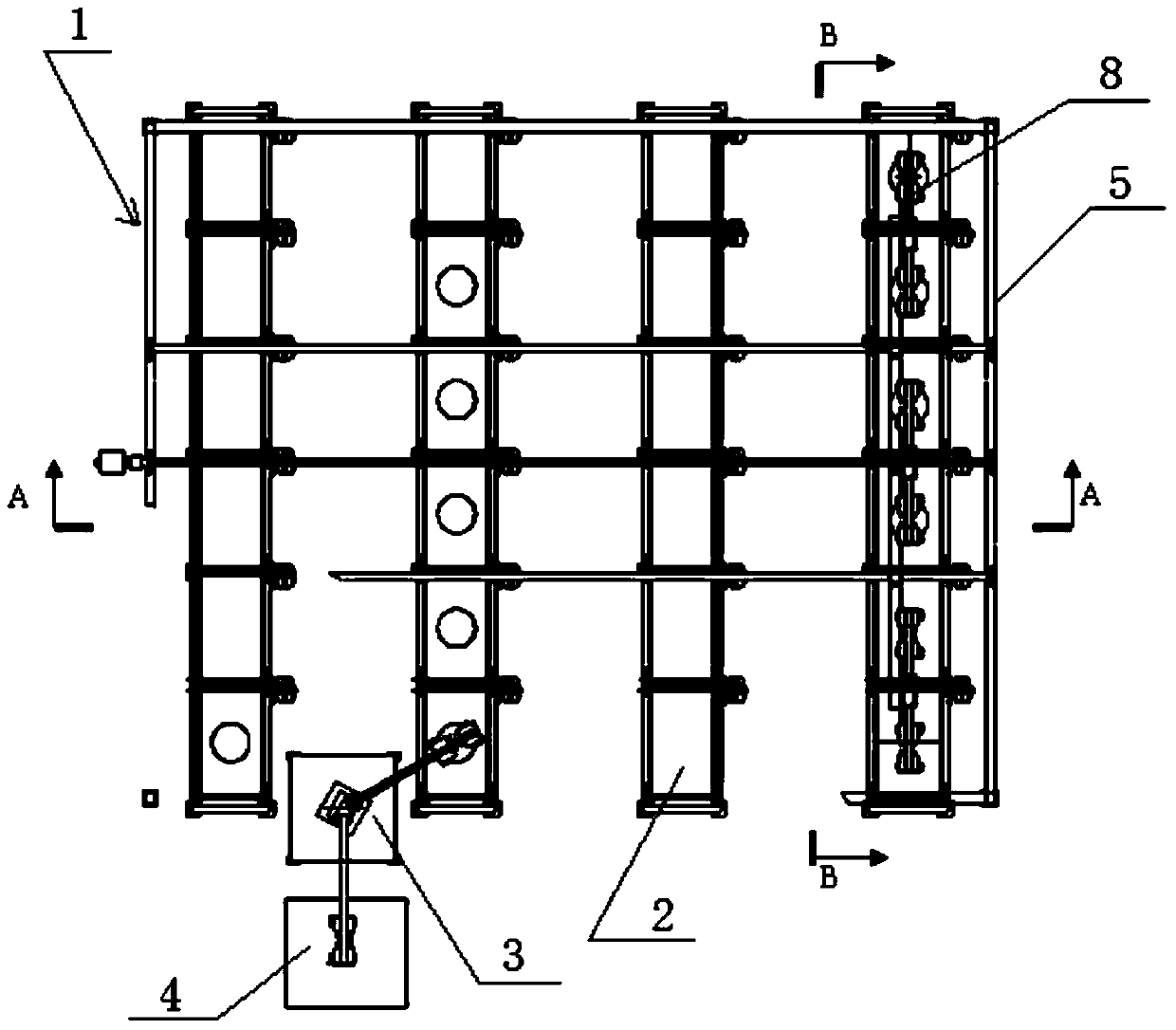

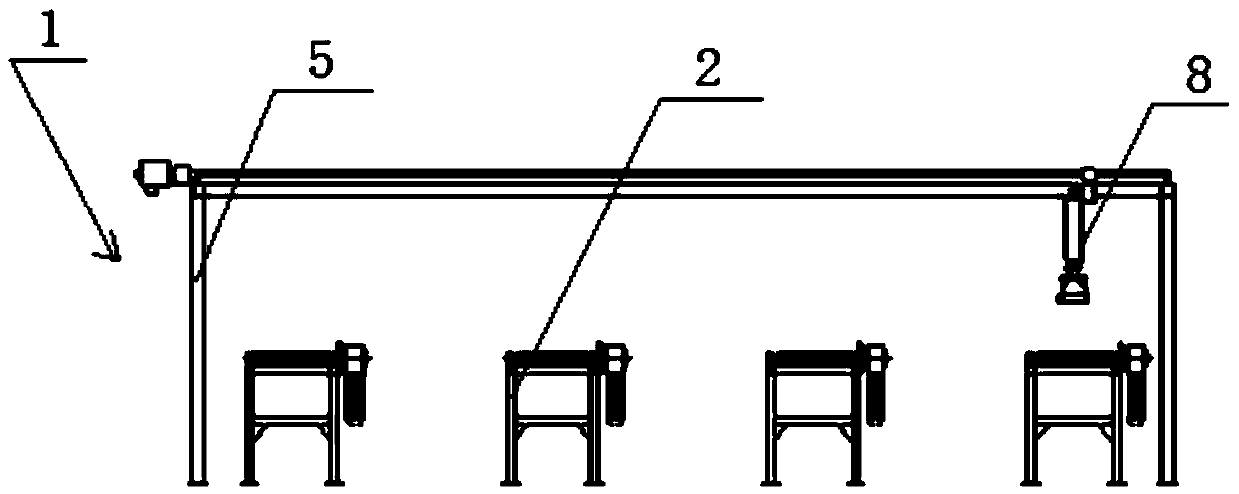

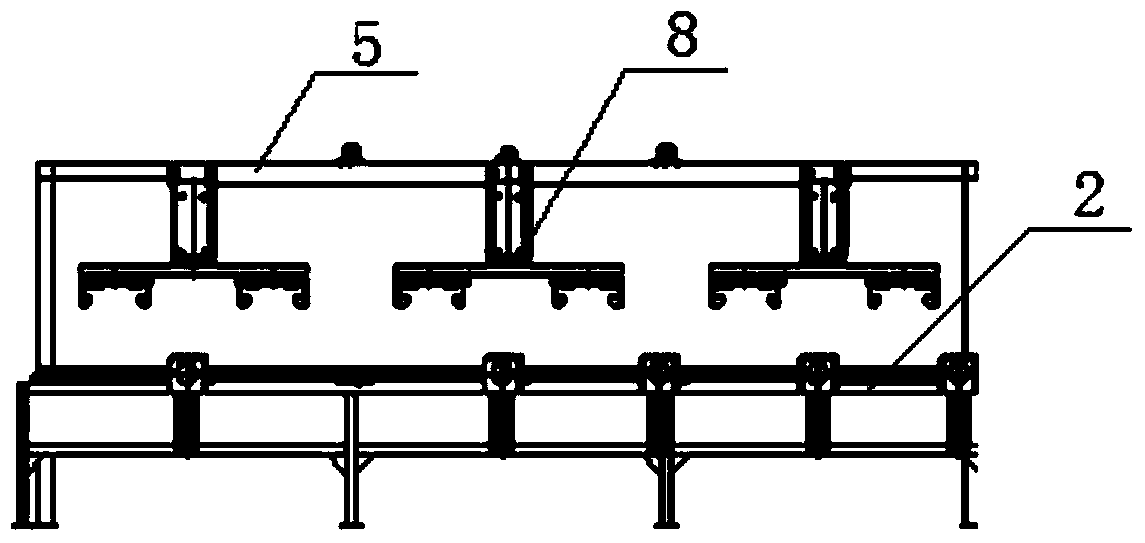

[0051] The grouped porcelain automatic charging device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0052] Such as Figure 1a , Figure 1b , Figure 1c As shown, the grouped porcelain automatic blanking device of the present invention includes: a frame assembly 5 and a movable set on the frame assembly 5 for grabbing and moving the unprocessed mud tire or processed porcelain located below A synchronous handling manipulator 1 composed of a synchronous grasping device 8 for blanks, more than 2 segmental conveyor belts 2 for placing unprocessed mud tires and processed porcelain blanks respectively arranged below the synchronous handling manipulator 1, and for placing The mud tire on the sectional conveyor belt 2 is moved on the molding machine 4, and the porcelain blank processed on the molding machine 4 is moved to the two-connected rotary manipulator 3 on the sectional conveyor belt 2.

[0053]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com