Forming device facilitating machining of special-shaped curved surface of automobile fairing

A special-shaped curved surface, forming device technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of low processing efficiency and high labor intensity, and achieve the goal of improving work efficiency, reducing labor intensity, and improving forming processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

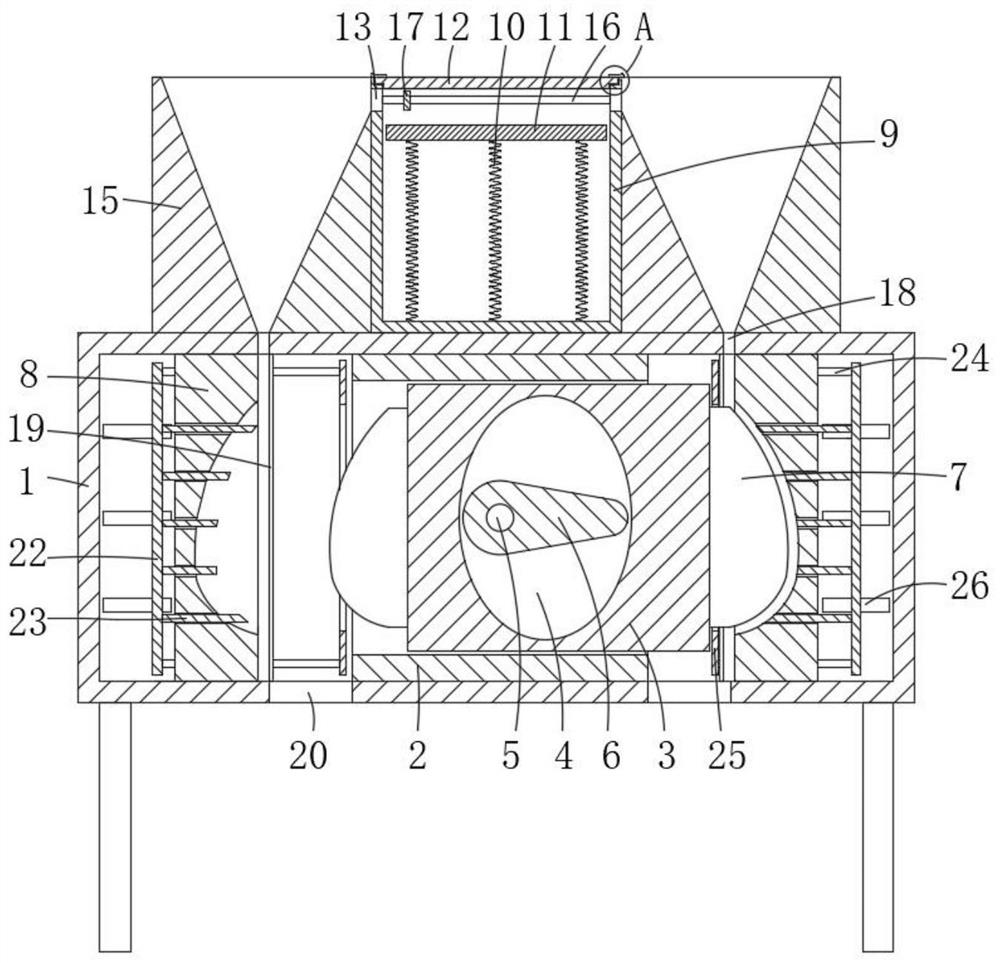

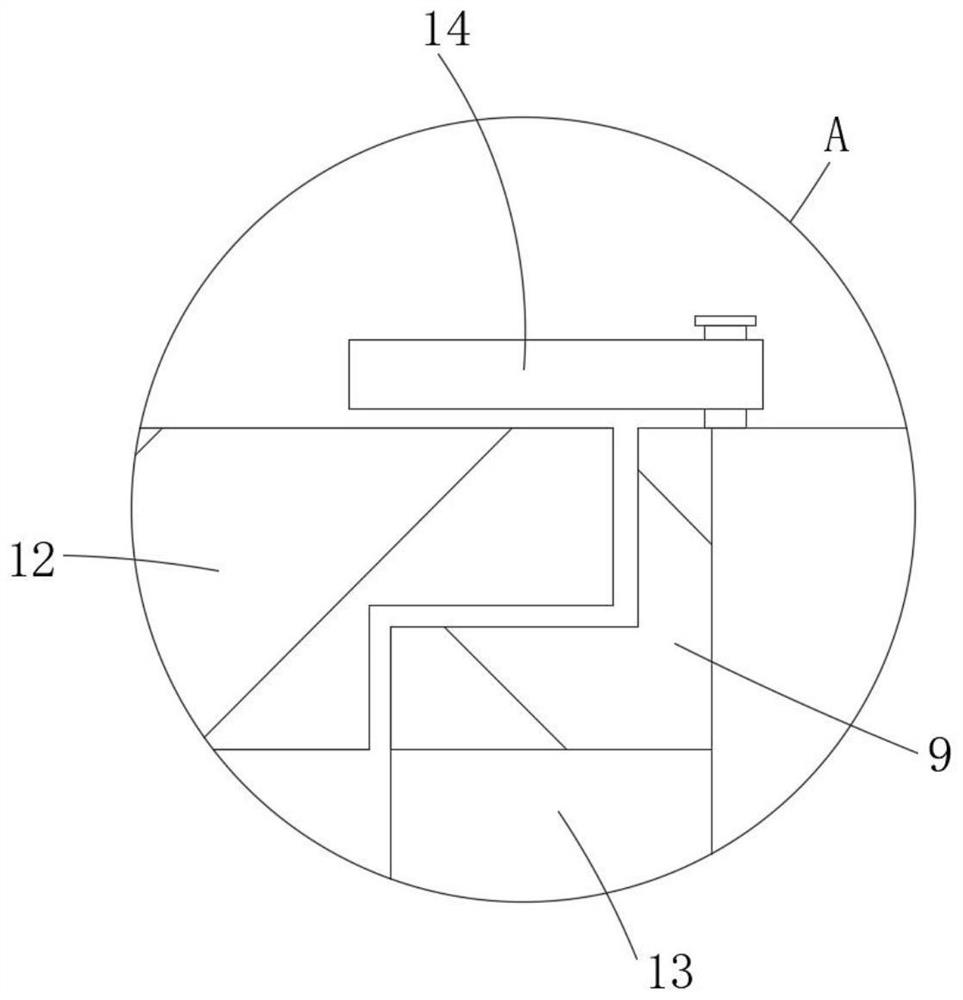

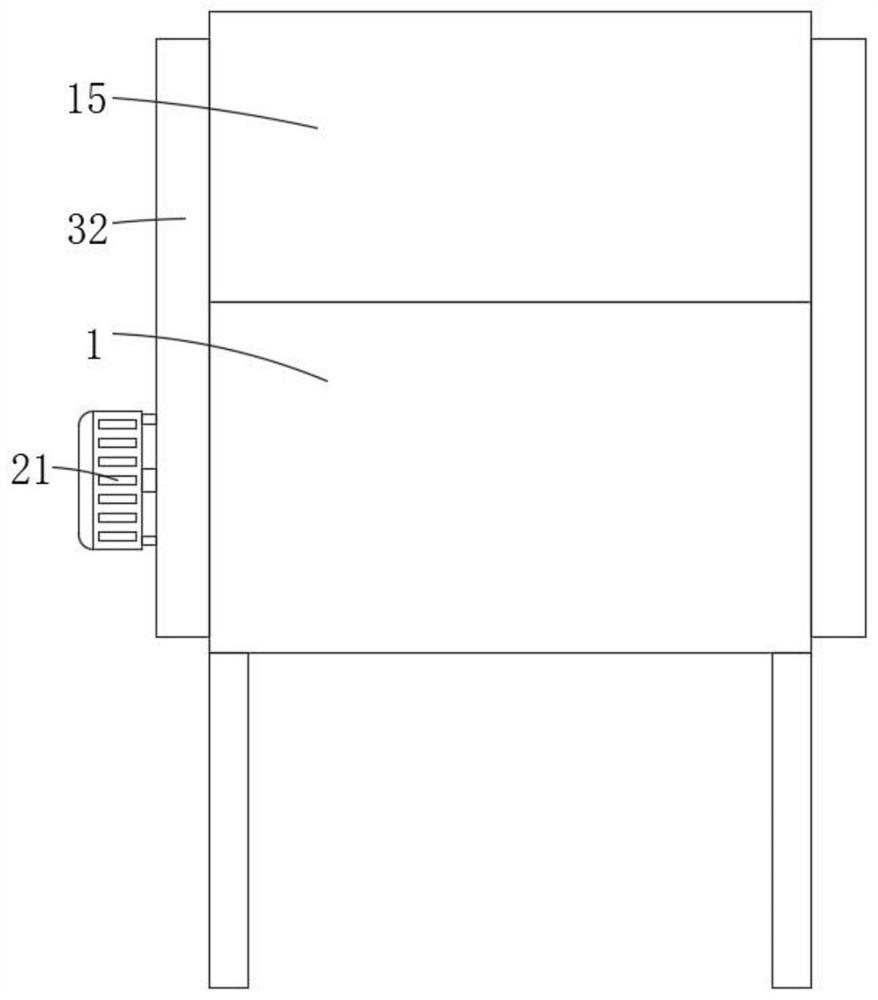

[0032] Refer Figure 1-6 A molding apparatus that facilitates the shaped surface of the automobile flow cover, including: housing 1, the inner side of the housing 1, has a slide 2, and the inside of the slide 2 is slid with mounting block 3, and two mounting blocks 3. The side walls are fixed, and the inner walls of the outer ends of the casing 1 are fixed, and the two cavities are opened outside the two recess 8 near the side of the convex mold 7. Each of the outer walls of the housing 1 are secured to the outer casing 32, and the outer casing 32 is mounted, and the drive motor 21 is mounted, the output terminal of the drive motor 21 is mounted, and the inner side of the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com