Patents

Literature

102results about How to "Easy and efficient processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing modified epoxy resin

ActiveUS20070027233A1Reduce removalEasy to excludeFilm/foil adhesivesCircuit susbtrate materialsSolubilityPolymer chemistry

This invention provides a process for producing an epoxy resin composition having core / shell rubber particles (rubber-like polymer particles) dispersed in an epoxy resin, wherein an epoxy resin composition excellent in the dispersed state of rubber-like polymer particles in an epoxy resin with a reduced amount of contaminants is produced easily and efficiently. The epoxy resin composition having rubber-like polymer particles dispersed well in an epoxy resin with less contaminant is obtained by bringing an aqueous latex of rubber-like polymer particles (B) into contact with an organic medium (C) showing partial solubility in water, then bringing an organic medium (D) having lower partial solubility in water than that of the organic medium (C) into contact therewith to separate water substantially, to remove the rubber-like polymer particles as a dispersion (F) having the polymer particles dispersed in the organic medium, and mixing it with an epoxy resin (A), followed by distilling volatile components away.

Owner:KANEKA CORP

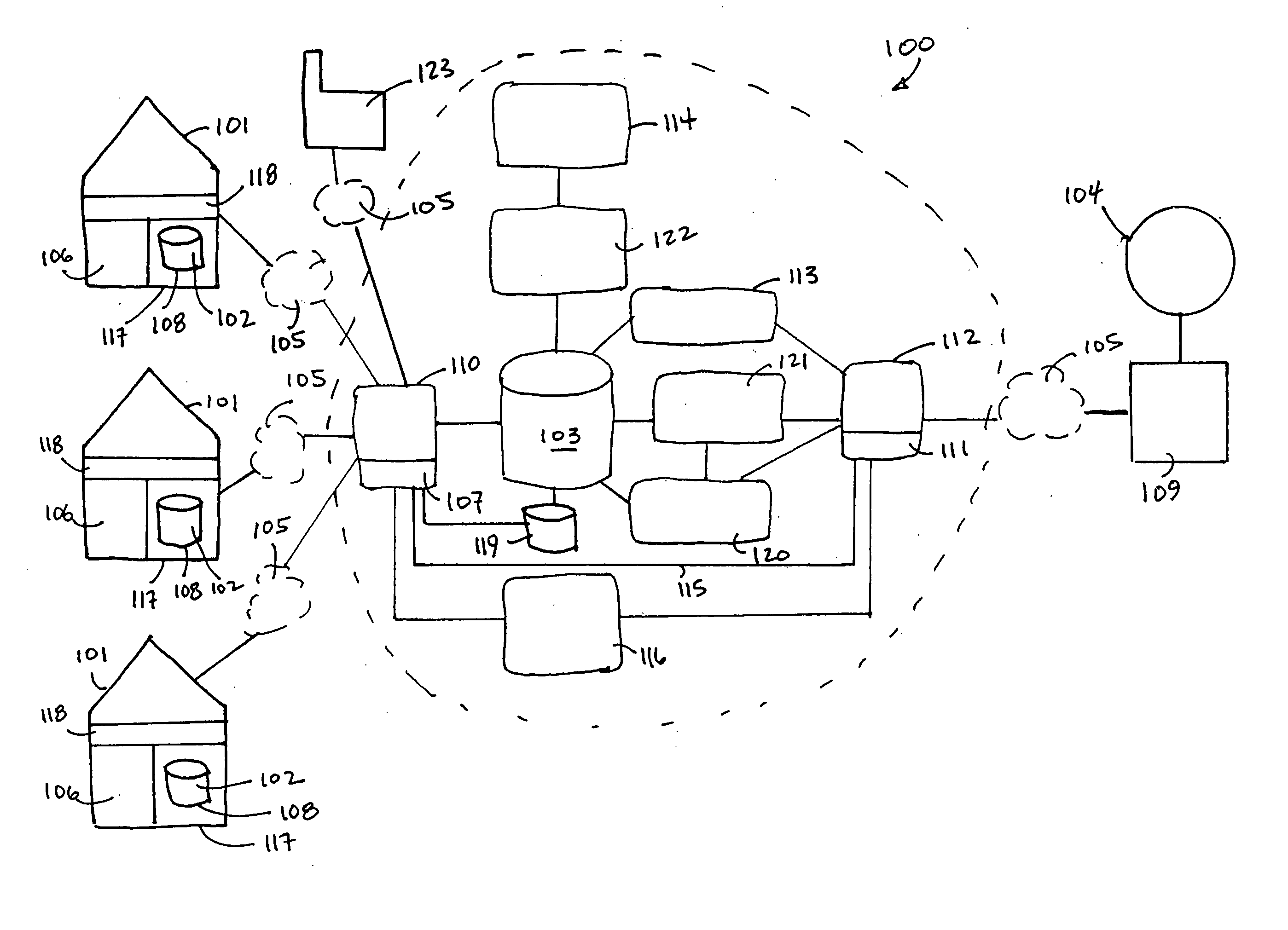

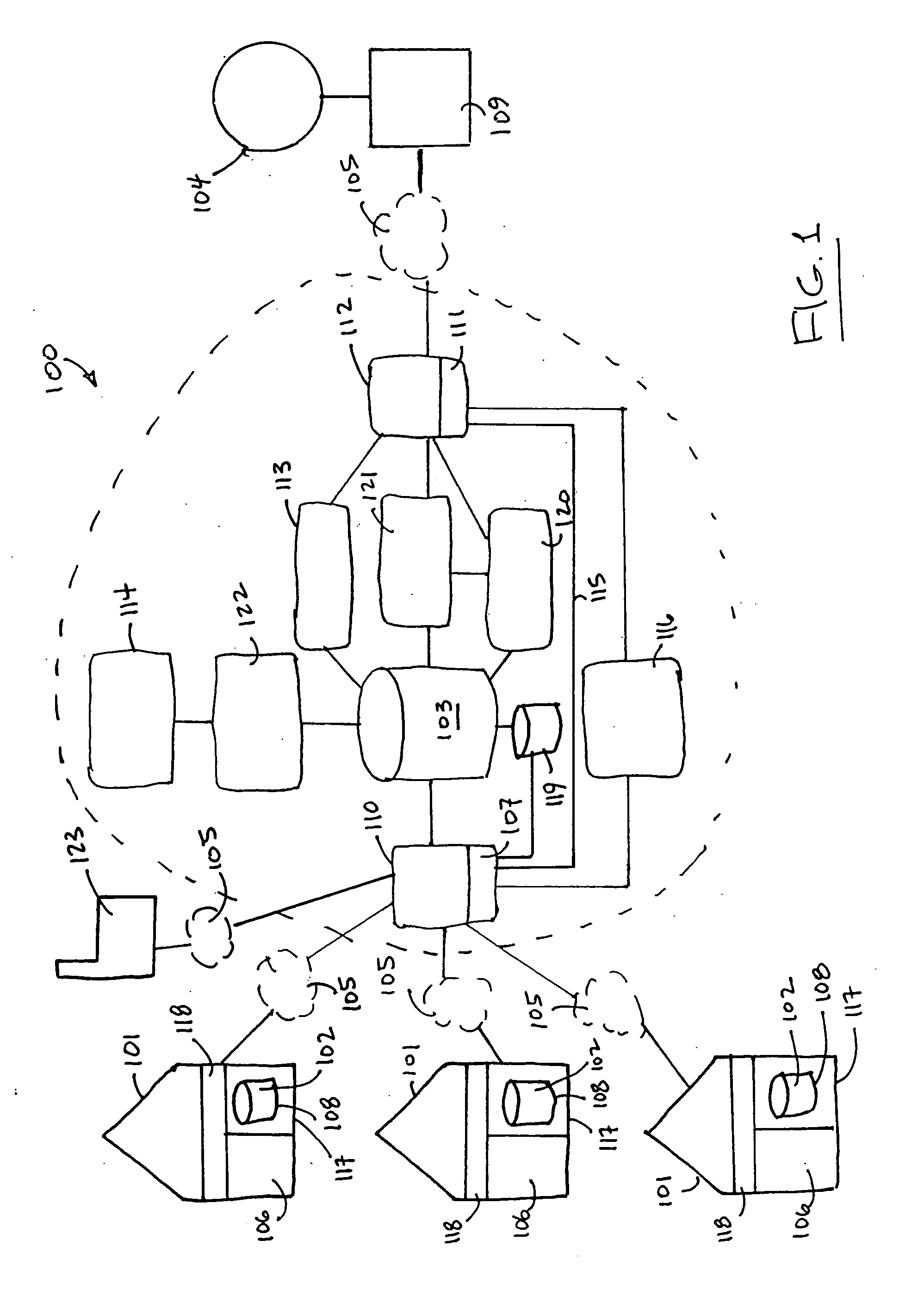

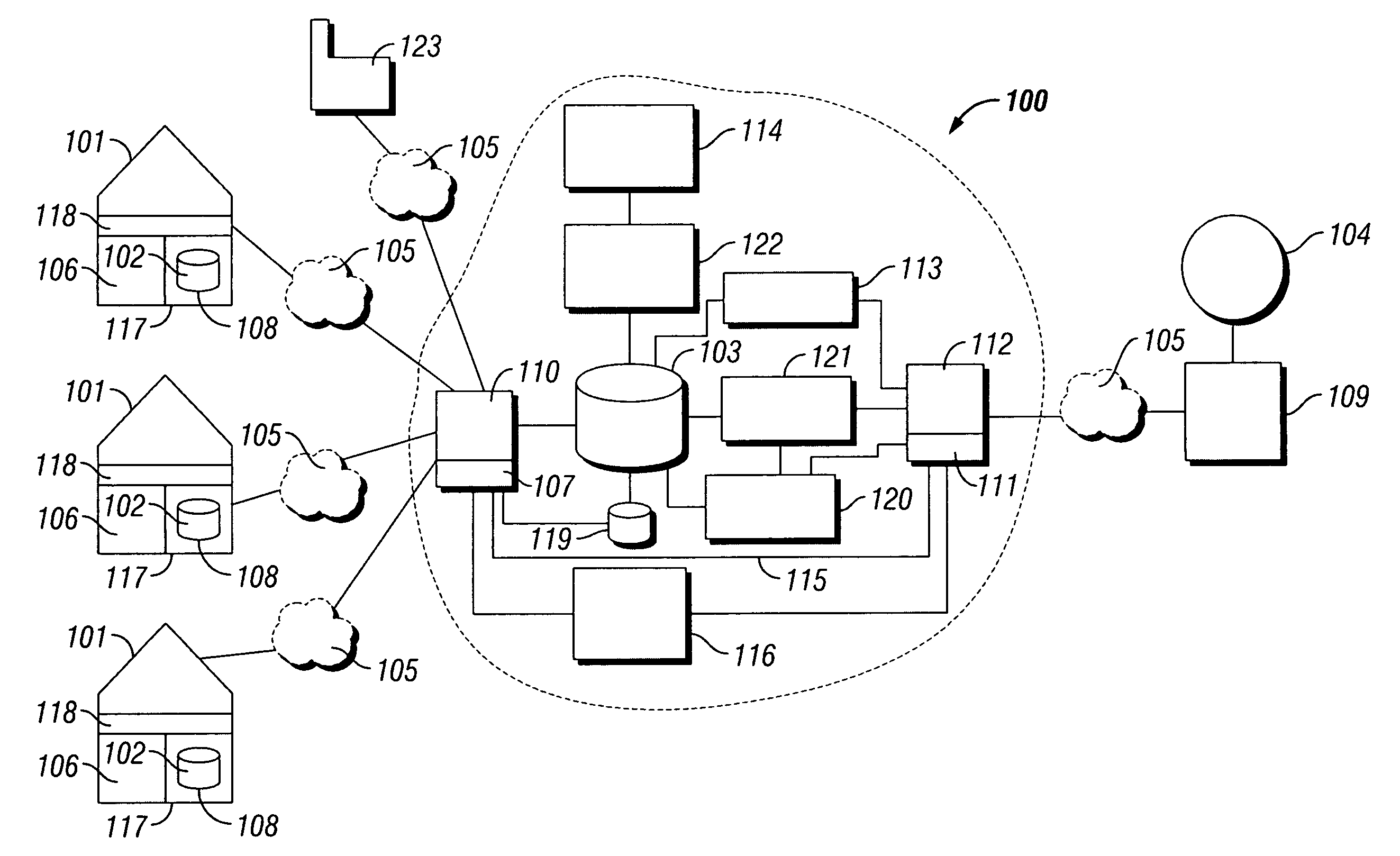

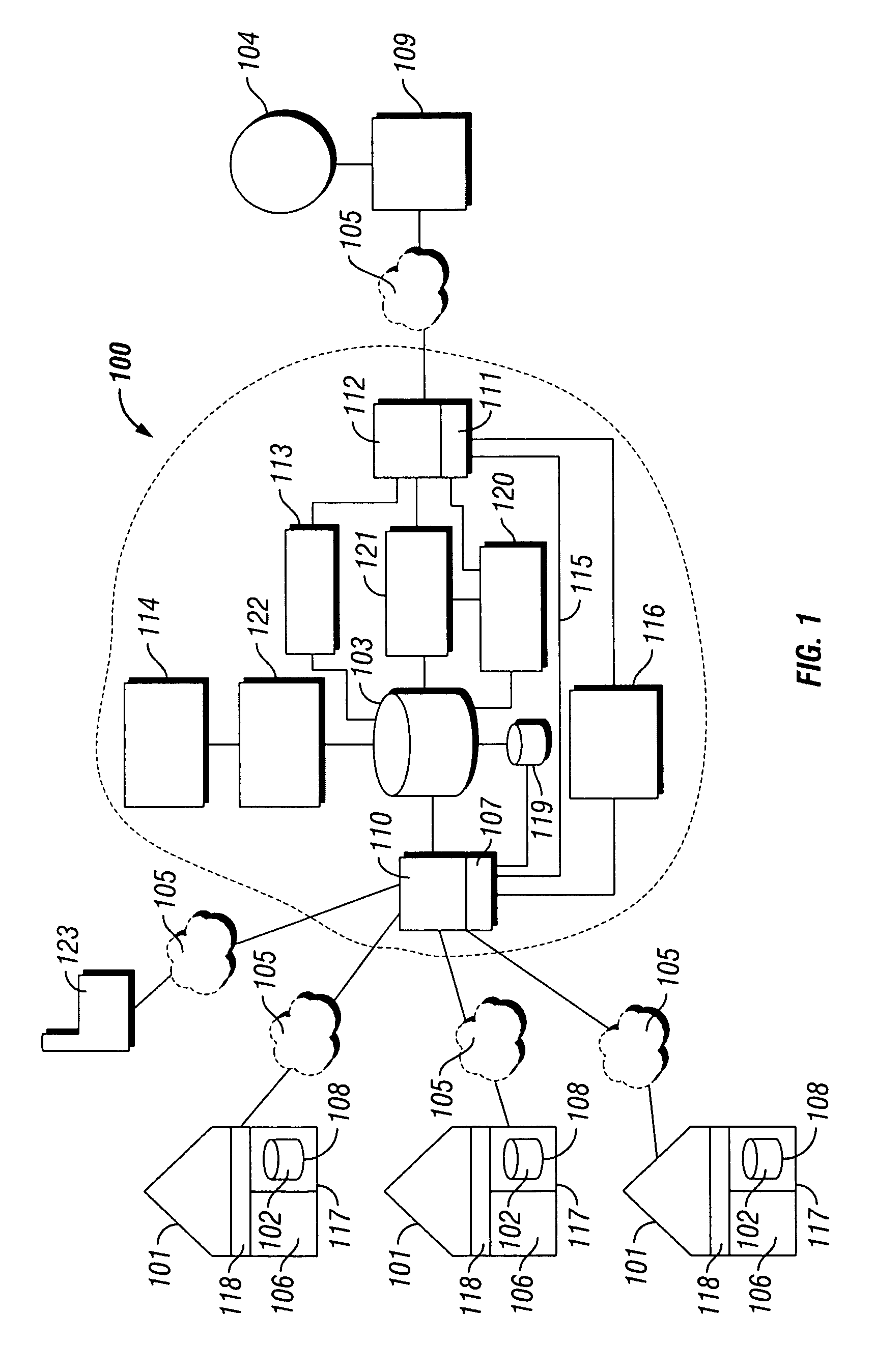

Internet enhanced local shopping system and method

ActiveUS20050097005A1Easy and efficient processingThe process is simple and effectiveCommerceSpecial data processing applicationsThe InternetDatabase

Internet enhanced local shopping system in which businesses having physical stores where products and services can be purchased submit their inventories and business terms, including their geographic locations, into a searchable database available to shoppers wanting to buy products and services locally so that shoppers can find stores in their area where the products and services they desire are available and can be purchased under specified terms.

Owner:INTUIT INC

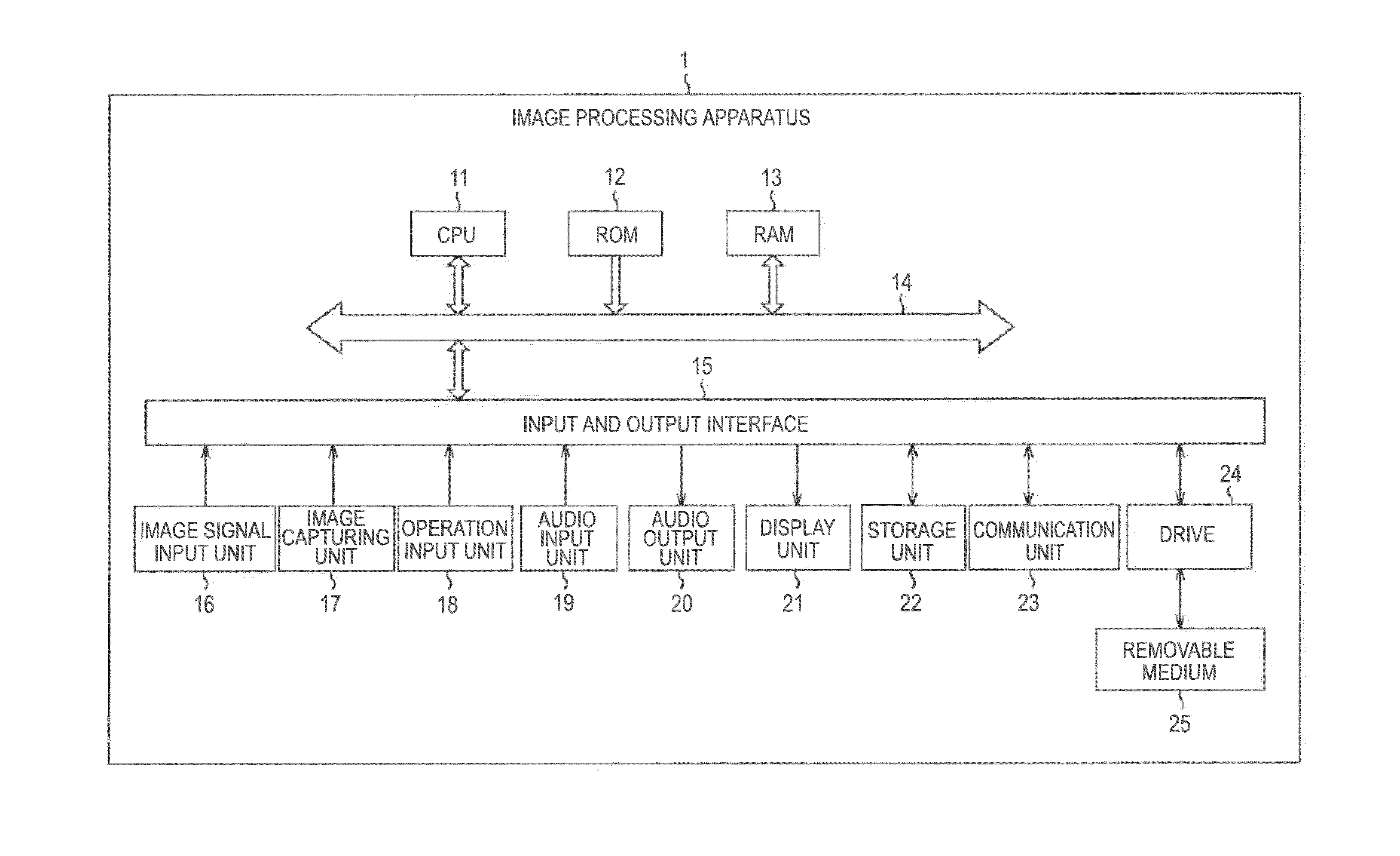

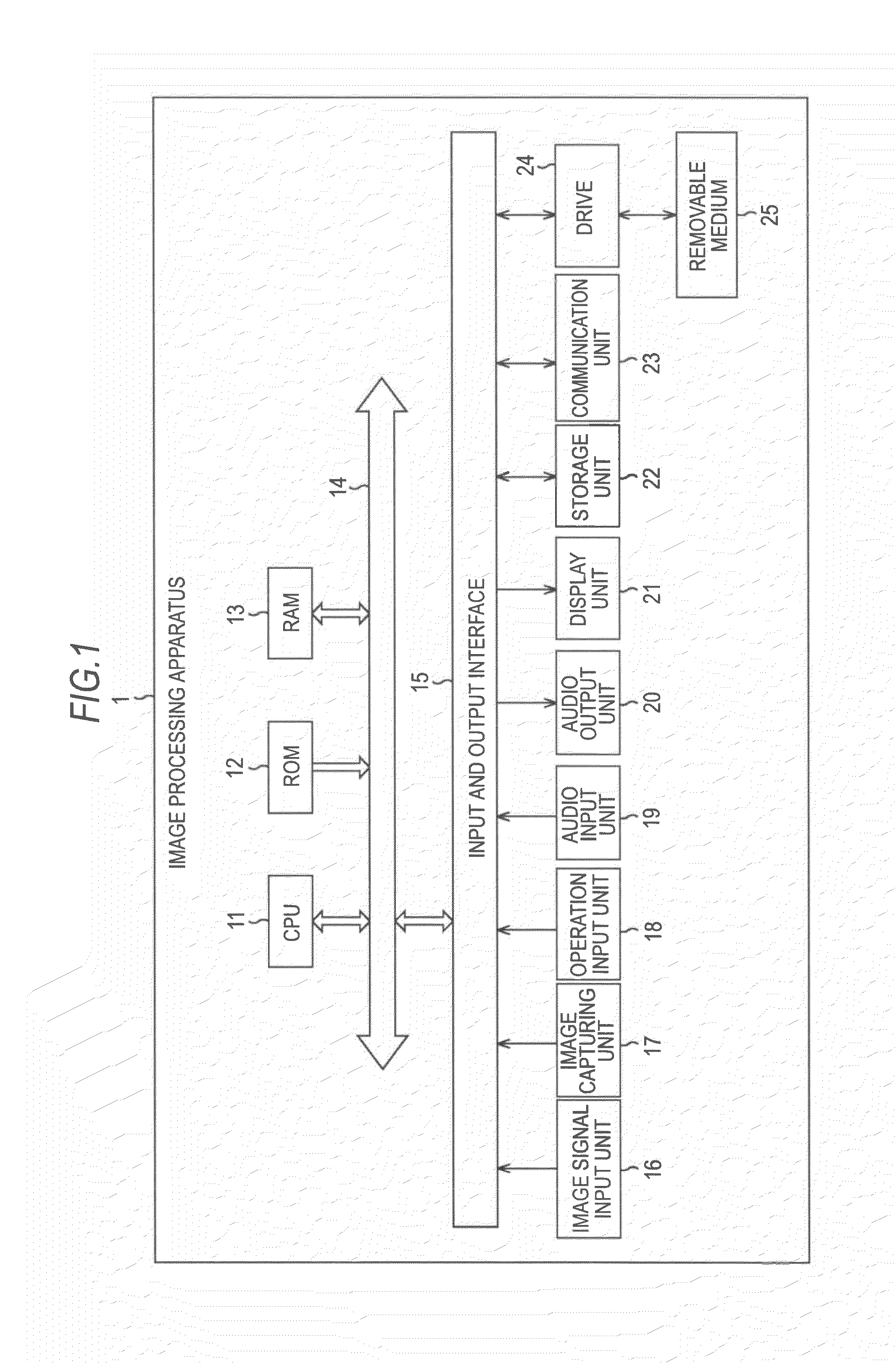

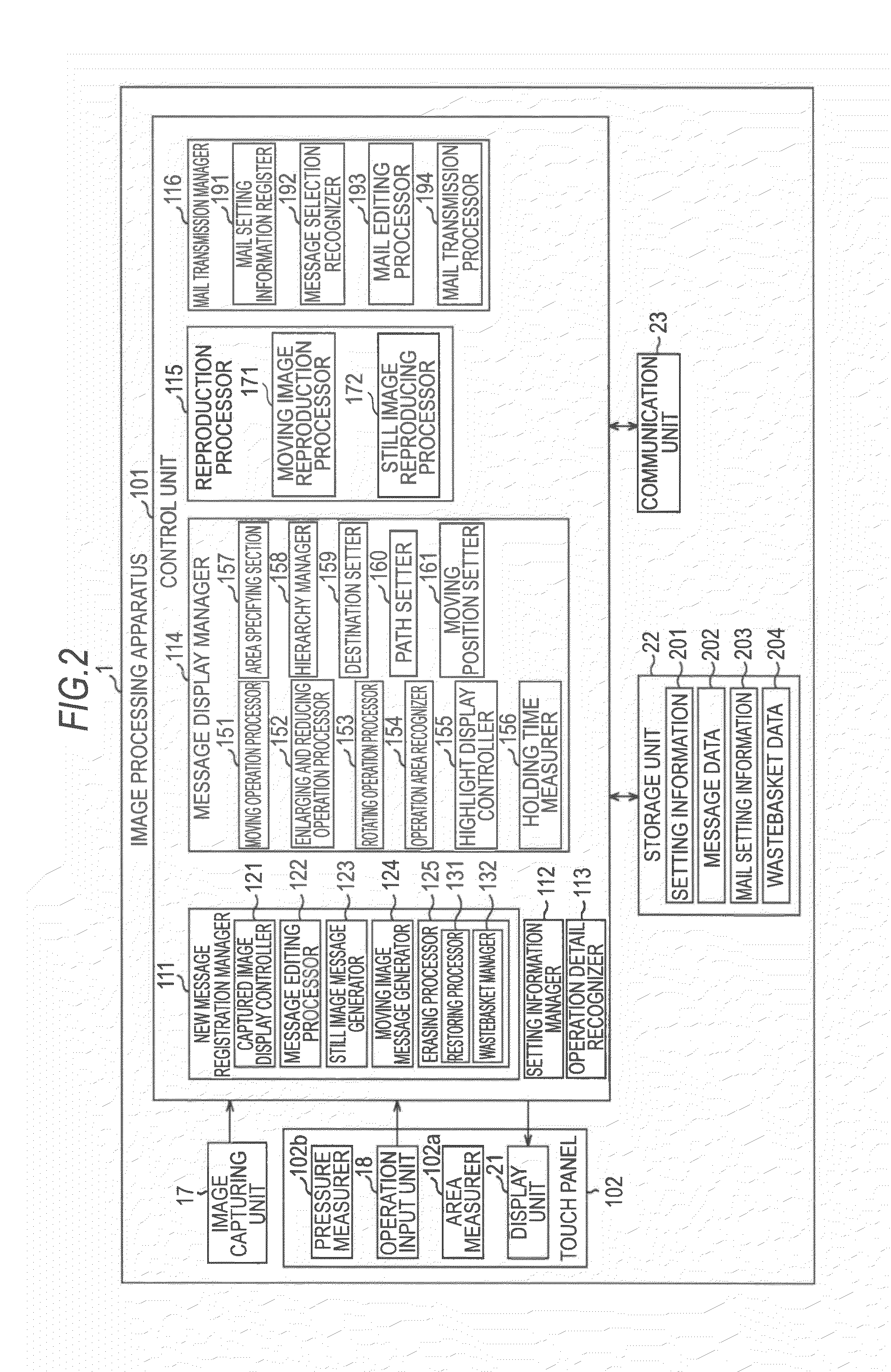

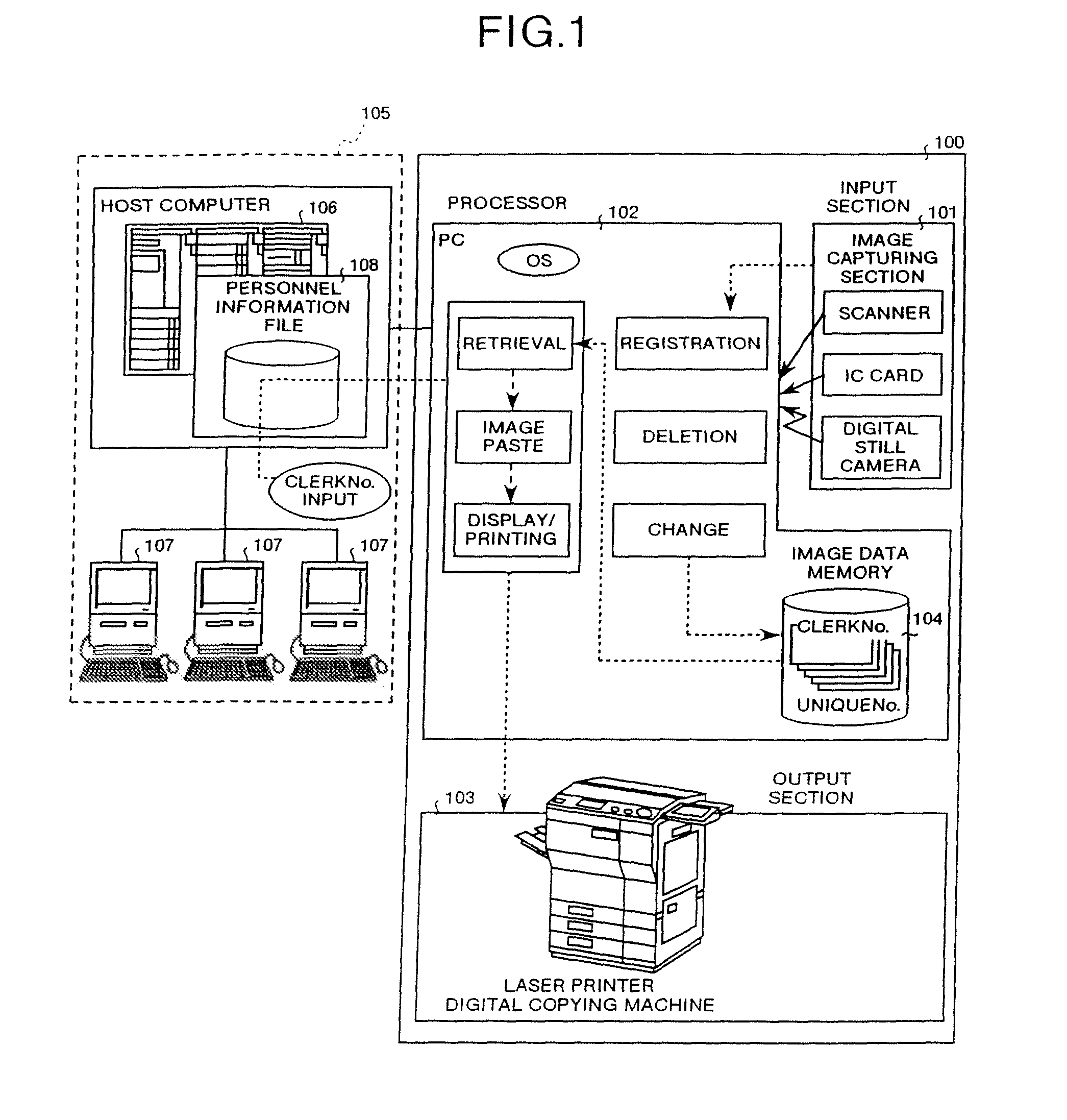

Image processing apparatus, image processing method, and image processing program

InactiveUS20110279852A1Easy and efficient processingEfficiently and easily selectDigital output to print unitsImaging processingComputer graphics (images)

An image processing apparatus having a display unit includes: an operation section configured to generate an operation signal based on a user's contact with the display unit; a posting area display control section configured to display a posting area in which an image is posted on the display unit and displaying previously-generated images in the posting area; an operation detail recognizing section configured to recognize an operation detail on the images posted in the posting area on the basis of the operation signal from the operation section; and a selection section configured to select an image corresponding to the operation detail recognized by the operation detail recognizing section as an operation object.

Owner:SONY CORP

Internet enhanced local shopping system and method

ActiveUS7596513B2Easy and efficient processingThe process is simple and effectiveCommerceGeolocationThe Internet

Internet enhanced local shopping system in which businesses having physical stores where products and services can be purchased submit their inventories and business terms, including their geographic locations, into a searchable database available to shoppers wanting to buy products and services locally so that shoppers can find stores in their area where the products and services they desire are available and can be purchased under specified terms.

Owner:INTUIT INC

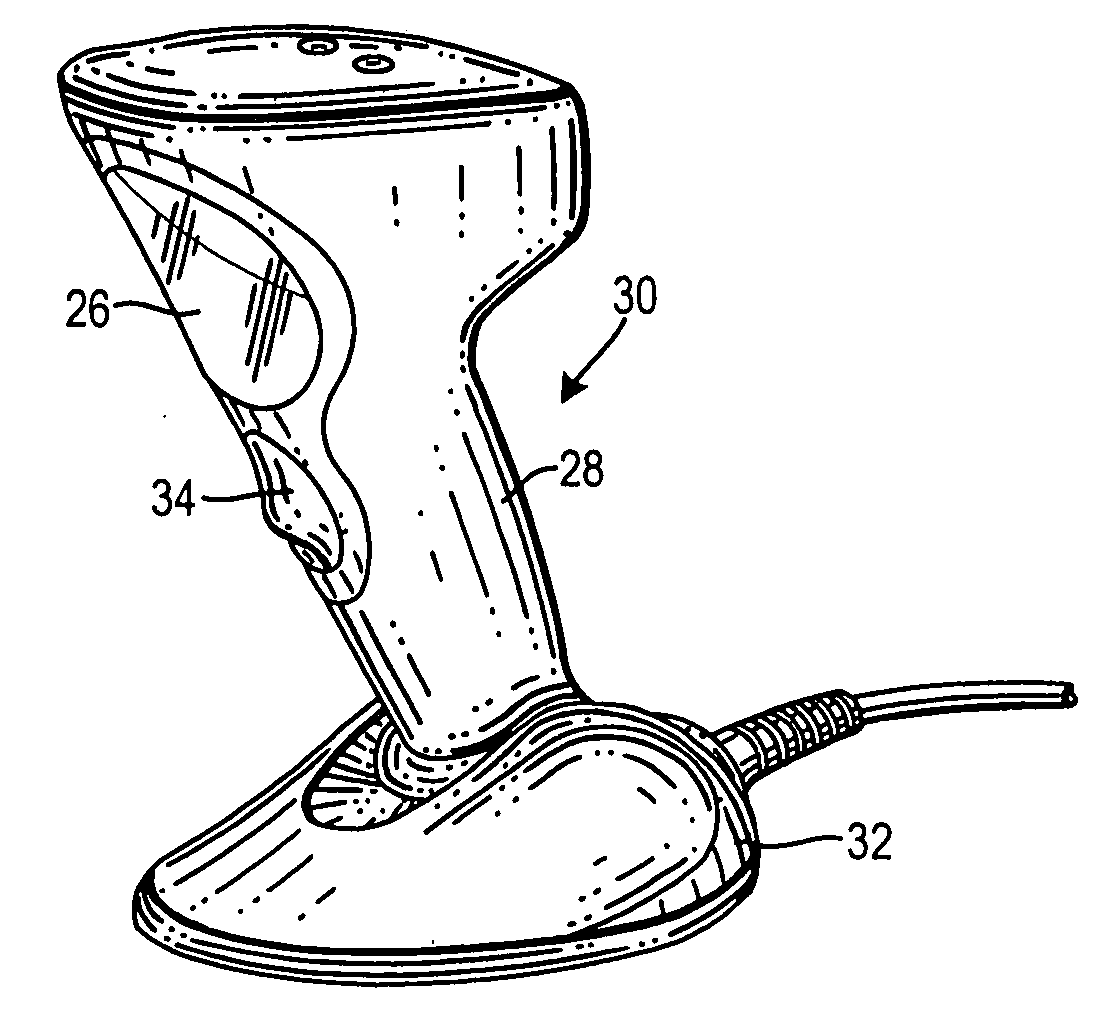

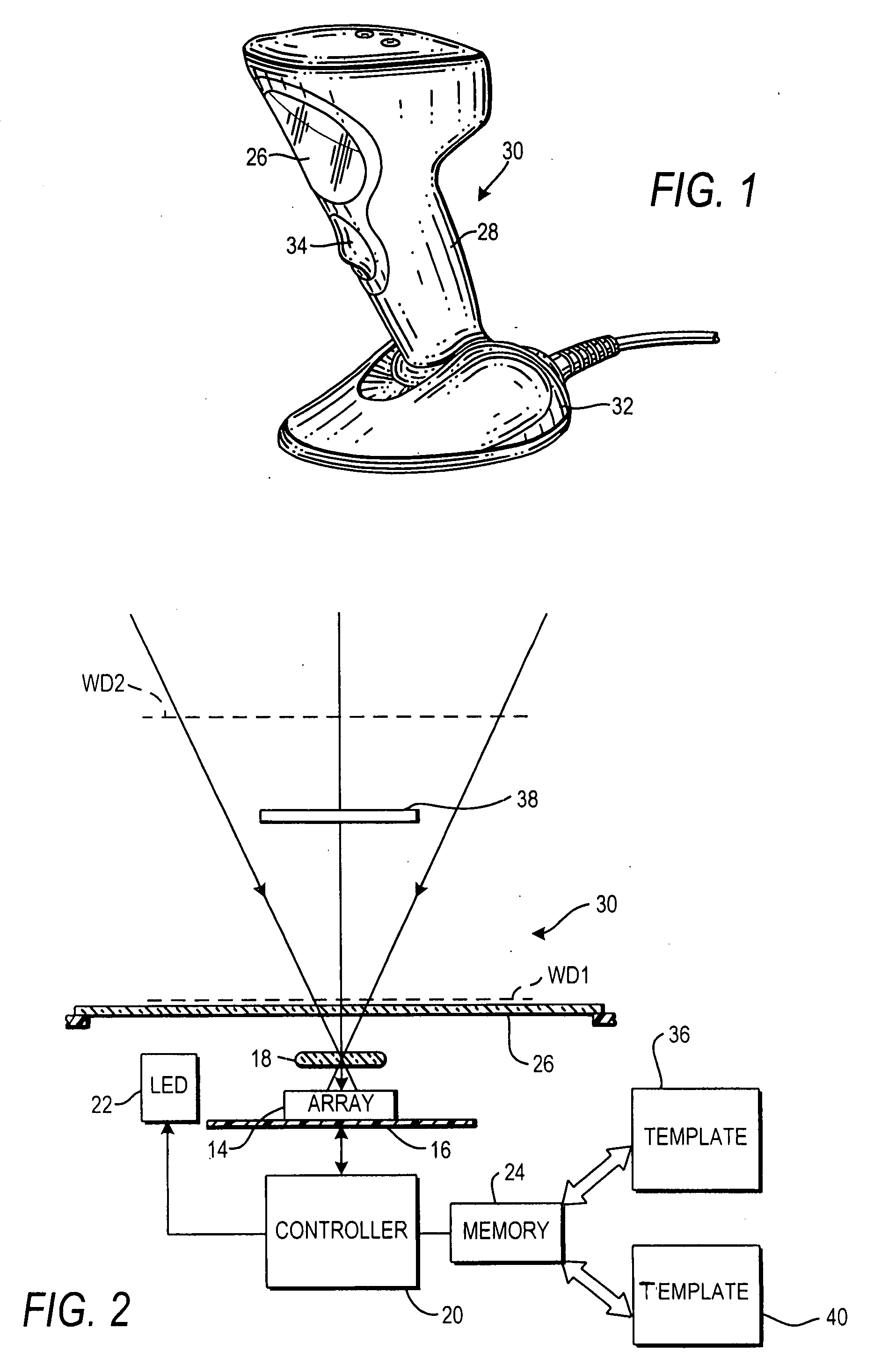

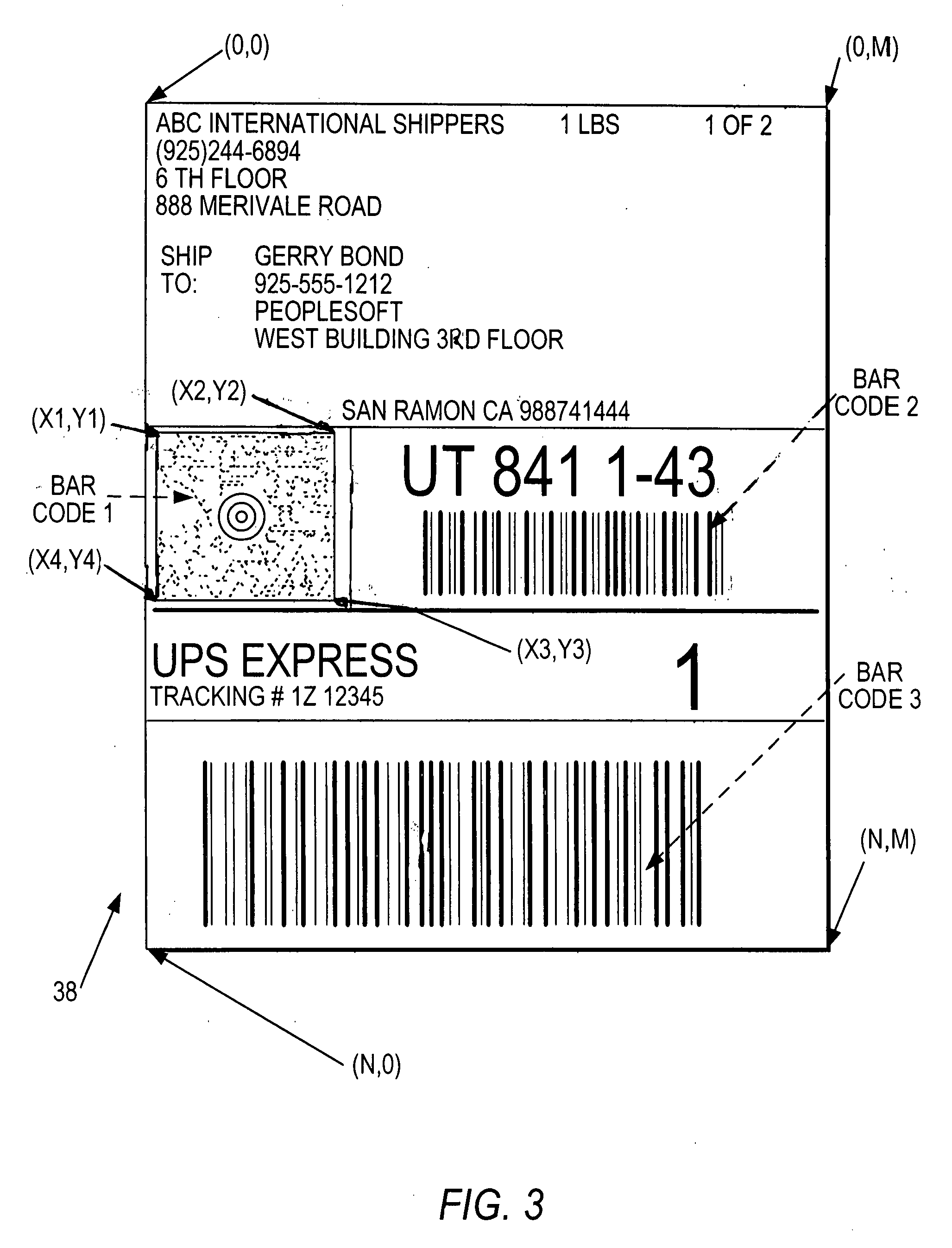

Imaging system for reading target with multiple symbols

ActiveUS20090057411A1Easy and efficient processingSpeedTransmission systemsSpecial data processing applicationsField of viewImage system

An imaging system for acquiring images of multiple indicia, such as symbols and non-symbols, on a target, such as a label, comprises a solid-state imager having an array of image sensors for capturing light from the indicia on the target over a field of view, and a controller having a stored template that identifies details of the indicia on the target, for controlling the imager to capture the light from the indicia based on the details identified by the template.

Owner:SYMBOL TECH LLC

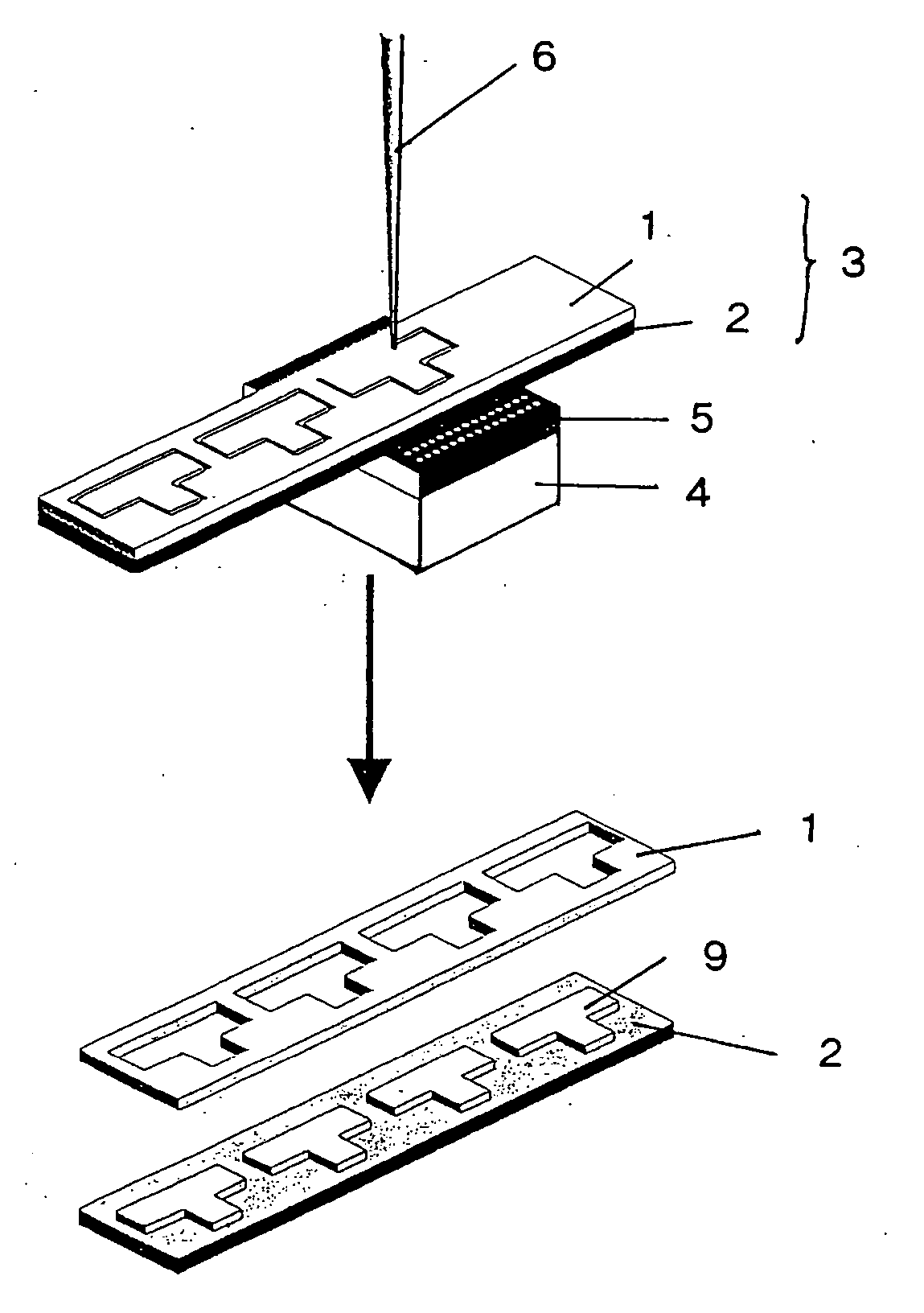

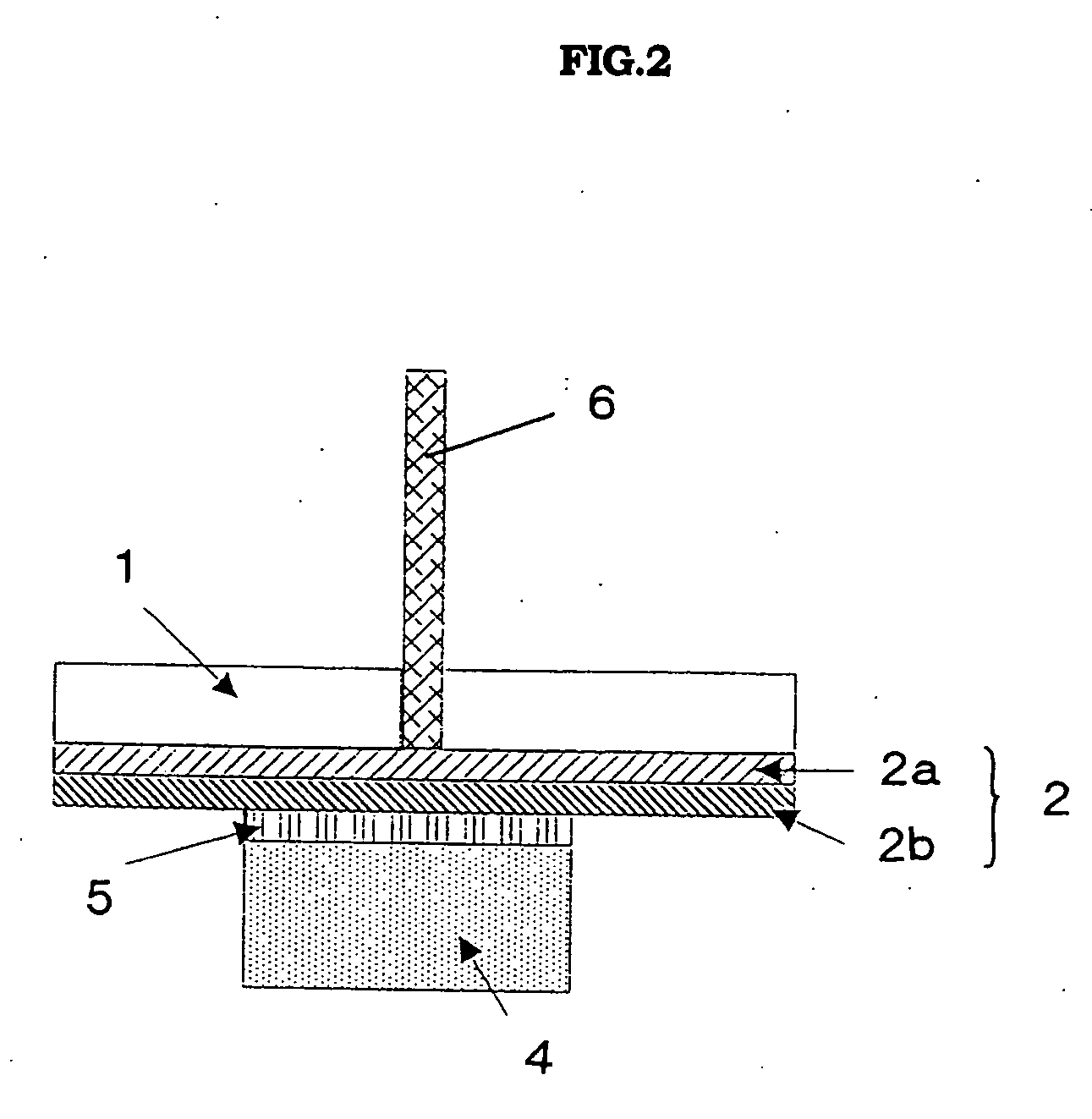

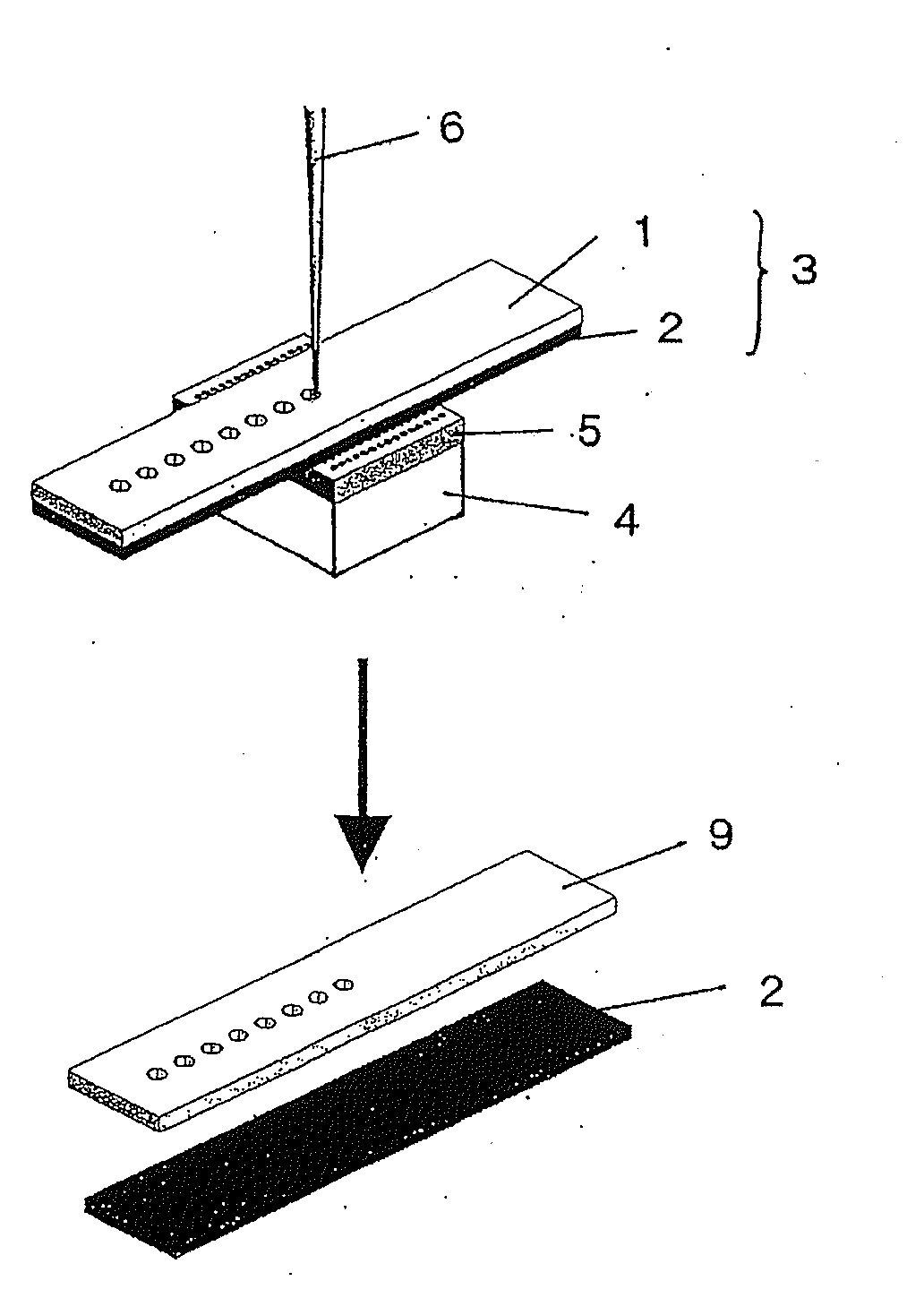

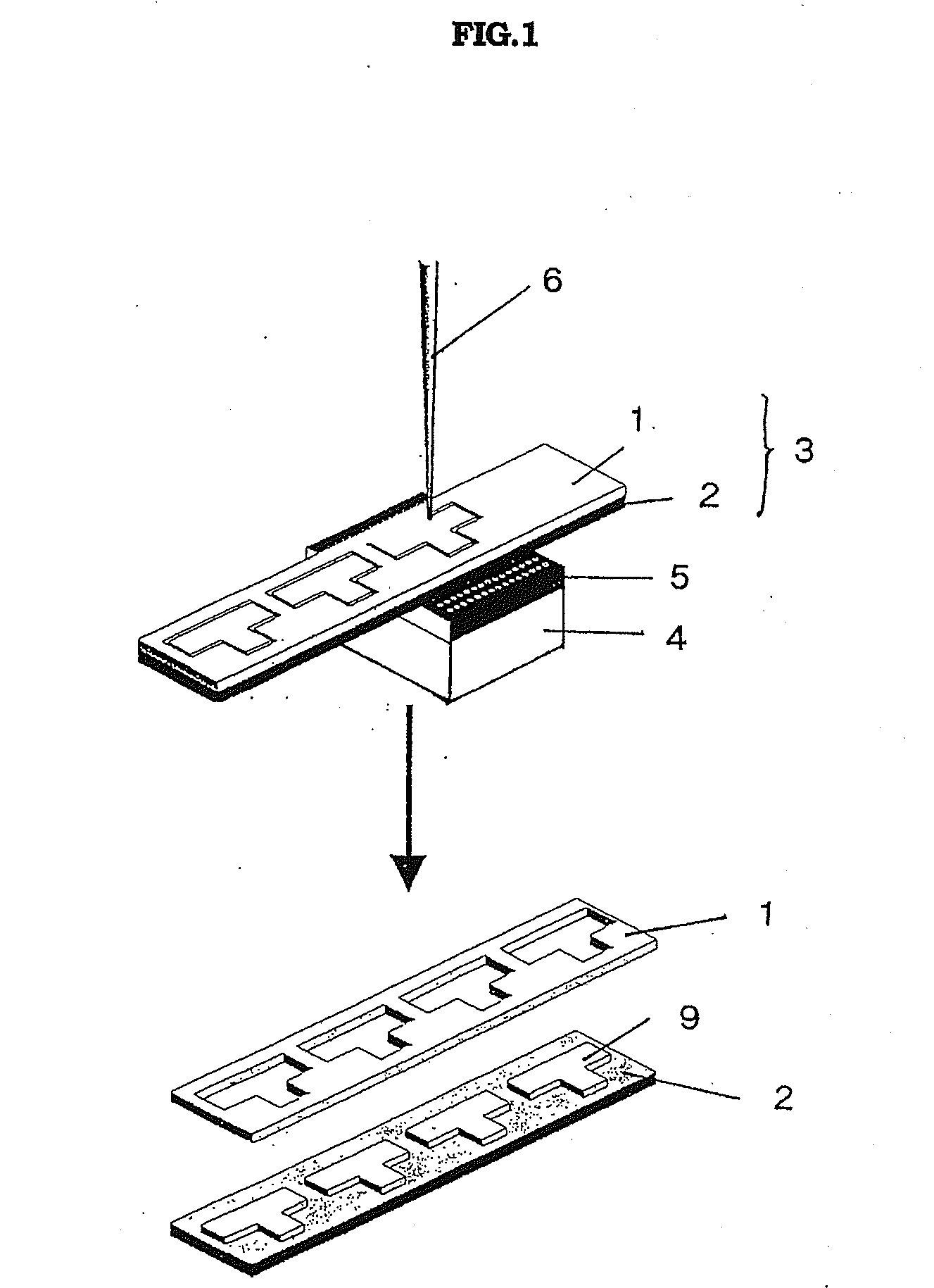

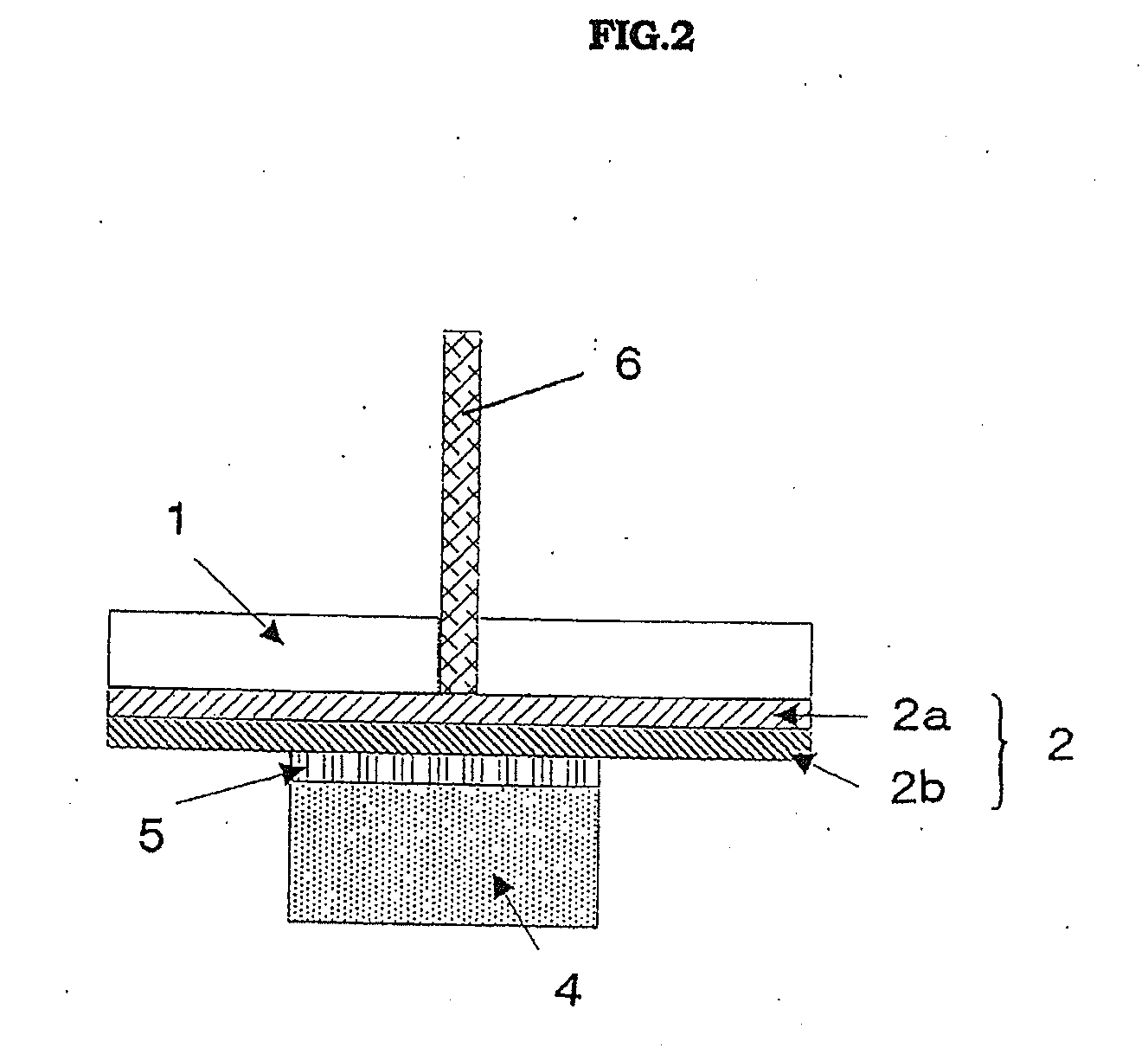

Method of producing laser-processed product and adhesive sheet, for laser processing used therefor

InactiveUS20060246279A1Easy and efficient processingPollution suppressionSemiconductor/solid-state device manufacturingPrinted circuit manufactureLaser processingDecomposition

A manufacturing method of laser processed parts is characterized in that at least a pressure-sensitive adhesive layer is provided on a base material as a pressure-sensitive adhesive sheet (2) for laser processing, using a material having specified physical properties, and this method comprises a step of adhering the pressure-sensitive adhesive sheet (2) for laser processing to the laser beam exit side of the work (1) by way of the pressure-sensitive adhesive layer, a step of processing the work by irradiating the work with a laser beam (6) of within 2 times of the irradiation intensity for forming a through-hole in the work (1), at higher than the irradiation intensity of threshold for inducing ablation of the work (1), and a step of peeling the pressure-sensitive adhesive sheet (2) for laser processing from the work (1) after the machining. Therefore, contamination of the work surface by decomposition products can be effectively suppressed, and laser processed parts can be manufactured easily and at high production efficiency.

Owner:NITTO DENKO CORP

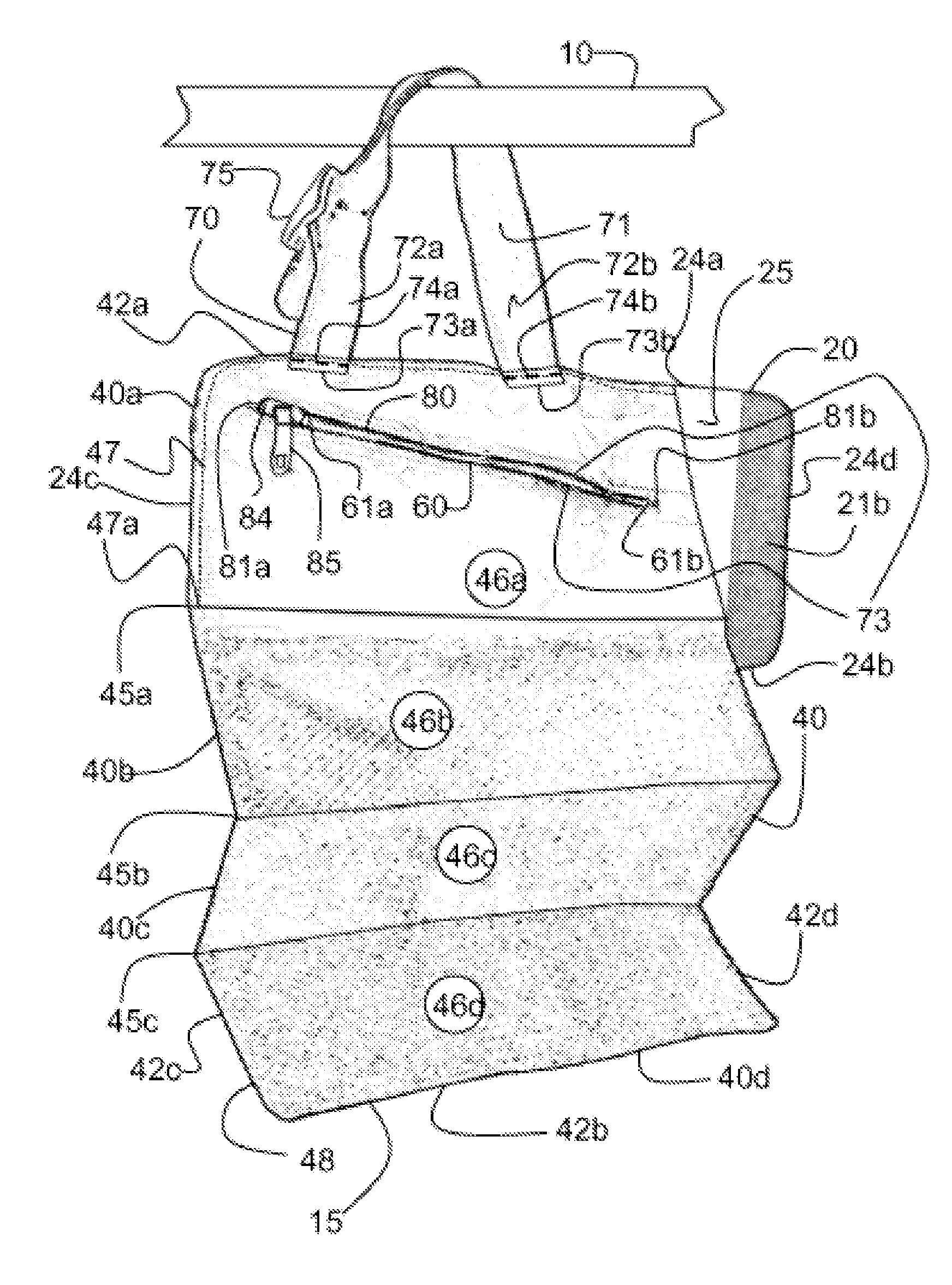

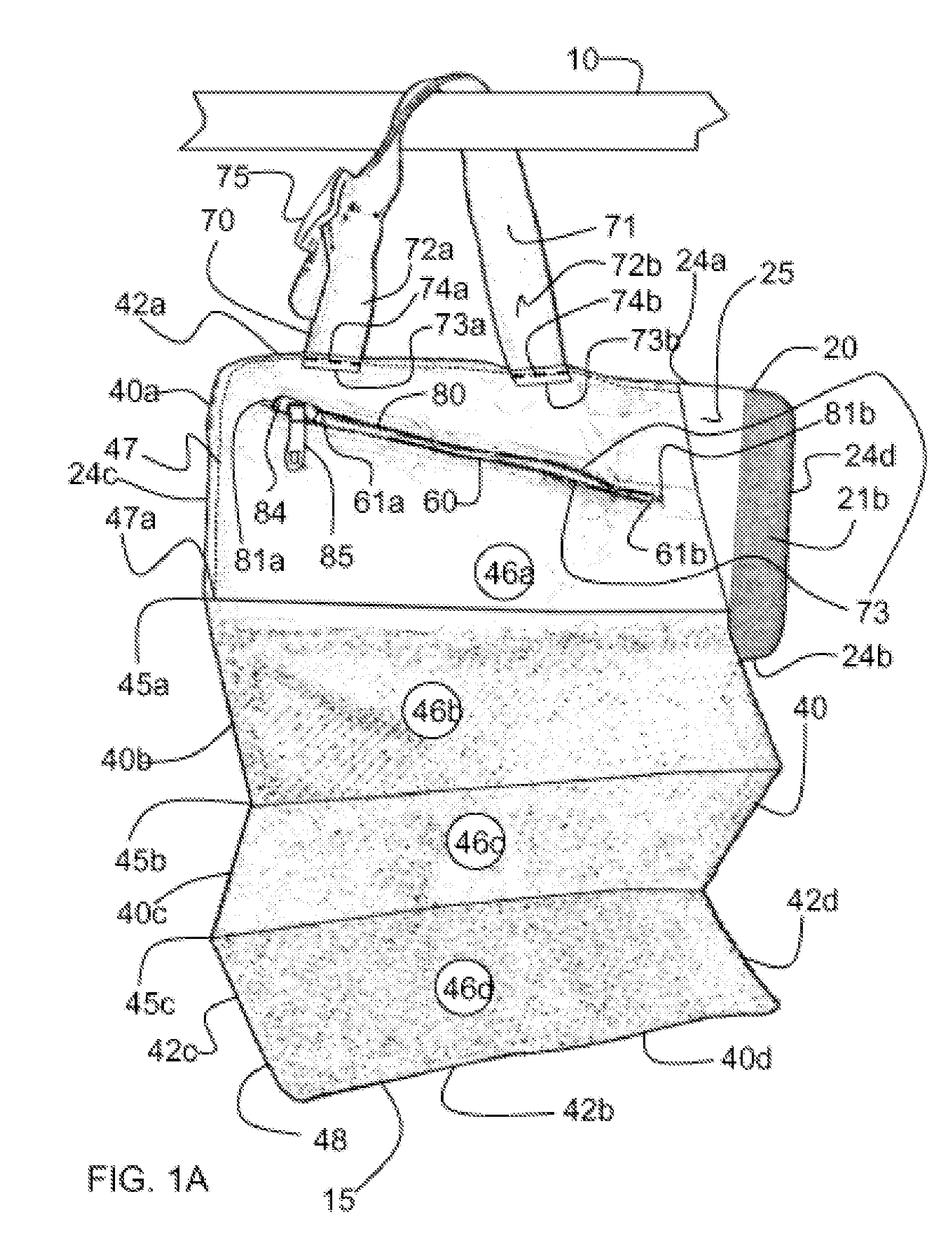

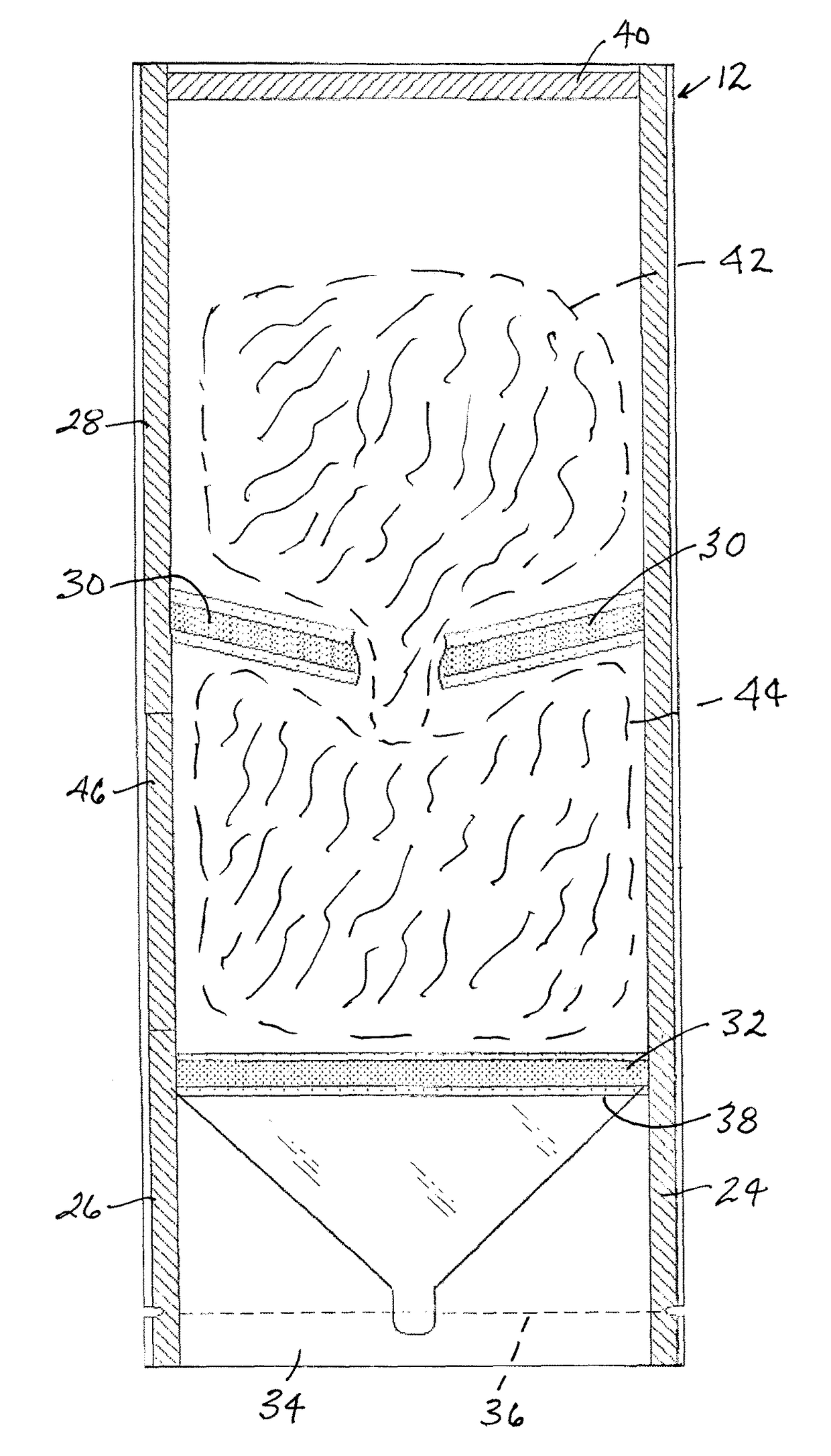

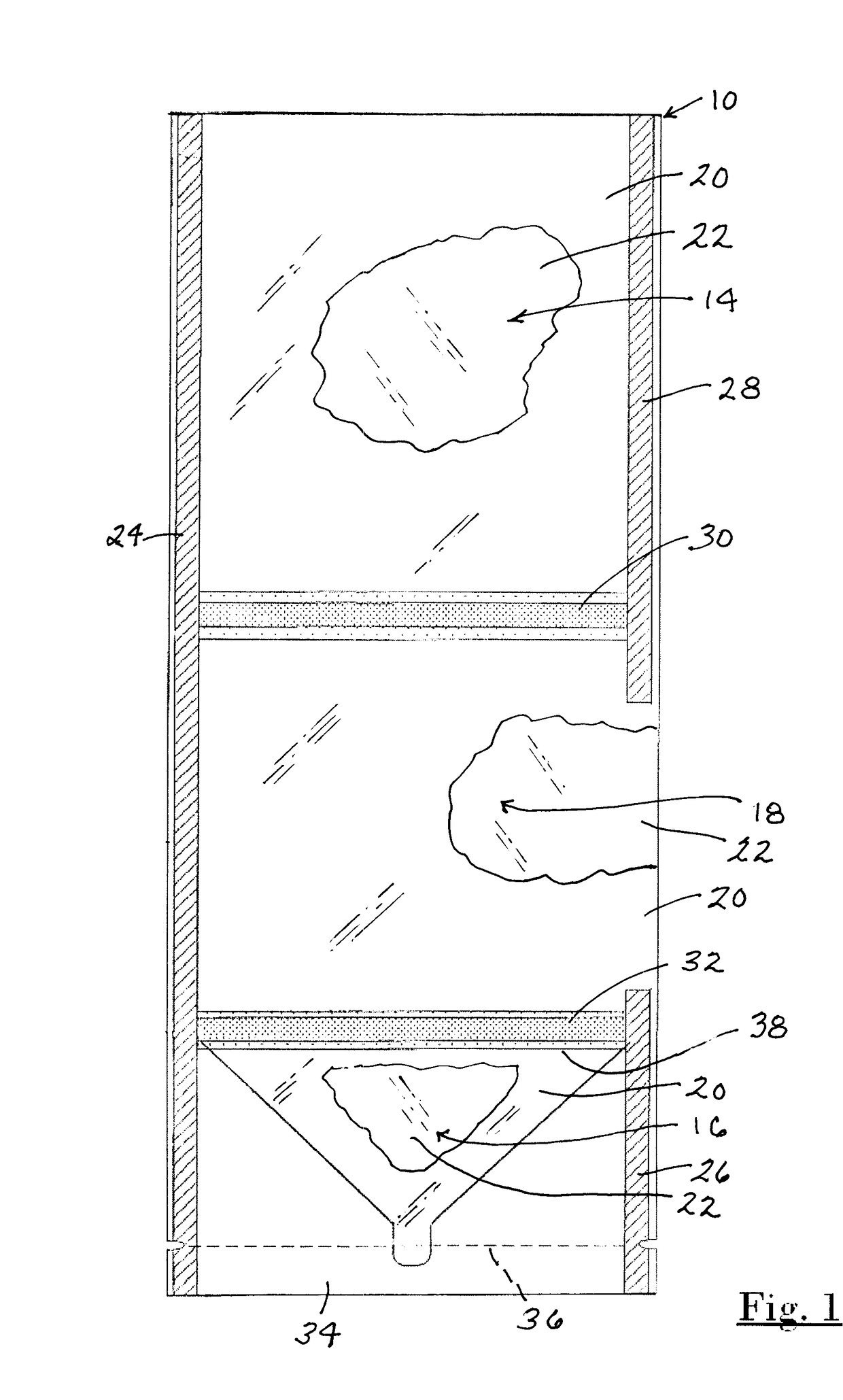

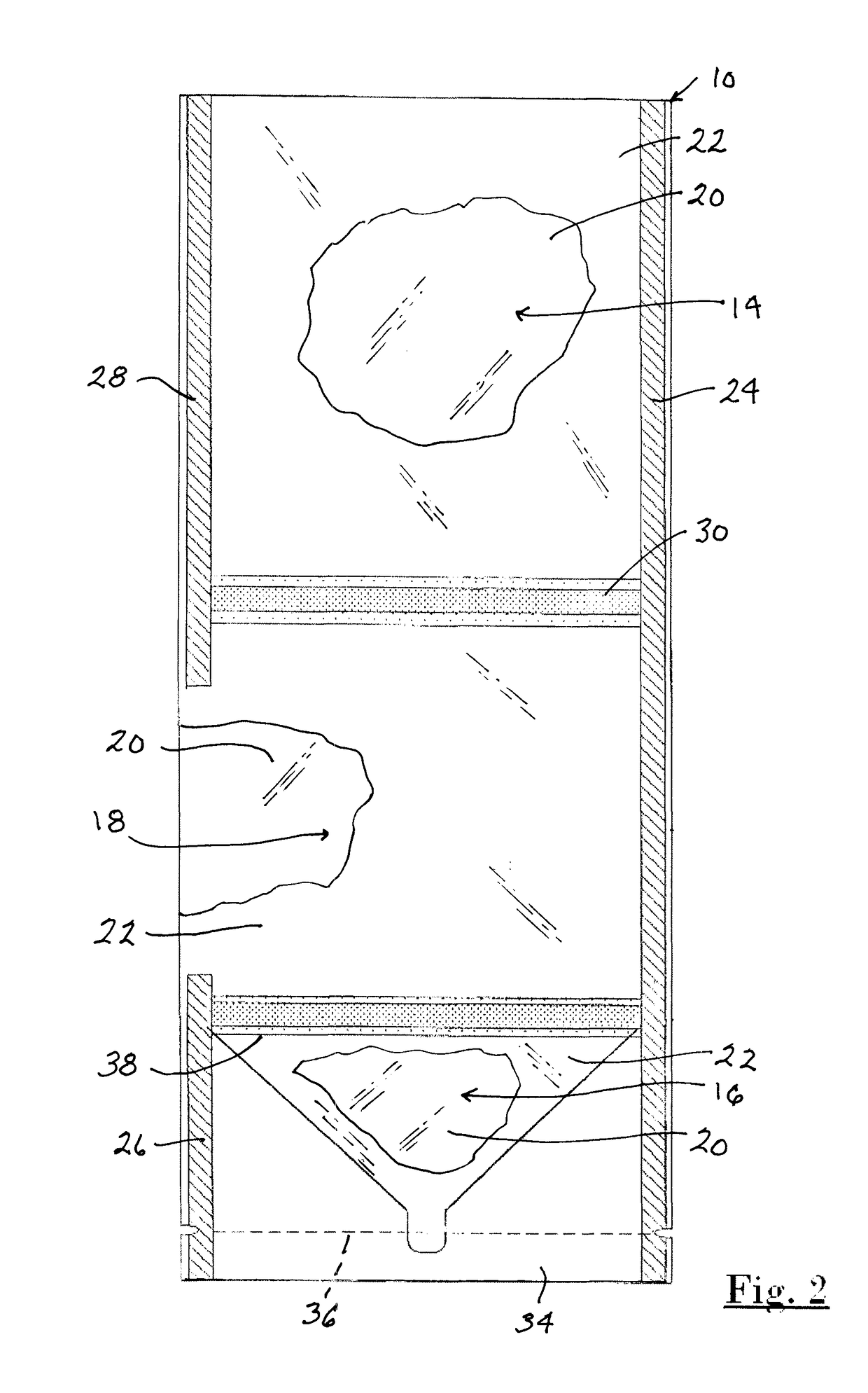

Readily deployed and stowed storage devices for temporary holding and transporting personal items

InactiveUS20070138222A1Easy and efficientEasy and efficient processingPursesMoney bagsCompact discEngineering

Disclosed are small, compact devices that provide readily deployed storage for small personal items, and they can also readily be returned to their stowed configuration. This toggling between deployed and stowed can be accomplished without a required change to the connection of any such device to another object, such as a travel case. The devices provide specific benefit to people going through an airport or building security checkpoint at which it is a requirement that pocket items such as cell phones, keys, and coins must be removed from one's pockets for assessment by a scanning apparatus.

Owner:GOLDMAN IRA

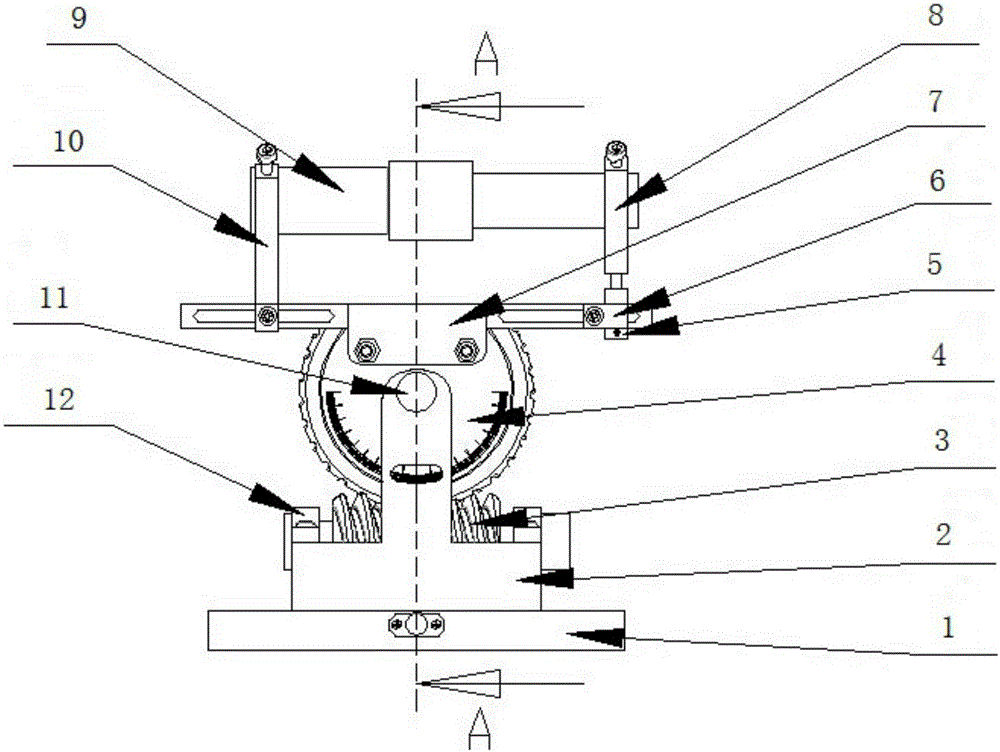

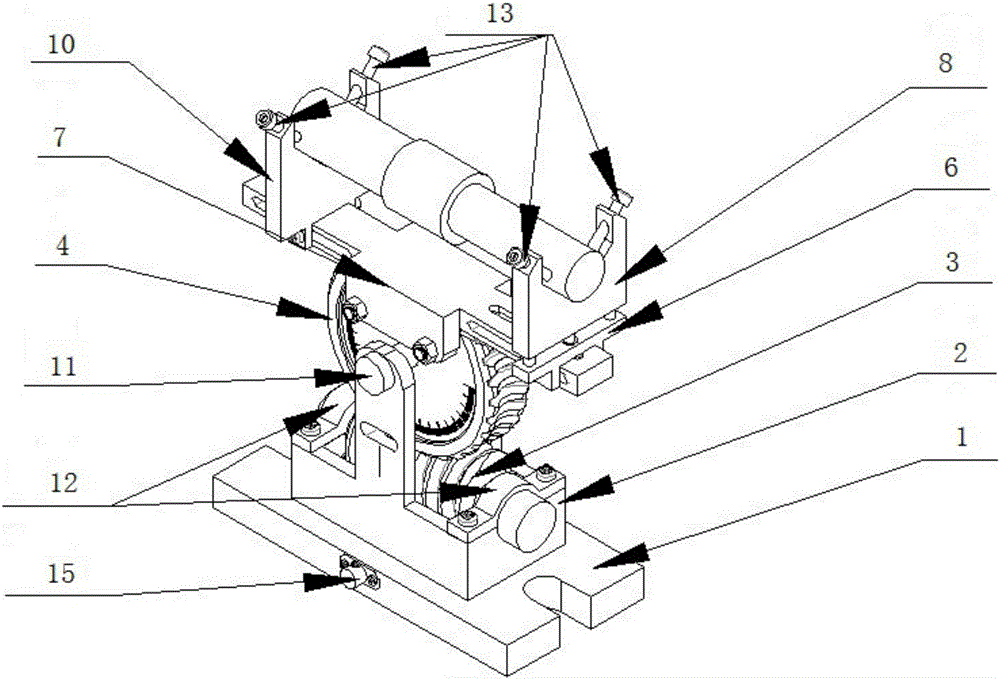

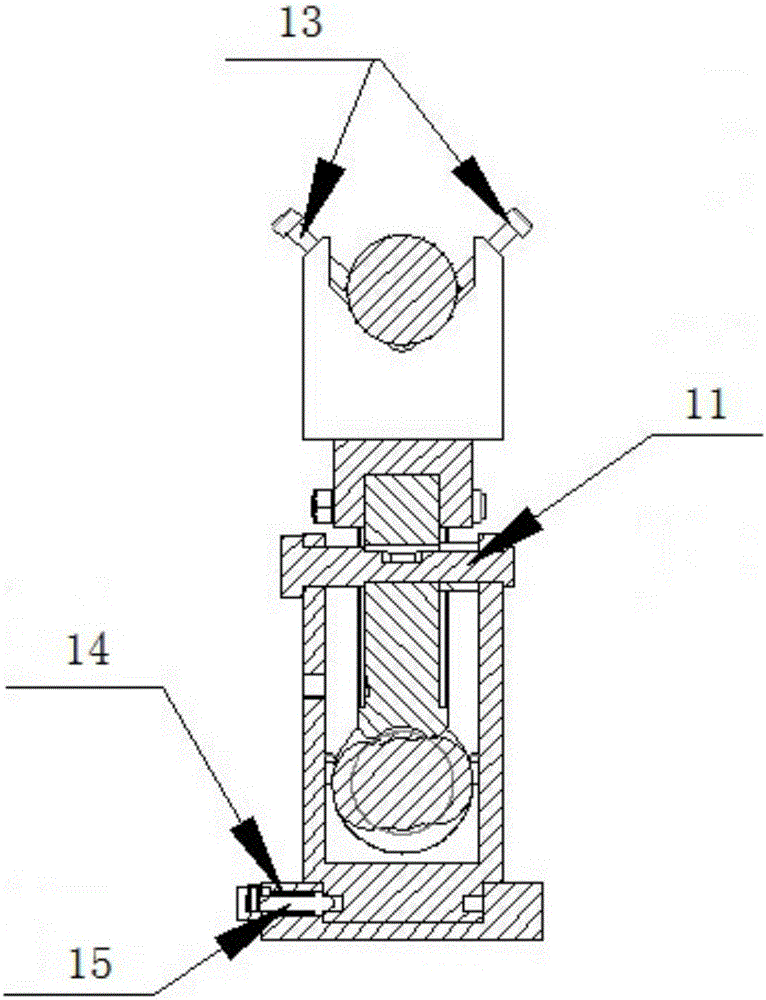

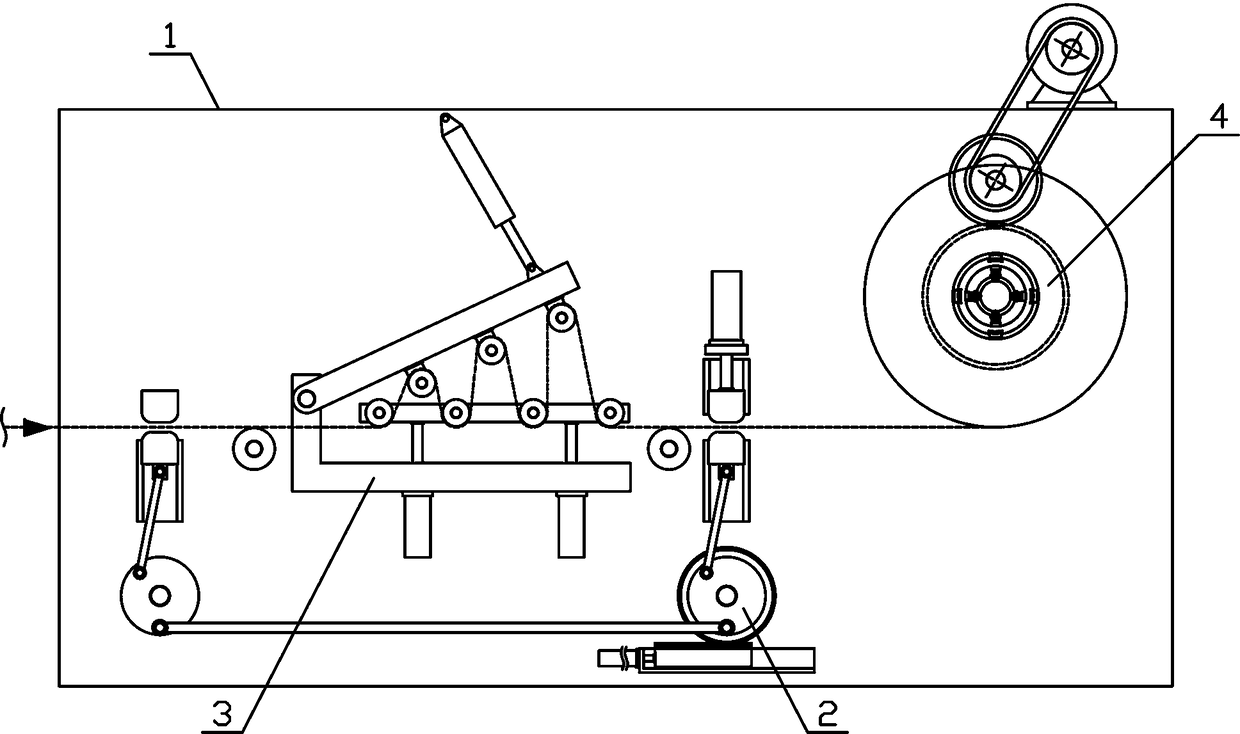

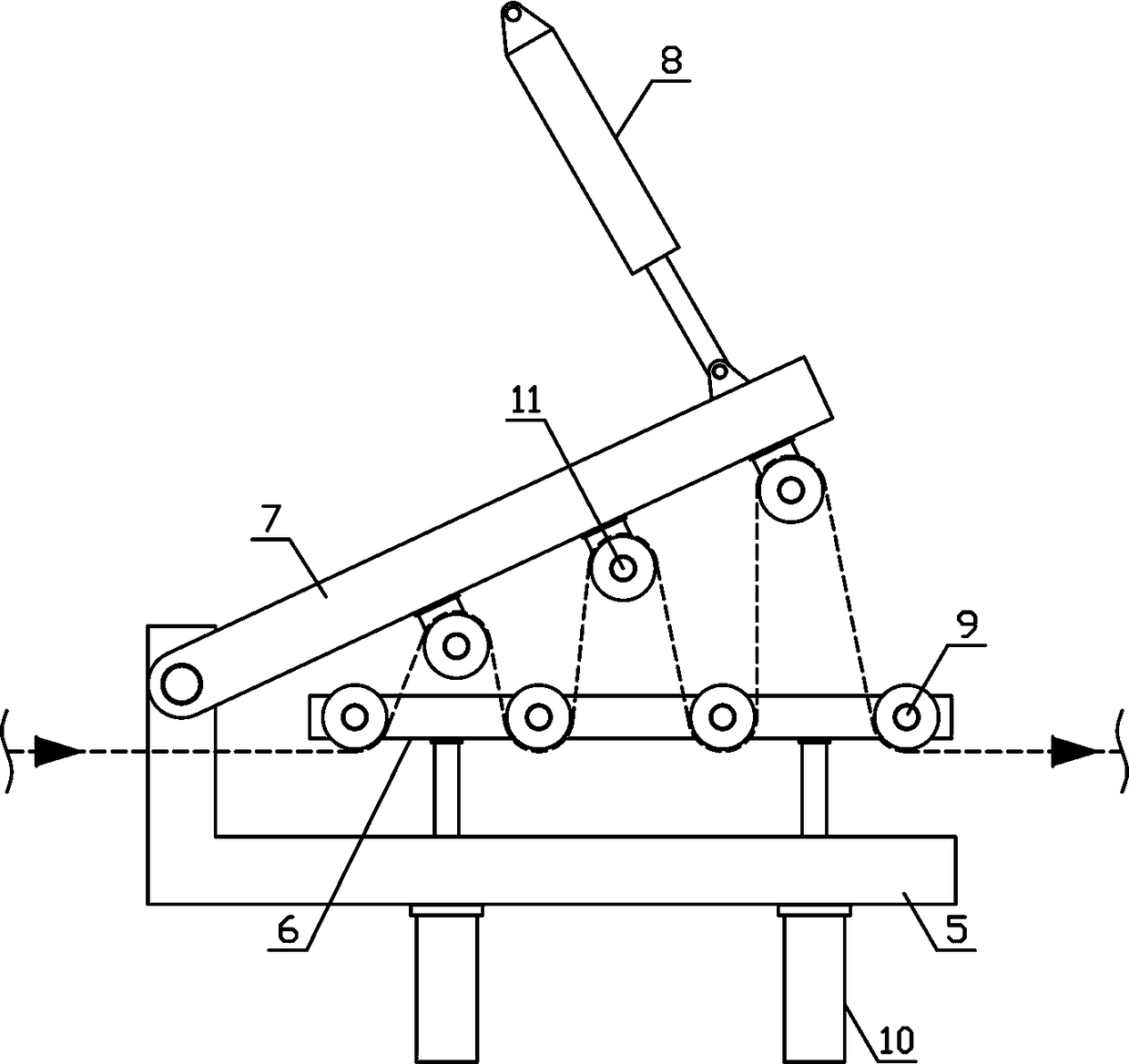

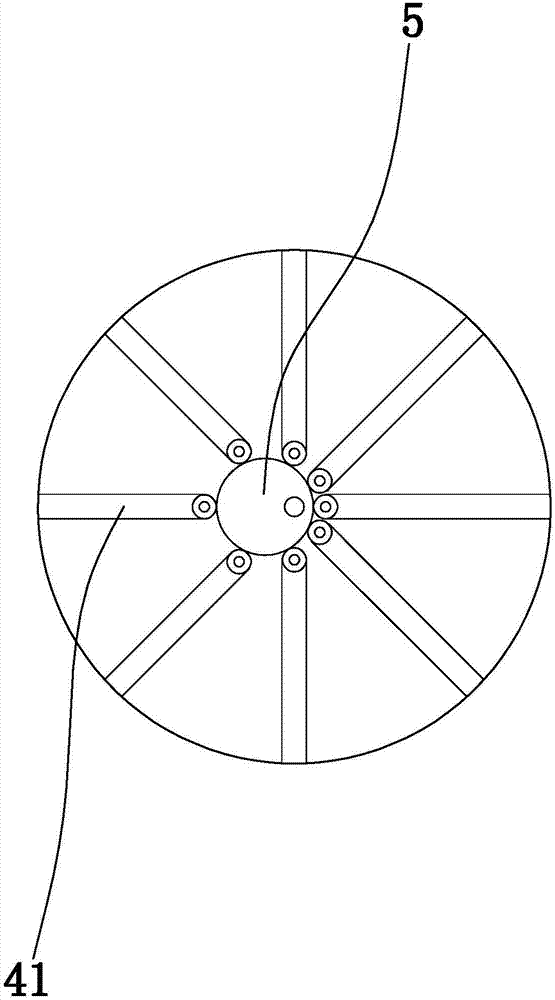

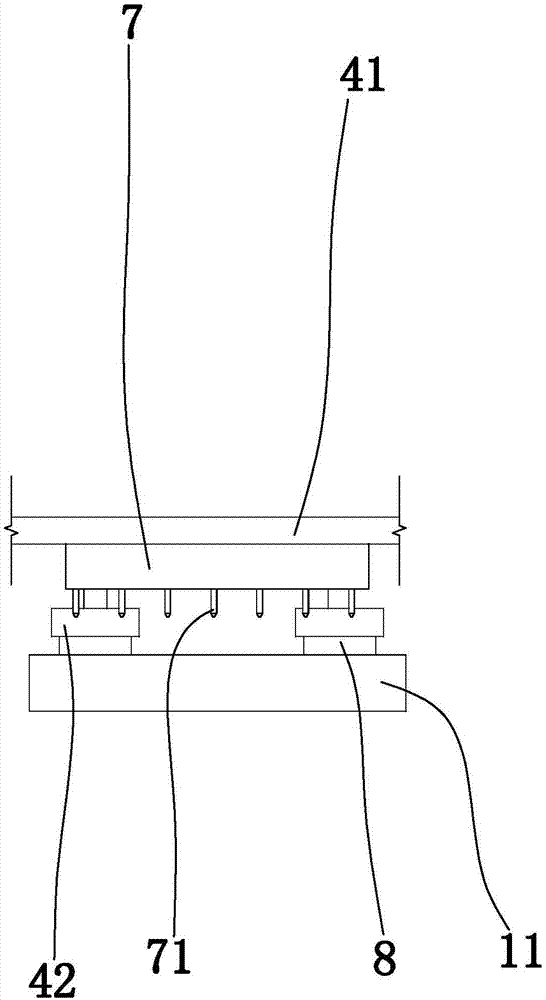

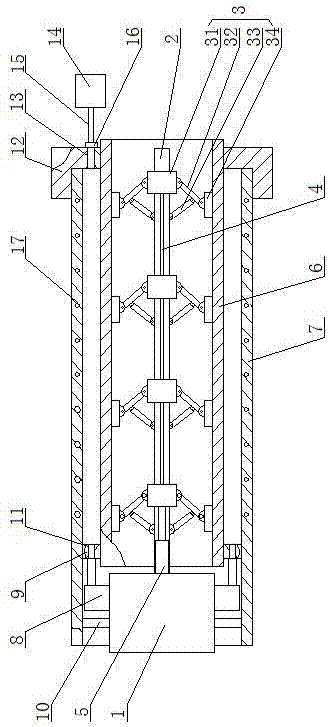

General frock clamp for shaft parts

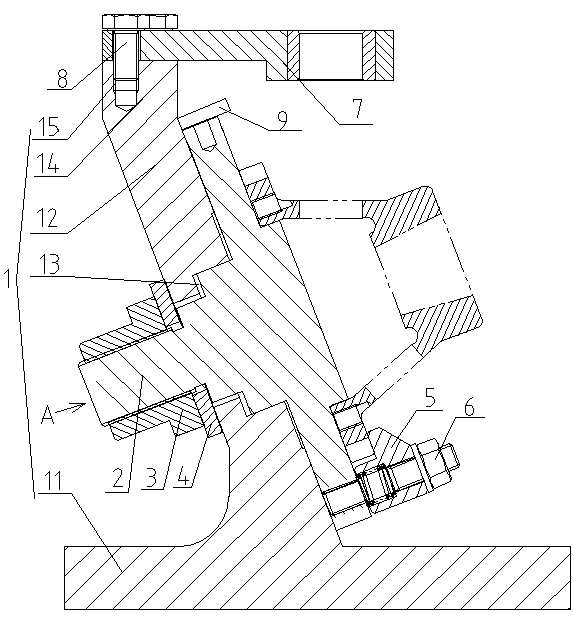

InactiveCN105855934AConvenient and efficient processingEfficient and convenient detectionPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a universal tooling fixture for shaft parts, which comprises a base fixed on a workbench, a clamping mechanism, an adjusting mechanism and an angle adjusting mechanism. Using the general tooling and fixture for shaft parts described in the present invention, an angle adjustment mechanism is set to realize the placement of shaft parts at any angle and all-round rotation, and the adjustment mechanism is set to adjust different shaft diameters and different lengths. As well as adjusting the clamping position of shaft parts with various shaft diameters on the same shaft, a clamping mechanism with adjustment parts is set up to clamp shaft parts. This device makes shaft parts more accurate during processing, testing and assembly. Efficient and convenient, especially for fast switching when clamping different positions of different shaft parts, which brings great convenience, and can effectively solve the problem of single specification of clamping parts, inflexible placement and troublesome operation of existing shaft parts tooling fixtures, etc. Problem, the device is simple in structure, easy to use, low in cost, and easy to popularize.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

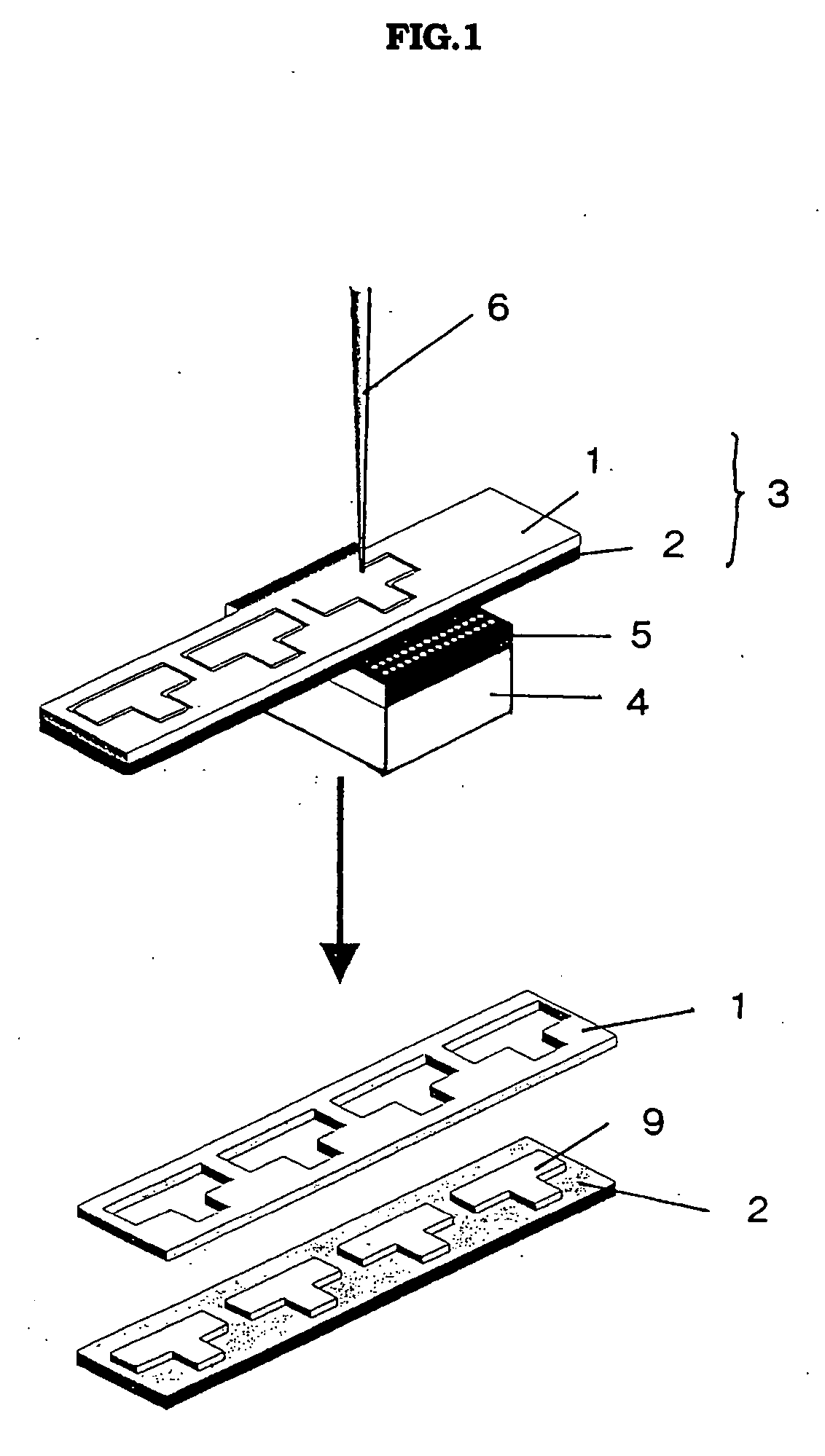

Manufacturing method of laser processed parts, and pressure-sensitive adhesive sheet for laser processing used for the same

InactiveUS20100273313A1Easy and efficient processingPollution suppressionLamination ancillary operationsSynthetic resin layered productsLaser processingDecomposition

A manufacturing method of laser processed parts in which at least a pressure-sensitive adhesive layer is provided on a base material as a pressure-sensitive adhesive sheet for laser processing, using a material having specified physical properties. This method comprises adhering the pressure-sensitive adhesive sheet for laser processing to the laser beam exit side of the work by way of the pressure-sensitive adhesive layer, processing the work by irradiating the work with a laser beam of within 2 times of the irradiation intensity for forming a through-hole in the work, at higher than the irradiation intensity of threshold for inducing ablation of the work, and peeling the pressure-sensitive adhesive sheet for laser processing from the work after the machining. Therefore, contamination of the work surface by decomposition products can be effectively suppressed, and laser processed parts can be manufactured easily and at high production efficiency.

Owner:NITTO DENKO CORP

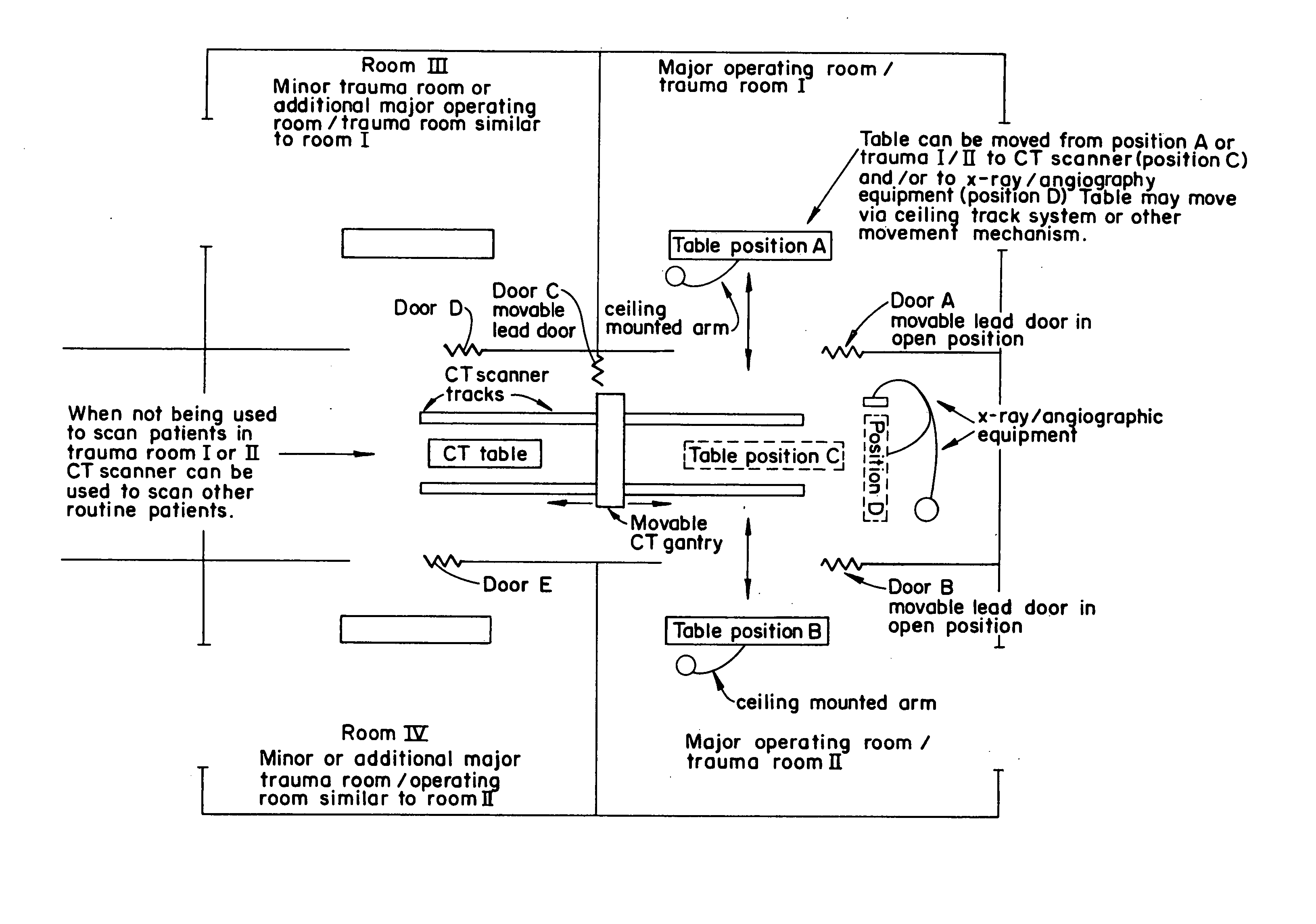

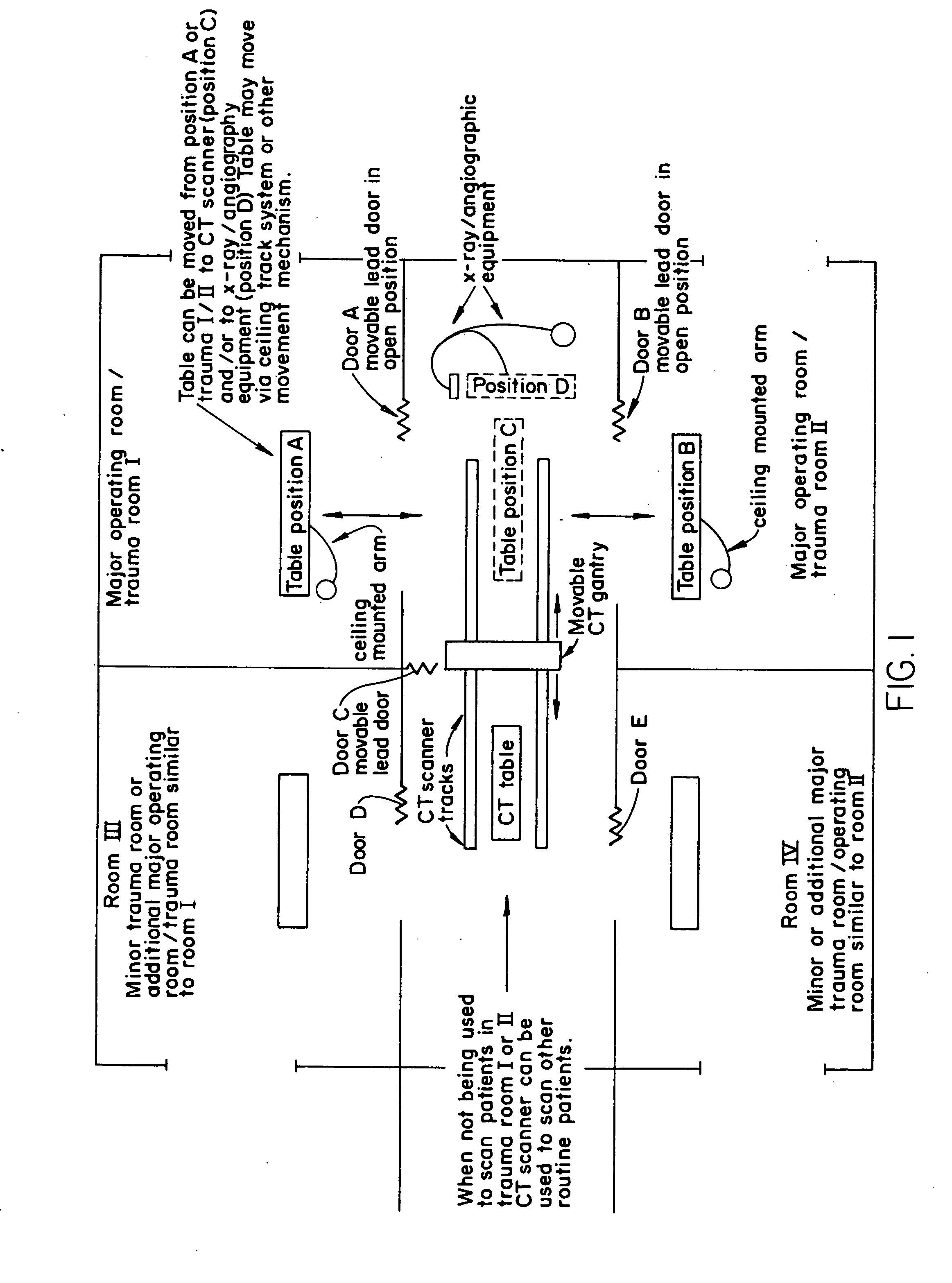

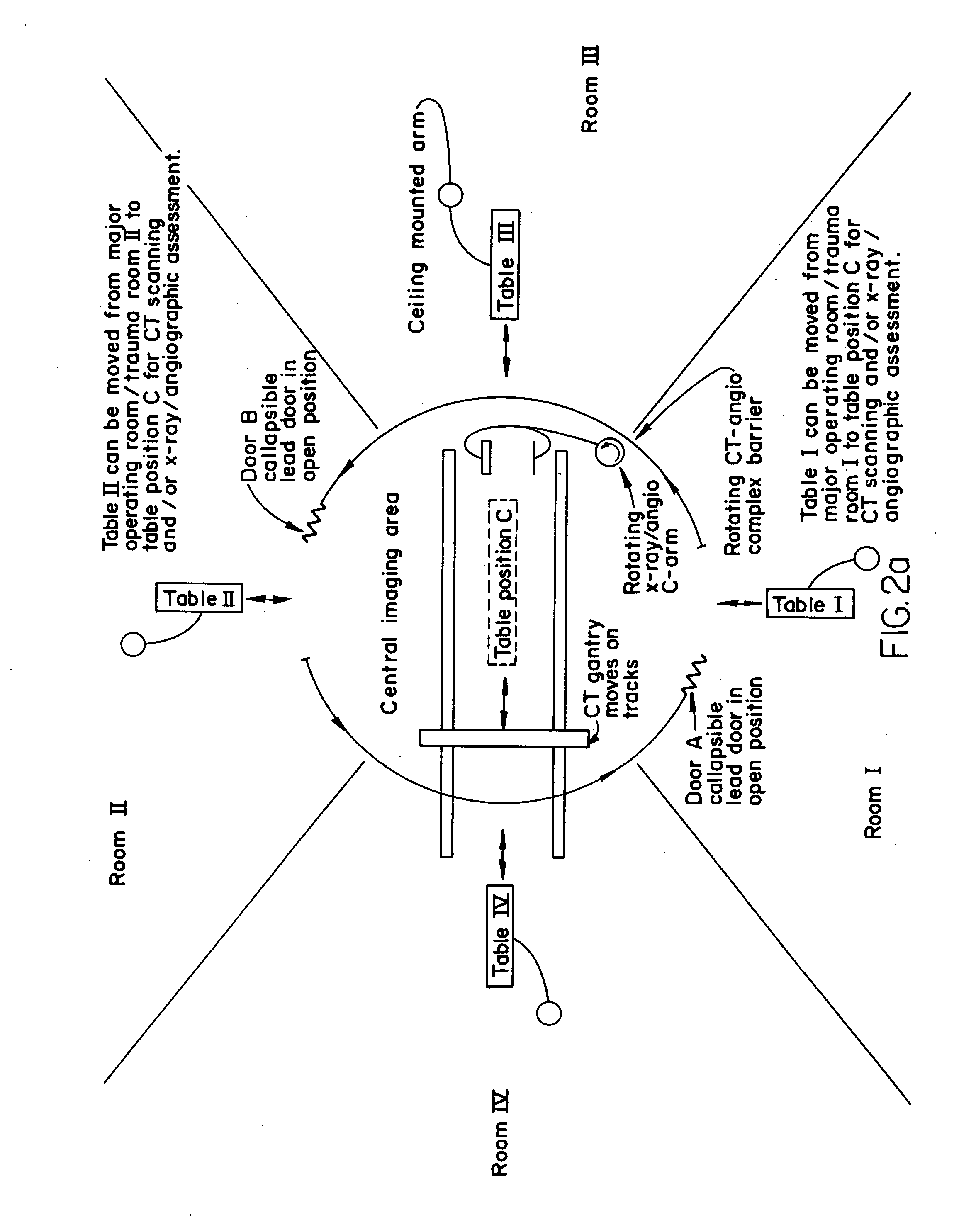

Multi-functional medical facility with diagnostic, therapeutic and interventional capabilities

InactiveUS20070033889A1Minimize patient discomfortEasy and efficient processingUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringCritically illElective surgery

A multi-functional medical facility permits emergent diagnostic imaging assessment, image guided therapeutic interventions, and open surgical procedures within the complex. The concept of bringing diagnostic and therapeutic imaging and operative equipment to the critically ill patient or the patient undergoing non-emergency, elective surgery, instead of bringing the patient to the equipment is a major clinical advantage that should improve efficiency, outcome and survival. An important economic advantage is that the components can be used separately and independently of each other, thus enabling them to also be used for routine emergency room (ER) work.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

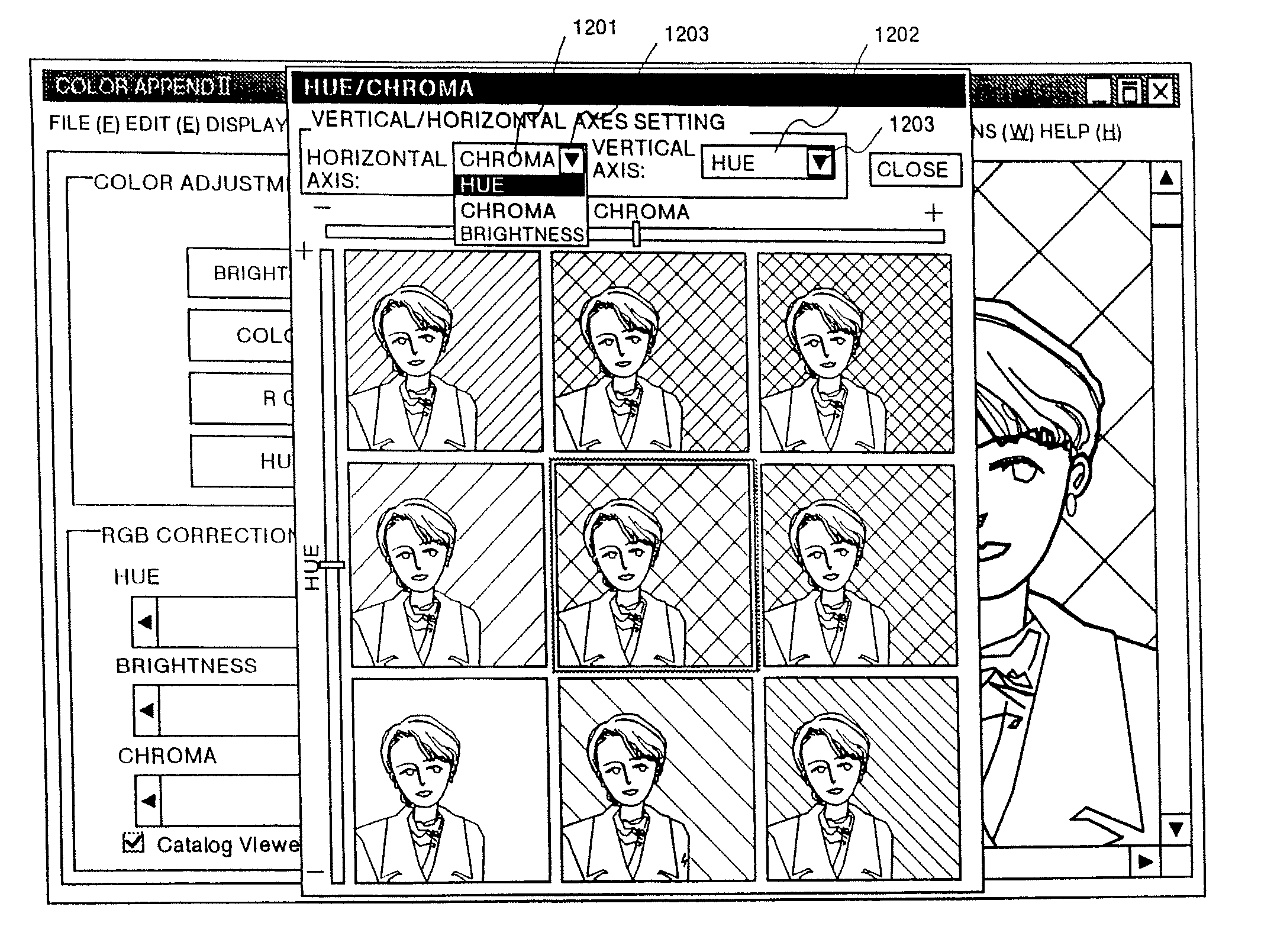

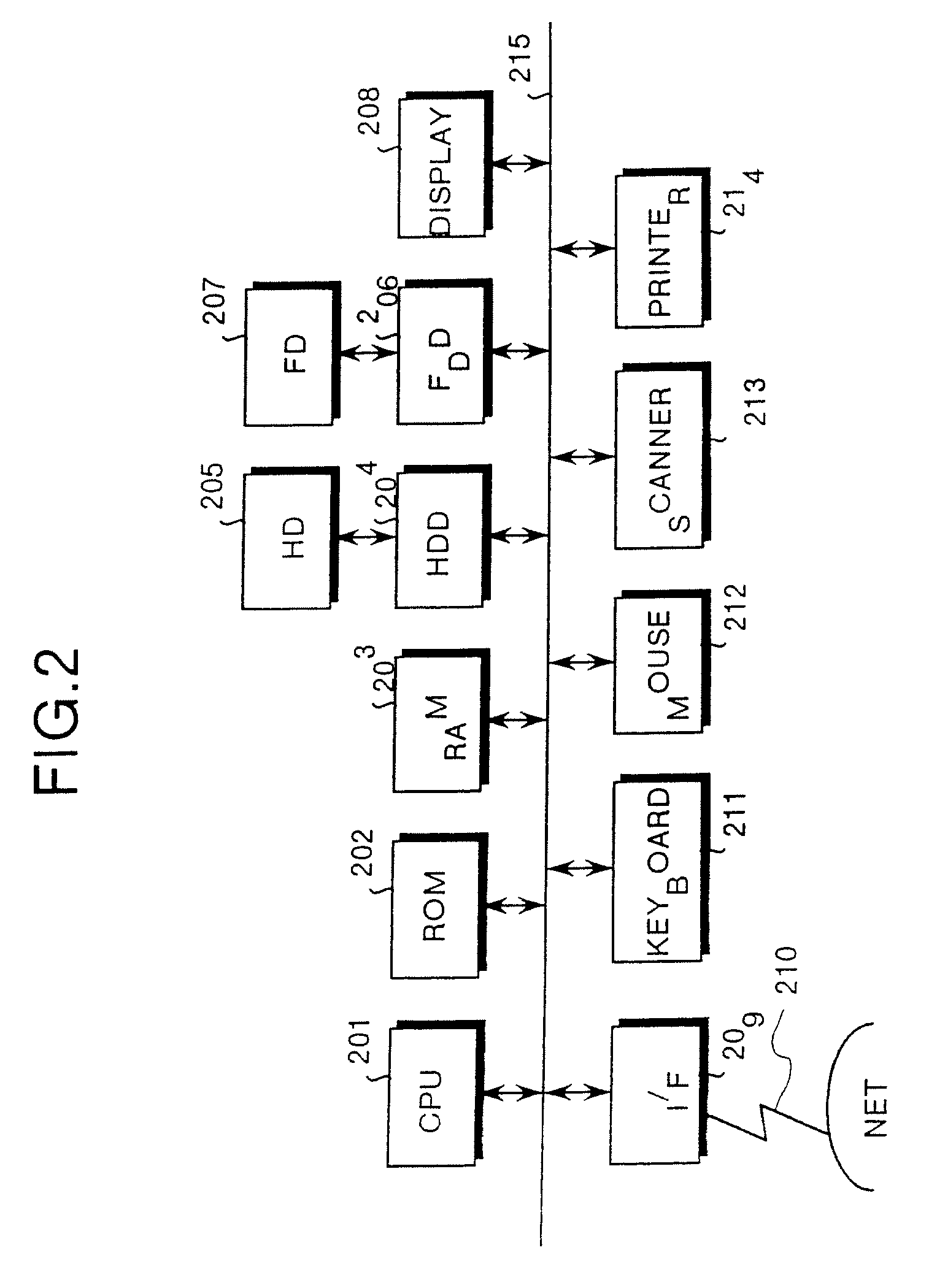

Image processing apparatus, image processing method, and a computer-readable storage medium containing a computer program for image processing recorded thereon

InactiveUS7765480B2Easily and efficiently editingEasy and efficient processingCathode-ray tube indicatorsInput/output processes for data processingImaging processingComputer graphics (images)

Owner:RICOH KK

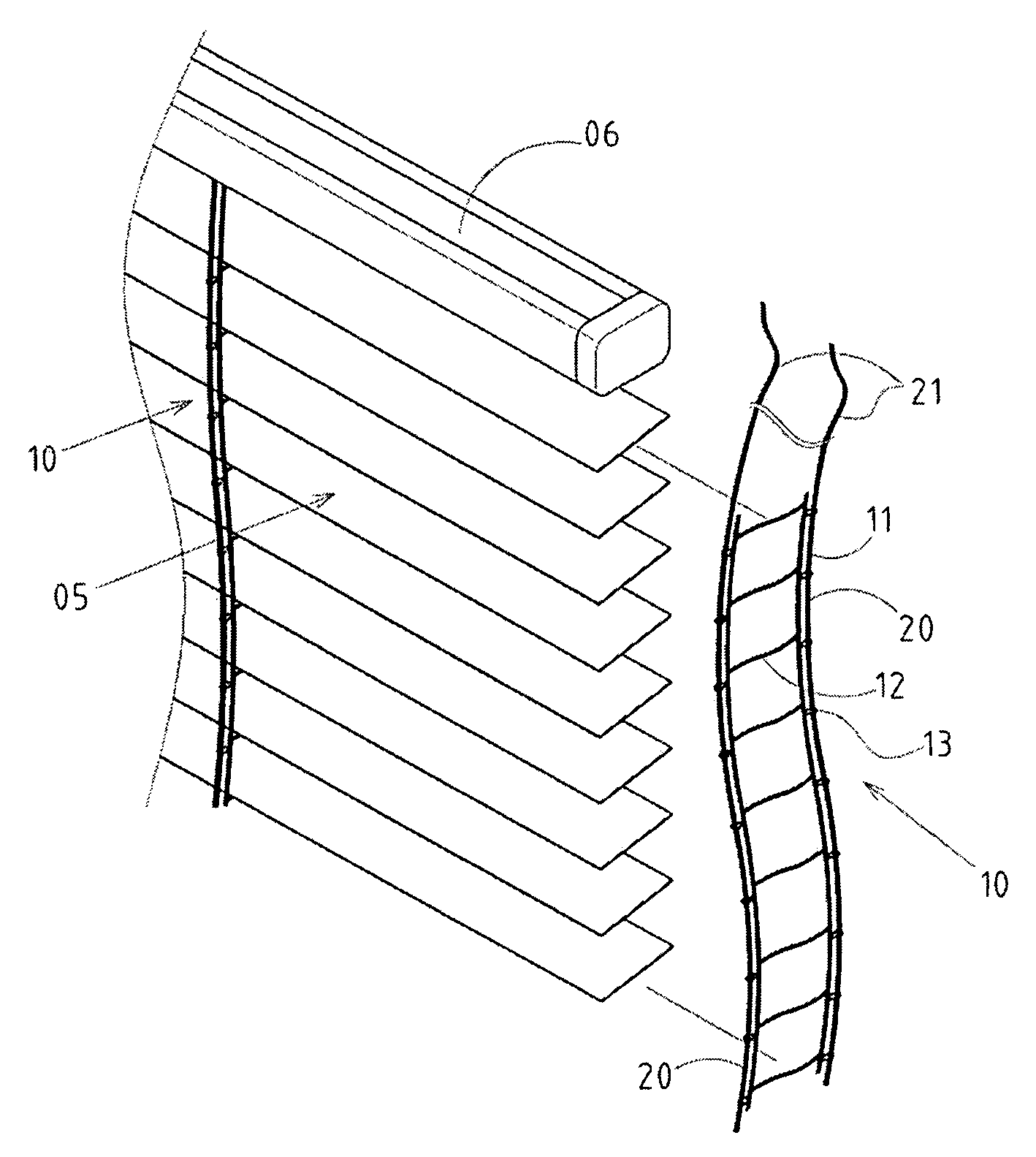

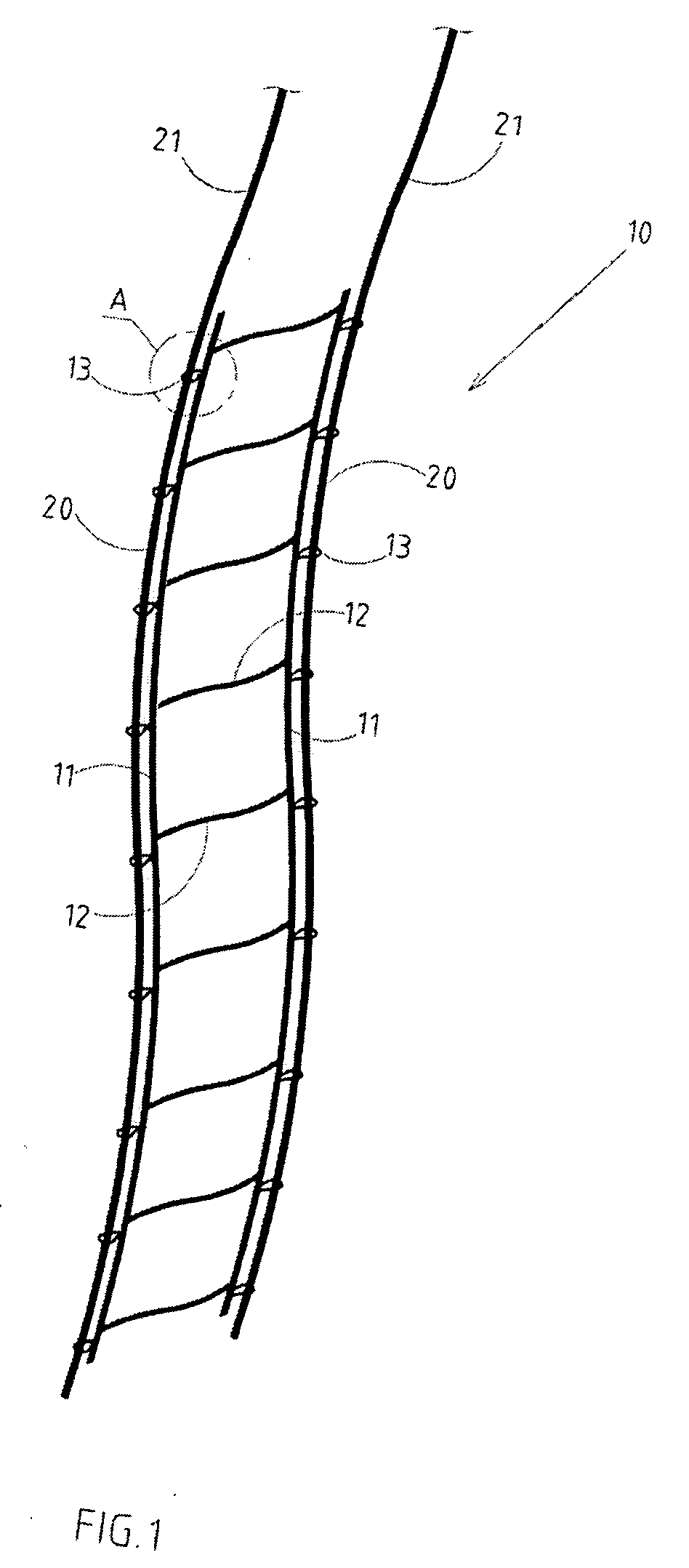

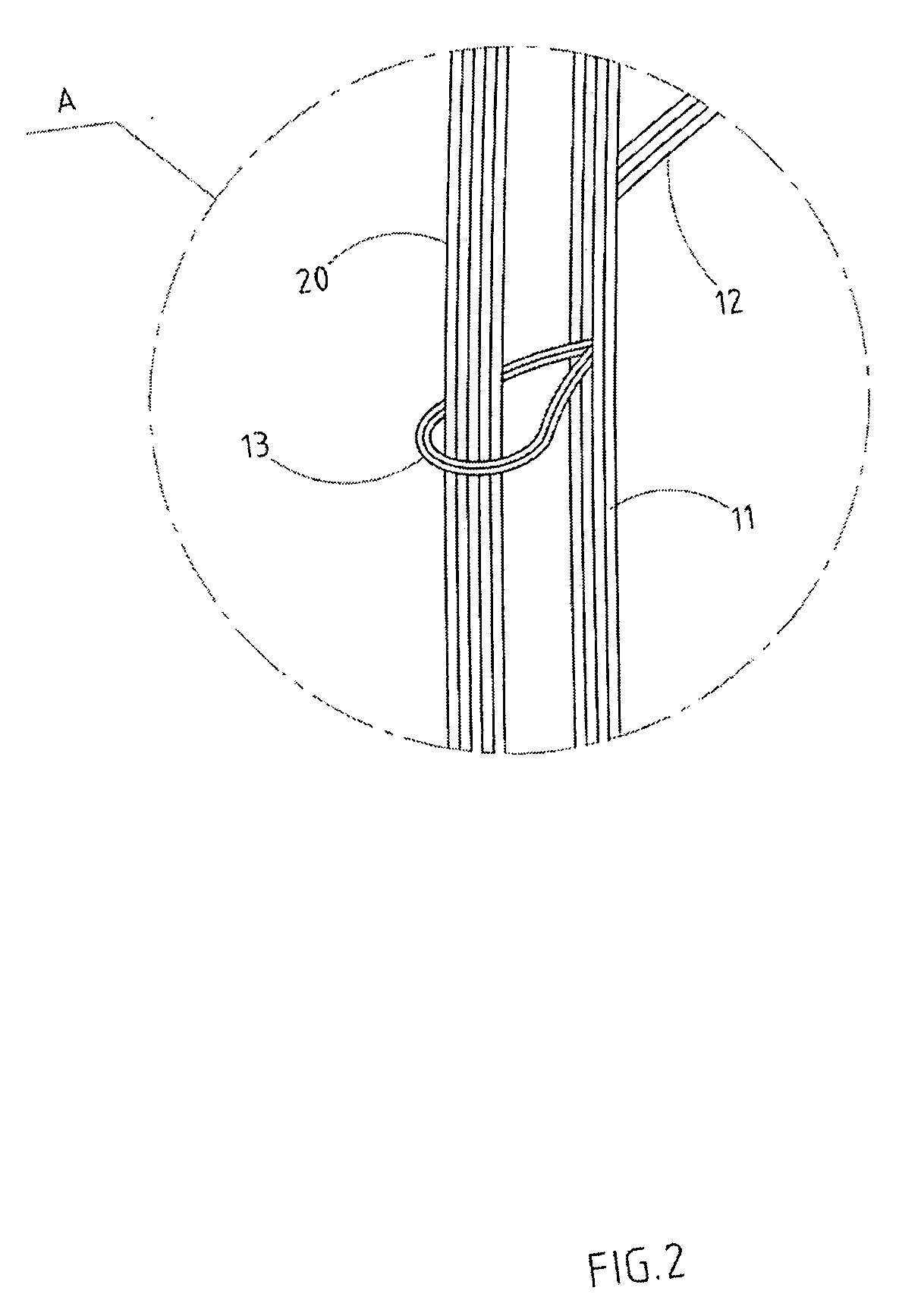

Grid strip component for shutters with pull cord

InactiveUS20060289124A1Easy to assembleReduce processDoor/window protective devicesEngineeringElectrical and Electronics engineering

The grid strip component for shutters with pull cords includes a grid strip having two vertical strips that are spaced vertically with certain length set aside, and between the two vertical strips are several horizontal strips, and on both sides of the vertical strips are several pull cord loops. There are two pull cords, which are to go through several pull cord loops that are on the outsides of the vertical strips; moreover, the length of at least one end of the two pull cords should be extra long, and this extra length is the length needed to install the shutters; and by so doing, the grid strip of the present invention uses the unique pull cord to make the assembly more convenient and more effective.

Owner:TAIHAO KNITTING BELT

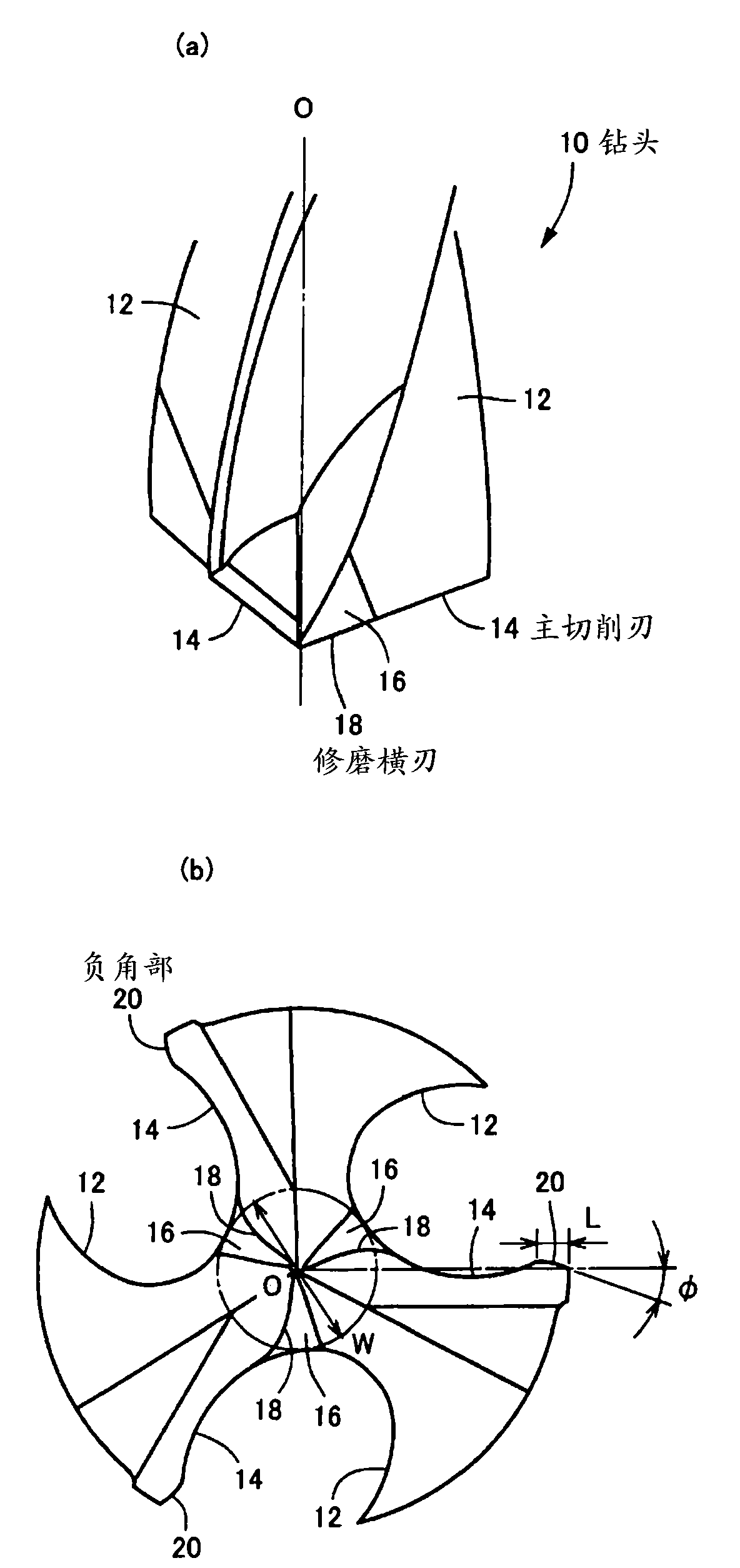

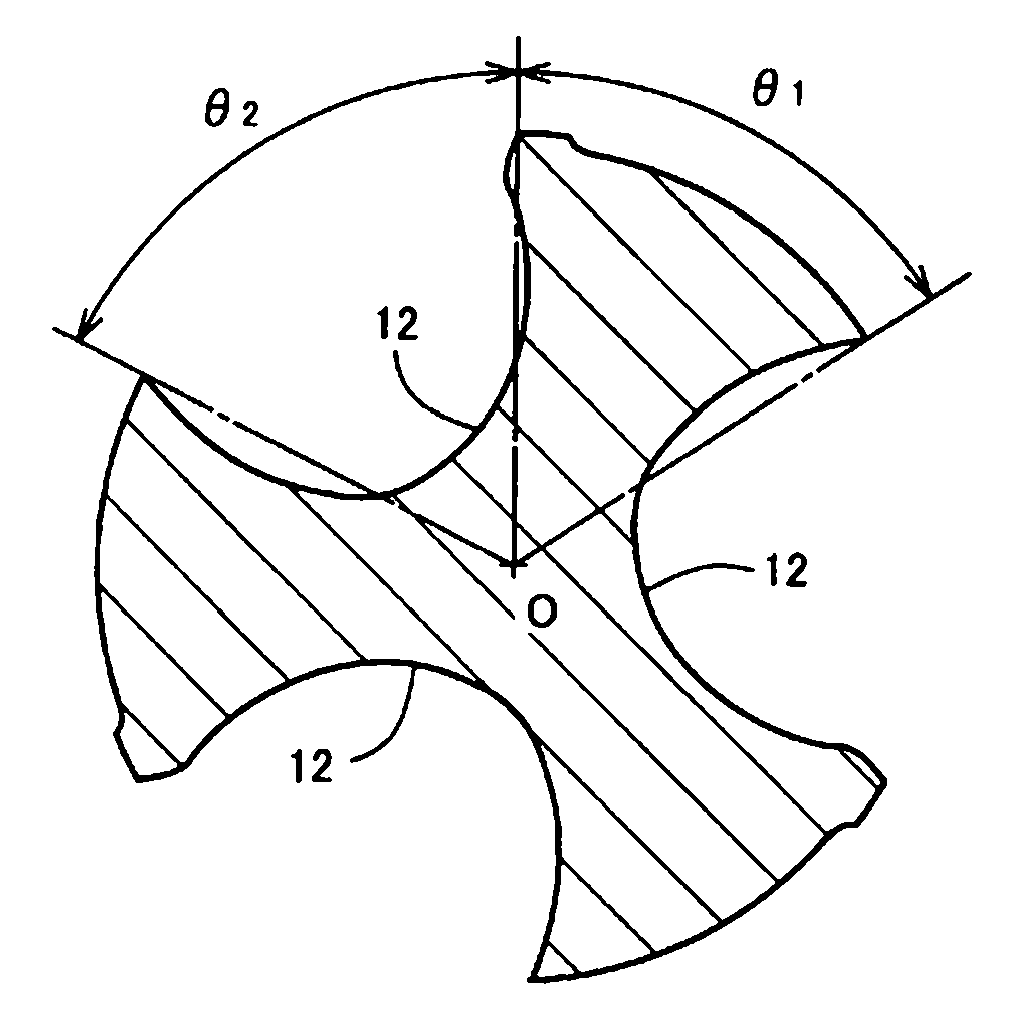

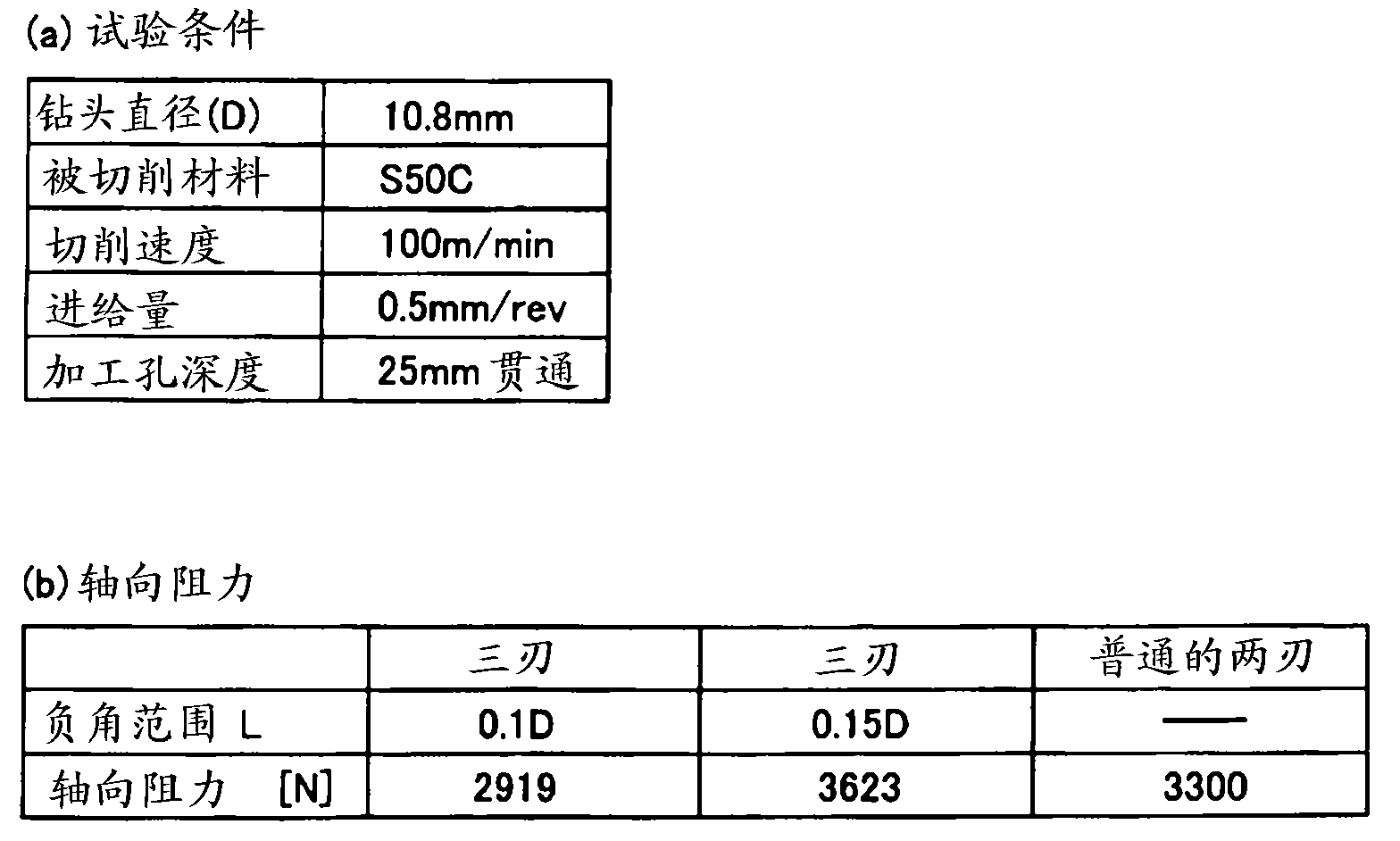

Drill

InactiveCN102170989AEasy to curlImprove discharge effectTransportation and packagingWorkpiecesEdge strengthEngineering

Owner:OSG

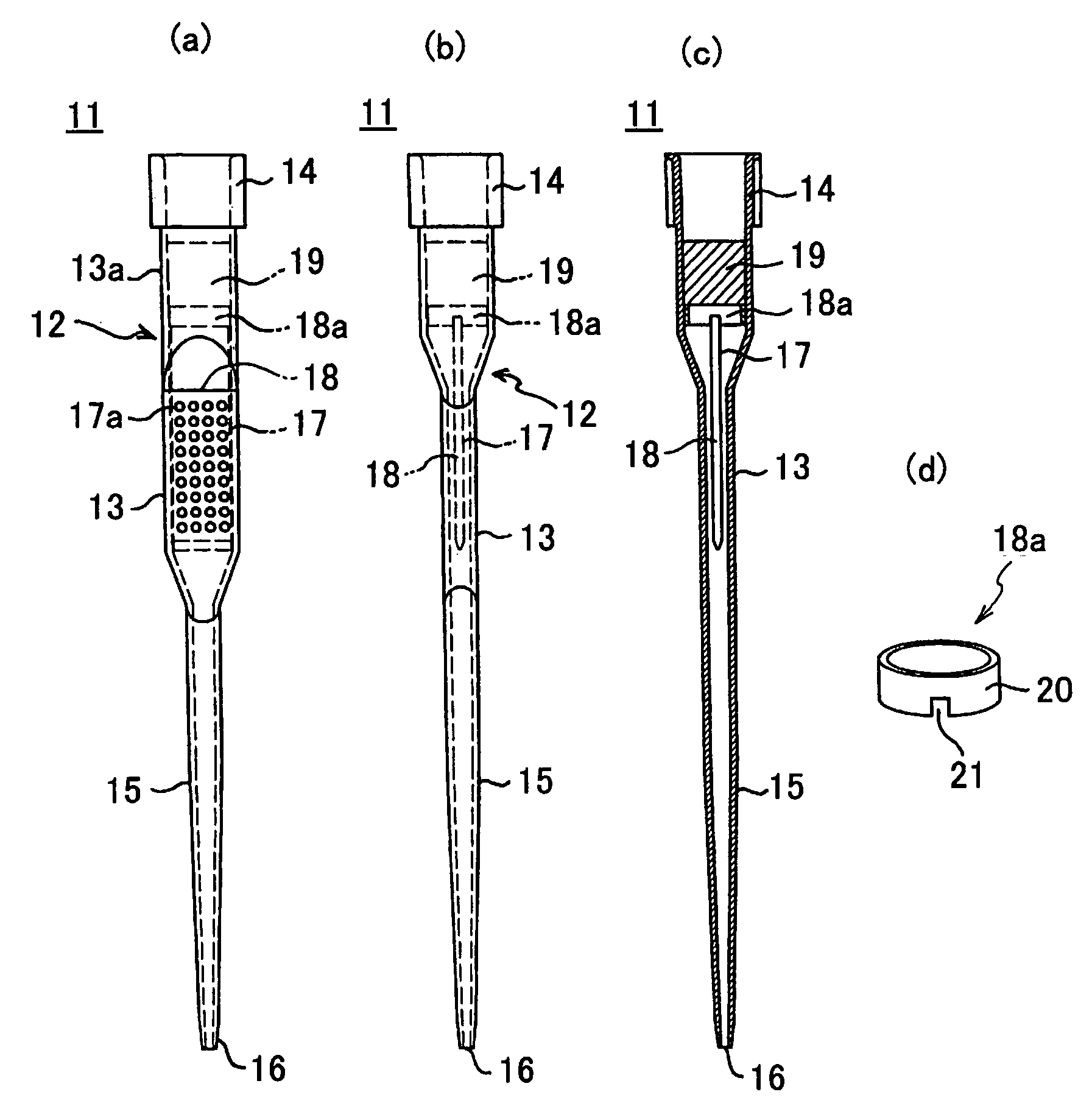

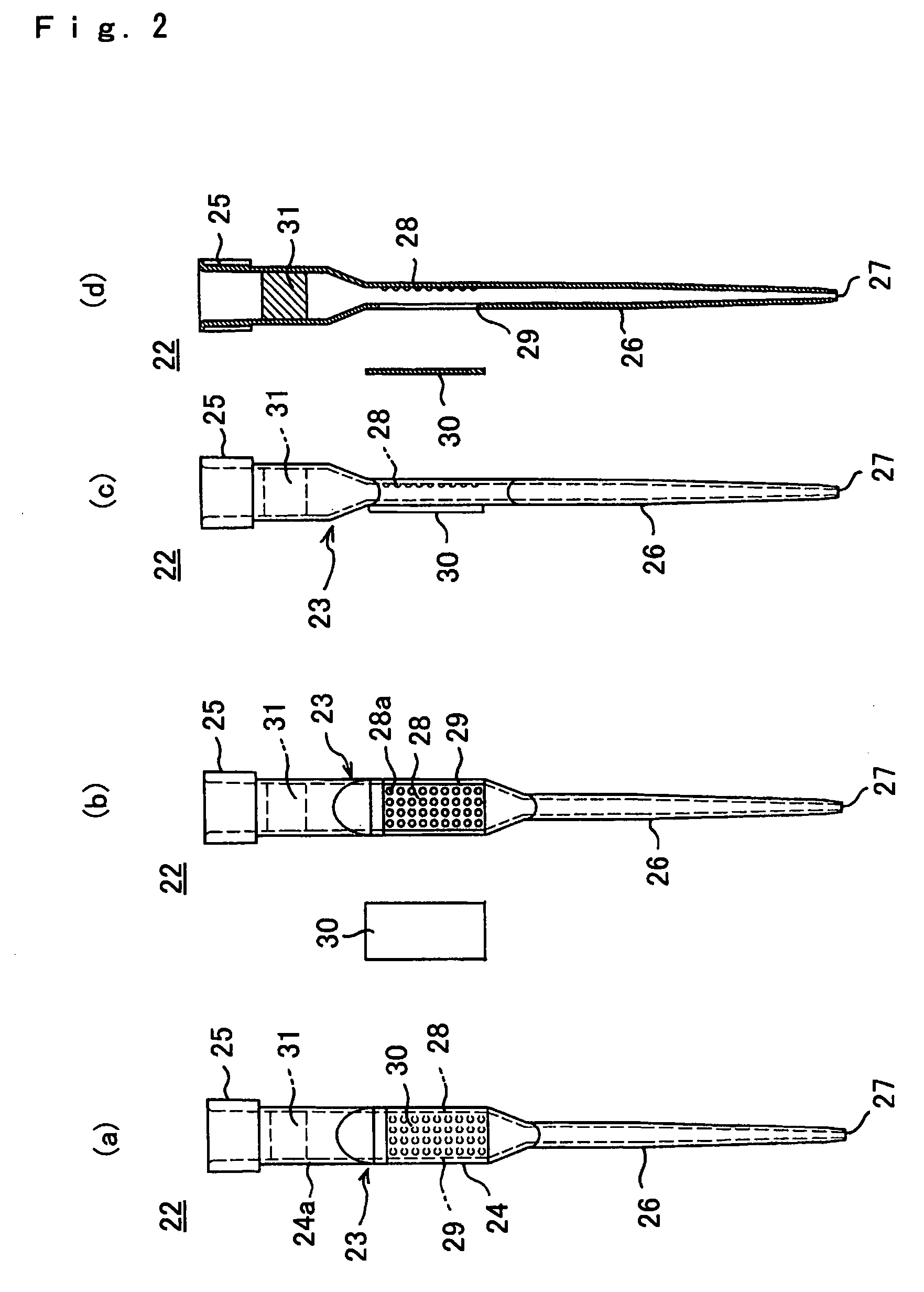

Biological material fixed region enclosing tip, biological material fixed region treatment apparatus, and treatment method thereof

InactiveUS8133454B2Specified accurately and reliablySimple to executeBioreactor/fermenter combinationsBiological substance pretreatmentsSpray nozzleEngineering

A biological material fixed region enclosing tip, a biological material fixed region treatment apparatus, and a treatment method thereof. An object is to enable processing to be performed while a fixing region is enclosed in an immovable state with respect to the tip form vessel, and to execute processing of high reliability with a simple apparatus. The biological material fixed region enclosing tip comprises: a tip form vessel having an installation opening part that is installable to a nozzle that performs suction and discharge of gas, and an opening through which inflow and outflow of fluid is possible by means of the suction and discharge of gas; a fixing region provided in the tip form vessel, in which a predetermined biological material is fixed or fixable in a plurality of different positions that are determined beforehand that are distinguishable from the exterior; and an enclosing section that encloses the fixing region within the tip form vessel such that the fixing region is able to make contact in an immovable state with the fluid that has flown into the tip form vessel from the opening.

Owner:UNIVERSAL BIO RESEARCH CO LTD

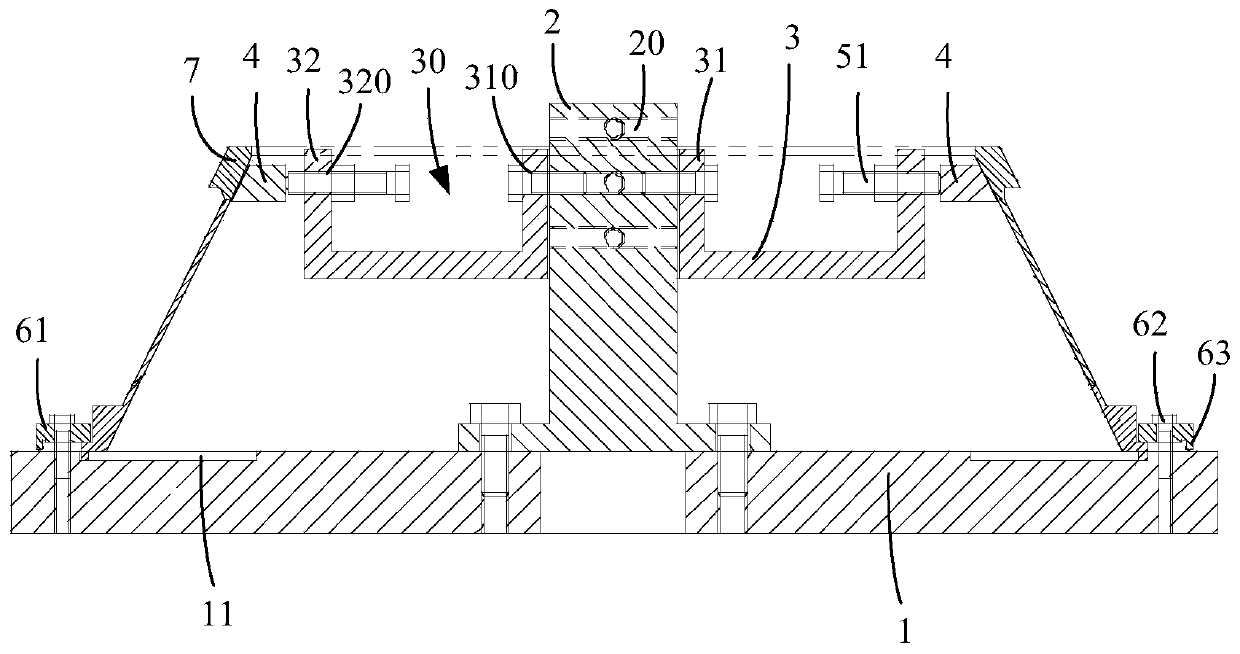

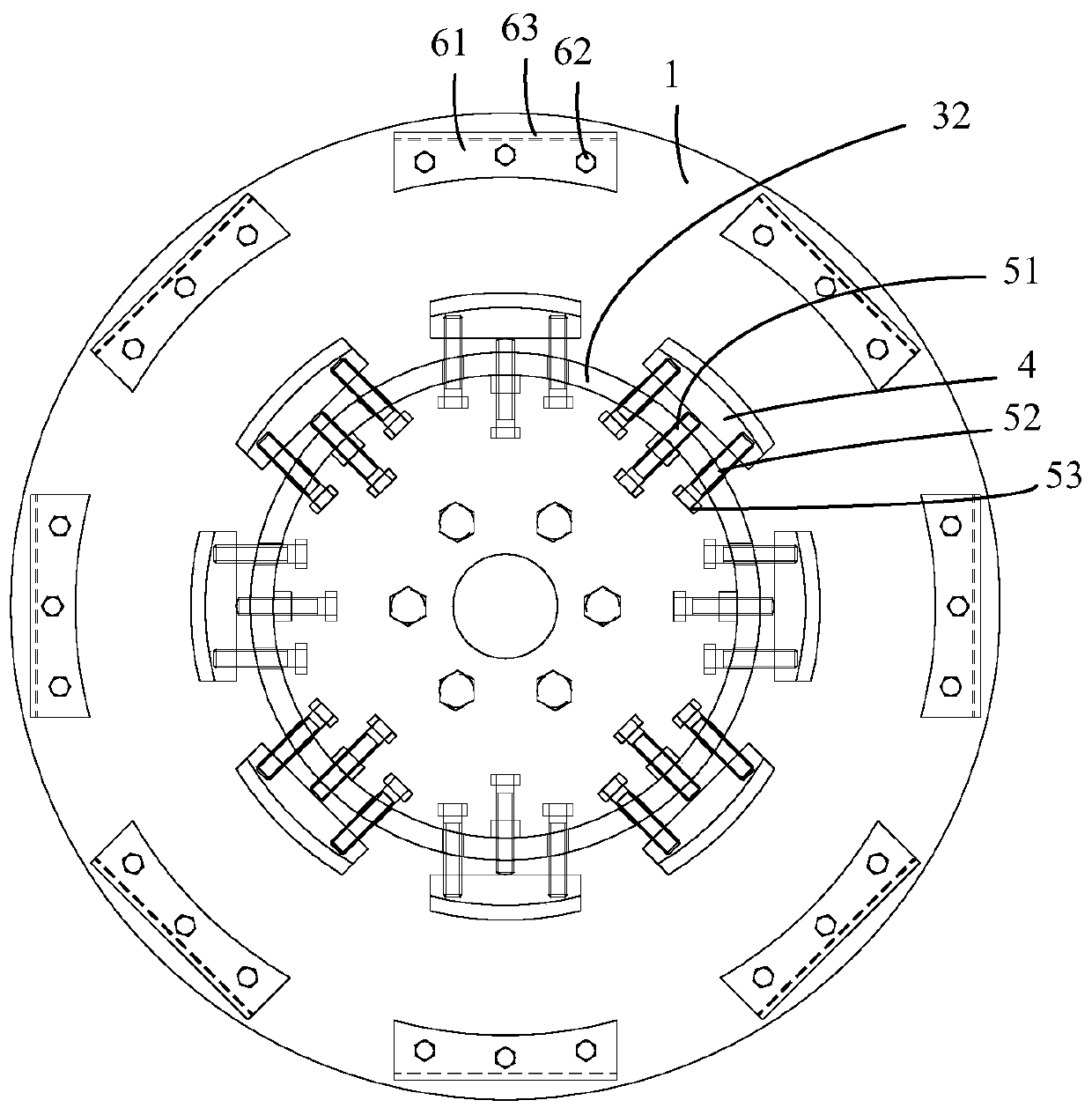

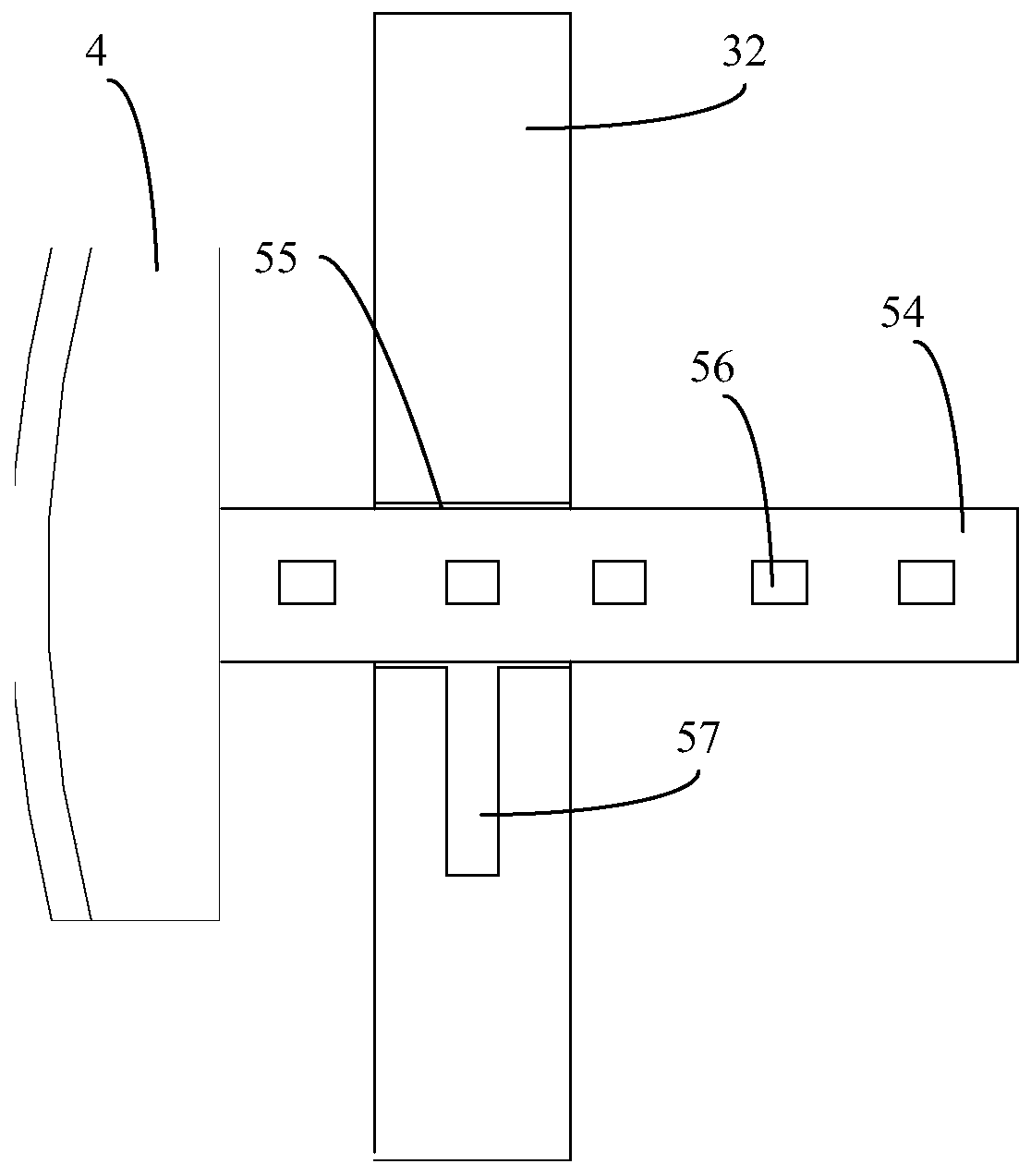

Clamping device for taper-cylindrical workpiece

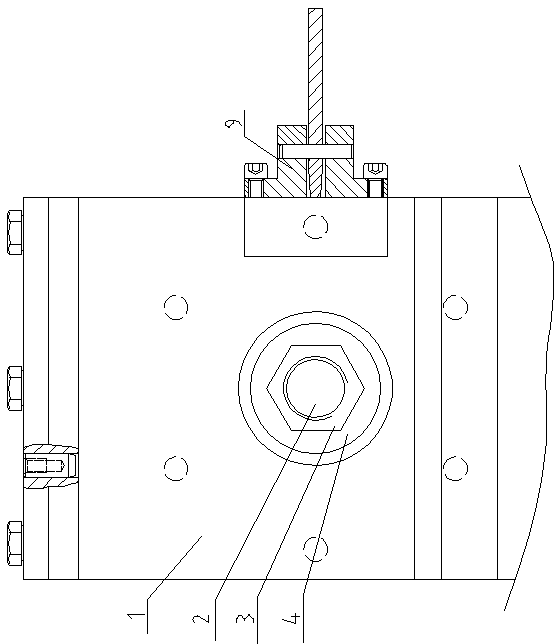

ActiveCN109773518AAvoid position shiftPrevent slippingPositioning apparatusMetal-working holdersProcessing accuracyMachining process

The invention discloses a clamping device for a taper-cylindrical workpiece. The clamping device includes a positioning disc, a positioning strut, a supporting ring, an expanding block, a position adjusting piece and a pressure plate assembly, an annular positioning groove is formed in the side face of the positioning disc, the annular side wall with the large diameter inside the annular positioning groove is used for fitting the outer wall of a flange at one end of the taper-cylindrical workpiece, the positioning strut is located on one side face of the positioning disc and coaxially arrangedon the positioning disc, and the supporting ring is coaxial mounted on the positioning strut in a sleeving mode; and the supporting ring is detachably connected with the positioning strut, the expanding block is located on the outer edge side of the supporting ring, the expanding block is movably connected with the supporting ring, the end face, deviating from the positioning strut, of the expanding block is fitted with the inner wall of the taper-cylindrical workpiece, the positioning adjusting piece is configured to control the expanding block to slide in the radial direction of the supporting ring, and the pressure plate assembly is used for pressing and mounting one end of the taper-cylindrical workpiece on one side face of the positioning disc. The clamping device can prevent the position offset of the taper-cylindrical workpiece in the machining process, and the processing precision is improved.

Owner:WUHAN MARINE MACHINERY PLANT

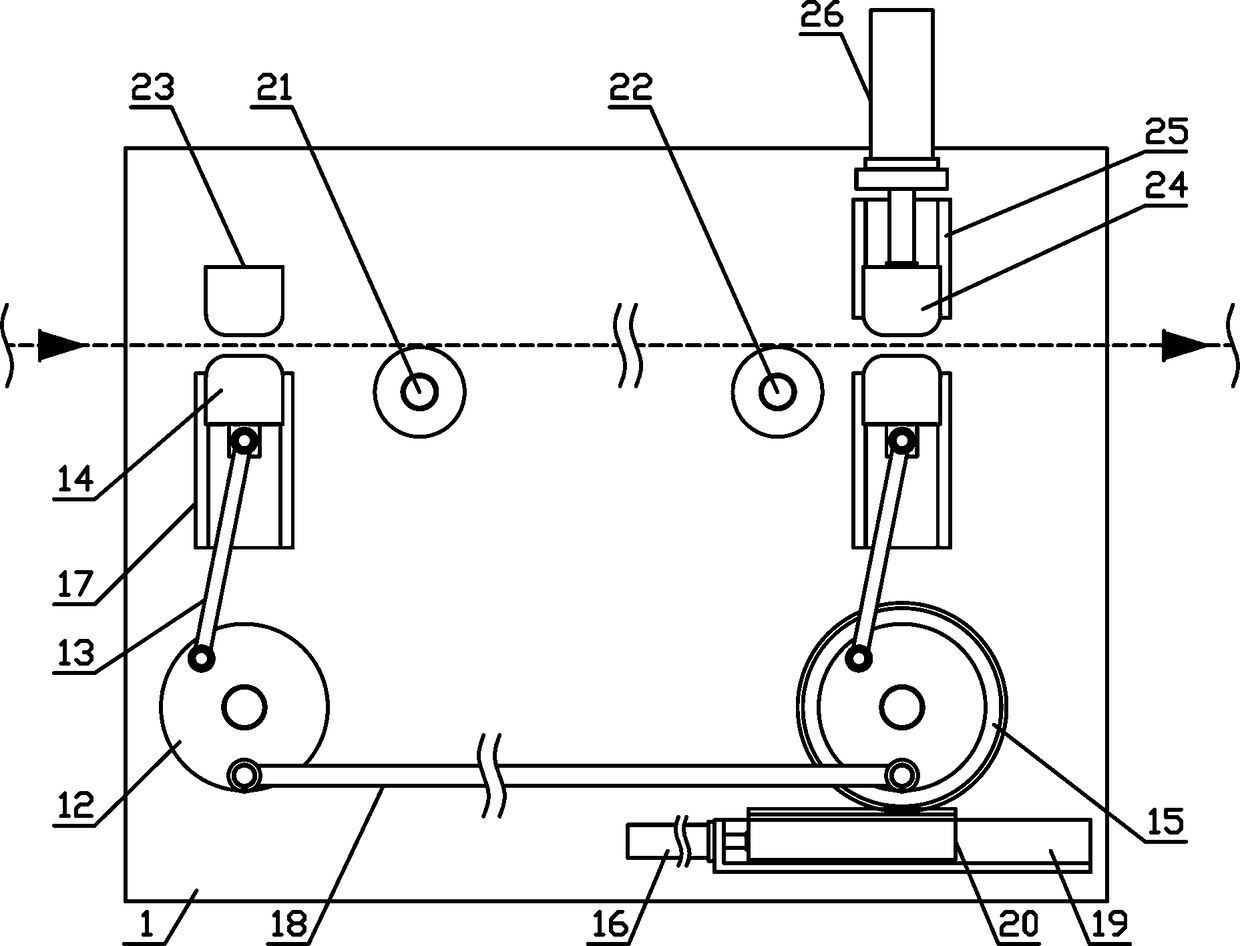

Yarn drafting and rolling mechanism

InactiveCN109230836AHigh degree of processing automationReasonable structural designFilament handlingTextiles and paperYarnMechanical equipment

The invention discloses a yarn drafting and rolling mechanism and belongs to the field of mechanical equipment for yarn conveying processing. Yarn press mechanisms are vertically arranged at the two sides of a drafting mechanism of the yarn drafting and rolling mechanism respectively, a rolling mechanism is arranged on a rolling support of one side of a yarn press mechanism, and multiple draftingrotation rollers are horizontally and rotatably connected to a lifting support of the upper side of a drafting support in the horizontal direction in sequence; multiple rotation rollers are horizontally and rotatably connected to a rotation support in the inclination direction in sequence, yarn press rotation discs are vertically and rotatably connected to rolling supports of the two sides of thelower portion of the drafting mechanism respectively, yarn press connection rods is arranged between lifting yarn press plates and the yarn press rotation discs, and a rolling yarn cylinder slidinglysleeves a rolling rotation roller in the horizontal direction. The yarn drafting and rolling mechanism is reasonable in structural design, the yarn can be stably and evenly drafted and processed segment by segment and can be conveniently and efficiently rolled, the automation degree of yarn processing is improved, and the demands of production and application are met.

Owner:桐乡市澳得利纤维股份有限公司

Planet continuous mill

InactiveCN107398808AEffective continuous grindingStrong automatic cleaning abilityGrinding machinesGrinding work supportsEngineeringMachining process

The invention discloses a planet continuous mill which comprises a main rack, empty stations, a drive gear ring and a main motor. A starting mill, a terminal mill and multiple middle mills are arranged on the main rack. Each empty station comprises a supporting table. A starting mill disc, middle mill discs, a terminal mill disc and the supporting tables are sequentially distributed in the circumferential direction of the drive gear ring. The drive gear ring is rotationally connected with the main rack. Multiple workpiece locating structures are arranged on the drive gear ring. A workpiece locating groove is formed in the bottom of each gravity press block. At least one vertical sliding rod is arranged on each transverse sliding rail rod. The vertical sliding rods are connected with the transverse sliding rail rods through locating pins. A vertical sliding groove is formed in each gravity press block. The vertical siding rods are in sliding fit with the vertical sliding grooves in the corresponding gravity press blocks. The planet continuous mill has the beneficial effects that workpieces can be effectively ground continuously, grinding machining from rough to fine can be achieved through one-time grinding, and the machining process is convenient, fast and efficient; and the automatic clearing capacity of grinding waste is high, the grinding furnaces can be cleared in advance before the workpieces arrive, and the grinding effect is good.

Owner:义乌市台荣超硬制品有限公司

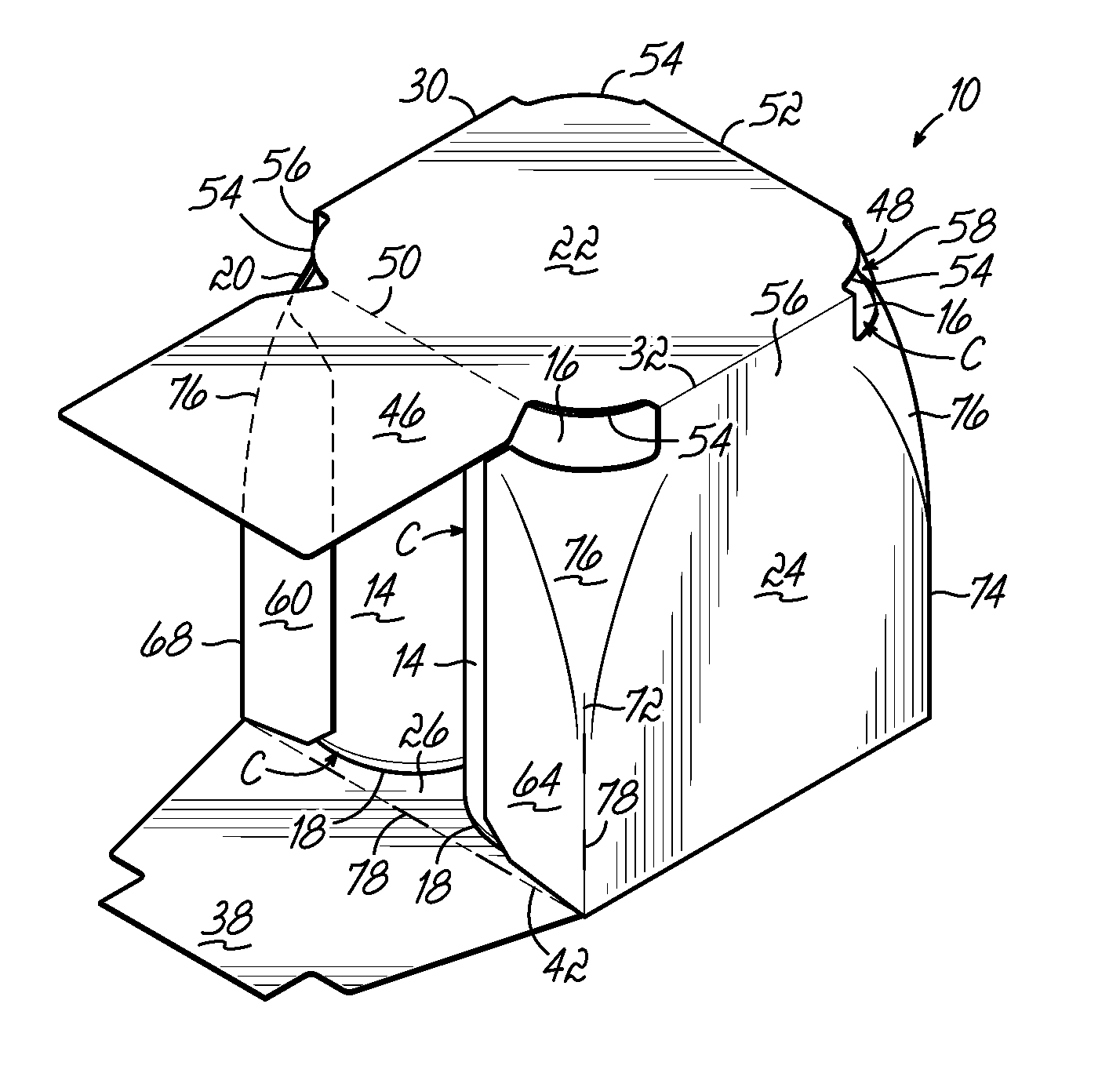

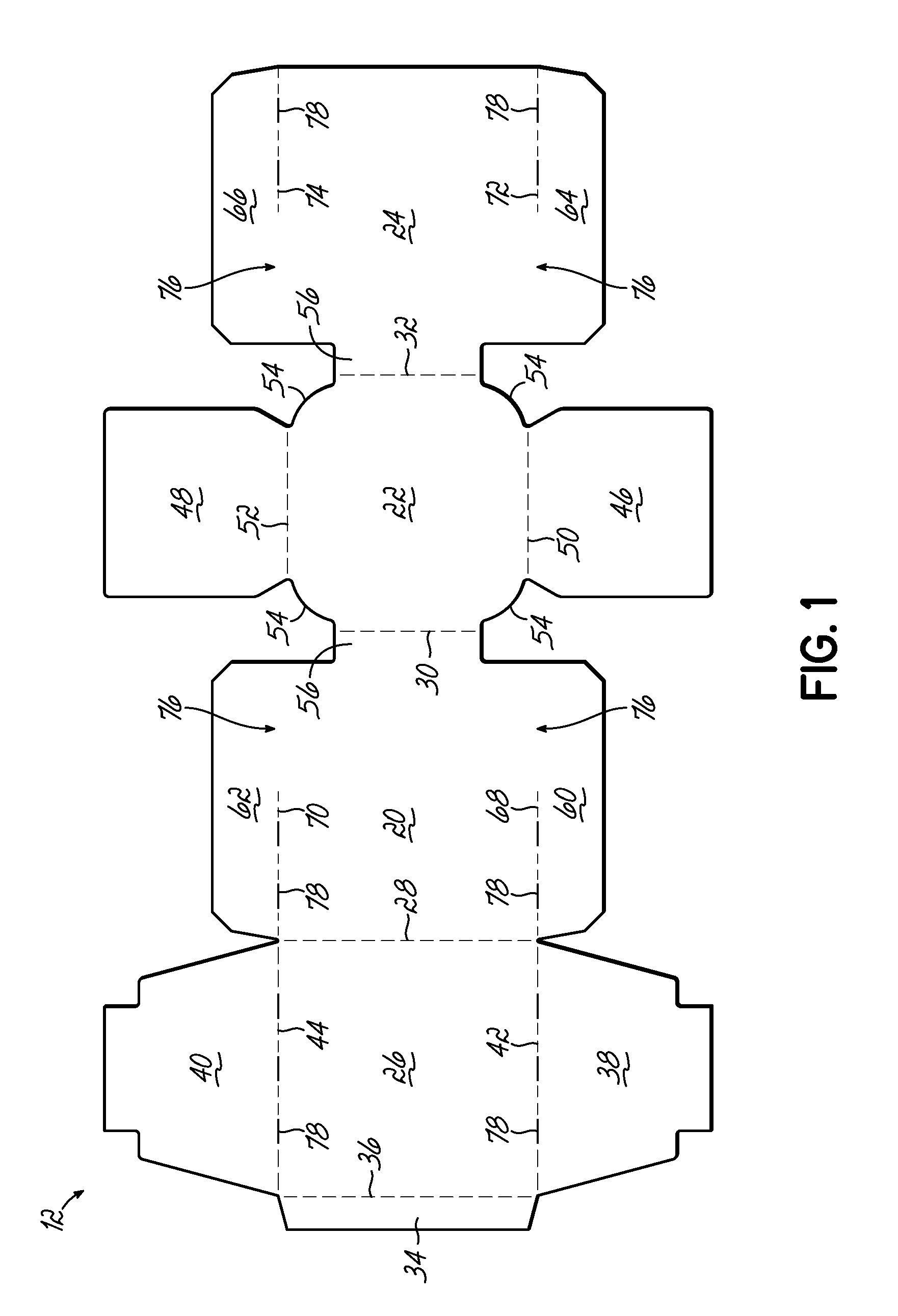

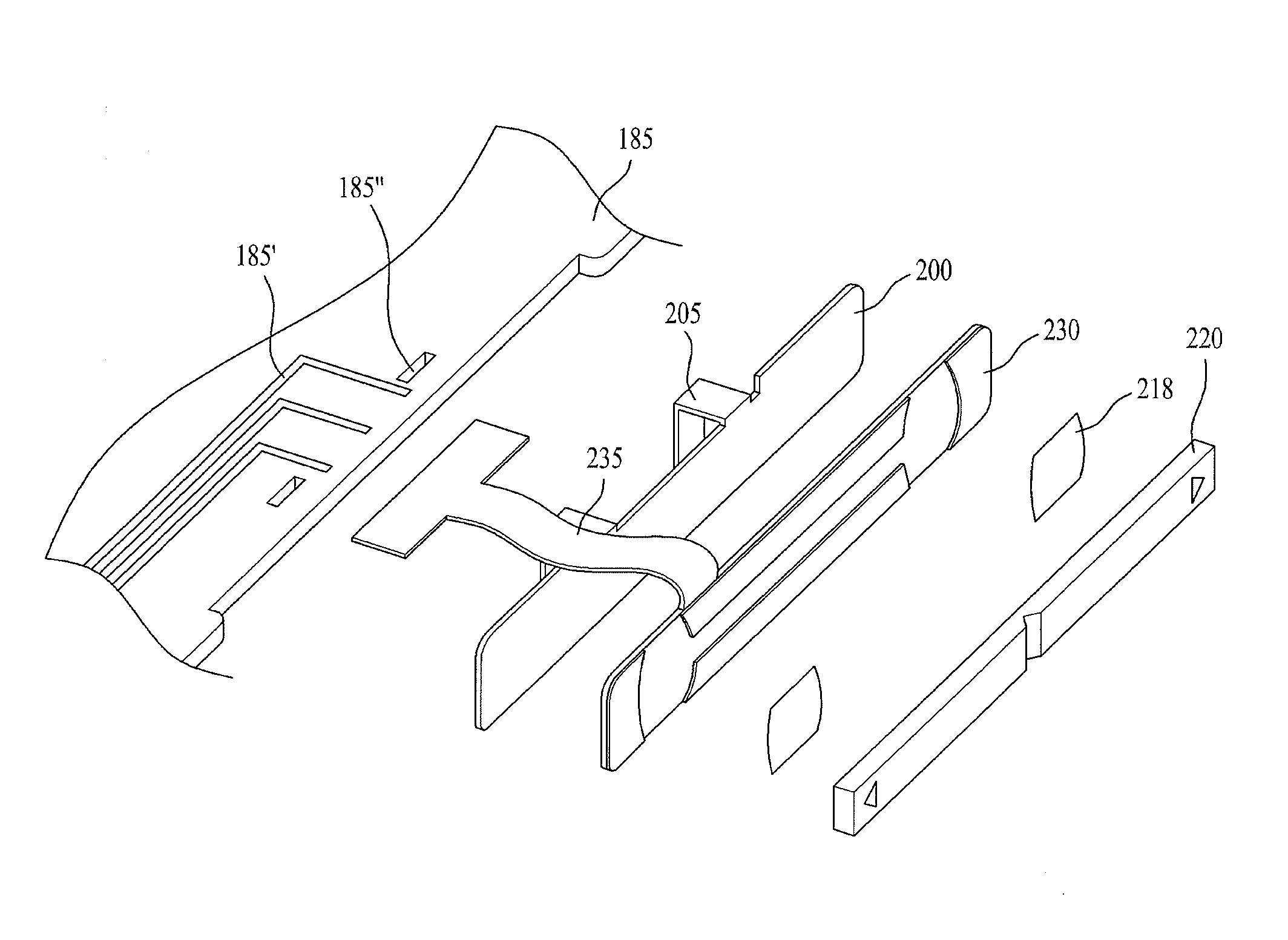

Wrap-around container carrier

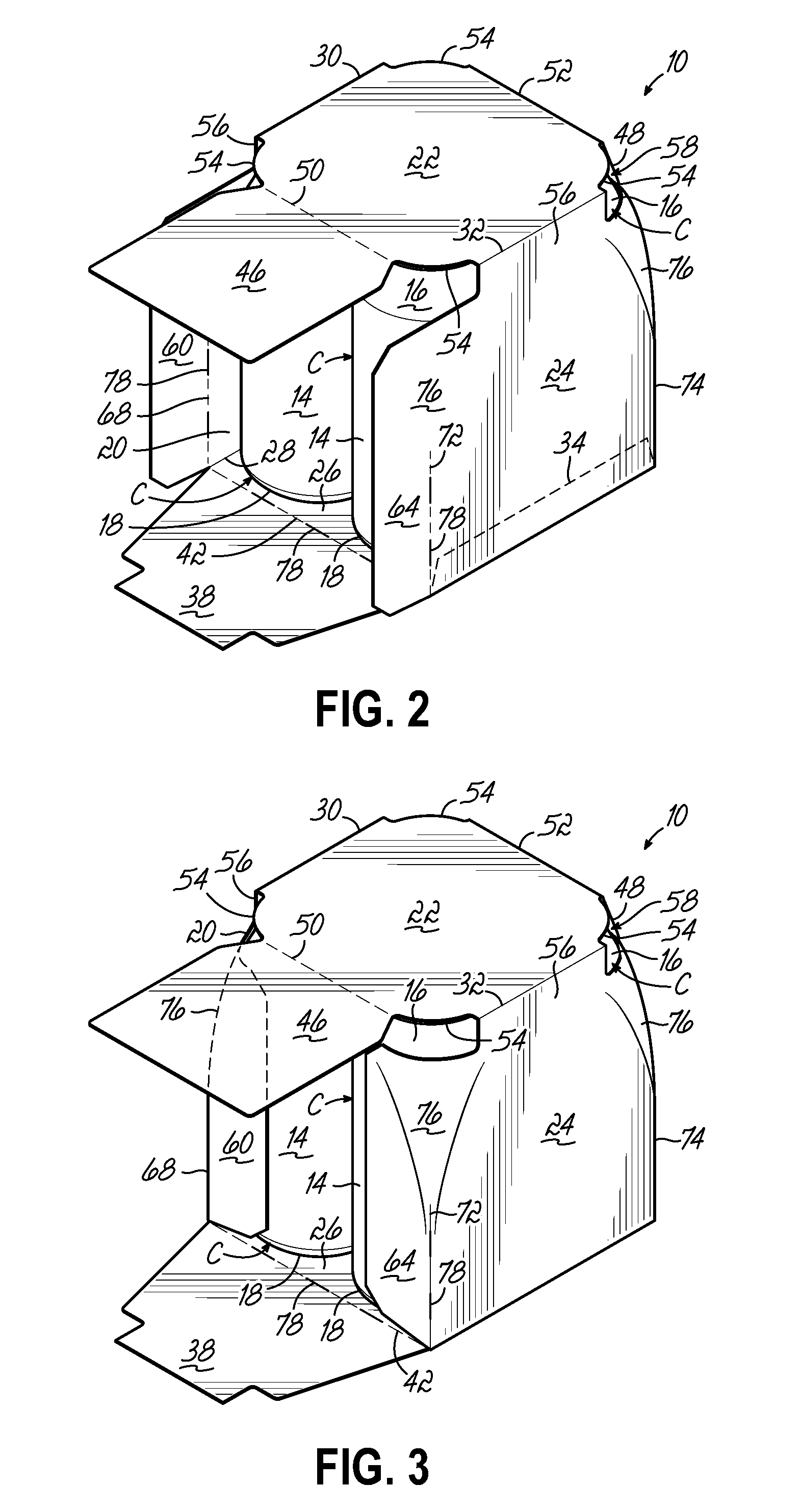

ActiveUS8997987B1Without sacrificing structural integrityEasy and efficient processingFlexible coversWrappersCardboardWrap around

A carrier is constructed from paperboard and includes a rounded or non-rectangular top in combination with a non-rounded or rectangular bottom. Dust flaps which extend from the top and bottom of the carrier overlap one another to form a pair of opposing composite side panels. The dust flaps which are attached to the side panels include a crease or fold line adjacent to the bottom of the carrier which only extends partially along the height of the carrier so that the juncture between the side flap and the associated side panel adjacent the top of the carrier does not include a crease or fold line. As such, the side panel and adjacent side flap adjacent the top of the carrier can be tightly wrapped around the arcuate sidewall of the containers within the carrier to thereby provide a neat and tightly packed package configuration.

Owner:C W ZUMBIEL

Forming tool device for oblique holes

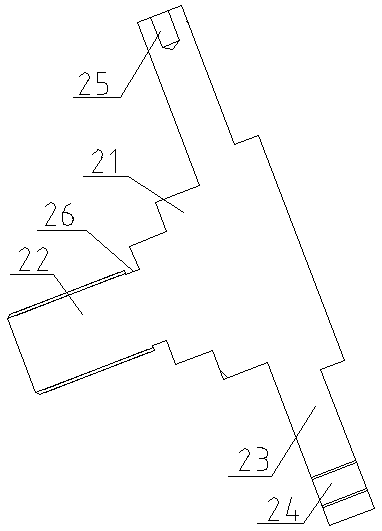

ActiveCN109454269AImprove machining efficiency and precisionEasy to replaceDrill jigsEngineeringMachining

The invention discloses a forming tool device for oblique holes. The forming tool device comprises a profiling apparatus which is used for shifting the oblique holes to be in a vertical machining state, and a pressing claw apparatus which is disposed on the profiling apparatus and used for clamping an oblique hole carrier. By means of the profiling apparatus, the oblique holes on the oblique holecarrier are vertically distributed, through the pressing claw apparatus, the oblique hole carrier is clamped onto the profiling apparatus, and thus the machining efficiency and accuracy of the side oblique holes are improved.

Owner:泰安泰山福神齿轮箱有限责任公司

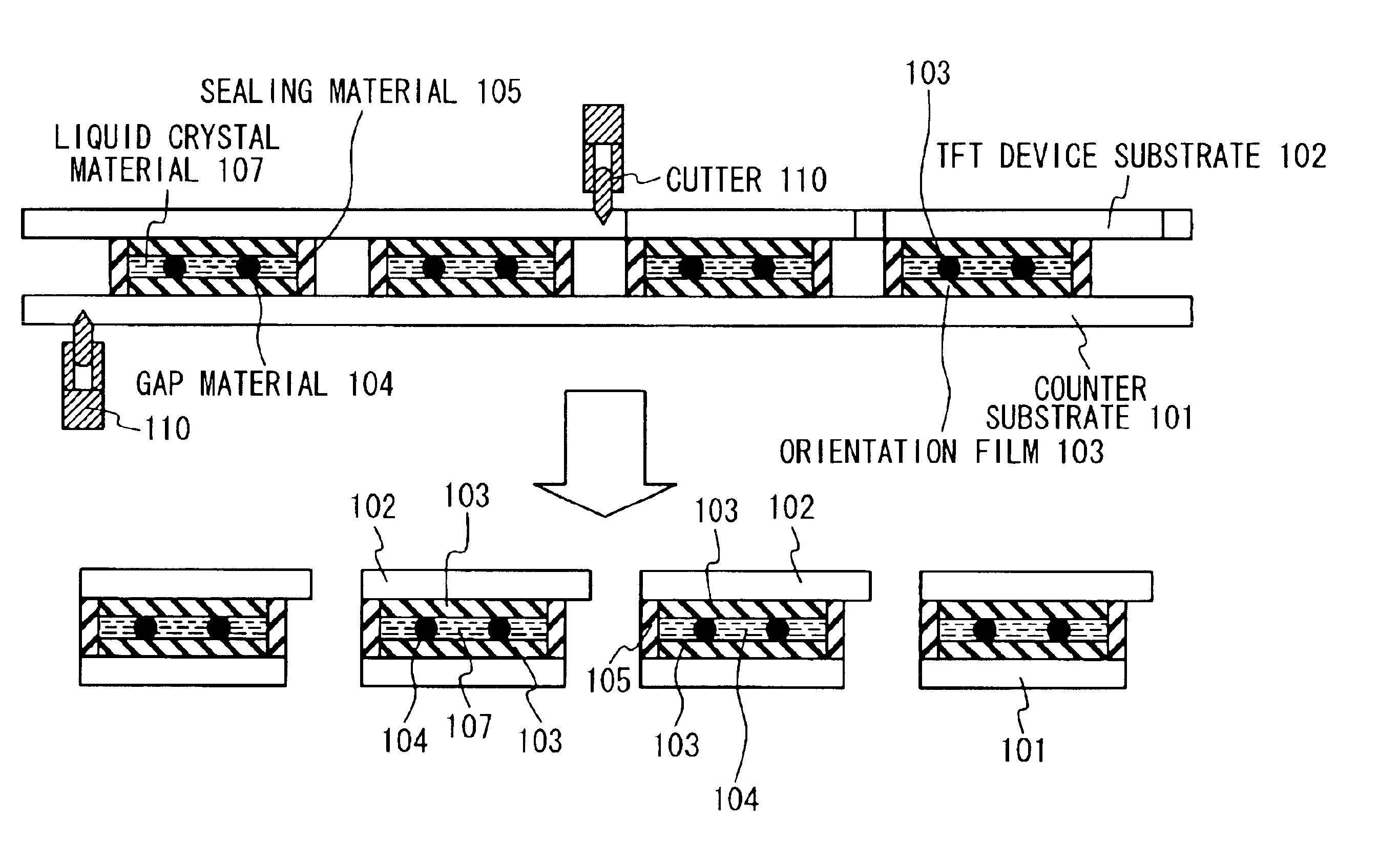

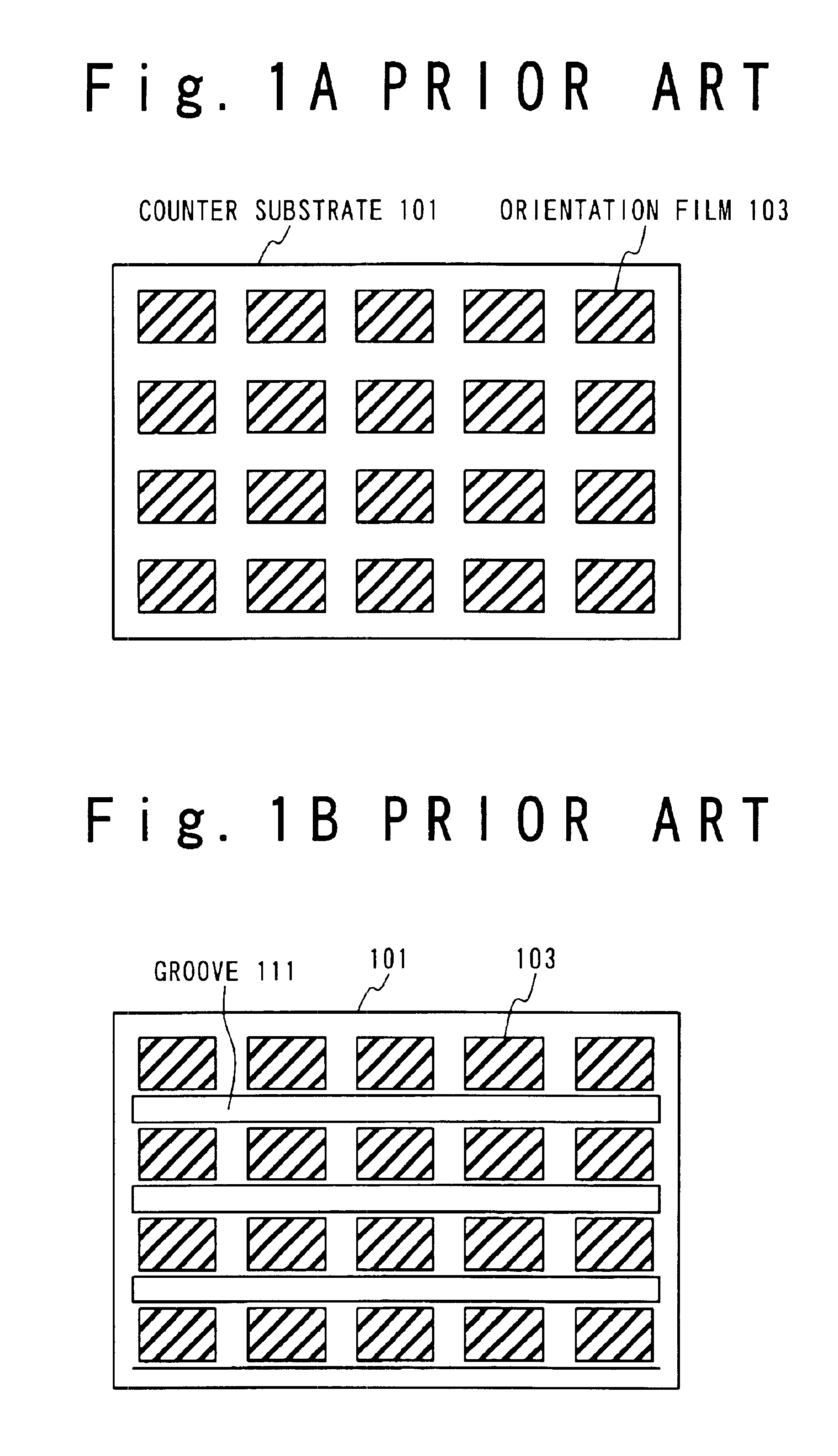

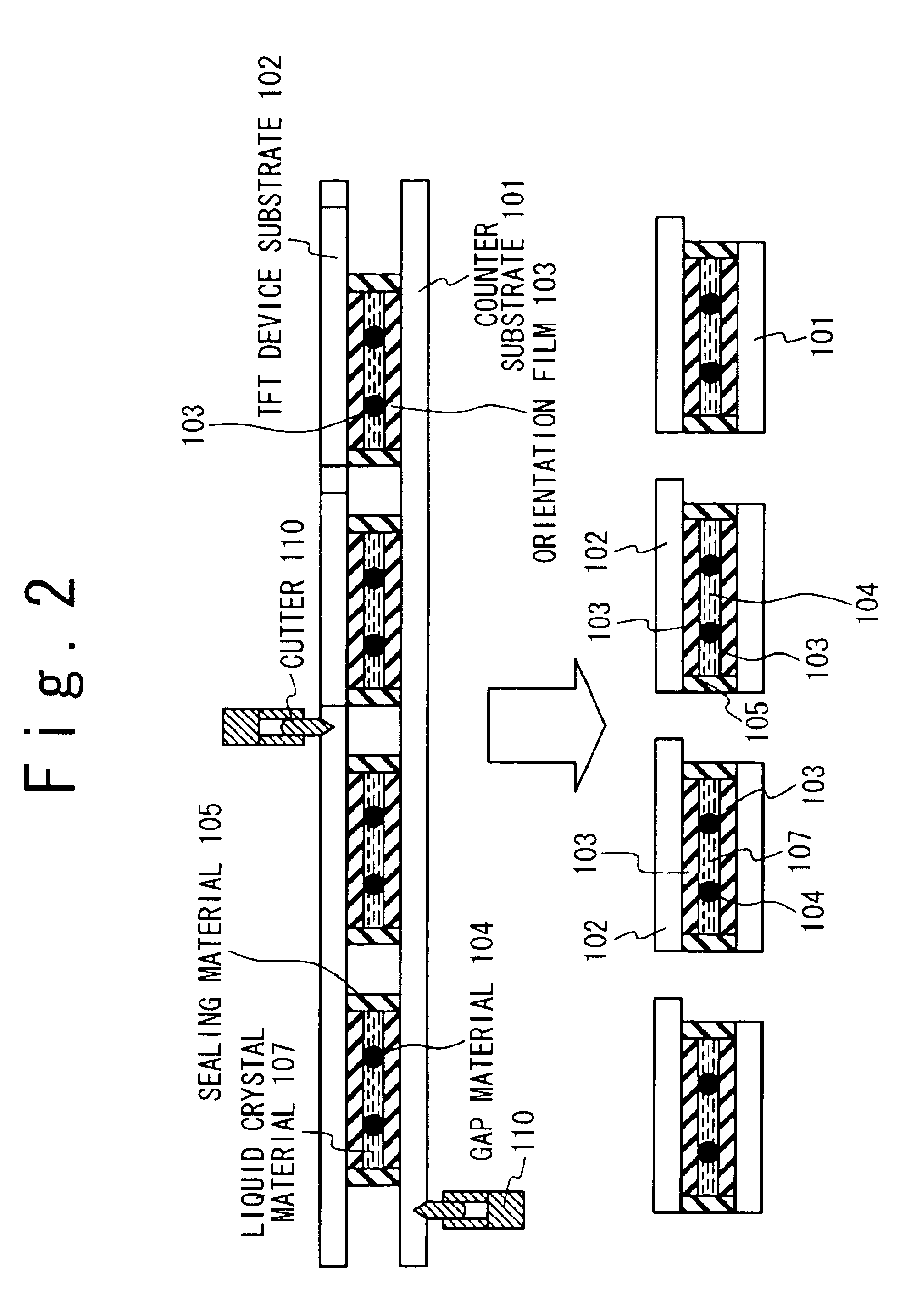

Producing method of the liquid crystal display panel

InactiveUS6873394B2Easy and efficient processingEasy and efficientMetal working apparatusNon-linear opticsLiquid-crystal displayLiquid crystal

A producing method of a liquid crystal display panel includes steps (a) to (e). The Step (a) is fixing a counter substrate on a fixing table, wherein the counter substrate includes a plurality of counter portions each of which includes a plurality of counter electrodes. The Step (b) is dividing the counter substrate into the plurality of counter portions. The Step (c) is putting a liquid crystal material on the each of plurality of counter portions. The Step (d) is attaching a device substrate and the counter substrate together, wherein the device substrate includes a plurality of device portions each of which includes a plurality of switching devices. The Step (e) is dividing the device substrate into the plurality of device portions. The each of plurality of device portions is attached to a corresponding one of the each of plurality of counter portions.

Owner:NEC LCD TECH CORP

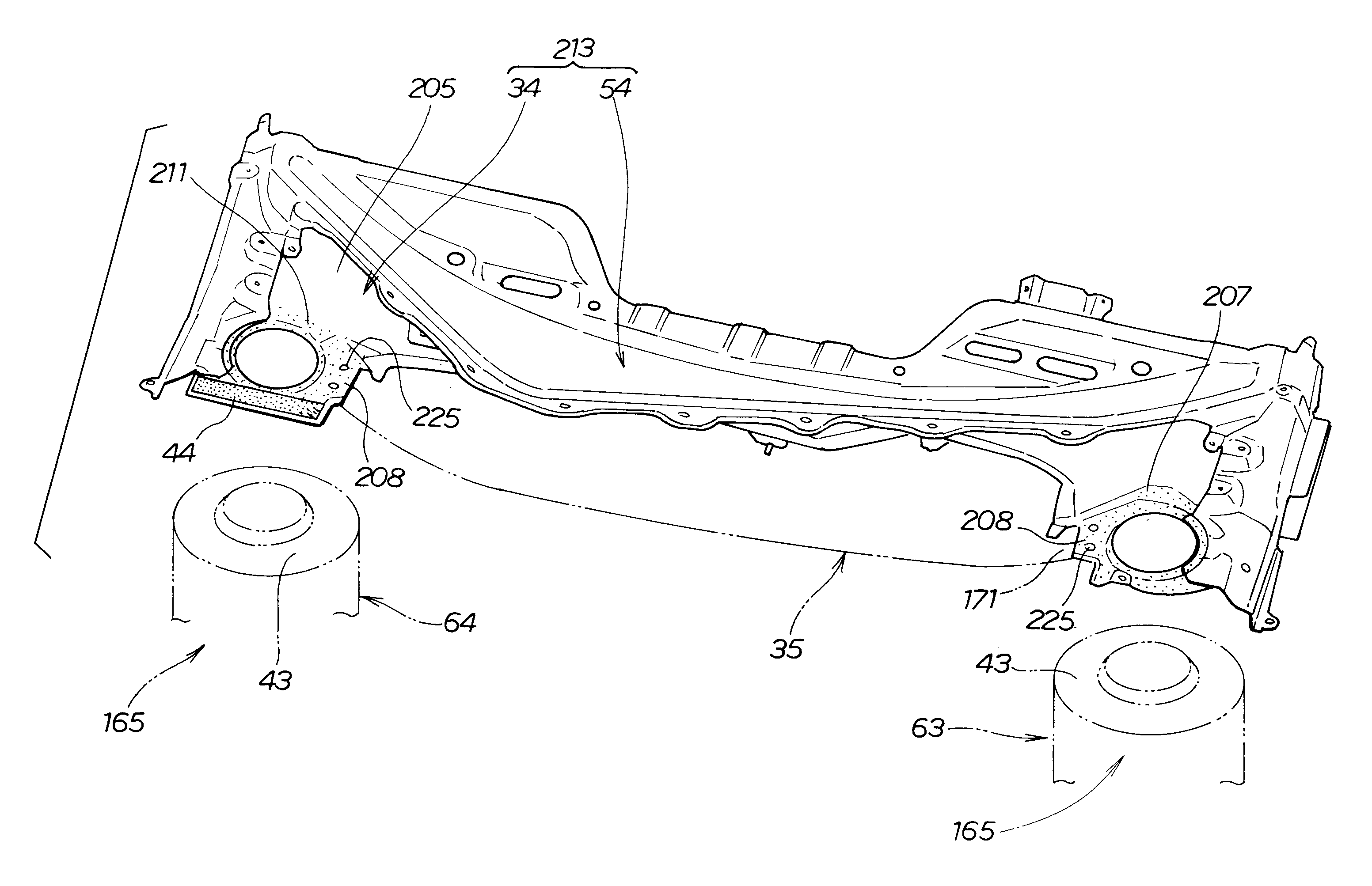

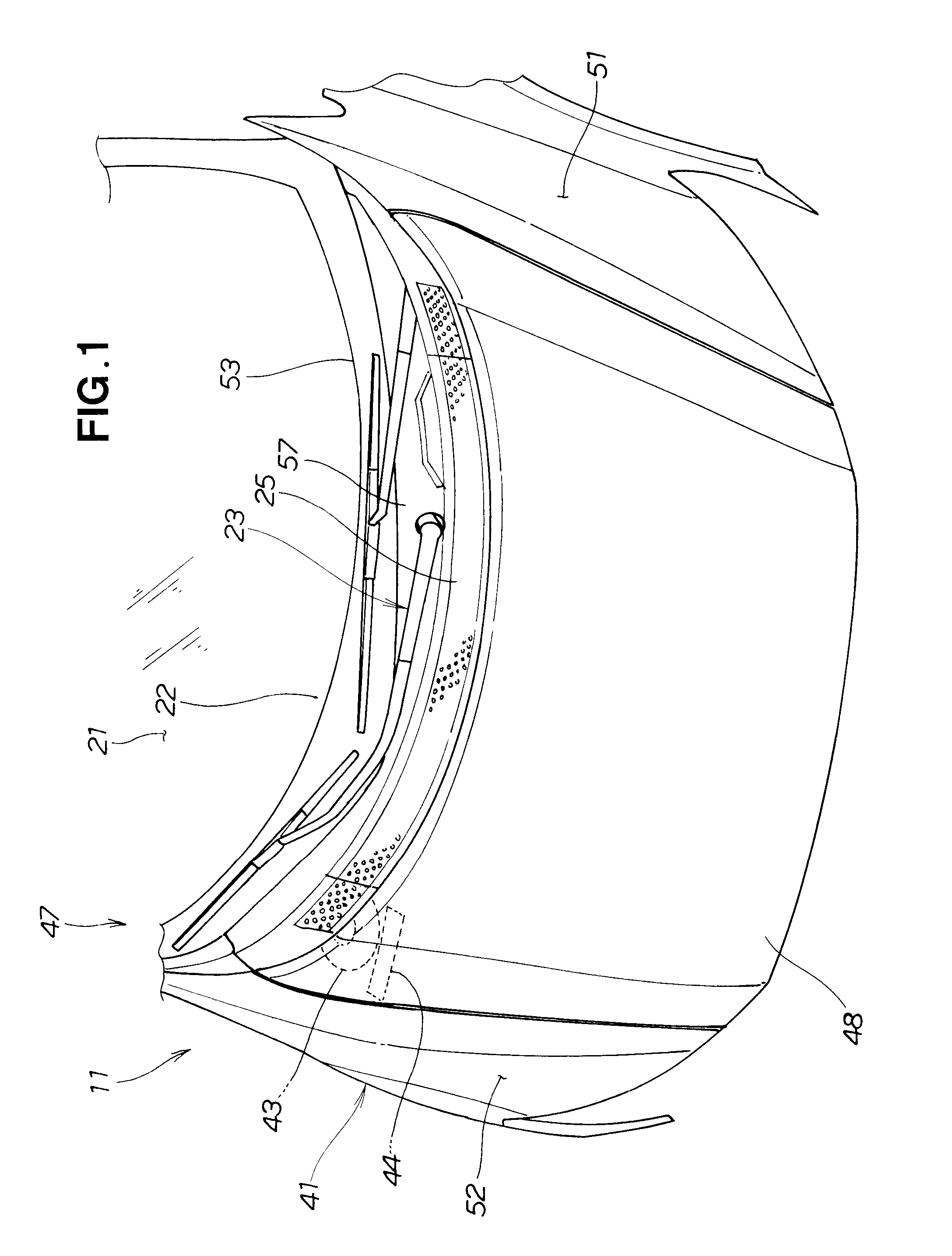

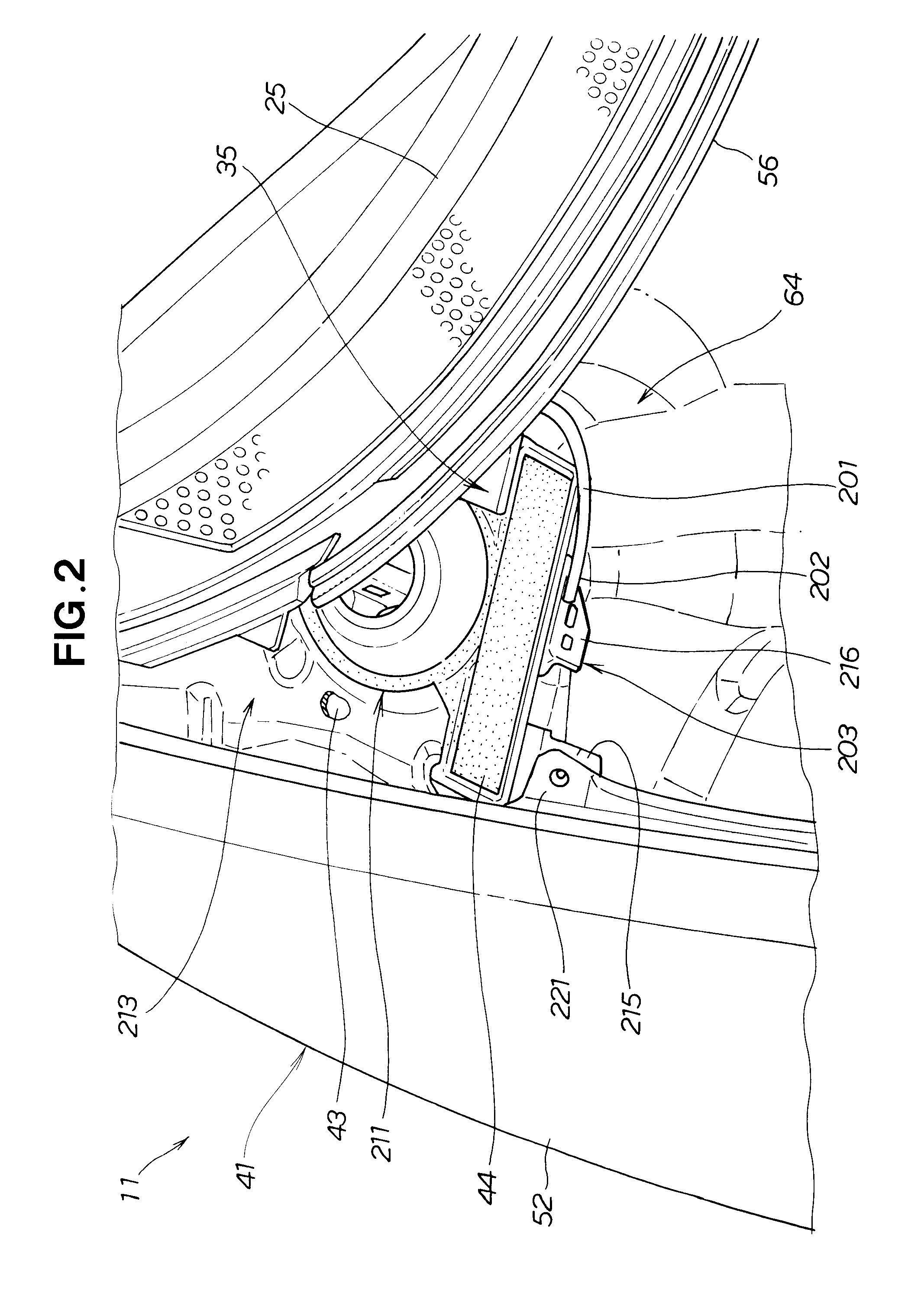

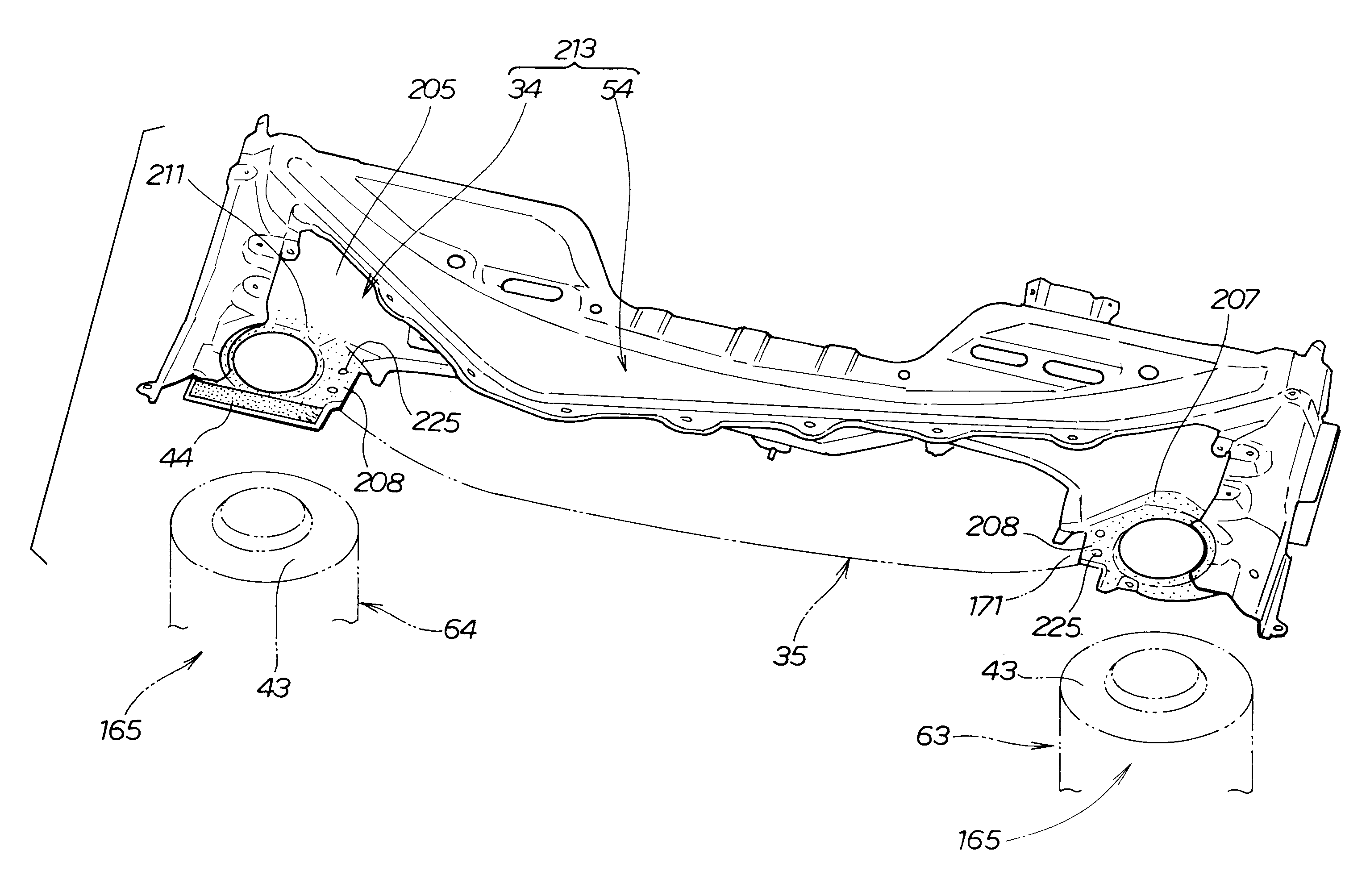

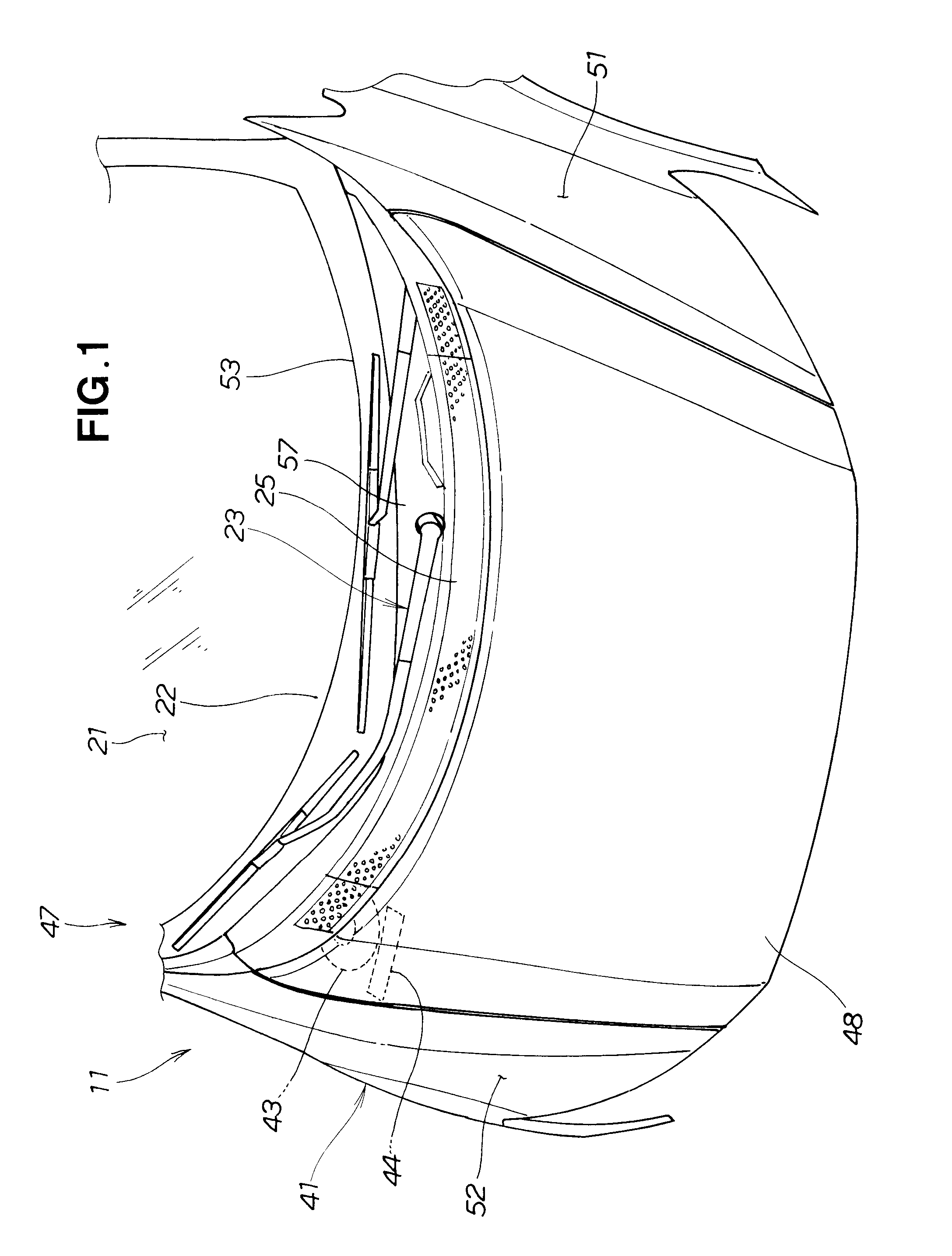

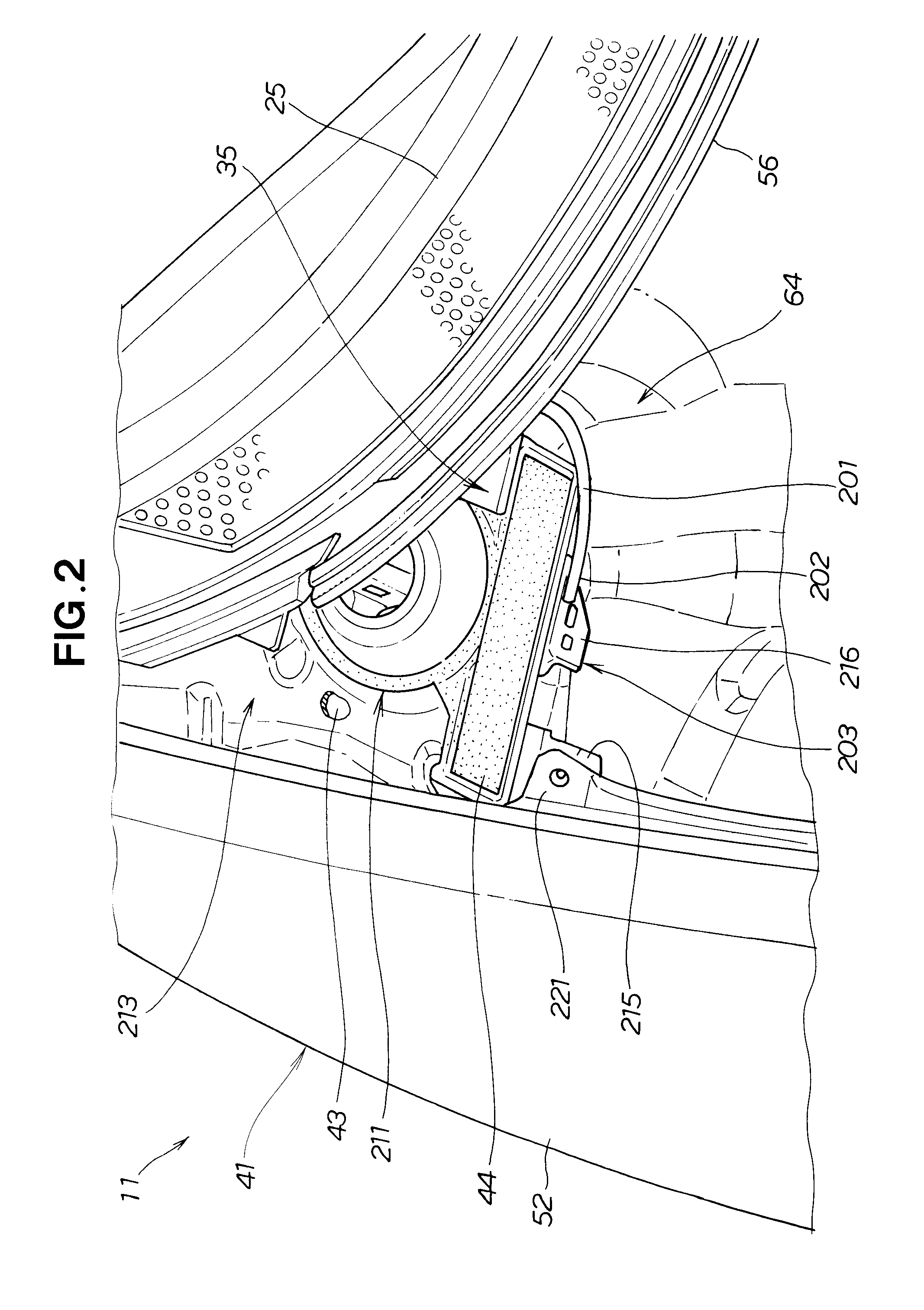

Vehicle front body structure

InactiveUS20110084518A1Resist damageResistance to deformationVehicle seatsSuperstructure subunitsEmbedded systemRolling chassis

A vehicle front body structure includes a chassis number marking section on which a chassis number or vehicle identification number (VIN) is applied by stamping. The chassis number marking section is provided on a cowl assembly and disposed above a damper base to which an end of the cowl box is secured.

Owner:HONDA MOTOR CO LTD

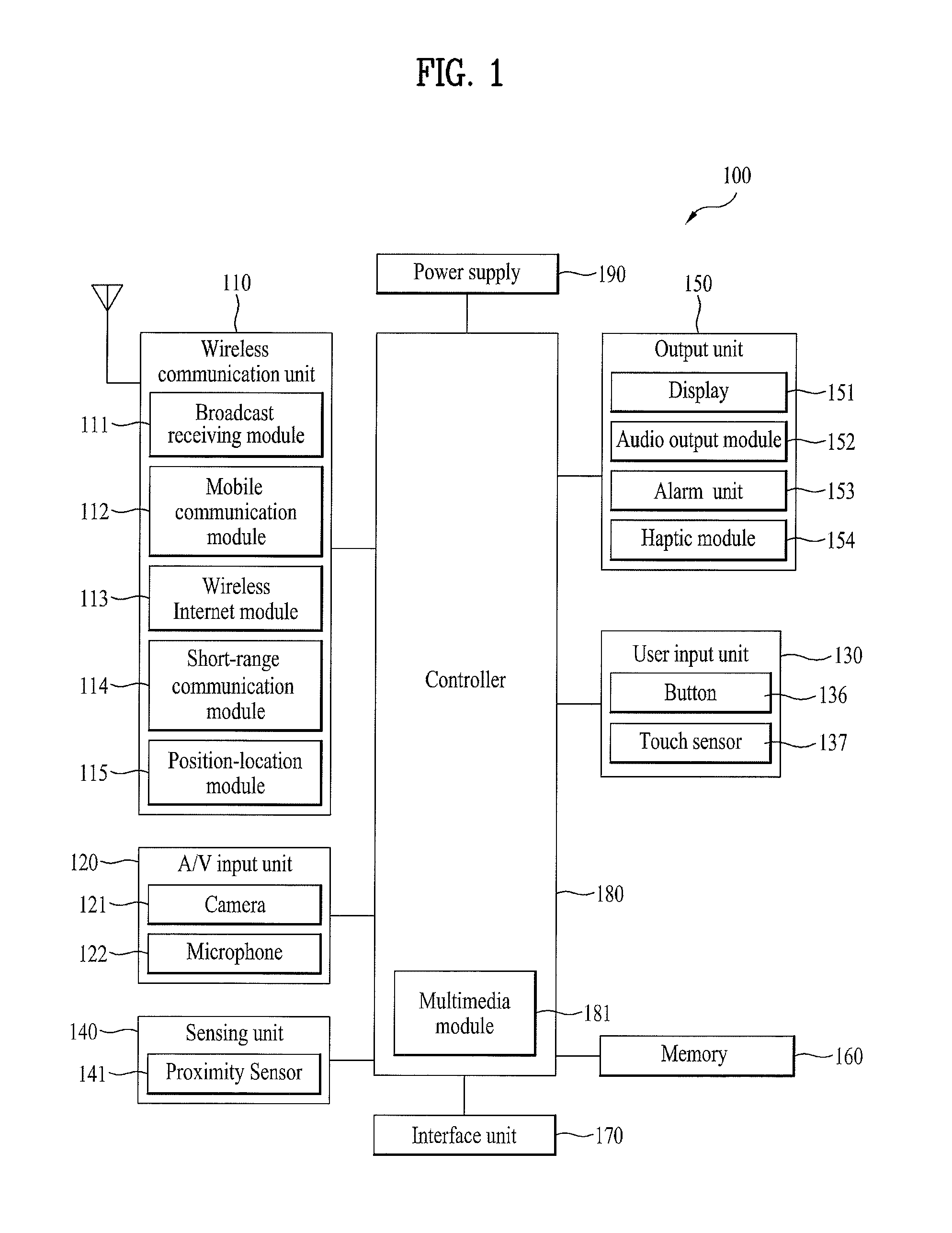

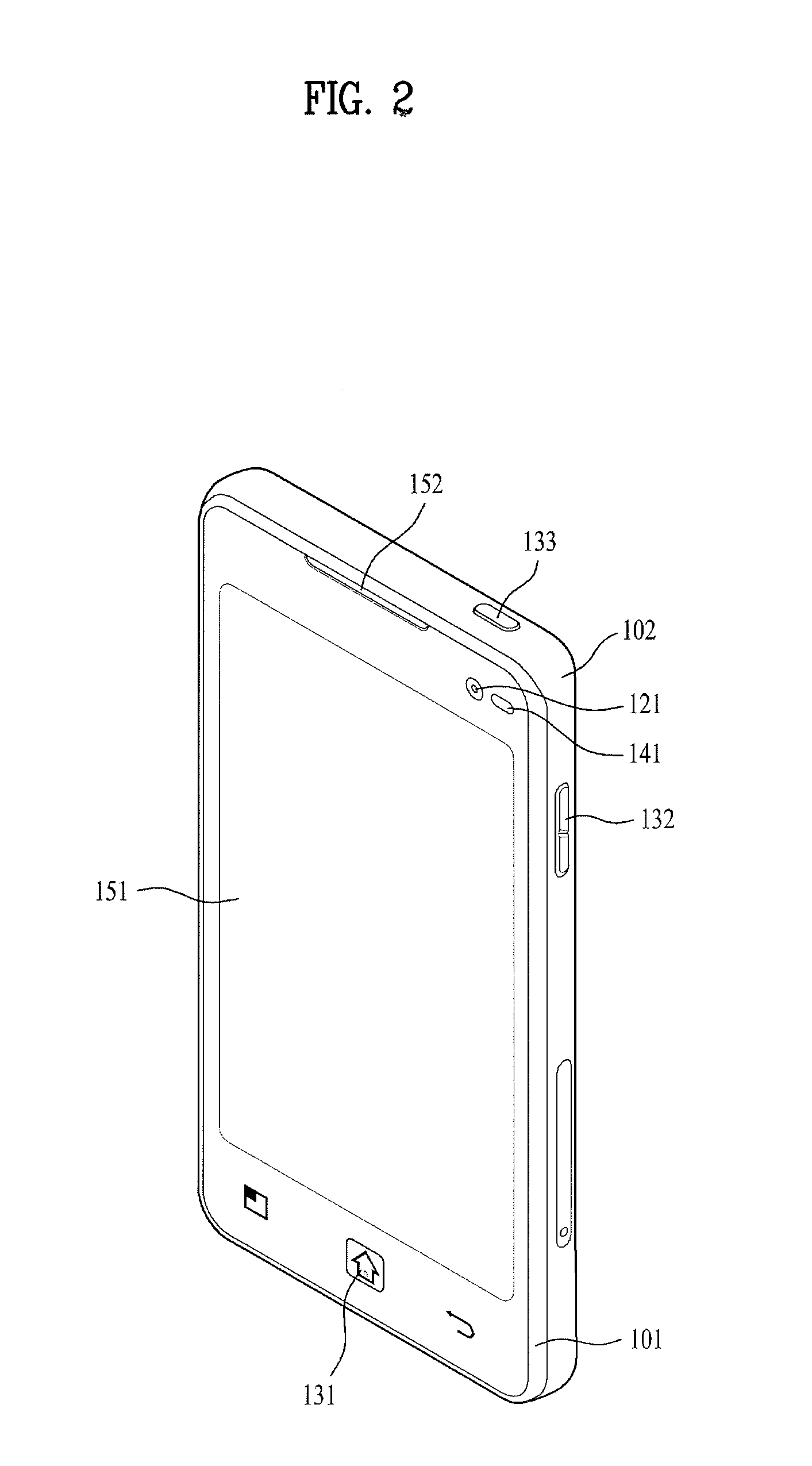

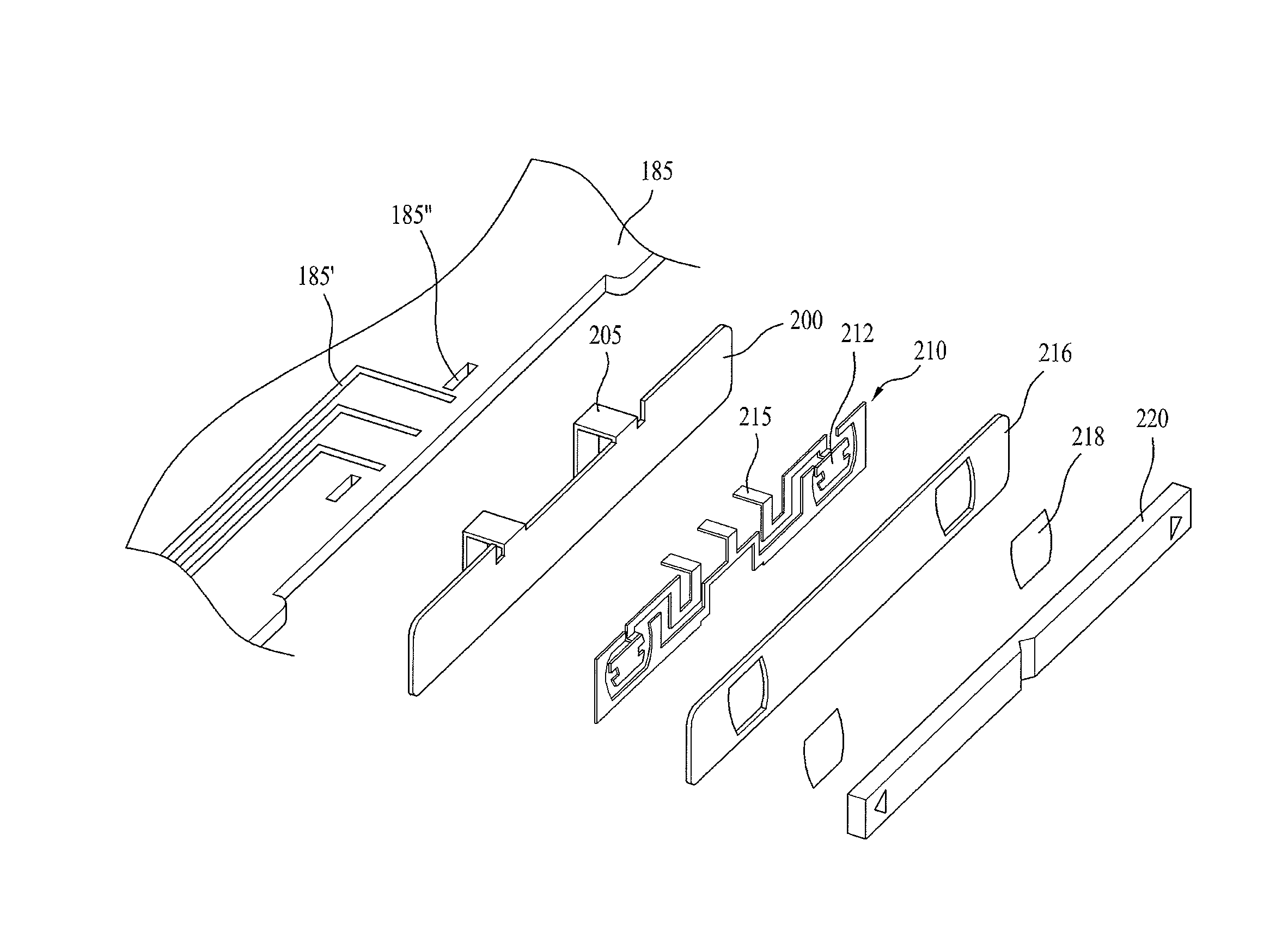

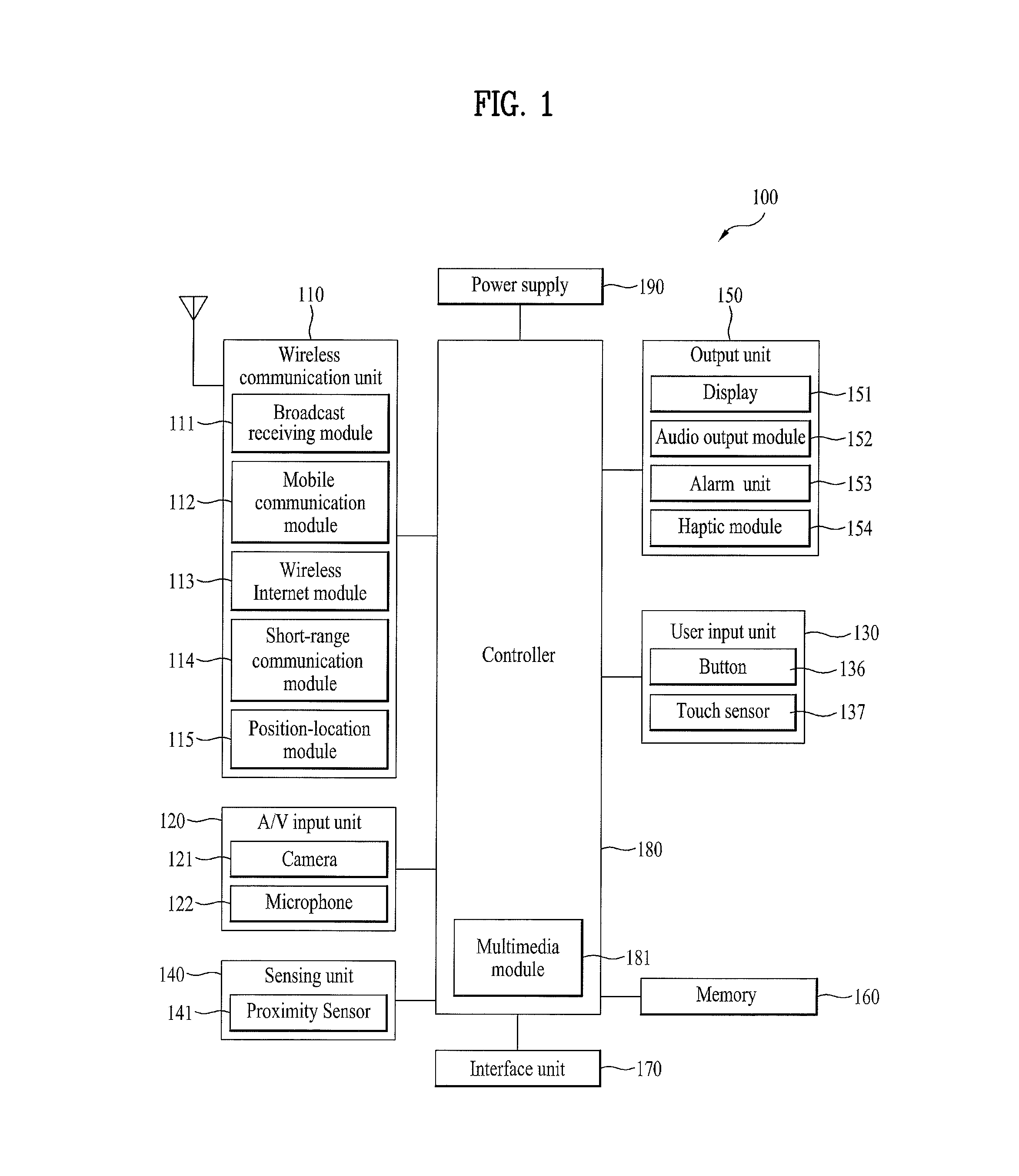

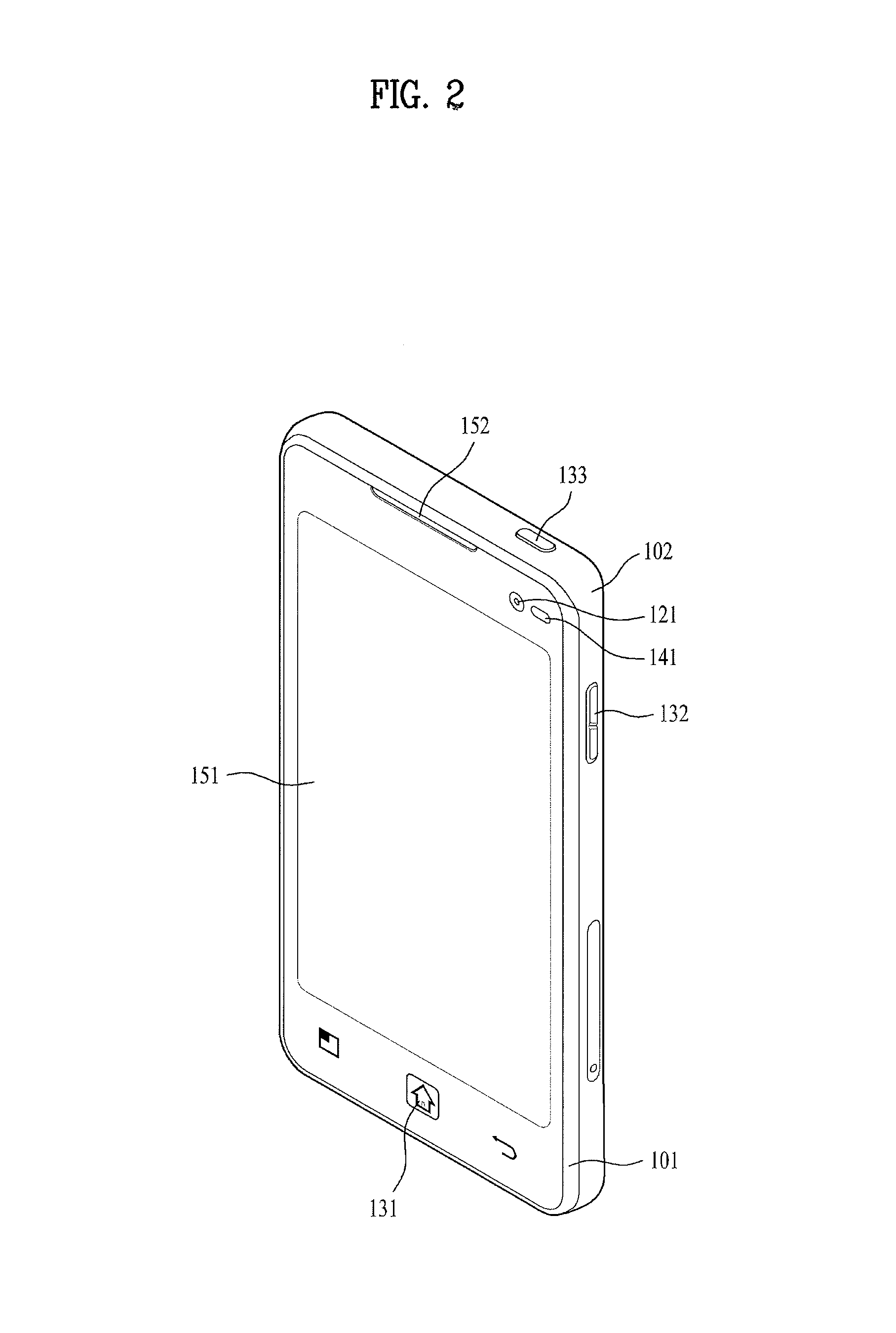

Mobile terminal

InactiveUS20140126163A1Reduce manual workReduce fabrication processEmergency actuatorsEmergency casingsElectric signalElectronic component

There is provided a mobile terminal a case having a hollow portion provided therein, a circuit board positioned in the hollow portion of the case to mount electronic components therein, the circuit board including a securing hole, a side button having an exposed front side at a lateral side of the case, a reinforcing frame positioned between the side button and the circuit board, the reinforcing frame being coupled to a lateral portion of the circuit board by a securing hook that projects from a backside of the reinforcing frame, the securing hook being received in the securing hole and a switch module coupled to a front side of the reinforcing frame so as to be located between the reinforcing frame and the side button, the switch module being configured to generate an electric signal when the side button is pressed.

Owner:LG ELECTRONICS INC

Fabrication of polymeric dental devices and aids

ActiveUS10011399B1Less-wasteful of materialLess-wasteful of timeLiquid surface applicatorsImpression capsHermetic sealDentistry

A hermetically sealed enclosure for use in fabricating a polymeric dental article. Monomers are mixed within the enclosure by squeezing a first burst pouch to break a first burst seal between it and a second burst pouch and manipulating the enclosure by hand to initiate a polymerization reaction while the enclosure remains hermetically sealed. A second burst seal between the second burst pouch and a dispensing funnel chamber is broken by further squeezing which forces the mixture into the dispensing funnel chamber. The mixture is dispensed from an outlet of the dispensing funnel chamber by further squeezing after a tear-off strip closing the outlet has been torn off.

Owner:TRIGROUP TECH LTD

Vehicle front body structure

InactiveUS8240746B2Resist damageResistance to deformationVehicle seatsSuperstructure subunitsEmbedded systemShock absorber

A vehicle front body structure includes a chassis number marking section on which a chassis number or vehicle identification number (VIN) is applied by stamping. The chassis number marking section is provided on a cowl assembly and disposed above a damper base to which an end of the cowl box is secured.

Owner:HONDA MOTOR CO LTD

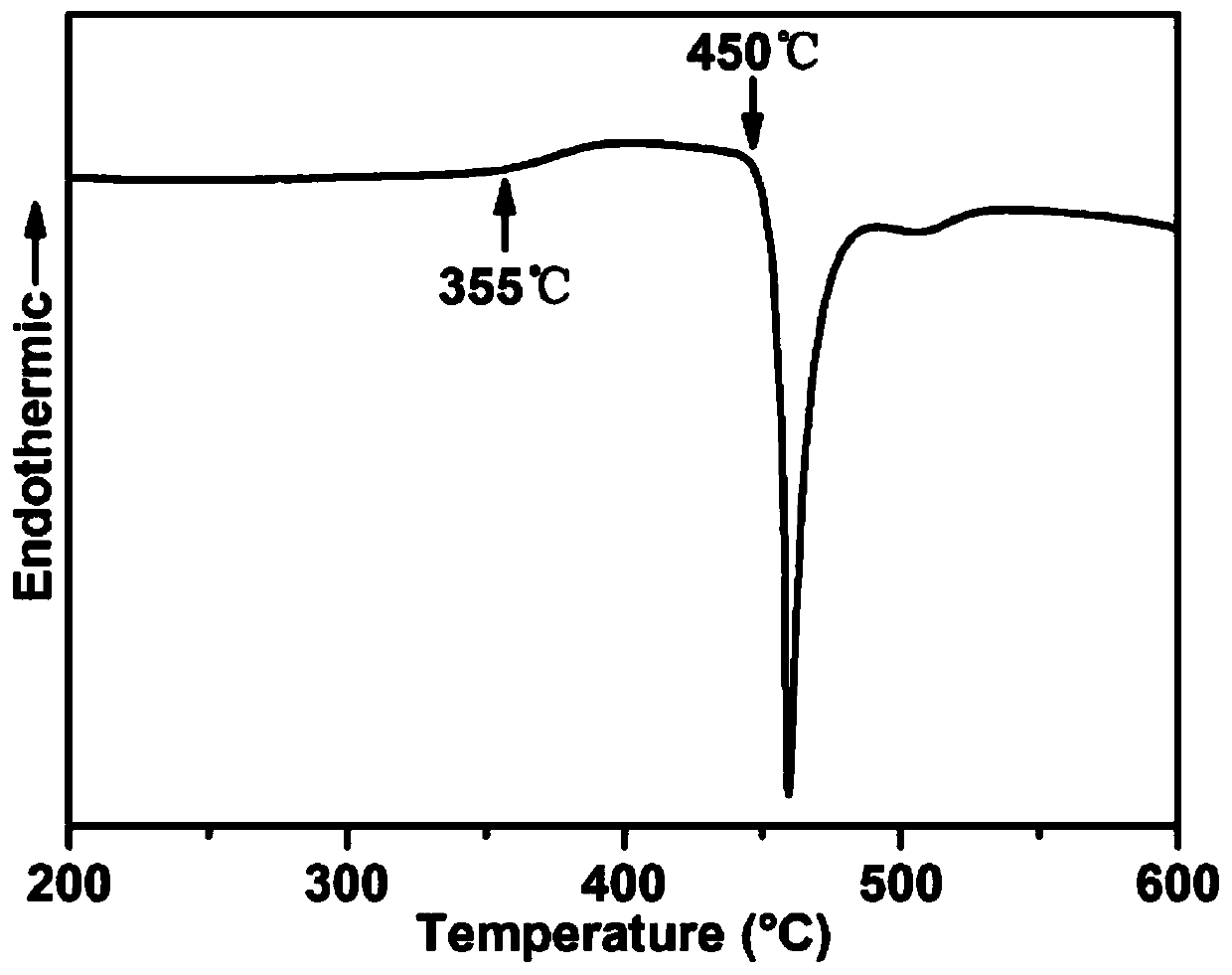

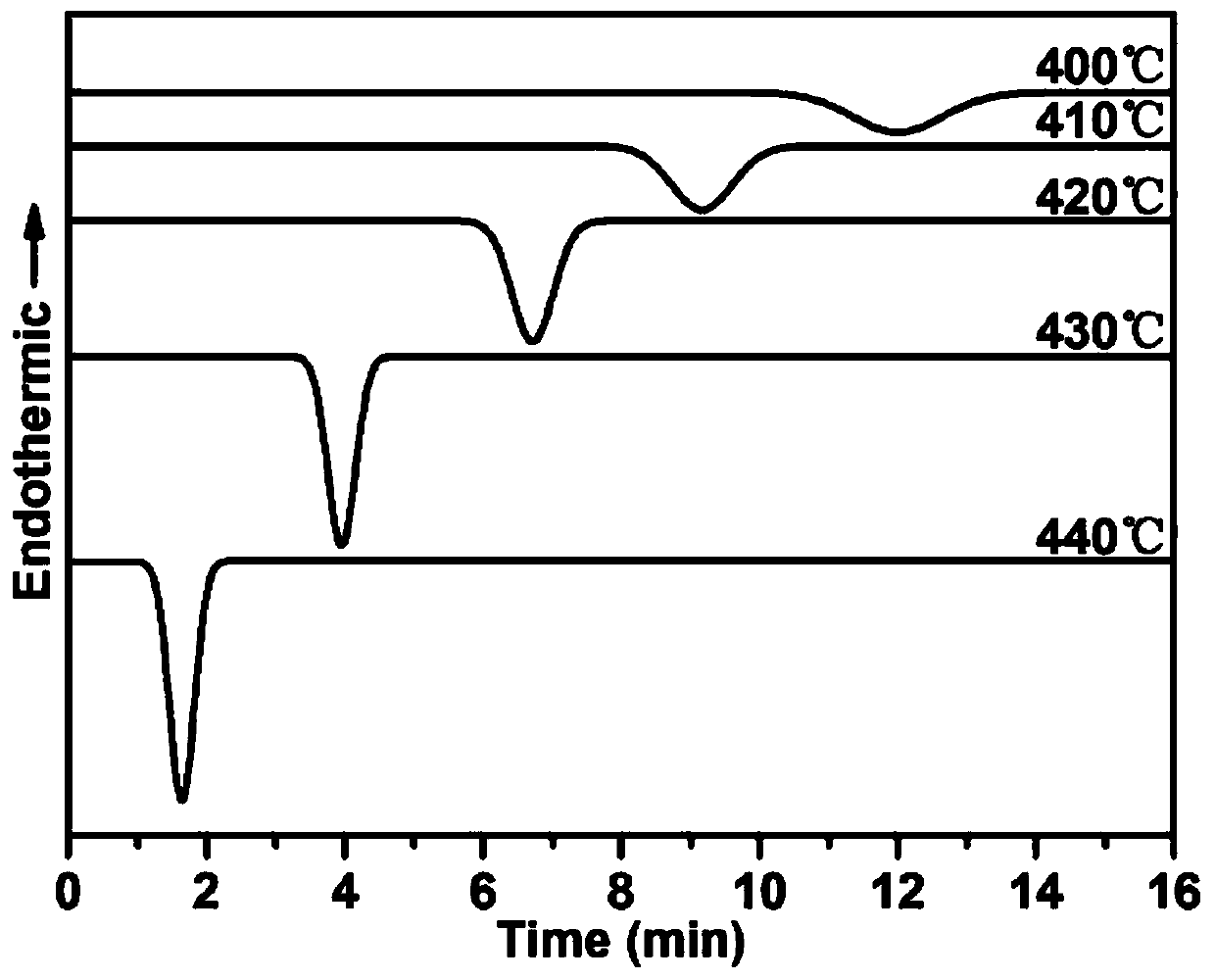

Processing method of amorphous alloy member

The invention discloses a processing method of an amorphous alloy member, and belongs to the technical field of amorphous alloy processing. The processing method comprises the following steps that theglass-transition temperature and the crystallization initial temperature of amorphous alloy under continuous heating conditions are measured; the crystallization starting time of the amorphous alloyunder the isothermal condition is measured; and the amorphous alloy is subjected to friction heat generation processing - rapid cooling, and amorphous alloy products are obtained. According to the processing method of the amorphous alloy member, the characteristic that the viscous resistance of the amorphous alloy is reduced in an overcooling liquid phase region is utilized to process the amorphous alloy, the problems that the amorphous alloy is difficult to machine at room temperature, long in processing period, high in cost and the like are solved, and feasibility is provided for the processing and application of the amorphous alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

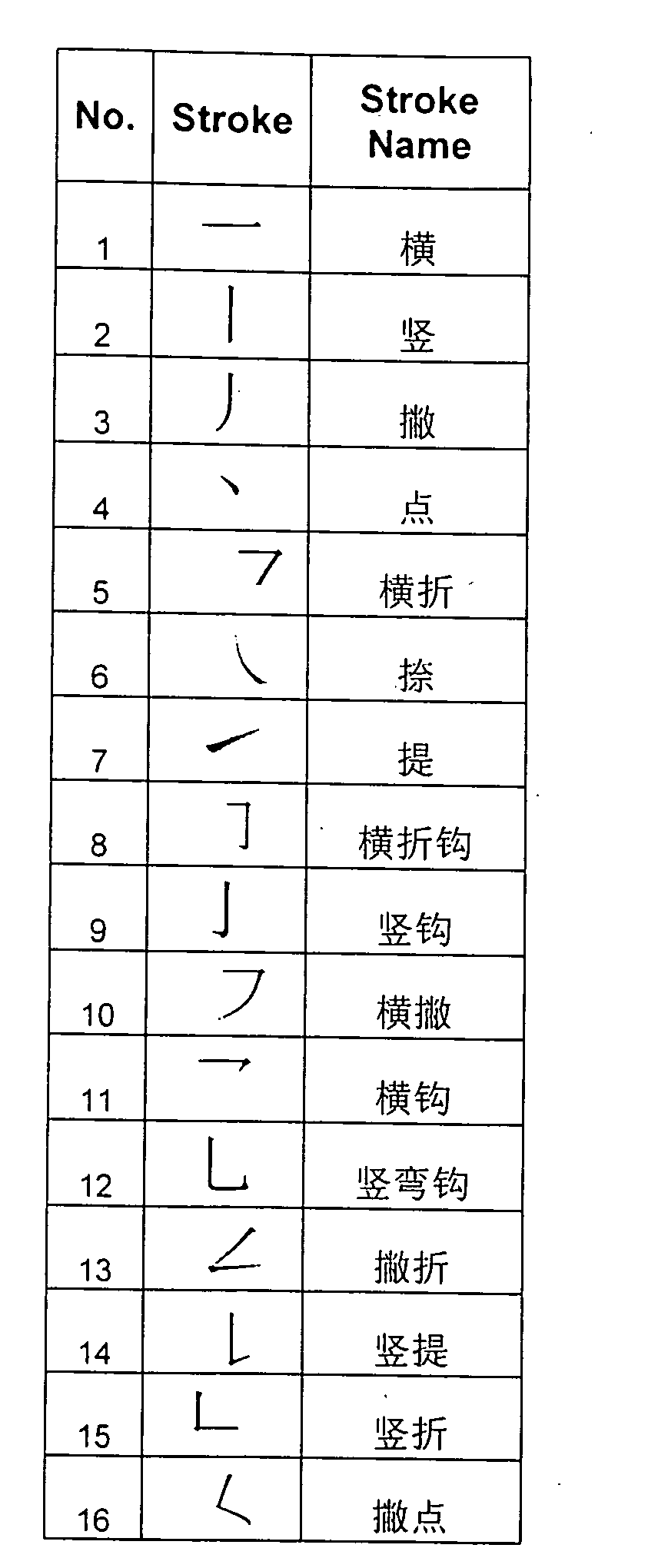

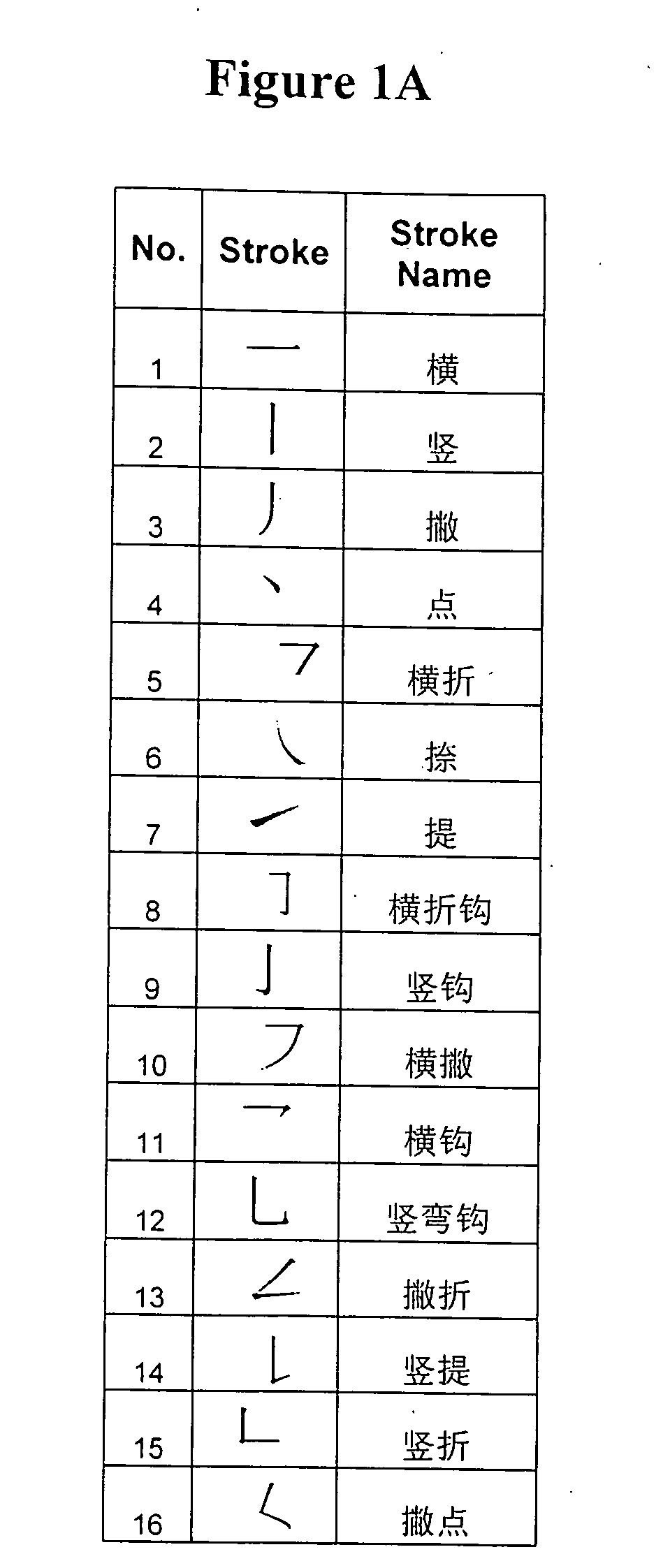

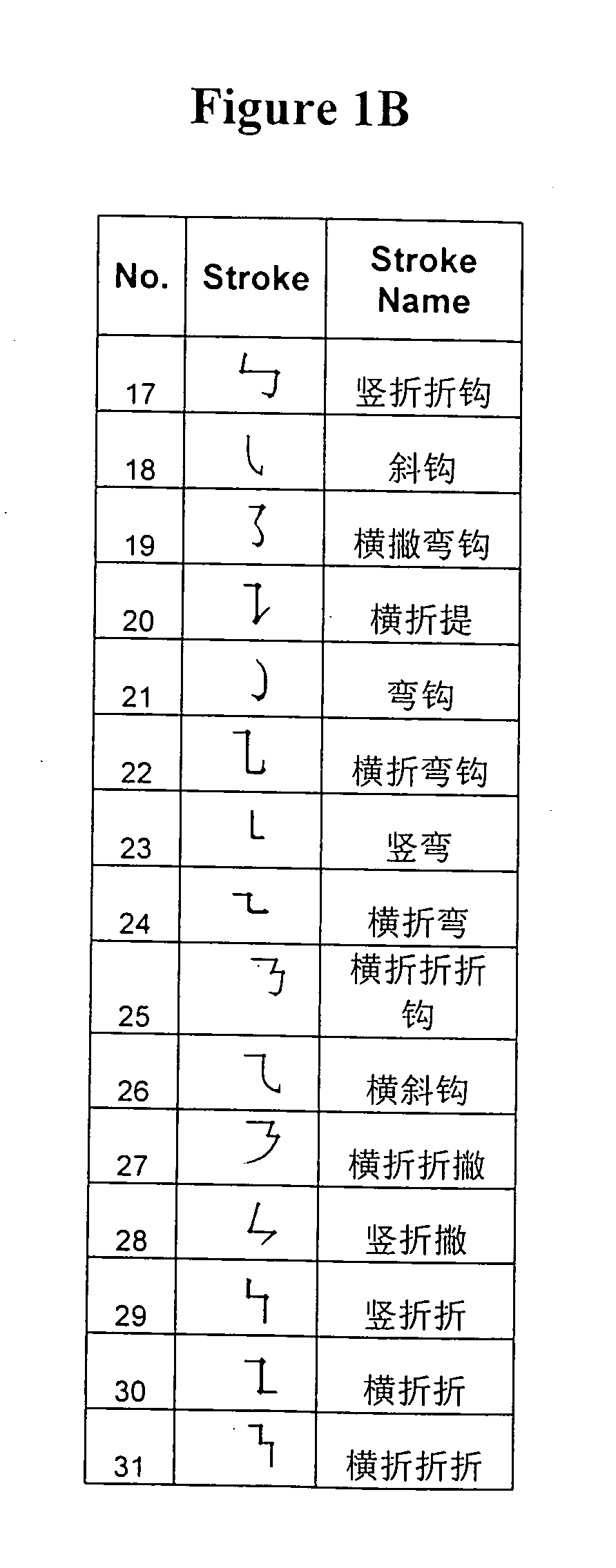

Method of organizing chinese characters

InactiveUS20090060339A1Easy and efficientEasy and efficient processingCharacter and pattern recognitionChinese charactersSpeech recognition

A method of organizing Chinese characters includes the steps of: generating Stroke Set; generating Symbol Set; generating Stroke Code Set; generating a sequential code for each of the Chinese characters to be organized; generating a spatial code for each of the Chinese characters to be organized; generating a character code for each of the Chinese characters to be organized; and organizing said character codes together with related the Chinese characters to be organized such that a Chinese character is adapted to be located by first locating the related character code of the Chinese character, then locating the Chinese character in responsive to the related character code of the Chinese character.

Owner:LIM SUTOYO

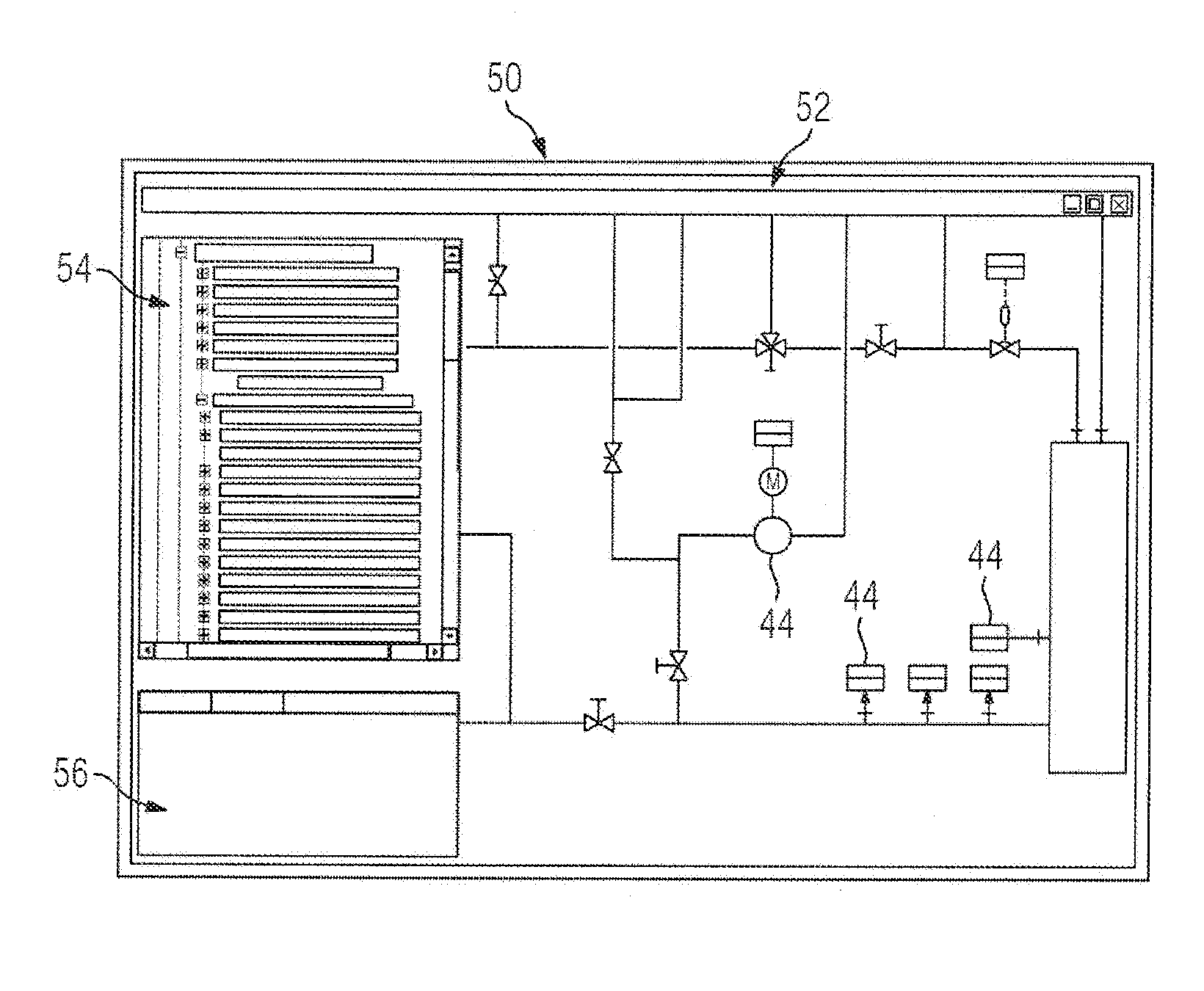

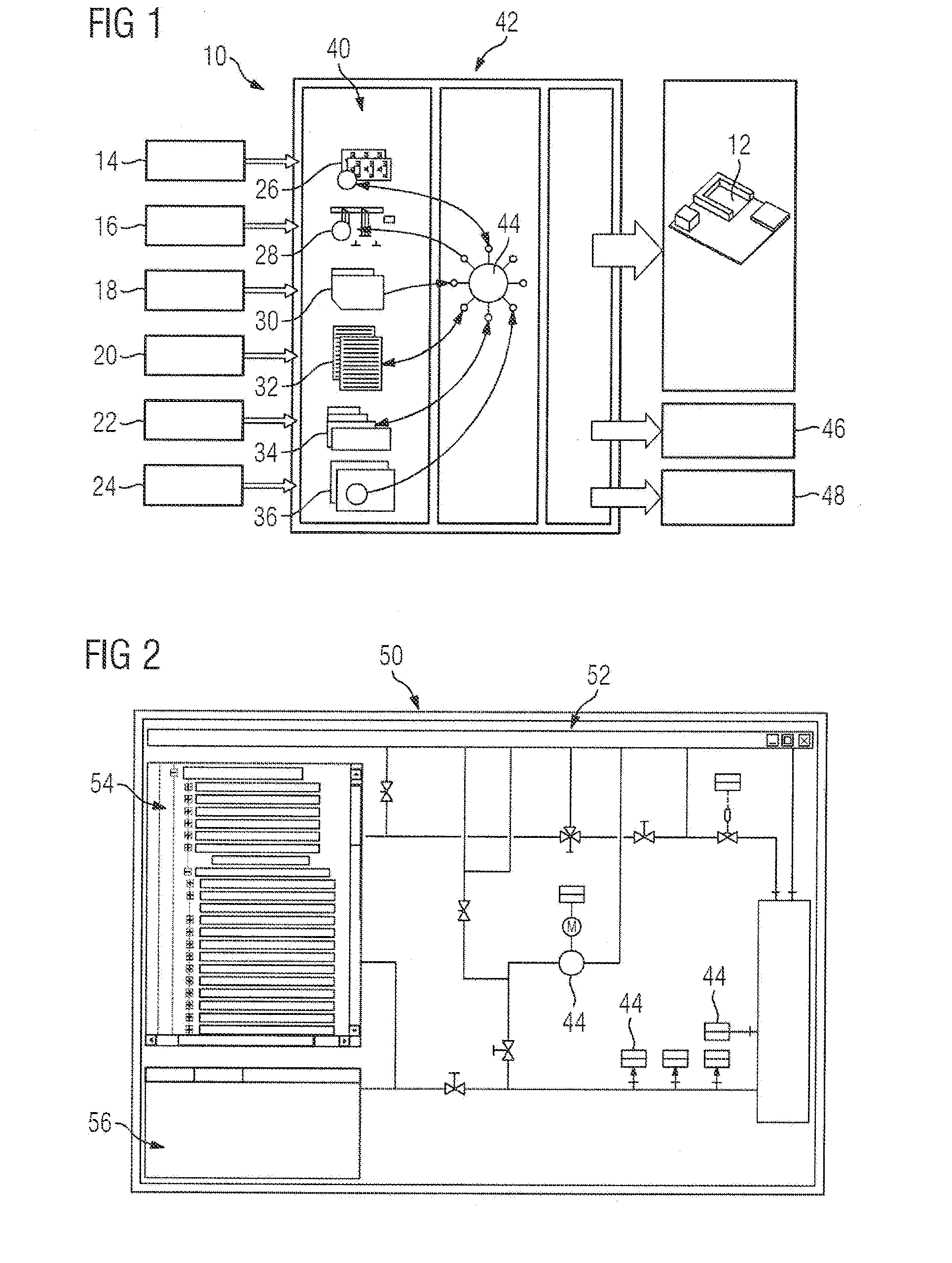

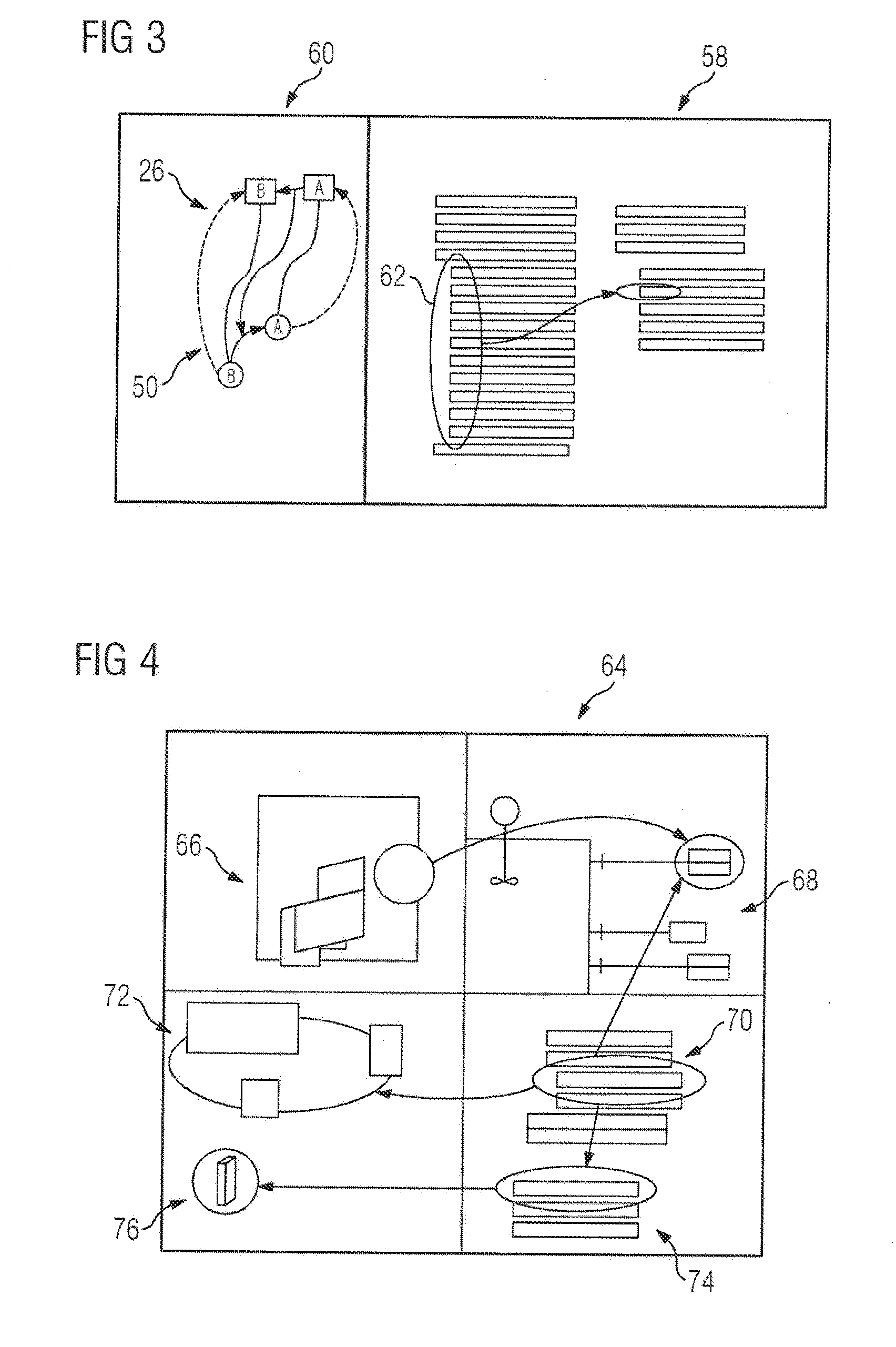

Method for Monitoring a Process and/or Production Plant

ActiveUS20140343911A1Monitored easily and efficientlyEasy and efficient processingProgramme controlSimulator controlAutomationSystems engineering

A method for monitoring a process and / or production plant, which includes a plurality of components and which is planned using a plurality of engineering systems, includes a step of providing first result data pertaining to at least one portion of the plurality of components using a first of the plurality of engineering systems, and second result data pertaining to at least one portion of the plurality of components using a second of the plurality of engineering systems. The method also includes a step of extracting topology data, which describe an arrangement of the plurality of components within the process and / or automation plant, and operating data for the plurality of components from the first and second result data. The method further includes creating a model for the process and / or production plant by using the topology data and the operating data. Also disclosed is an apparatus for carrying out the method.

Mobile terminal

InactiveUS9053878B2Easy and efficient processingSimple structureEmergency actuatorsEmergency casingsElectronic componentElectric signal

There is provided a mobile terminal a case having a hollow portion provided therein, a circuit board positioned in the hollow portion of the case to mount electronic components therein, the circuit board including a securing hole, a side button having an exposed front side at a lateral side of the case, a reinforcing frame positioned between the side button and the circuit board, the reinforcing frame being coupled to a lateral portion of the circuit board by a securing hook that projects from a backside of the reinforcing frame, the securing hook being received in the securing hole and a switch module coupled to a front side of the reinforcing frame so as to be located between the reinforcing frame and the side button, the switch module being configured to generate an electric signal when the side button is pressed.

Owner:LG ELECTRONICS INC

Machining device for multilayer composite heat preservation and corrosion preventing pipeline

InactiveCN107020694AGood insulation and anti-corrosion effectIncrease productivityAuxillary shaping apparatusSurface layering apparatusMechanical engineeringCorrosion

The invention discloses a machining device for a multilayer composite heat preservation and corrosion preventing pipeline. The machining device comprises a frame. A horizontal inner rod is arranged on the right side of the frame. The left end of the inner rod is fixedly connected with the frame. Multiple sets of fixing devices are arranged on the inner rod. Each fixing device comprise a sliding sleeve, multiple first connecting rods, multiple second connecting rods and multiple arc plates, wherein the sliding sleeve is arranged on the inner rod in a sleeving manner, the sliding sleeve can slide left and right along the inner rod, one ends of the multiple first connecting rods are connected with the outer side of the sliding sleeve in a hinged manner, the multiple first connecting rods are evenly distributed with the central axis of the sliding sleeve as the center, the other ends of the first connecting rods are connected with the inner side faces of the arc plates in a hinged manner, the second connecting rods are located on the left side of the sliding sleeve and are evenly distributed with the central axis of the inner rod as the center, one ends of the second connecting rods are connected with the inner rod in a hinged manner, and the other ends of the second connecting rods are connected with the side faces of the corresponding first connecting rods in a hinged manner. By means of the machining device, a ceramic outer layer which is even and has very good heat preservation and corrosion preventing effects can be rapidly formed on the periphery of a common pipeline at a time.

Owner:东营恒力威管件有限公司

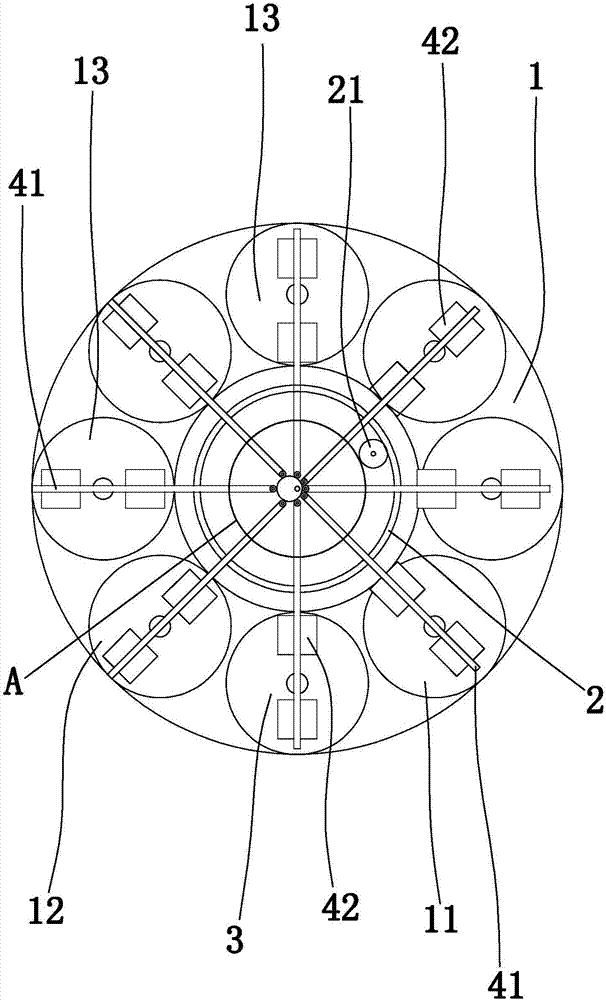

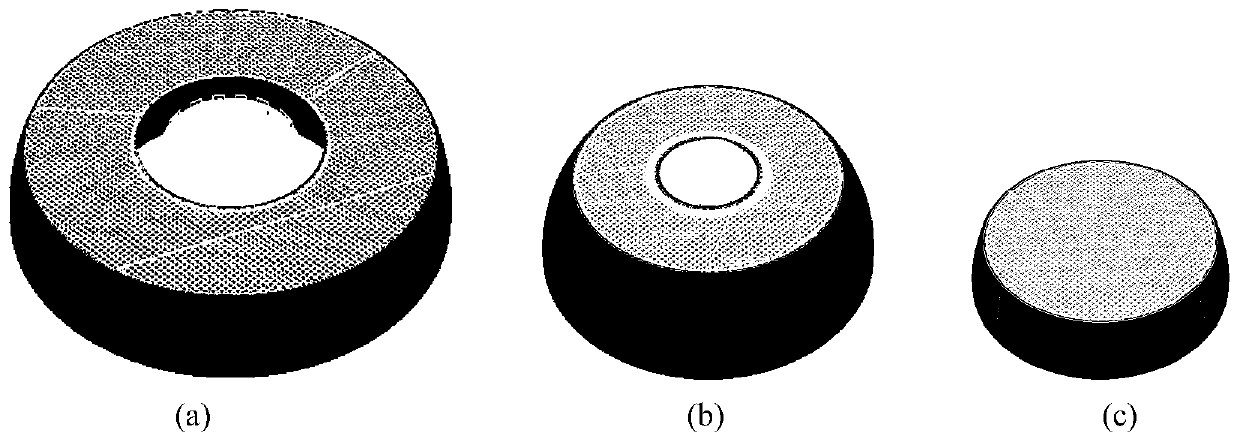

Low-cost Luneberg lens antenna designed based on 3D printer

InactiveCN110336135ASimplify the design processSimplify the optimization processAntenna supports/mountingsRadiating elements structural formsAntenna designRadar

The invention provides a low-cost Luneberg lens antenna designed based on a 3D printer, which mainly solves the problems of complicated structure and inconvenient processing in the prior art. The antenna comprises a hemispherical lens (1), a circular metal reflecting plate (2), a plastic bracket (3) and a Vivaldi feed source (4). The hemispherical lens is fixed on the upper surface of the circularmetal reflecting plate, and the spherical center coincides with the circular center of the reflecting plate. The Vivaldi feed source is fixed at the focal length position of the hemispherical lens. The hemispherical lens is a meshed filling structure composed of a spherical core (11) and two layers of hemispherical shells (12, 13), wherein a first layer of hemispherical shell is nested outside the spherical core, a second layer of hemispherical shell is nested outside the first layer of hemispherical shell, and the spherical core and the two layers of hemispherical shells have different equivalent dielectric constants and correspond to filling media with different filling rates. The antenna of the invention has the advantages of simple structure, low cost, high gain, convenient processingand manufacturing and good scanning beam consistency in the whole frequency band, and can be used in satellite communication, automobile anti-collision radar and microwave remote sensing.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com