Pipe maker for all-plastic hose forming

A pipe making machine and hose technology, which is applied in applications, household appliances, tubular objects, etc., can solve the problems of hose quality decline, hose friction disconnection, and production cost increase, so as to improve the molding processing efficiency and accuracy The effect of stable positioning and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention improves the existing hose forming machine, improves its welding process, increases its automation degree, thereby improving production efficiency, reducing labor intensity and reducing production cost.

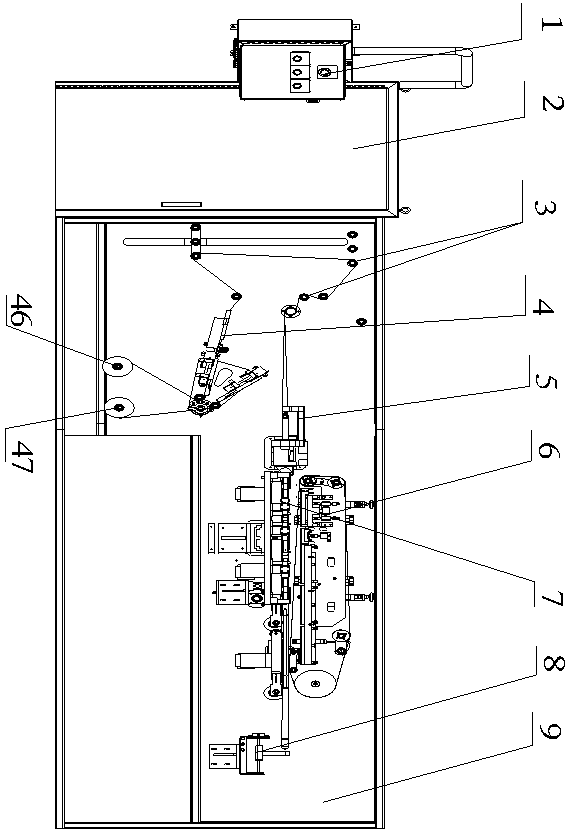

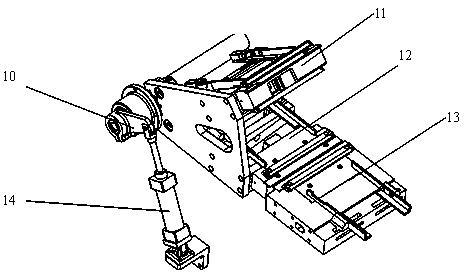

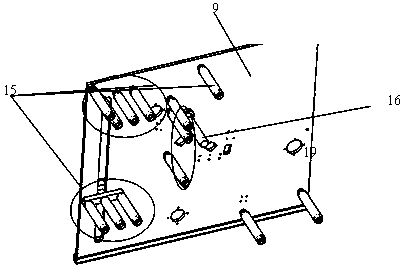

[0037] Such asfigure 1 As shown, a pipe making machine for all-plastic hose molding includes a frame 9, and also includes a sheet conveying device 3 fixed on the frame 9, a sheet overlapping device 4, and a hose forming device 5 , Interface welding device 6, hose delivery device 7, hose cutting device 8. Wherein the sheet material overlapping device 4 is below the sheet material conveying device 3, the sheet material conveying device 3 is in front of the hose forming device 5, and the hose forming device 5 is in front of the interface welding device 6 and the hose conveying device 7, and the soft The pipe joint welding device 6 is located above the hose delivery device 7 , and the hose cutting device 8 is behind the hose delivery device 7 . The raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com