Automatic plastic-spraying device used for high-speed hose shoulder-molding machine

A molding machine and hose technology, applied in the field of automatic plastic ejection devices, can solve the problems of low production efficiency, low degree of automation, increased production cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention improves the existing hose forming machine, increases its degree of automation and high-speed operation, thereby improving production efficiency, reducing labor intensity and reducing production cost.

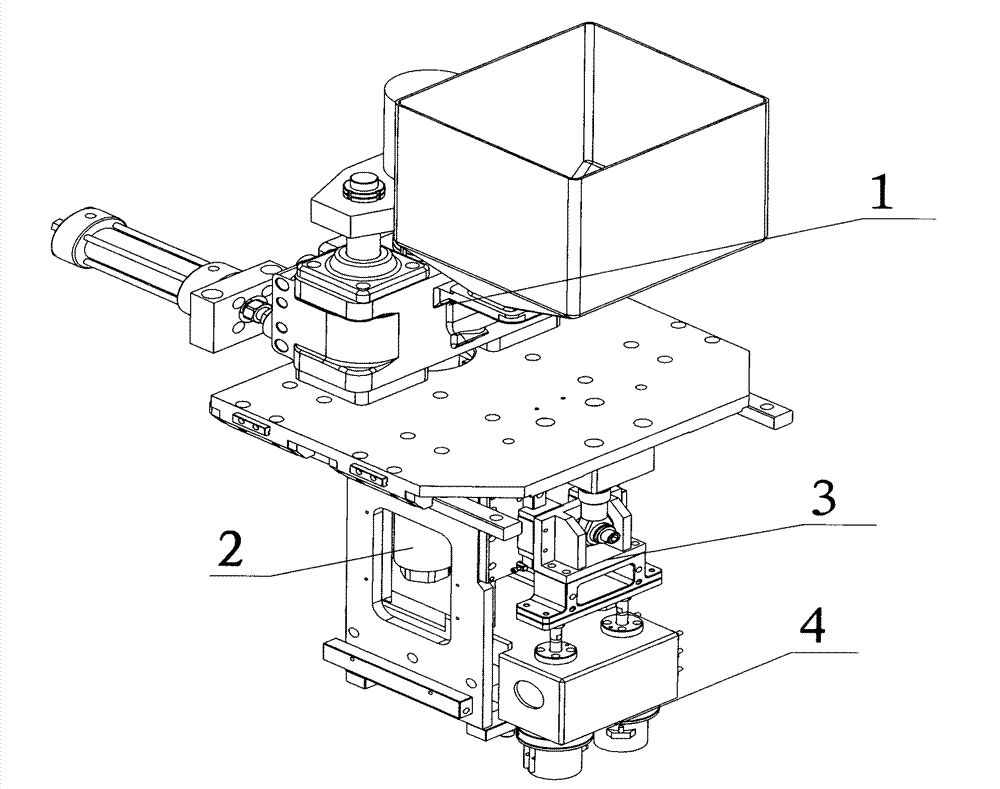

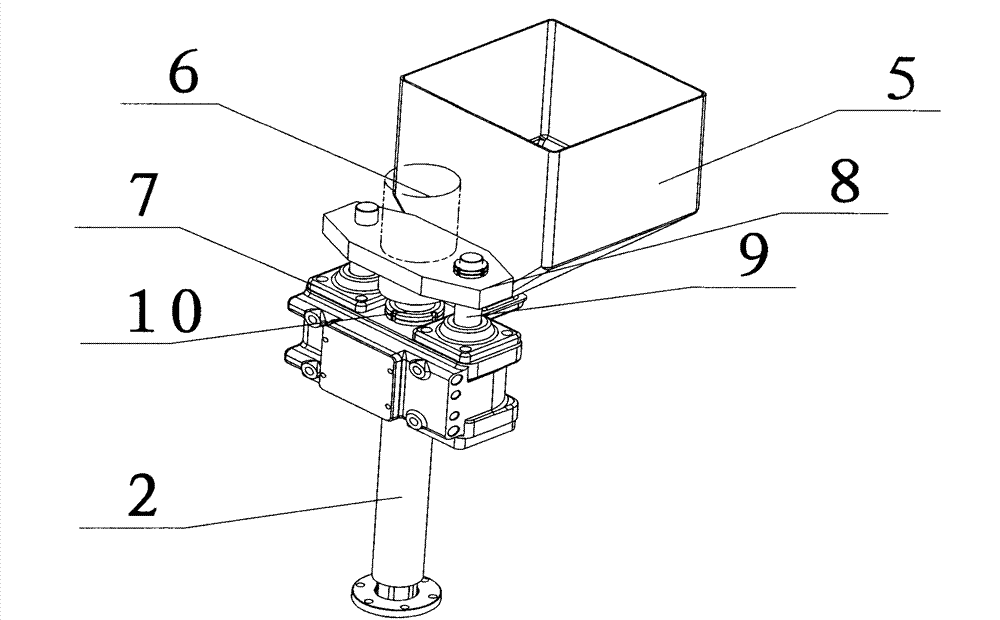

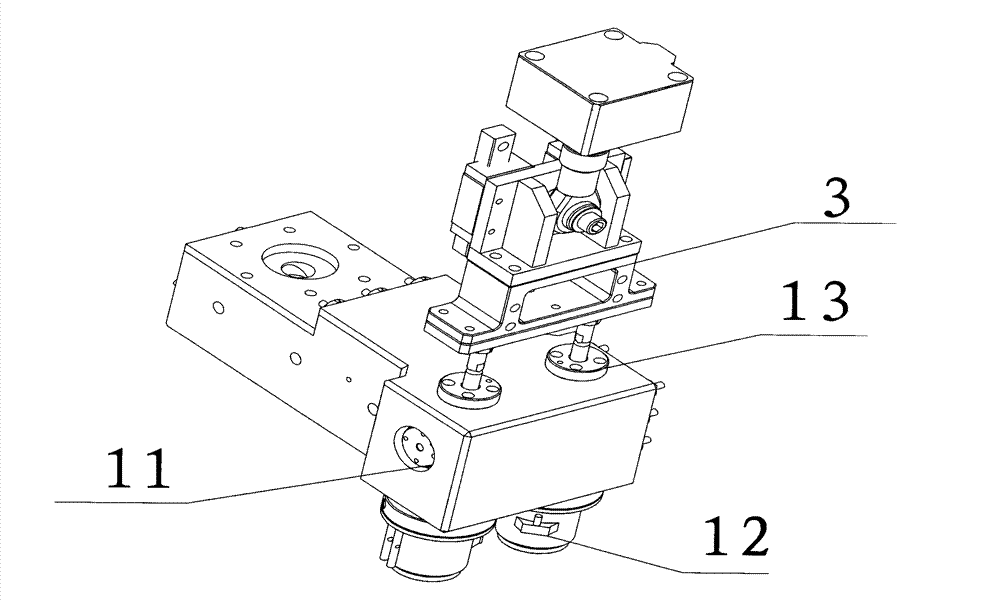

[0016] Such as figure 1 As shown, an automatic ejecting device for a high-speed hose shoulder forming machine, including a frame and a top plate installed on the frame, is characterized in that: the device includes a material storage mechanism 1, a heating barrel 2, a breaker The material storage mechanism 3 and the discharge mechanism 4, the storage mechanism 1 is located above the top plate, the heating barrel 2, the material breaking mechanism 3 and the discharge mechanism 4 are all located below the top plate, and the upper port of the heating barrel 2 It is connected with the outlet of the storage mechanism 1, the lower port of the heating cylinder 2 is connected with the discharge mechanism 4, the material breaking mechanism 3 is located above the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com