Working handpiece of numerical control wire bending machine

A technology of wire bending machine and head, applied in the field of wire bending machine manufacturing, which can solve the problems of increased head load, low wire processing efficiency, heavy head load, etc., and achieves high positioning angle accuracy and high wire forming efficiency , the effect of light load of its own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

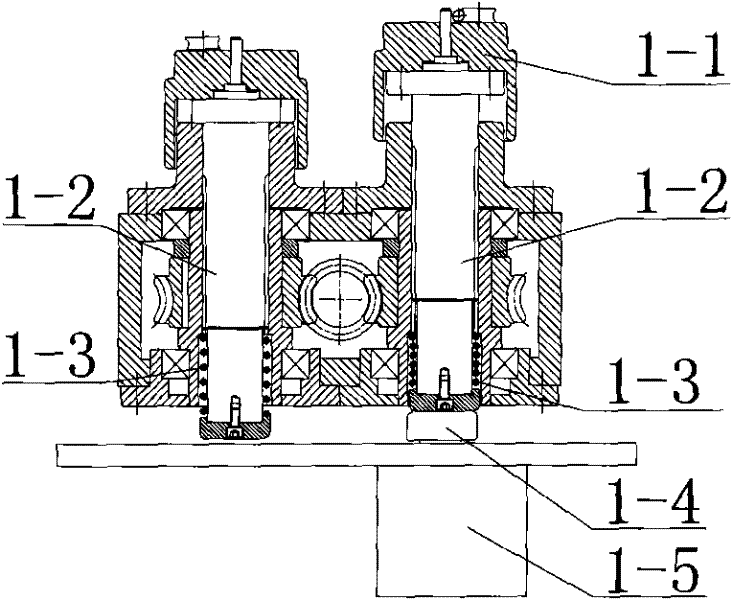

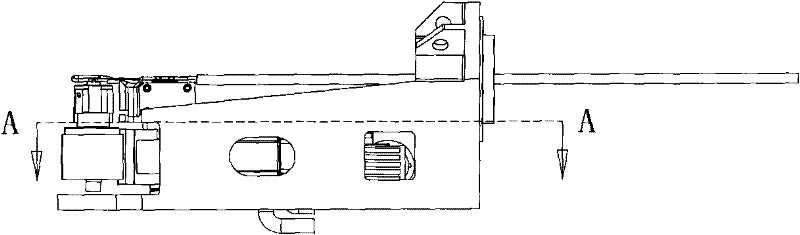

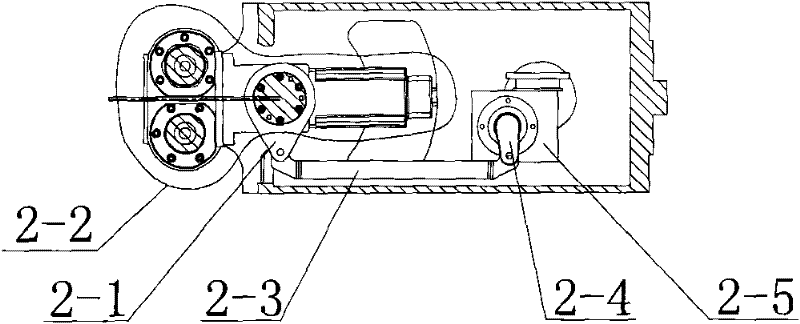

[0018] Embodiment 1: with reference to attached Figure 1-8 . The working head of the CNC wire bending machine, which includes the working head of the CNC wire bending machine, the two die heads 1-1 in the wire bending machine die change and steering die lifting avoidance mechanism in the CNC wire bending machine are respectively connected to the The two spline shafts 1-2 are connected without relative displacement, the bottom of the spline shaft 1-2 is in contact with the lower end of the compression spring 1-3, and the upper end of the compression spring 1-3 is in contact with the inner step of the main shaft and drives the spline shaft 1-2 move down. When the die head 1-1 that needs to work is turned to the center of the station, the piston head 1-4 in the oil cylinder or cylinder 1-5 lifts up the spline shaft and the die head 1-1 together, and the compression spring 1-3 is compressed again; When the mold needs to be changed or the die head 1-1 turns, the piston head 1-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com