Automatic high speed flexible pipe shoulder forming machine

A fully automatic, forming machine technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of low production efficiency, low degree of automation, and increased production costs, so as to improve production efficiency, reduce labor intensity, and operate smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention improves the existing hose forming machine, increases its degree of automation and high-speed operation, thereby improving production efficiency, reducing labor intensity, and reducing production costs.

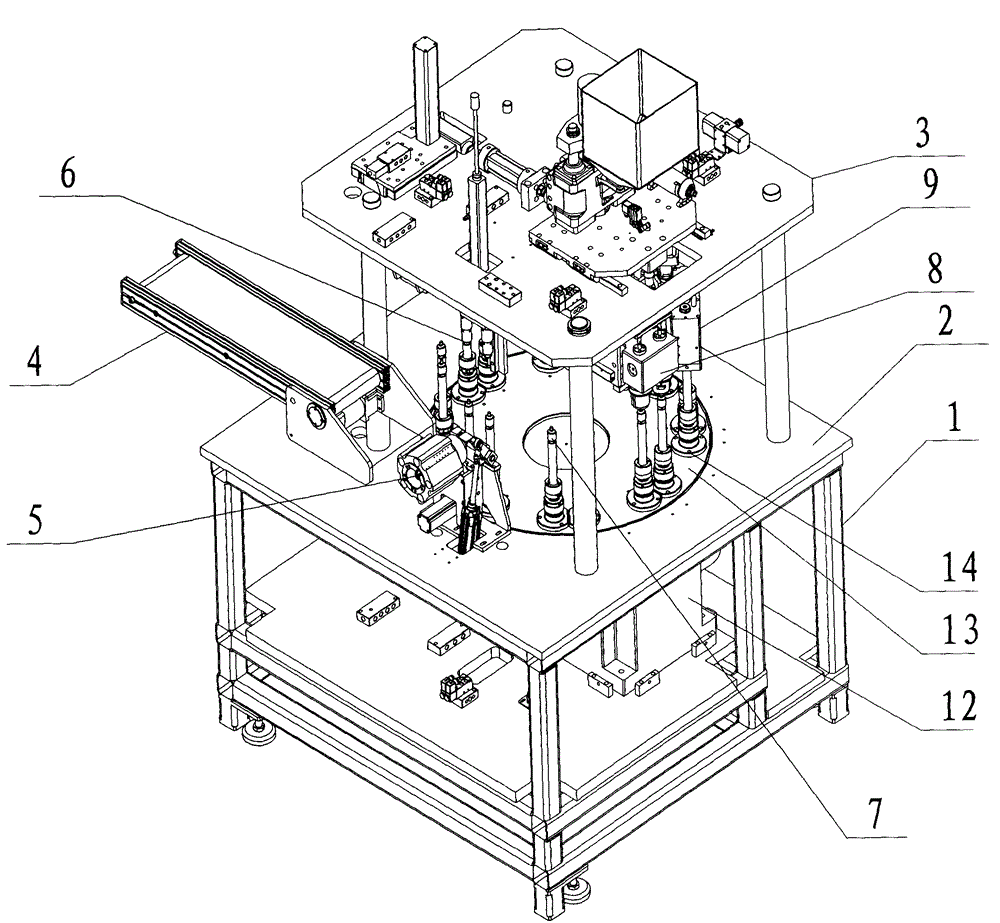

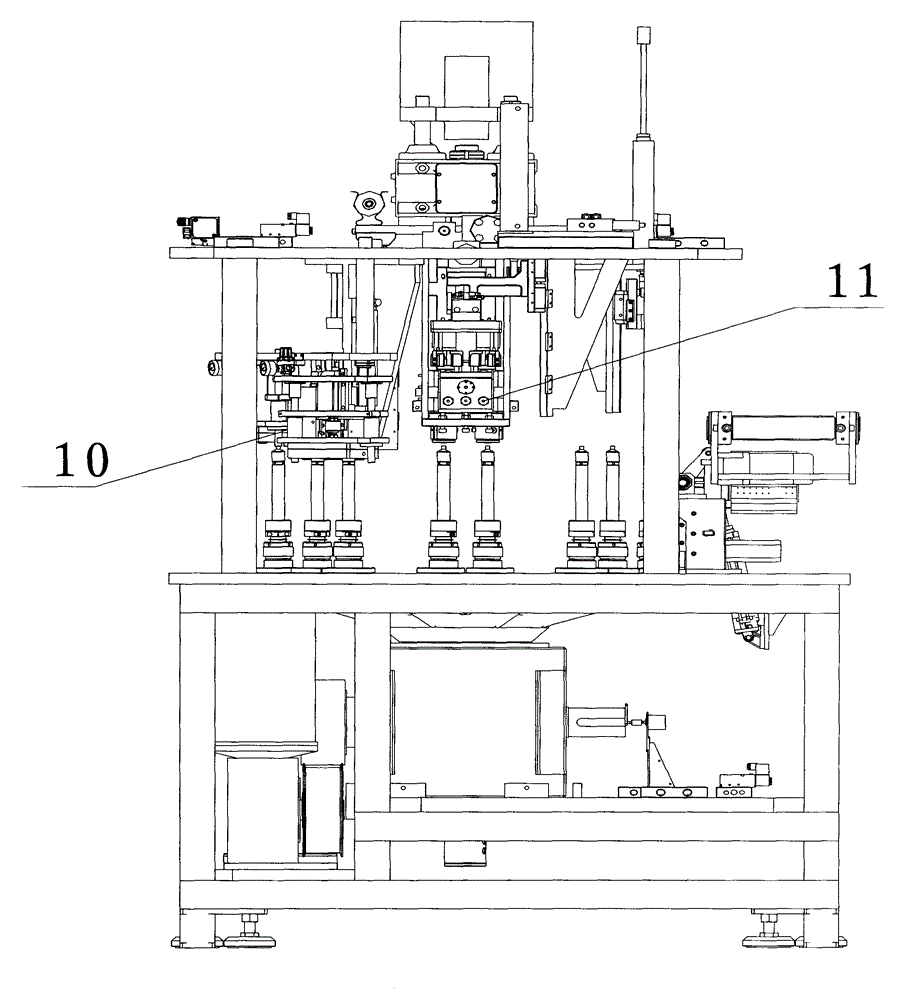

[0030] Such as figure 1 with 2 As shown, a full-automatic high-speed hose shoulder forming machine includes a frame 1 and a working platform 2 installed on the frame 1, on which a circular turntable mechanism driven by a main drive motor 12 is installed 13. It is characterized in that: the circular turntable mechanism 13 is provided with several pairs of material cups 14. Around each pair of material cups 14, there are correspondingly an automatic pipe feeding device, a detection device 7, an automatic spitting device 8, an automatic The forming device 9, the cooling device 10 and the automatic pipe dropping device 11, all of the above devices are controlled by PLC.

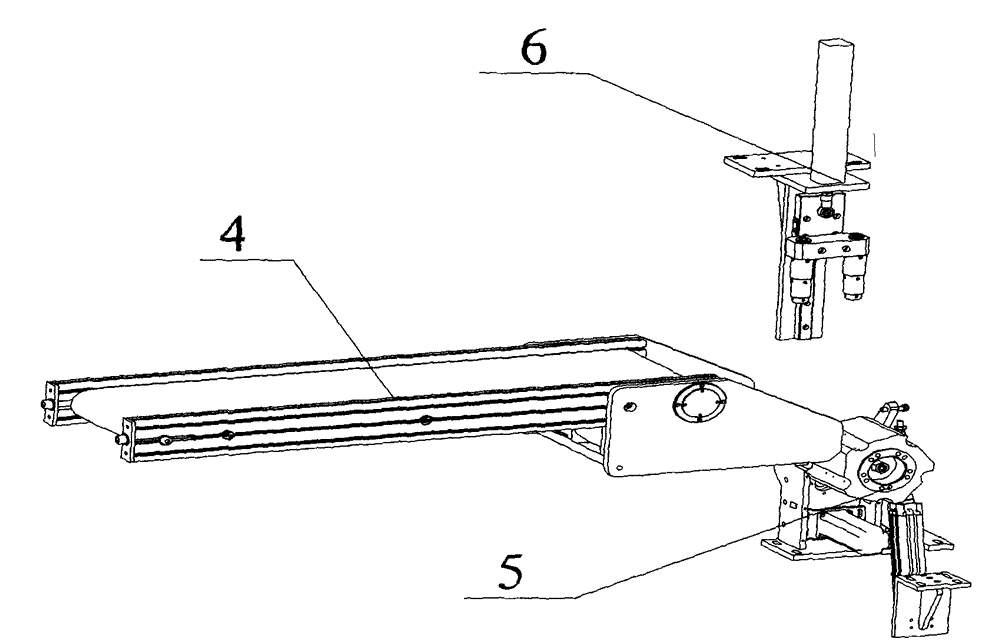

[0031] Such as figure 1 , 3 , 4, 5, and 6, the automatic tube loading device includes an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com