A circuit board forming and processing equipment

A molding process, circuit board technology, applied in the processing of insulating substrates/layers, printed circuits, printed circuit manufacturing, etc., can solve the problems of incoherent operation steps, low work efficiency, complicated production, etc., to reduce the transfer time, Easy maintenance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

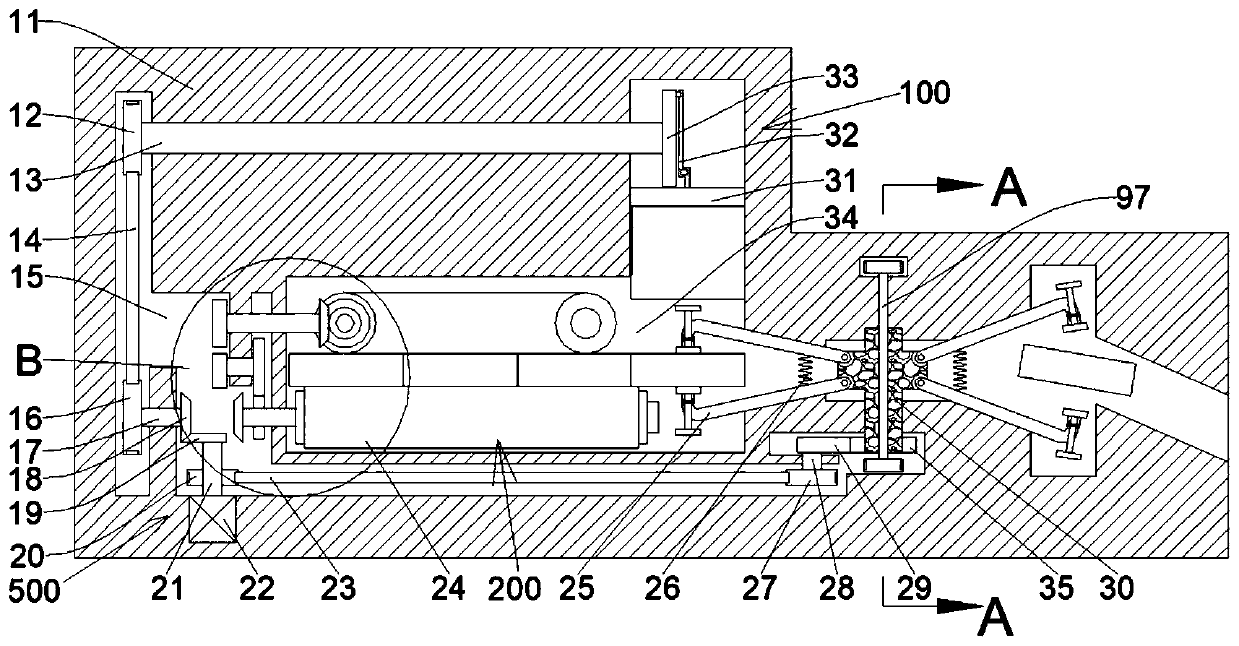

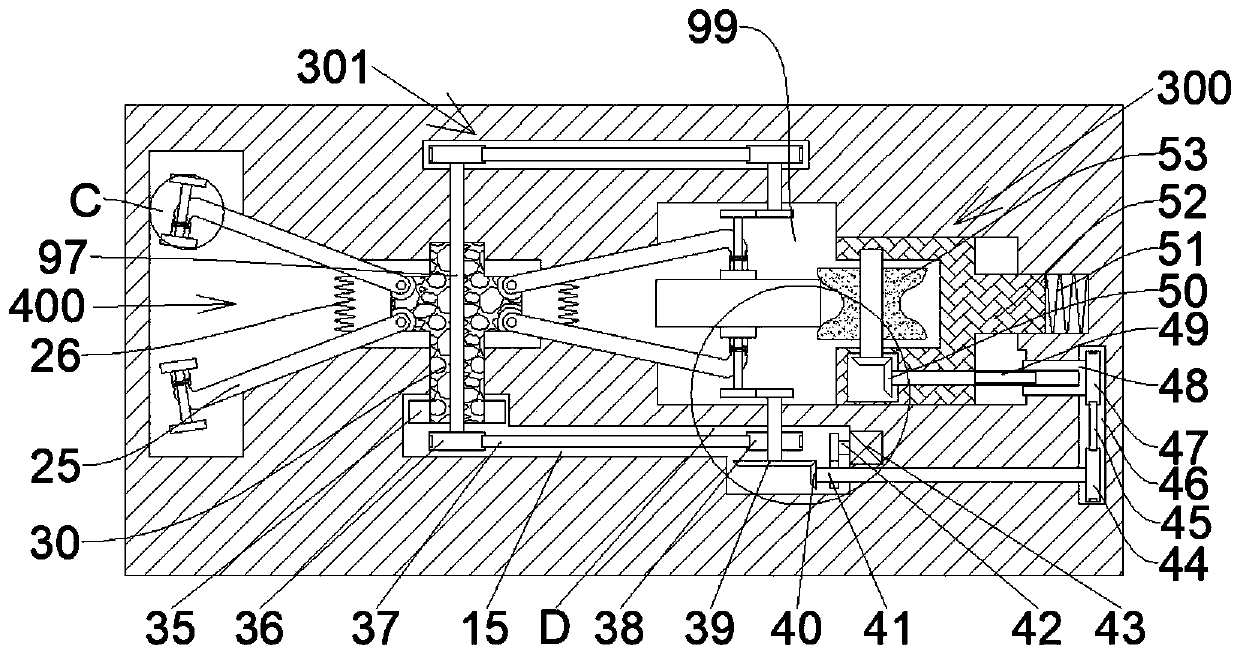

[0022] The present invention will be described in detail below in conjunction with the above-mentioned diagrams, wherein, for the convenience of description, the orientations mentioned below are stipulated as follows: figure 1 The up and down directions of the projection relationship are the same.

[0023] Such as Figure 1-6 As shown, a circuit board forming and processing equipment of the present invention, wherein the equipment includes a main body 11, a cutting cavity 34 is provided in the main body 11, a cutting device 100 is provided in the cutting cavity 34, and the cutting cavity 34 The left wall is provided with a main chamber 15, the cutting chamber 34 is provided with a conveying device 200, the cutting chamber 34 right wall is provided with a grinding chamber 99 communicating with the cutting chamber 34, and the grinding chamber 99 is provided with a grinding chamber 99. There is a grinding device 300, the grinding chamber 99 is provided with a clamping device 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com